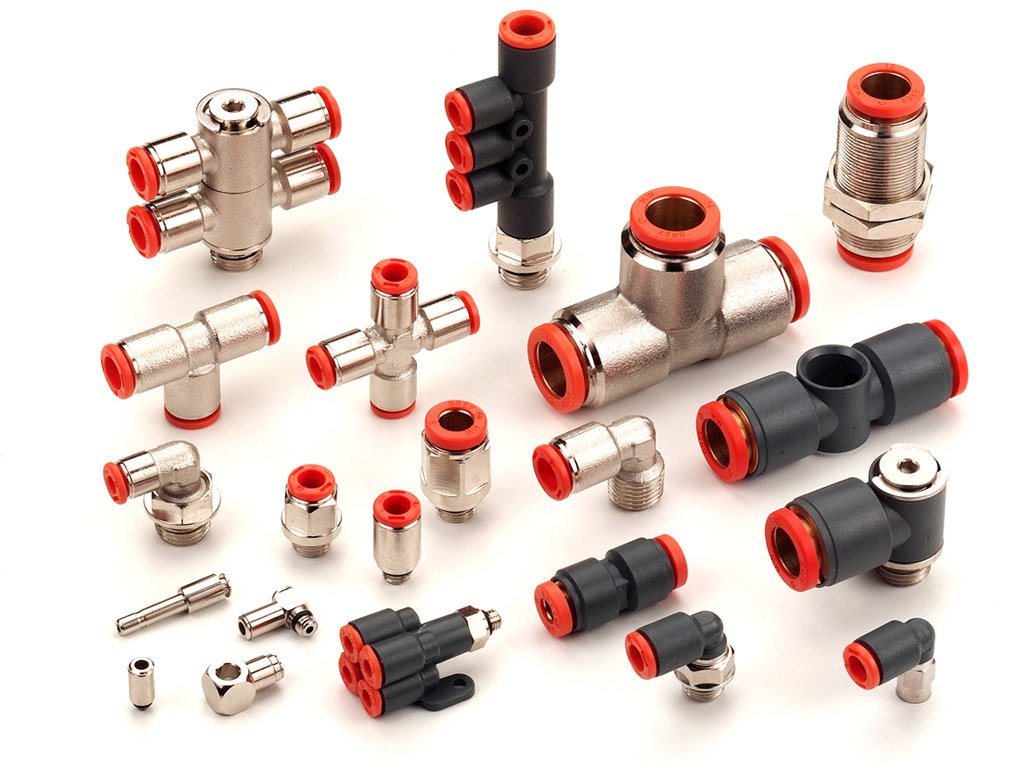

Types of Pneumatic Fittings_ Pneumatic fittings are components used to connect divisions of pipe, tube, and hose in pneumatic systems (pressurized gas). Compared to hydraulic fittings, pneumatic fittings are typically identified by tighter seals and lower pressure specifications. They are generally used in pneumatic logic control systems and instrumentation.

The Linquip website offers everything you need to know about pneumatics, from the basics to the most advanced systems. Whenever you need assistance with a pneumatic fitting, our experts are available to help. Read Linquip’s article “What Is Pneumatics?” to gain a basic understanding of these industrial devices.

Do you have any experience using pneumatic tools and machines? Find the pneumatic fitting that meets your requirements in Linquip’s selection of Pneumatic Products. Do you have any particular types of pneumatic tools in mind? The Linquip website offers free access to all available Pneumatic Devices for Sale. Linquip also allows you to submit a free request for quotes to all Pneumatic Suppliers and Companies when you want pneumatic fitting prices.

What Are Pneumatic Fittings?

Pneumatic power systems involve any type of mechanized or automated processes or machinery in which action is driven by pressurized gas or compressed air. The clear counter-reference here would be hydraulic operations, in which action is driven by liquids kept under similar compression forces in a sealed system.

