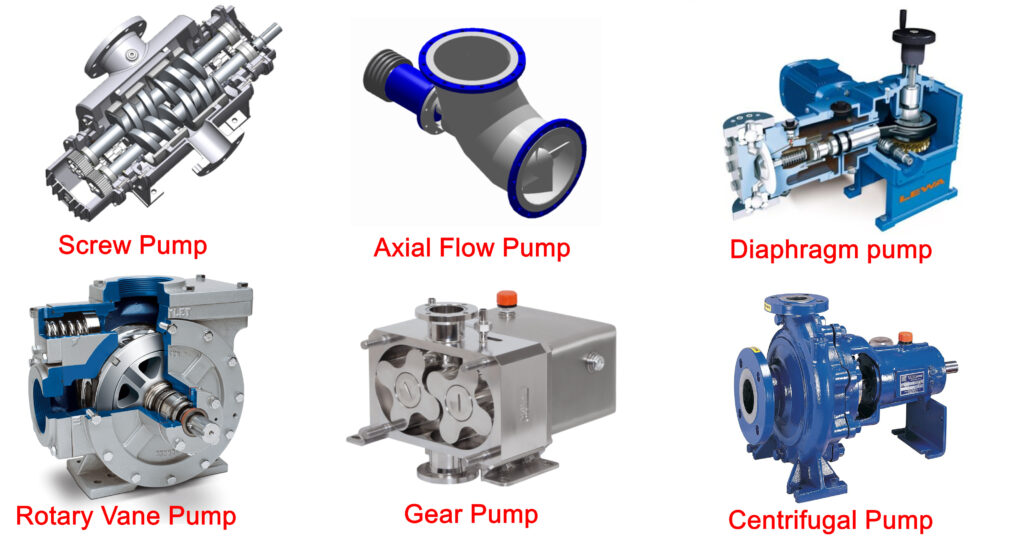

Types of pumps are usually classified based on different methods. These methods can be according to the energy conversion mechanism, the fluid type or application. Positive displacement and dynamic pumps are two basic types of pumps according to the mechanism of energy transfer. Let us first introduce the pump, its function and its application. Then, we will describe all the types of pumps.

⇒ View a List of Pumps for Sale and Their Suppliers ⇐

Basics of Pumps

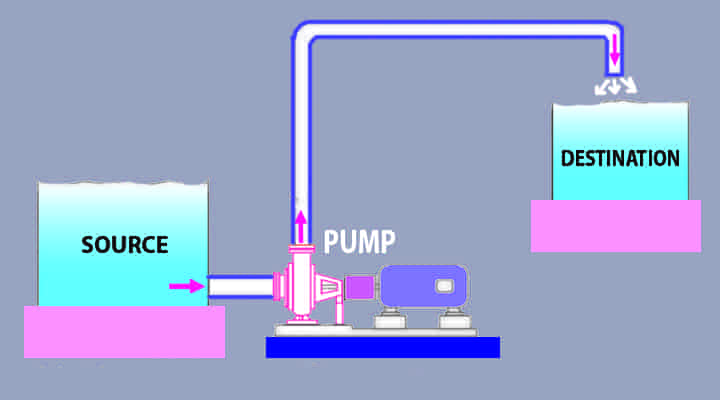

A pump is a machine to transfer fluids (liquids or gases), or even slurries, by converting the electrical energy into mechanical action.

Various classifications are proposed for pumps. For example, according to how they are used to move the fluid, they are one of the three major groups, including direct lift, displacement, and gravity pumps. Also, some pumps are submerged in the fluid, while some others may be placed external to the fluid.

The pumps work via a mechanism (reciprocating or rotary) and use energy to convert into mechanical work to move the fluid. Many energy sources can be considered for a pump working. Manual operation, electricity, engines, wind power are some sources to supply the energy required by the pump. The pumps come in a wide range of sizes, from microscopic in medical applications to large industrial pumps.

Mechanical pumps work for a variety of purposes:

- Pumps are employed to pump water from wells as well as water-cooling and fuel injection in the car industry.

- In different sections of the energy industry, pumps are used to transfer oil and natural gas and also in cooling towers and other heating, ventilation, and air conditioning systems.

