PVC couplings are one of the simplest and most inexpensive types of PVC fittings. Couplings are a very short lengths of pipe or tube applied in the piping system. These couplings find use to connect the pipes and to adjust the thickness of the tubing. They also help to patch broken or leaking pipes. PVC couplings are widely used for water supply, water treatment, petroleum, gas, chemical industry, environmental protection, pharmaceutical, and other fields. PVC couplings commonly serve to prolong or stop pipeline operations.

They are applicable in diameters ranging from 1/4 to 12 inches. These couplings are of high quality, corrosion-resistant, and available in multiple sizes and configurations to fit the pipe they will connect. In this article, we review the types of PVC couplings to help you find the best one that suits your needs. Follow this new blog in Linquip to find out more.

On the Linquip platform, you’ll discover all the information about the PVC couplings you need. If you have any questions about the PVC couplings, we are here to help. To start, visit Linquip and explore the article “What Is PVC Coupling?” for a basic understanding of these fitting tools.

Are you in need of a PVC coupling? For free, you can view a wide selection of PVC Couplings Products here at Linquip. What types of PVC Couplings equipment are you looking to purchase? Linquip provides no-cost access to all available PVC Couplings Devices for Sale. Linquip also provides you the option to send inquiries to all PVC Couplings Suppliers and Companies and receive quotations for free if you are trying to find coupling prices. In order to make a PVC Couplings, a machine called a Dakumar plastic injection molding machine is needed.

What Are The Different Types of PVC Couplings?

Several popular types of these couplings are as follows:

- Full Couplings

- Half Couplings

- Reducing Couplings

- Compression Couplings

- Slip Couplings / Repair Couplings

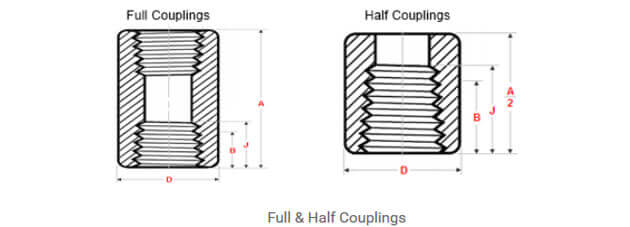

Full Couplings

Full coupling is used for connecting small bore pipes. They find use to connect pipe to pipe or pipe to swage or nipple. Full couplings have both ends of threaded or socket welded connection. These couplings can be threaded or socket ends types.

A socket weld full coupling is used to join small-bore plain end pipes where the pipe spec requirement is socket weld.

A threaded full coupling is used to join small bore pipes with threaded ends. If the two ends of coupling are different, then it is usually referred to as an adapter.

Half Couplings

Half couplings are called so due to their half-size and also because they have a socket or thread end on only one side. They find a use for small-bore branching from a vessel or large-bore pipe. These couplings can be threaded or socket-type.

A socket weld half coupling can be directly welded to a large bore pipe, to make a branch connection. It is used to take a small bore pipe branch-off from a large bore pipe where the pipe spec requirement is socket weld in a small bore size.

A threaded half coupling only has one thread end and another end of the coupling should be a butt welding end with either a plain end or a bevel end.

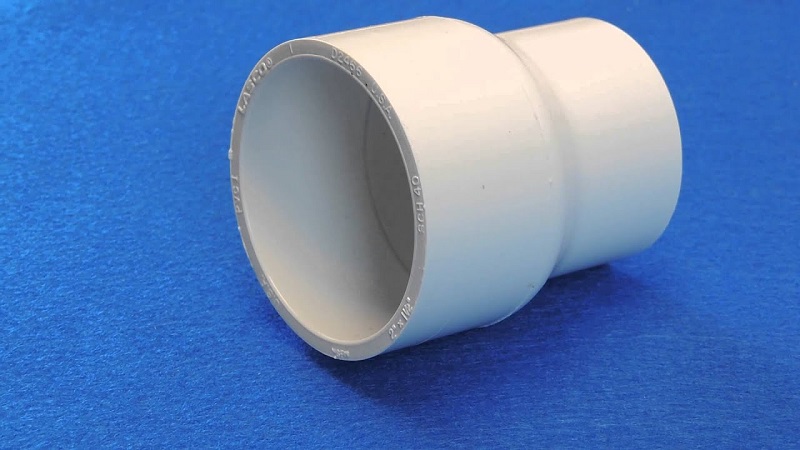

Reducing Coupling

Couplings whose ends use the same connection method but are of different sizes are called Reducing couplings or Reducers. These types of PVC couplings are used to connect pipes of dissimilar diameters. They have two different sizes of threads on each side. Reducing couplings are typically used to extend an existing pipe where small process feeder lines are joined into large supply circuits or where small diameter fittings are installed or where repairing broken pipes is needed.

- Features a simple, stepped-down profile

- Screws in the same way a standard pipe joint does

- Welded reducing coupling designs are similar to threaded designs without the threads.

