Types of Scaffolding – Scaffolding is only a temporary structure that serves as a platform for the construction workers to operate from while also supporting the original building. The kind of scaffolding will vary depending on the type of construction work. It’s critical to select the appropriate scaffolding system for your construction project in order to provide the highest level of worker safety. To support employees and other construction materials placed on it, scaffolding has to be well-built, sturdy, and solid. Scaffolding is built of either steel or wood.

Linquip website contains a lot of information about scaffolding. No matter what situation you are in, we can help you determine the appropriate scaffolding. Linquip provides a diverse range of Scaffolding Products to ensure that you can find one that meets your requirements.

On Linquip’s website, a comprehensive list of scaffolding is available to all OEM fleets. Linquip vendors can help you with this. Please contact Scaffolding Experts to learn more about how to find a diverse choice of Service Providers who consistently supply high-quality products. The Linquip platform provides a cost-free quotation request service from available Scaffolding Suppliers and Companies if you want to know the cost of scaffolding .

What Is Scaffolding?

Scaffolding is a transient elevated structure made to support personnel and tools as they work, typically next to another permanent structure like a building. Although there are 17 various types of scaffolding, wood and steel are the most often used materials. Steel is the chosen material for scaffolding due to its durability and safety, while being more expensive. The term “wood pole scaffolding” refers to scaffolding composed completely of wood components.

There are two types of scaffolding: single frames and double frames. One frame is all that is needed to hold one side of the scaffolding, with the building itself serving as an additional support. A double frame indicates that the scaffolding is separate from the building.

We’ve prepared a list of the most prevalent sorts, as well as two alternatives and safety precautions below. But first, a short rundown of scaffolding’s components.

Scaffolding Components

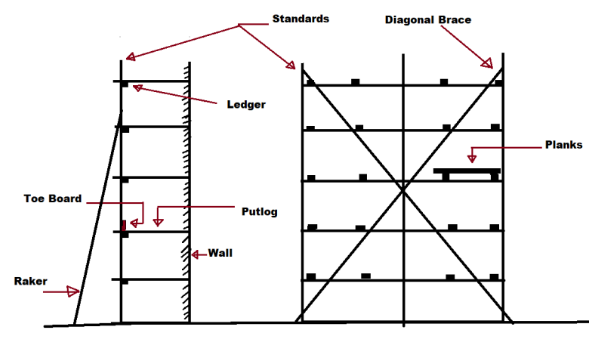

Here is a short explanation of basic terms before we discuss the various types of scaffolding:

- Standards: the vertical components that are somehow attached to the earth

- Ledgers: the horizontal components parallel to the building that the scaffolding encloses

- Braces: the diagonal components that attach to the standards and ledgers and give support.

- Putlogs: the small pieces that link the ledger to the structure itself in single-frame scaffolding.

- Boardings or platforms: the broad, flat surfaces that employees walk on

- Guardrails: the pieces that link the standards horizontally at around waist level to assist prevent falls.

- Toeboards: narrow pieces of wood that run horizontally immediately above the boardings or platforms to prevent falls.

Types of Scaffolding

16 Types of Scaffolding include:

- Catenary Scaffolding

- Float Scaffolding

- Interior Hung Scaffolding

- Two-Point (Swing Stage) Scaffolding

- Multilevel Scaffolding

- Multipoint Adjustable Scaffolding

- Needle Beam Scaffolding

- Cantilever Scaffolding

- Single-point Adjustable Scaffolding

- Frame Scaffolding

- Ladder Jack Scaffolding

- Mast Climber Scaffolding

- Mobile (Manual or Propelled) Scaffolding

- Pole/Wood Pole Scaffolding

- Trestle Scaffolding

- Tube and Coupler Scaffolding

All scaffolding can be sorted into two main categories:

- Suspended scaffolding, and

- Supported scaffolding.

Suspended Scaffolding

Platforms that are suspended from above, often a rooftop, by flexible materials like ropes or wires, make up suspended scaffolding. Suspended scaffolding is chosen for reaching the tops of big structures, when supported scaffolding would be too costly and time-consuming to create. However, weight restrictions exist, and horizontal reach may be limited. In strong winds, using suspended scaffolding can also be risky since a swaying platform might cause the support lines to shatter.