- In the medical industry, pumps are utilized for biochemical processes in the manufacture of medicine and as man-made replacements for body parts, such as the artificial heart and penile prosthesis.

The power applied to a fluid increases its energy per unit volume. The energy is transferred from mechanical energy to hydraulic energy. In general, the governing differential equations, known as the Navier–Stokes equations, describe this energy conversion. However, a simple equation called Bernoulli’s equation can be used, which relates only to the different energies in the fluid. The following equation gives the original form of Bernoulli’s equation for incompressible fluids at any arbitrary point along a streamline.

\frac{v^2}{2}+gz+\frac{p}{\rho }=constant

v, p, z, and ρ are fluid speed, pressure, elevation above a reference plane, and density at a point, respectively. Also, g is the gravitational acceleration.

Accordingly, the total pressure difference between the inlet and outlet of the pump is expressed by:

\mathit{\Delta}p=\ \frac{\left(v^2_2-v^2_1\right)}{2}+g\mathit{\Delta}z+\frac{\mathit{\Delta}p_{static}}{\rho }

The last term in the above equation is a static pressure difference. The efficiency of the pump is defined as the ratio of the power applied to the fluid by the pump to the power given to the pump and is calculated by the following relation:

\eta =\frac{Q\mathit{\Delta}p}{P}

Q is the volume fluid flow rate given in m3/s.

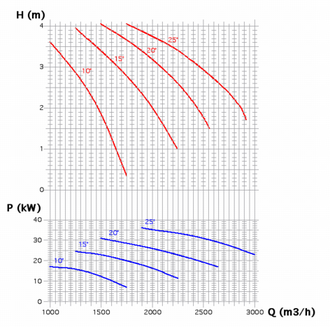

The pump efficiency may be given by the manufacturer’s information, sometimes in the form of a pump curve. It is typically derived from fluid dynamics simulation such as the Navier–Stokes solutions for the particular pump geometry or tests. The pump efficiency depends on the pump configuration and operating conditions, including rotational speed, fluid viscosity and density, and so on.

Its value is not constant for a specific pump and is a function of the discharge rate and operating head (H) as following:

\eta =\frac{\rho gQH}{P}

The Centrifugal pump efficiency increases with flow rate to a point in the middle-performance range (Best Efficiency Point (BEP) ) and then decreases as flow rates rise further. In addition, pump efficiency tends to reduce over time due to wear effects, such as increasing clearances and decreasing impeller size.

Classification of Pumps

Pumps can be classified in different ways, as said at the beginning of this article. In this section, we will describe the classification by general mechanical configuration. Accordingly, there are two basic types of pumps: dynamic and positive displacement pumps.

Dynamic Pumps

In dynamic pumps, the energy transfer is continuous. Dynamic pumps are categorized into three main types:

Turbopumps

Turbopumps are the most commonly used pumps in the industry. The main moving part of turbopumps or impeller pumps is a rotor with several blades installed on a rotating shaft. Because of the action of blades, the moment of momentum of the liquid passing through the impeller is increased. These pumps are the most common types of pumps due to the simple structural elements, low ratio of volume to the input power, and numerous uses in the industry. All turbopumps are members of the turbomachinery family.

The most common method for the classification of turbopumps is based on the path of liquid inside the rotor.

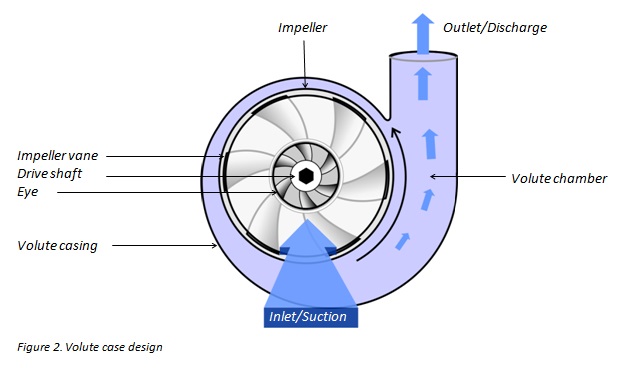

Centrifugal Pumps

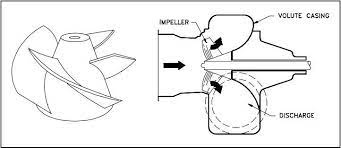

Centrifugal pumps are used to transfer fluids by converting rotational kinetic energy to hydrodynamic energy. Rotational energy usually comes from an engine or motor. The fluid enters the pump along to the rotating axis and then is accelerated by the impeller. Finally, it flows radially outward into the pump diffuser or volute chamber from which it exits.