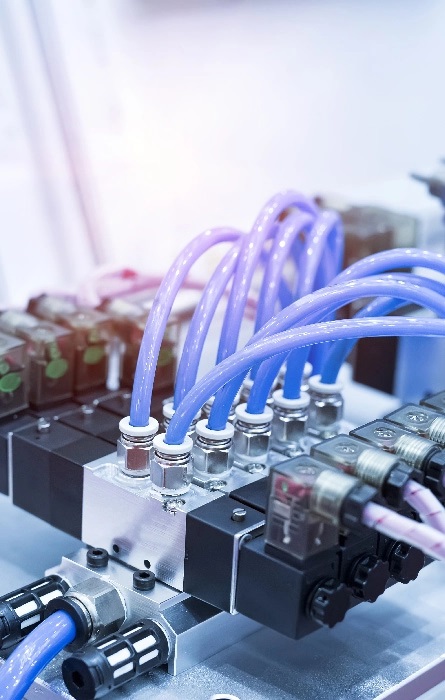

‘Pneumatic’ denotes the delivery of power explicitly through the controlled flow of pressurized gases (including air). In every pneumatic-powered system, the pressurized gases that run the required mechanisms are delivered to wherever they are required through an airtight network of robust hoses, rigid pipes, or lengths of flexible tubing.

The vast majority of these channels are connected to each other and several devices are powered by a wide diversity of pneumatic fittings, valves, couplings, and adaptors. As a piece of general information, a pneumatic fitting can be any connector designed to join components or devices in a sealed and pressurized dry-air arrangement.

These systems and fittings are generally applied today in all industries and purposes, ranging from assembly and production line setups to a wide type of industrial machinery, construction, handheld gadgets and workbench equipment. In many workplace circumstances, the power that a pneumatic system presents can often prove more reliable, versatile, cost-effective and safer than a comparable setup powered by different electric motors and actuators.

Picking the correct Pneumatic Fitting Type for a special application depends on many factors. These factors are:

- Tubing type required ( Thermoplastic or Metal, Size in inch or Metric)

- Air pressure or P.S.I. condition

- Thread type of fitting required (pipe, British pipe, metric, SAE Straight Thread)

- Fitting material required (brass, thermoplastic, stainless steel, nickel-plated brass)

- Approvals required (for instance, Department of Transportation, FDA, Underwriters Laboratory)

- Vibration concerns

Once these decisions have been made, there are a wide collection of fitting kinds to choose from. Here a listing of the more popular styles is available with a description of their applications.

What Are Pneumatic Pipes, Tubes, and Hoses

It is essential to distinguish what type of vessels are being used in the system to determine what fittings are suitable.

- Hoses are flexible vessels that are composed of multiple layers of several materials. Fittings for hoses are usually not permanent because they are often replaced in time due to wear.

- Pipes are rigid vessels composed of one solid material. Usually, pipes are defined by their inside diameter dimension.

- Tubes are relatively rigid vessels composed of one solid material. Generally, tubes are characterized by their outer diameter dimension.

Types of the Pneumatic Fittings Based on the Function

There are vast types of fittings installed in pneumatic systems which act in different functions. The most common types are described below:

Fittings that Extend or Terminate Pipe Lengths

Some of The Fittings are used for making a much longer line or for blinding it.

Adaptor_ Connects two different pipes by solvent welding, soldering, or threading.

Coupling_ Connects two similar pipes by solvent welding, soldering, or threading.

Union_ It is a Couplings that can be disconnected without cutting. Their connection (typically threading) provides for easy release.

Caps_ Covers the end of a division, attaching to the pipe by a weld, thread, solvent, or solder.

Plug_ Closes off the flow at the end of a part, fastening inside the pipe by a weld, thread, solvent, or solder.

Fittings that Add or Change Direction

Some of The Fittings are used for changing the direction or having multiple branches of a line.

Elbow_ Changes the direction of a flow at various angles. The most common angles are 45° and 90°, but 22.5° elbows are also designed.

Tee_ Connects three flow divisions in a T-shaped intersection. This allows fluid flow to be merged or split apart.

Cross_ 4-way connections, presenting one inlet and three outlets or vice versa.