1. Catenary Scaffolding

Ropes or wires are suspended from a building above in catenary scaffolding. Two ropes or wires that run horizontally and parallel to the building are joined by these vertical wires or ropes. On the horizontal ropes or wires, a platform is supported.

Catenary scaffolding cannot be easily moved to a different location or raised to a different height because it is immobile.

2. Float Scaffolding

fixed-length ropes or wires suspended from a support beam that runs perpendicular to the building. The two ledgers that support the platform are held up by the ropes or wires.

Float scaffolding is stationary, much like catenary scaffolding. It is additionally known as ship scaffolding.

3. Interior Hung Scaffolding

Similar to float scaffolding, interior hanging scaffolding suspends the ropes or wires from two parallel support beams that run parallel to the building.

4. Two-Point (Swing Stage) Scaffolding

The most popular kind of suspended scaffolding, two-point (swing stage) scaffolding consists of a platform that can be raised and lowered and is supported at either end by wires or ropes.

Scaffolding that is hanging from the sides of tall buildings is typically two-point (swing stage) scaffolding.

5. Multilevel Scaffolding

Multilevel scaffolding is hung from the structure by ropes or wires, each of which holds a ladder that faces perpendicular to the structure. Between the two ladders is a platform that rests on the rungs.

If the ladders are long enough, additional platforms can rest on them to construct many tiers, unlike all other types of suspended scaffolding.

6. Multipoint Adjustable Scaffolding

In multipoint adjustable scaffolding, four ropes—typically one in each corner of the platform—hold a platform hung from the ceiling. It can be raised or lowered to the required height, making it more versatile than the other suspended scaffolding types we’ve studied thus far.

This kind of scaffolding is widely employed in stacks, tanks, silos, and chimneys due to its flexibility in height.

7. Needle Beam Scaffolding

The name “needle beam scaffolding” refers to the needle beams that are putlog-adhered perpendicularly to the structure. Ropes or wires suspended from the ceiling support the beams’ outside edges. The platform is then supported by the needle beams on top.

8. Cantilever Scaffolding

When the ground cannot sustain a scaffolding structure or when there is not enough area for the platforms at lower levels, cantilever scaffolding is employed.

Similar to needle beam scaffolding, cantilever scaffolding also uses needle beams that are put into the building’s framework and often fastened to the inside floor. However, unlike needle beam scaffolding, they don’t run perpendicular to the structure; instead, they run at an angle to support the standards, which run vertically and parallel to the building.

9. Single-point Adjustable Scaffolding

If you’ve ever seen a window washer working alone to clean a skyscraper, they were undoubtedly using single-point adjustable scaffolding. Similar to multipoint adjustable scaffolding, but suspended from a single rope or wire as opposed to numerous ones.

In allusion to the hanging chair a boatswain employs to survey the ship’s side, this kind of scaffolding is also known as boatswain scaffolding.

Supported Scaffolding

Support scaffolding, which comprises platforms that are supported by standards that are somehow fixed to the ground, is the second type of scaffolding. They are constructed from the ground up, in other words.

Supported scaffolding is reliable, and you may build as many levels as you like with some of them. However, they can be difficult to utilize when the terrain is uneven or if the base’s footprint is constrained by a road.

10. Frame Scaffolding

The most popular form of supported scaffolding is frame scaffolding, commonly referred to as manufactured scaffolding, since it is the least expensive, the simplest to build up and take down, and the most adaptable.

This kind of scaffolding is constructed from the ground up using modular sections. It is often constructed in one or two stages, but because the foundation must be absolutely level, it can be challenging.

Painters and residential contractors prefer frame scaffolding.

11. Ladder Jack Scaffolding

A ladder jack scaffold is one of the most basic forms of scaffolding that is accessible. A jack scaffold is made up of two or more leaning ladders that are angledly set against a building. The ladder has brackets on it that allow it to reach perpendicularly to the building. The brackets are parallel to the structure, and a platform (or perhaps just another ladder) lies on top of them.

Ladder jack scaffolding should only be used for carrying small weights.

12. Mast Climber Scaffolding

The ideal scaffold to use if you have a large load is a mast climber. A sizable platform that is powered up and down by a motor is anchored to a tall structure that resembles a ship’s mast. Two masts may be utilized for platforms that are bigger.

13. Mobile (Manual or Propelled) Scaffolding

The only scaffolding that can be moved on the ground rather than up and down is this one. A platform is situated roughly halfway up four standards that are connected by ledgers and guardrails. In order to prevent injuries, the scaffold should only be utilized while the wheels are fastened on each standard. The scaffolding may have a motor to move it from the platform or may be handled manually from the ground.