These pumps are used in various areas, including water, agriculture, sewage, petroleum, and petrochemical pumping. The main cause of the wide selection of these pumps is their capability in high flow rates, mixing potential, abrasive solution compatibility, and relatively simple engineering.

Watch Video About Types of Pumps

Axial Flow Pumps

An axial flow pump is a common type of pump that basically consists of an axial impeller (propeller) in a pipe. The impeller can be run directly by a motor, electric motor, or petrol/diesel engine.

Fluid particles do not change their radial locations during their flow through the pump because the change in radius at the suction (inlet) and the discharge (outlet) of the pump is very small. This is why the name axial is given to this type of pump.

The propeller-type of impeller runs in a casing. The pressure is developed by the flow of fluid over the impeller blades. The fluid moves in a direction parallel to the impeller shaft. It allows the fluid to travel through the impeller axially.

The performance characteristics diagram of an axial flow pump is demonstrated in the figure. As shown, the head at the zero flow rate can be three times greater than the head at the best efficiency point of the pump. Additionally, as the flow decreases, the power requirement decreases so that the highest power is drawn at the zero flow rate.

This feature is opposite to the radial flow centrifugal pump in which the required power increases as the flow increases. Furthermore, with an increase in pitch, the required power and pump head increase. Thus it allows the pump to adjust to the system conditions to perform the most efficient operation.

The main benefit of an axial flow pump is its application in relatively high flow rates and relatively low heads.

Mixed Flow Pumps

A mixed flow pump is a centrifugal pump, including a mixed flow impeller. It has the characteristics of both axial flow and centrifugal pumps and works on a horizontal plane relative to the direction of the fluid flow. When the liquid flows through the impeller, the blades send the liquid out, away from the pump shaft at an angle larger than 90 degrees.

In general, a mixed flow pump is used for applications with a medium or high flow rate and a medium head. It is usually used in irrigation, agricultural, sewage applications, cooling water in thermal and nuclear power plants, handling seawater, industrial utilization, and water supply.

Mixed-flow pumps are mainly supplied in single-stage vertical forms with diffusers. However, the designs in horizontal and vertical configurations, including volute casing, are optional, as well as two-stage designs. The rotor of the pump is a mixed flow impeller with fixed blades.

Peripheral Pumps

Peripheral pumps are a niche pump type with characteristics between centrifugal and positive displacement pumps as they can generate the high head of positive displacement pumps, with the operational flexibility of centrifugal pumps but with a lower flow rate.

Their working kinetic principle is similar to centrifugal pumps. However, instead of utilizing an impeller with vanes, they have turbine-like impellers radially orientated to transfer fluid. As the impeller turns, the fluid velocity is increased in a circular path. This circular path provides the diffusion to transform the velocity to pressure. The design of peripheral pumps is more compact with less internal clearances than centrifugal pumps, so they are noisier. These pumps are usually single stage. However, multistage versions are also available.

They typically have a flow rate ranging from 1 to 200 gpm, a total head between 50 and 1,200 ft, and a power range between 0.5 and 75 hp. They are excellent for purposes requiring a high head, low flow rate, flexible operation, and compact configuration. For example, they are used deep well pumping, cooling water circulators in industrial applications and commercial uses such as bakeries, dry cleaners, and breweries.

Special Pumps

Eductor-jet pump, hydraulic ram, electromagnetic pump, and gas lift are other different types of dynamic pumps.

Eductor-jet Pump

This type of pump uses a jet, often steam, to produce a low pressure. The low pressure sucks fluid inside and moves it into a higher pressure region.