Fittings that Connect Pipes of Smaller size

Some of The Fittings are used for changing line size, such as Reducers that Cover all connections which join between two or more vessels of various sizes.

Fittings that Provide Special Connections or Functions

Some of The Fittings have specific functions in a system, as described below.

Nipple_ Allows two separate fittings to be attached to each other. Regular nipples are straight, including male threads on both ends.

Valve_ Connects vessels with the addition of a valve for controlling flow.

Types of Pneumatic Fittings Based on the Connection

Pneumatic fittings can be categorized based on the connection they have with lines and each other.

Compression Fittings

Compression fittings are all types of fittings which use compressive force to connect the vessel to the fitting.

Standard Compression Fittings

This type uses metal gaskets, rings, or ferrules that seal the vessel through compression. The compression is performed by tightening a nut onto the fitting over the piping and ferrule, securing and compressing the vessel inside. Standard compression fittings do not need tools to assemble, making them suitable for quick field installations. Characteristics of this type are:

- No flaring or soldering needed

- Available in inch dimension only

- Thread availability: Male pipe, Female pipe

- Body material: Brass; Copper, Aluminum, TFE, PEA, PFA, Thermoplastic

- Approvals: UL listed for flammable liquid, SAE J-512 compliant.

Bite-type fittings

They are compressive fittings that include a sharpened ferrule that “bites” the tube when compressed and presents the seal. Like standard compressive fittings, Bite-type fittings require no special tools to assemble but present a more robust, higher pressure connection.

Mechanical grip fittings

This type is two-ferrule assemblies. The back ferrule holds the vessel while pressing up against the head ferrule, which spring-loads the front ferrule and produces a seal between the piping and fitting body. We can reassemble these fittings multiple times without damaging parts or piping. They have excellent resistance to mechanical vibration.

Flare fittings

This type consists of a body with a flared or coned head. Special flaring instruments are used to connect the vessel inside the flared end, producing a deep seal. Flare fittings can handle higher pressures and a wide range of working parameters than standard compression fittings.

Hi-Duty Flareless Tube Fittings

Preassembled fitting including a captive sleeve for high-pressure applications (1000 to 4300 P.S.I.)

Tube Compatibility: Available in inch dimension only

Thread availability: Male pipe, Female pipe

Body material: Brass, Copper, Brass, Seamless Steel, Thermoplastic

Push-to-Connect

The push-to-connect fitting has ends that are designed to take tubing by pushing it into the end. These fittings typically disconnect by some sort of collar retraction. These connections are useful for applications in a system needing frequent reconnection and disconnection.

Prestolok Metal

this type is one of the push to connect types with the following characteristics:

- One-piece push to connect fitting

- Low-pressure applications that provide easy disassemble and reassemble.

- Come with a pre-applied thread sealant.

- Tube Compatibility: Most Thermoplastic ( 85A Polyurethane excluded) in both inch and metric dimensions

- Body material: Nickel Plated Brass

- Thread Availability: Male pipe, Female pipe, British Parallel Pipe, British Tapered Pipe, Metric;

Prestolok Composite

this type is one of the push to connect types with the following characteristics:

- One-piece push to connect fitting including glass-reinforced black nylon body

- Tube compatibility: Nylon Semi-rigid, Polyurethane, Nylon, Fluoropolymer,

- Available in both inch and metric dimensions;

- Thread availability: Female pipe, Male pipe, British Parallel Pipe, British Tapered Pipe, Metric

- Body material: Silicone-free glass-reinforced nylon

PrestoWeld

this type is one of the push to connect types with the following characteristics:

- weld splatter resistant and silicone-free to meet the necessities of the robotic welding industry

- Thread availability: Male pipe, Female pipe, British Tapered Pipe;

- Tube compatibility: Parker Microweld tubing

- Body material: Nickel-plated brass

Threaded Fittings

As the name indicates, the threaded fittings have screw threads on their inner (female) or outer (male) surfaces intended to accept connections with mating threads. Threads that provide a simple connection but no assured seal are known as straight threads. Tapered threads are designed to present a tight seal which is essential for pneumatic purposes. These precise threads produce a “dry fit”, expressing they seal without the requirement for an additional sealant, which is vital in applications where sealant addition could make contamination or corrosion.