14. Pole/Wood Pole Scaffolding

Pole scaffolding is any scaffolding design that uses wood for every structural component. Steel scaffolding has taken the role of pole scaffolding, with the exception of bamboo scaffolding, which is mostly utilized in Asia since it is safer, stronger, and more reusable.

15. Trestle Scaffolding

Step ladders or tripods can be used to support a platform to make trestle scaffolding instead of utilizing standards. The only level that trestle scaffolding may have is one, unlike other supported scaffolds.

16. Tube and Coupler Scaffolding

Tube and coupler scaffolding, sometimes referred to as systems scaffolding or patented scaffolding, is made up of a number of prefabricated components that are simply coupled together. Kwikstage and HAKI are two popular systems.

Alternatives for Scaffolding

If you need to increase height but are afraid of scaffolding or don’t have enough space for it, try the scaffolding alternatives listed below.

Scissor Lifts

A scissor-shaped platform that travels vertically on a series of cross beams that are motorized and mounted on wheels makes up a scissor lift, a sort of movable support structure.

Scissor lifts vary in that some can be moved while the platform is elevated and others can only be moved after the platform is down. Most of the time, the platform itself has the controls for raising it, allowing the person on the scaffold to move it without the aid of another person.

Aerial Lifts

Aerial lifts include all lift types that do not employ the scissors beam construction and are supported scaffolding as well. They are frequently referred to as vertical lifts, buckets, booms, or towers. They can be controlled by one person because they are on wheels and have a control panel on the platform, just like scissor lifts. It is essential to remember that there are certain safety precautions for scissor lifts and aerial lifts that must always be observed.

As long as people have been building taller structures, scaffolding has been a crucial part of building construction. Steel scaffolding has mostly replaced wooden scaffolding over the years, and several projects that once required scaffolding are now finished with scissor or aerial lifts. Without a doubt, as people try to construct taller structures, scaffolding will continue to develop.

FAQs about Types of Scaffolding

-

What Does The Scaffolding 3 To 1 Rule Mean?

A freestanding scaffolding tower’s overall working height should be three (3) times the width of its base’s narrowest side (if this is a measurement of outriggers, they must be set symmetrically about the tower).

-

How Do You Determine The Load On A Scaffold?

Light-duty scaffolding, or 25 pounds per square foot, is what is being employed. The maximum weight that may be placed onto the scaffolding is 875 pounds when 35 square feet are multiplied by 25 pounds per square foot.

-

What Does A Scaffolding Dead Load Mean?

The weight of the scaffold itself is typically referred to as the dead load. This weight comprises the standard’s weight as well as the weight of any attached parts, such as frames, cross braces, planks, guardrails, and attachments. The height of the scaffold raises the dead load.

-

What Is The Scaffolding Safety Factor?

To prevent tipping, make sure a scaffold is constructed with a 4×1 safety factor. When guardrails are not accessible at heights greater than 10 feet, require employees to utilize a personal fall arrest system (PFAS). If a power source is exposed, build scaffolds at least 10 feet away from it, unless it has been insulated or de-energized.

Download Types of Scaffolding PDF

There is an option to download the article in PDF format if you find that to be more convenient for you. You can download the file by clicking on the following link.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- 8 Types of O-Ring + Applications (Clear Guide)

- 18 Types of Machining Vises (Clear Guide)

- 28 Types of Clamps: A Complete Guide

- The 10 Best Electric Lawnmowers in 2022

- The 6 Best Leaf Blowers of 2022 + Buying Guide & PDF

- The 10 Best Snow Blowers of 2022 + Buying Guide & PDF

- The 10 Best Electric Pressure/Power Washers in 2022

- The 10 Best Torque Wrenches For 2022 + PDF & Buying Guide

- The 8 Best Attic Ladders in 2022 + Buying Guide & PDF

- The 10 Best Electric Space Heater in 2022 + Buying Guide

- The 9 Best Cordless Impact Wrenches in 2022

- The 7 Best Portable Band Saws in 2022 + Tips for Choosing

- The 10 Best Circular Saws in the USA in 2022

- The 10 Best Hammers (2022 Review)

- 33 Types of Pliers & Their Names: A Comprehensive Explanation