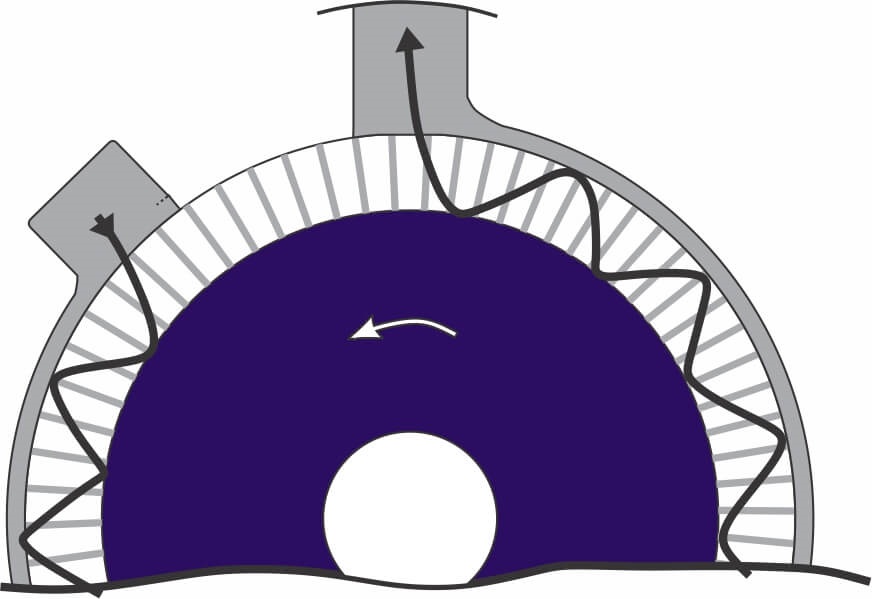

Hydraulic Ram (Hydram)

A hydraulic ram is a cyclic water pump that is powered by hydropower. This machine uses the effect of a water hammer to create pressure that allows a part of the input water to be lifted to a position higher than the original starting point of the water.

Gas Lift or Bubble Pumps

Gas lift uses the artificial method of raising a fluid by inserting bubbles of compressed air, water vapor, or other bubbles into the outlet tube. This reduces the hydrostatic pressure at the outlet tube versus the hydrostatic pressure at the inlet tube. This technique is utilized widely in the petroleum industry. For example, in the United States, gas lift is applied in 10% of the oil wells with inadequate reservoir pressure to create the well.

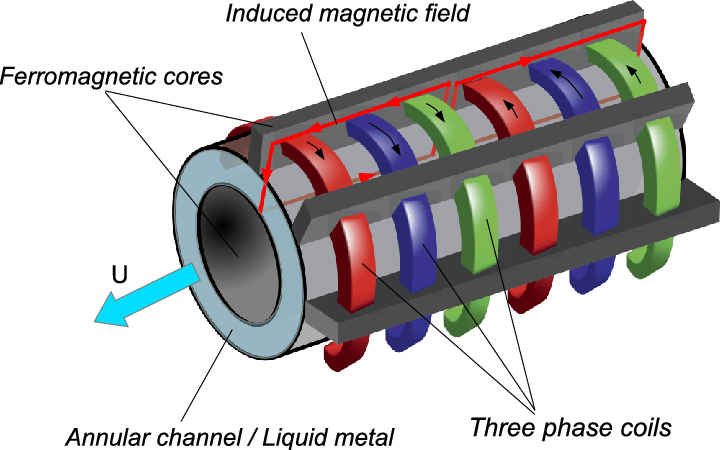

Electromagnetic Pumps

An electromagnetic pump is a device that pushes liquid metal (or any electrically conductive liquid) utilizing electromagnetism. The magnetic field is applied at right angles to the direction that liquid travels in, and a current is transferred through it. This creates an electromagnetic force that moves the conductive liquid. This pump can be used in pumping liquid metal applications in a cooling system.

Positive Displacement Pumps

A positive displacement pump creates a fluid motion toward the discharge pipe by trapping a certain amount of fluid and forcing (displacing) it.

Some positive displacement pumps utilize an expanding cavity on the suction side and a decreasing one on the discharge side. Fluid flows into the pump as the suction side cavity expands, and it flows out of the discharge when the cavity collapses. The volume is constant in each operation cycle.

Unlike centrifugal pumps, positive displacement pumps can theoretically provide the same flow at a certain speed (rpm) regardless of the discharge pressure. Therefore, a positive displacement pump is a constant flow machine. However, a small increase in internal leakage with an increase in pressure prevents a really constant flow rate.