Design Tip

We should improve straight threads in pneumatic fittings by adding a coating or seal tape (Teflon). In utilisation where adding a coating could cause corrosion or contamination, use tapered threads.

The thread size is based on the inside diameter of the vessel. Few thread size standards are BSP (British Standard Pipe) and NPT (National Pipe Thread), though many other standards and usage often vary by country and industry. Each thread size compares to a unique number of threads per inch (TPI). You can find pipe thread sizing in various references, including this link which provides an excellent overview of pipe thread sizing.

Ball and Sleeve Fittings

Ball and sleeve fitting joins an outer sleeve to an inner (ball) fitting. The sleeve retracts to disconnect the two ends of the fitting. Some ball and sleeve fittings perform as push-to-connect fittings, which are suitable for applications demanding frequent disconnection and reconnection of the hose part.

Crimp Fittings

Crimp fittings include putting a hose over a tubular end and crimping it with a ring, sleeve, or crimp socket. These fittings typically need crimping tools or instruments to make the connections.

End Fittings

End fittings present specific surfaces for uniting vessels in pneumatic systems.

Clamp ends: they are fittings that provide hoses or tubes to be clamped over the section.

Plain ends: they are fittings with surfaces that allow tubes or pipes to be connected by solder, adhesive, welding, or other permanent means.

Sizing

Once the type of fitting expected has been determined, the most fundamental feature of pneumatic fittings can be approached: proper sizing. Proper sizing is necessary to the successful fitting preference, as oversized or undersized parts will both be wholly incompatible or will seal or connect inefficiently.

The two measurement systems are Metric (mm) and English (“, inch). The first action to proper sizing is choosing the appropriate measurement system for compatibility with the tools or assembly being fitted.

The size of vessels defines the sizing of a pneumatic fitting it connects to. Tubes, hoses, and pipes are sized based on the outside diameter (OD) and inside diameter (ID), measured in millimeters (mm) or inches (in). A fitting produced to connect to a tube with a 2” OD is considered as a 2” OD fitting. Inside diameter measures the diameter of the hollow part of the cylinder, while the outside diameter includes the tubing wall thickness.

Operation

Pneumatic fittings are often determined for certain temperatures, and pressure ranges depend on what they are designed to handle.

The operating pressure range is the practical range of pressures or the pressure classes at which the fitting was designed to work. The operating pressure is typically measured in pounds per square inch (psi). Operating beyond or below this rating may cause the fitting to fail; for example, it could break, leak or lose its seal).

The operating temperature range is the operating range of temperatures or the temperature classes at which the fitting was designed to work, measured in degrees Celsius (°C) or degrees Fahrenheit (°F). Operating beyond or below this rating may cause the fitting to fail.

Types of Pneumatic Fittings based in Materials

Fitting material is crucial in determining several physical properties of the part as well as gas compatibility. Material options include:

- metals

- plastics

- composites

Metals

Fittings can be manufactured with metal materials such as Aluminum, brass, steel, stainless steel

Aluminum

Aluminum is lightweight and corrosion-resistant. It has low tensile strength and is accepted for its low density and corrosion resistance in low-pressure applications. It is mixed with zinc, silicon, copper, manganese, and/or other metals to increase its strength and hardness.

Brass

Brass is strong, corrosion-resistant, durable, has high-temperature ductility and good conductivity. Brass is a combination of copper and zinc. It is the most typical metal for smaller compression and threaded fitting standards of pneumatic systems due to its machinability and its outstanding performance properties.

Steel

Steel is durable and strong and has high resistance to heat. Steel is a combination of iron and carbon; it is usually alloyed with other metals to increase its corrosion resistance. Galvanized steel is coated with zinc for rust protection and chemical resistance.