Compression Coupling

Compression couplings or tees are special fittings designed for joining existing PVC pipes or tubes. They consist of three parts: The compression nut, the compression ring, and the compression seat. As regular couplings, they prevent leakage by the arrangement of gaskets or rubber seals on both sides, otherwise, glue is provided. These couplings connect two perfectly aligned pipes in which a slotted tapered sleeve is placed over the junction and two flanges are drawn over the sleeve so that they automatically center the pipes and provide sufficient contact pressure. They are primarily used for underground connections.

- Easy installation

- Fits both schedule 40 and 80 PVC

- Turns water back on right away

- Suitable for potable drinking water

- Applicable for cold water applications

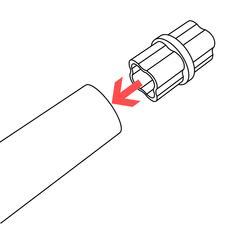

Slip Coupling / Repair Coupling

The PVC slip coupling is a fitting that allows up to two inches of PVC pipe to be removed and repaired using one fitting. Slip couplings, also called repair couplings, are the most efficient way to repair a burst pipe or leak. Slip coupling is deliberately made without any internal stop, to allow it to be slipped freely into place in tight locations, such as the repair of a pipe that has a small leak due to corrosion or freeze bursting, or which had to be cut temporarily for some reason. Slip couplings do the job of two couplings and an extra pipe.

These couplings contain two pipes which are arranged as one into another, the inner pipe can slide up to various lengths. So, slip coupling can fix long-length damaged pipes.

The installer should carefully measure the final location of the slip coupling to ensure that it is located correctly as the alignment stop is missing.

- Quick and easy installation

- No special tools or glue needed for installation

- Can be installed in wet lines

- Compatible with schedules 40, 80, and 120 PVC

- Ideal to have on hand for emergency freezes

- Rated for 200 psi and 200°F (93°C)

PVC Repair Couplings Vs Couplings

PVC repair couplings differ from regular couplings in the following ways:

- The purpose of PVC repair couplings is to join PVC pipes. With their threaded connection, they screw onto pipes, along with the possibility of cutting and gluing them together using PVC cement. However, Pipes of various materials can be connected using standard couplings, including PVC, metal, and plastic ones. The smooth connections slide over the pipes, and clamps or screws can be used to secure them.

- The PVC repair coupling is an easy and quick way to repair plumbing leaks. On the other hand, the versatility of regular couplings makes them ideal for a wide range of applications.

- The cost of PVC repair couplings is lower than that of regular couplings.

- There may be difficulty in finding PVC repair couplings because they are less common than regular couplings.

- There is a wide variety of sizes and shapes available for regular couplings, but only a few sizes are available for PVC repair couplings.

PVC Couplings connect two PVC pipe segments inline to extend pipe lengths. They are also used to add breakdown points within your PVC structure. Two types of PVC couplings options are as follows:

-

Internal Couplings

These couplings connect inside PVC pipe and leave a smooth appearance.

-

External Couplings

These couplings connect over PVC pipe and leave a visible connection.

The two other main categories that couplings under the scope of PVC fittings can be divided into:

-

Permanent Couplings

In the case of steel or copper tubing or adhesives, permanent pipe couplings generally make use of soldering or brazing in the case of PVC pipes. If properly mounted, these permanent couplings provide excellent rigidity, outstanding stability, and sealing properties where no potential piping improvements are foreseen.

-

Removable Couplings

Removable pipe couplings are most commonly of a threaded design that allows them to be screwed onto the pipes to be joined and tightened. The ends of the pipes are also threaded, and the coupling is conveniently sealed and set with hemp or sealing tape and screwed onto both pipes.

The most simple and smallest of these is a much wider base pipe segment slightly larger than the pipes to be joined and cut by an internal thread.

So, there you have every single fact about the types of PVC couplings. If you enjoyed this article in Linquip, let us know by leaving a reply in the comment section. Is there any question we can help you with? Feel free to sign up on our website to get the most professional advice from our experts.

FAQs about PVC Coupling Types

- What is the difference between pipe coupling and pipe union?

There is a fundamental difference between a coupling and a union: a coupling joins pipes or connects pipes to swedges, whereas a union is used for the assembly and disassembly of parts in a piping system (a steam trap, a control valve, etc.) during maintenance or replacement.

Download Types of PVC Couplings PDF

The PDF version of this article can also be downloaded to your computer.

Watch Video for PVC Coupling Types

In this video, you’ll learn the most common types of PVC couplings.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- A Cheat Sheet For The Types of Pump Couplings

- Advanced Guide: Types of Rigid Couplings

- What Is a Fluid Coupling? With the Focus on the Working Principle and Usages

- The Practical Guide To Types of Coupling in 2021

- Types of Gear Coupling: a Basic Yet Crucial Description of the Types

- What is Grid Coupling: Essential Details You Need To Know

- What is Disc Coupling: A Complete Guide

- What is Sleeve Coupling? Ultimate Guide

- What is Jaw Coupling? Working Principle & Size Chart

- The Complete Library of Types of Flexible Coupling

- Types of Shaft Couplings: A Simple Guide to The Types