A positive displacement pump must not work against the closed valve on the pump discharge side since it does not have a shutoff head like centrifugal pumps. If a positive-displacement pump continues operating against a closed discharge valve to produce flow, the pressure in the discharge line rises until the line bursts. So, the pump would be severely damaged. Therefore, on the discharge side, a relief or safety valve is necessary. It can be internal or external.

Based on the mechanism used to transfer the fluid, Positive displacement pumps can be classified into rotary pumps and reciprocating pumps.

Rotary pumps

Rotary pumps transfer fluid using a rotating mechanism that produces a vacuum that draws in the liquid. They are very efficient because they can work with highly viscous fluids at high flow rates as viscosity increases.

However, the nature of the pump needs very narrow clearances between the rotating part and the outer edge, which causes a slow and steady speed rotation. If the rotary pump operates at high speeds, the fluid creates erosion, which ultimately makes larger clearances through which the liquid can pass, leading to reduced efficiency.

Rotary pumps divided into the following main types:

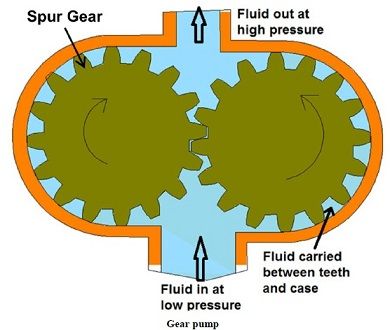

Gear Pumps

This is the simplest type of rotary pump. It includes two meshed gears rotating in a fitted casing. The spaces between the teeth trap fluid and push it around the external periphery. The fluid does not return to the meshed part because the teeth are located closely in the center. Gear pumps are widely used in car engine oil pumps and different hydraulic power packs.

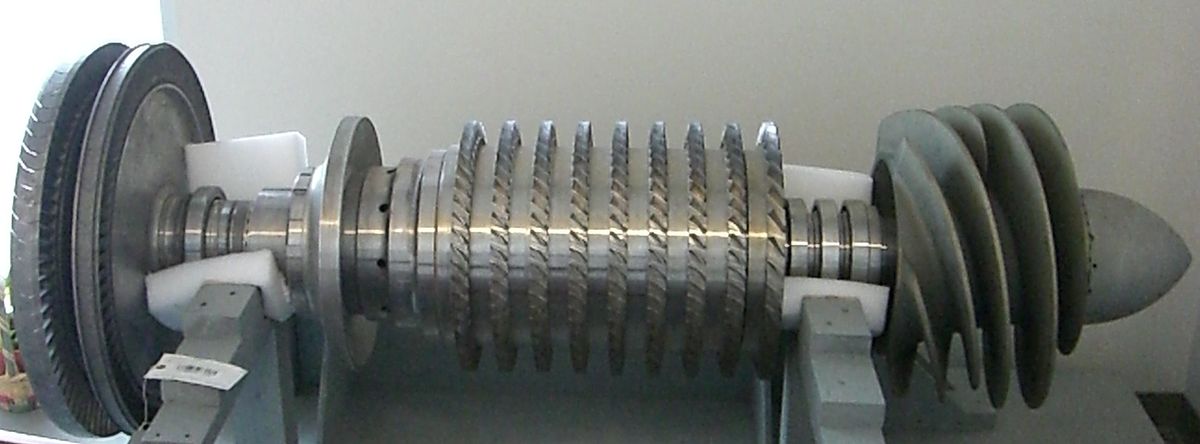

Screw Pumps

A screw pump is a type of rotary pump with a more complicated structure using two or three screws with opposing thread; for example, one screw rotates clockwise and the other counterclockwise. The screws are installed on parallel shafts. The screws drive the fluid through the pump. As with different types of rotary pumps, the clearance between moving components and the casing is minimal.

Rotary Vane Pumps

A rotary vane pump consists of vanes attached to a rotor that turns inside a cavity. In some cases, the vanes have variable lengths and are tensioned to keep contact with the walls as the pump rotates. The weaknesses of this type include being less used than other vacuum pumps for fluids with high viscosity and high pressure, as well as their complex operation. They can withstand short periods of dry performance and are considered suitable for low-viscosity fluids. Visit here to see the working basics of a rotary vane pump.