Stainless Steel

Stainless steel is a strong material with superior chemical and corrosion resistance. Stainless steel is a combination of steel that comprises over 10.5% chromium. It has the durability and strength of steel while also presenting excellent corrosion resistance, however at a higher cost.

Plastics

Fittings can be manufactured with plastic materials such as Polypropylene, Fluororesins.

Fluororesins

Polytetrafluoroethylene (PTFE) and polyvinylidene fluoride (PVDF) are fluorocarbon-based polymers typically used for temperature conditions above 500°F (250°C). They present excellent chemical resistance and dielectric properties.

Polypropylene

Polypropylene is a thermoplastic material used extensively for pneumatic fittings due to broad material compatibility, price, and durability. It shows excellent cold flow, bi-axial strength, and yield elongation features and can be used in exposed applications as it is resistant to weathering, UV, and ozone.

Composites

Composite fittings are made from combinations of materials, such as fiberglass, carbon, and graphite. These materials have high melting points and are construction materials for applications that need high-temperature durability and chemical resistance. They also display thermal conductivity and low electrical .

Different Features of a Pneumatic Fittings

Pneumatic fittings may have other characteristics which add the functionality required for certain applications.

- Bulkhead fittings are designed to be installed in a wall or bulkhead to provide tube connections on either side of a barrier.

- Connect-under-pressure fittings are designed to provide installation or connection of the instrument while the system is under pressure.

- Expansion joints and couplings connect tube sections and provide an allowance for mobility due to service shock, load, or thermal cycles.

- Lined fittings are produced with an integral lining. The linings are frequently made from engineered polymers for application with process materials or in purposes such as food processing, where media sanitation is important.

- Plated fittings have a surface treatment, plating, or coating which provides enhanced thermal properties, corrosion resistance, chemical durability, or other desirable surface characteristics.

- The swivel feature enables one or more fitting ends to swivel or rotate.

- Pre-insulated fittings have insulating materials or jacket constructions intended to insulate the vessel and media from outdoor temperatures.

Advantages of Pneumatic Fittings

Here some of the benefits of these fittings are presented.

Making the Most Use of Compressor

Without fittings, we can not use a compressor at all. Just imagine filling a tire without having a fitting. The fittings are essential to connect all the components of the compressor. They direct the air into the line so that we have the desired pressure.

Diversify of Pneumatic Tools

If we do not have the proper fitting for a function, the air compressor is a whole lot less valuable. These small pieces are responsible for connecting specific tools to their pneumatic source.

Wide Range of Applications

You have Possibly used your compressor just as a tire inflator (a convenience item). But preparing controlled air pressure has practically endless applications, such as operating a nail gun at a worksite to paint a car, restoring wheels, or driving advanced power tools. Having the right fittings introduces a world of possibilities.

Helping Environment

Proper fittings present a better seal. That indicates less air is wasted and less energy is used to do the same amount of work. Every little bit helps not only the ecosystem but your wallet too. Proper fittings are an investment.

Download Types of Pneumatic Fittings PDF

This document is also available in PDF format, which you can download to your computer. You can download the file by clicking the link below.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- 3 Main Types of Pneumatic Cylinders With Application

- Types of Electrical Wire + Application (Complete Guide)

- 10 Types of Molding Machinery + PDF (Clear Guide)

- 3 Common Types of Electrical Connectors (Clear Guide)

- Types of Sensors Detectors/Transducers: An Entire Guide

- 15 Types of Electrical Power Connectors (Clear Guide) + PDF

- 10 Types of CNC Machine + Applications & PDF

- 7 Types of Capacitors and Their Uses

- 3 Different Types of Hygrometers and Their Applications

- 4 Types of Thermowell: Application and Duty

- Types of Resistor: Classification, Application, and Finally Clarification

- A Useful Guide to Different Types of Inductors

- What is Multiplexing and Their Types? A Complete Guide

- What is Film Capacitor? Different Types & Working

- What is Thermowell? Types & Working Principle

- What is Non-Polarized Capacitor? Types & Function

- Types of Electric Circuits: All Classification with Application