Hollow Disk Pumps

Hollow disk pumps (eccentric disc pumps or Hollow rotary disc pumps) are similar to scroll compressors, with a cylindrical rotor within a circular housing. As the rotor rotates to some degree, it traps the liquid between the rotor and the casing, pulling the fluid through the pump. It is applied for highly viscous fluids such as petroleum-derived products. It can also operate at high pressures up to 290 psi. To know more, you can see this video.

Vibration Pumps

The working principle of Vibration pumps (or vibratory pumps) is similar to linear compressors. They work utilizing a spring-loaded piston with an electromagnet joined to AC through a diode. The only moving part is the spring-loaded piston that is placed in the center of the electromagnet.

During a positive cycle of the AC, the diode passes the energy through the electromagnet. This created a magnetic field that pushes the piston backward, compressing the spring and causing suction. During a negative AC cycle, the diode blocks the current to the electromagnet, allowing the spring to uncompress, running the piston forward. So, the fluid is pumped similar to a reciprocating pump.

Because of its low cost, it is extensively applied in inexpensive espresso machines. However, vibratory pumps cannot work for more than a minute since they produce large amounts of heat.

Reciprocating Pumps

Reciprocating pumps transfer the fluid utilizing one or more oscillating pistons, plungers, or diaphragms, while valves guide the fluid to a certain direction. In order for suction to be accomplished, the pump must first pull the plunger outward to reduce pressure in the chamber. Once the plunger is pushed back, the pressure increases and the pressure inside the plunger then opens the discharge valve and discharges the fluid into the delivery pipe at high velocity.

The positive displacement pumps include expanding and collapsing cavities on the suction side and the discharge side, respectively. As the cavity on the suction side expands, the fluid flows into the pump, and as the cavity collapses, it flows out of the discharge. The volume is constant with respect to each operating cycle.

Pumps of this type include simplex (with one cylinder), duplex (with two), triplex (with three cylinders), and in some cases quad (with four cylinders), or even more. They can operate with suction during one direction and discharge on the other direction of piston motion (single-acting) or with suction and discharge in both directions (double-acting). The power of pumps can be supplied manually or by an engine.

Reciprocating pumps are typically used to pump highly viscous fluids such as concrete and heavy oils and, in particular, applications requiring low flow rates against high resistance. For example, manual reciprocating pumps were broadly used in pumping water from wells. Also, usual bicycle pumps and foot pumps for inflation apply reciprocating action.

Reciprocating pumps fall into the following main types:

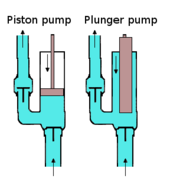

Piston Pumps

A piston pump includes the high-pressure seal and the piston. It can operate in a wide range of pressures. The high-pressure operation can be accomplished without a remarkable effect on flow rate. Another application of this pump is in viscous media and those containing solid particles. The piston pumps are applied in situations requiring high and consistent pressure and also in water irrigation or delivery systems.

The operating is based on an oscillation mechanism in which down-strokes fill the pump chamber, and up-stroke sends the pump fluid out.

Plunger Pumps

A plunger pump is a positive displacement pump in which there are a stationary high-pressure seal and a smooth cylindrical plunger sliding through the seal. This distinguishes them from piston pumps and makes them suitable for higher pressures. Plunger pumps are usually used to move municipal and industrial sewage.

Diaphragm Pumps

Diaphragm pumps work on the same basis as plunger pumps. The plunger pressurizes hydraulic oil used to bend a diaphragm in the pumping cylinder. Diaphragm pumps are used to pump dangerous and toxic fluids.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Types of Screw Pumps: How Each Type Gives Benefits?

- Different Types of Hydraulic Pumps: a Complete Guide

- 12 Types of Water Pressure Pumps with Applications & Characteristics

- A Cheat Sheet For The Types of Pump Couplings

- Types of Centrifugal Pumps: All Classification & Working Principles

- Types of Submersible Pumps: All Classification With Details

- Types of vane pumps: review the types, select the best

- Pump: Working Principles, Function & Diagram

- Types of Water Pumps and Their Principles

- Types of Fire Hydrant Systems

- Types of Piston Pumps

- Pump Efficiency

- Types of Dynamic Pumps

- Types of Fuel Pump