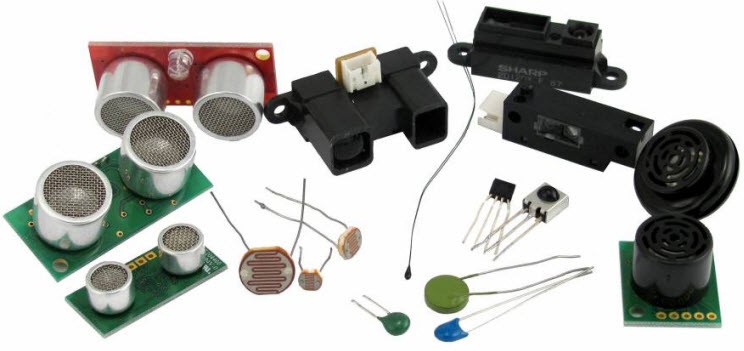

Types of Sensors Detectors/Transducers – Sensor/Detector/Transducers are electrical, opto-electrical, or electronic devices made of specialized electronics or other sensitive materials that are used to determine whether an object or function is present. There are many different kinds of sensors, detectors, and transducers out there, such as those for sensing physical presences like flame, metals, leaks, levels, or gas and chemicals, among others. Some can detect motion or proximity, while others can sense physical characteristics like temperature, pressure, or radiation. Based on the application, they can function in a variety of ways, including electromagnetic fields and optical. Sensors, detectors, and transducers of different types are utilized in numerous applications across a wide range of industries to test, measure, and control various machine functions.

Linquip contains a lot of information about Sensors/Detectors/Transducers. No matter what situation you are in, we will be able to assist you with finding the right sensors/detectors/transducer. Linquip offers a wide selection of Sensor/Detector/Transducer Products to ensure that you can find the one that suits your needs.

All OEM fleets can access a comprehensive list of sensors/detectors/transducers on Linquip’s website. Linquip vendors can assist you with this. Please get in touch with Sensors/Detectors/Transducer Experts to find out more about how to find a board range of Service Providers who consistently deliver high-quality goods. The Linquip platform provides a cost-free quotation request service from available Sensor/Detector/Transduce Suppliers and Companies if you want to know the cost of a Sensors/Detectors/Transducer.

What Is A Sensor?

A sensor is a device or module that detects changes in physical quantities such as pressure, force, or electrical quantities such as current or any other type of energy. The sensor transfers the observed input to a microcontroller or microprocessor after observing the changes.

Finally, a sensor generates a readable output signal, which can be optical, electrical, or any other type of signal corresponding to a change in the input signal. Sensors play an important part in every measuring system. In reality, sensors are the first part in the measurement system’s block diagram that comes into direct touch with the variables to provide a valid output.

Examples: The mercury in the thermometer turns the recorded temperature into an expansion and contraction of the liquid, which may be readily measured using a calibrated glass tube. The thermocouple also converts temperature to an output voltage, which the thermometer measures.

Classification of Sensors

The sensors can be classified as follows:

- Active and Passive Sensors

- Analog and Digital Sensors

Active Sensors

Active sensors are the sort of sensors that generate output signals with the aid of an external stimulation supply. The sensor’s physical characteristics change depending on the applied external influence. As a result, it is also known as Self-Generating Sensor

Passive Sensors

Passive sensors provide output signals without the help of an external stimulation supply. They do not require any further excitation or voltage. A thermocouple, for instance, produces a voltage value in proportion to the heat applied. There is no need for an external power supply.

Analog and Digital Sensors

The many types of digital and analog sensors, along with their uses, are given below.

Different Types of Sensors

The following are the main categories of sensors:

- Position Sensors

- Pressure Sensors

- Temperature Sensors

- Force Sensors

- Vibration Sensors

- Piezo Sensors

- Fluid Property Sensors

- Humidity Sensors

- Strain gauges

- Photo Optic Sensors

- Flow and Level Switches

These categories can all be subdivided further; for example, among position sensors, there are the following types:

- Contacting

- Non-contacting

- Rotary

- Linear

And these categories of sensors may be further subdivided; non-contacting sensors include the following types of sensors:

- Hall effect

- Capacitive

- Eddy Current

- Ultrasonic

- Laser

- Proximity

By dividing one category – Position Sensors – it is evident that the number of sensors existing in today’s world is so enormous that one blog article could not cover every type of sensor.

What Is A Transducer?

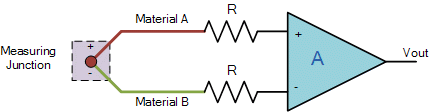

An electrical transducer is a device that can transform physical quantities into proportionate electrical quantities such as voltage or current. As a result, it transforms any amount to be measured into a usable electrical signal. Pressure, level, temperature, displacement, and other physical quantities can be monitored. The output from the transducer is in electrical form and is comparable to the measured quantity. A temperature transducer, for example, will convert temperature to an equivalent electrical potential. This output signal can be used to regulate or show the physical quantity.

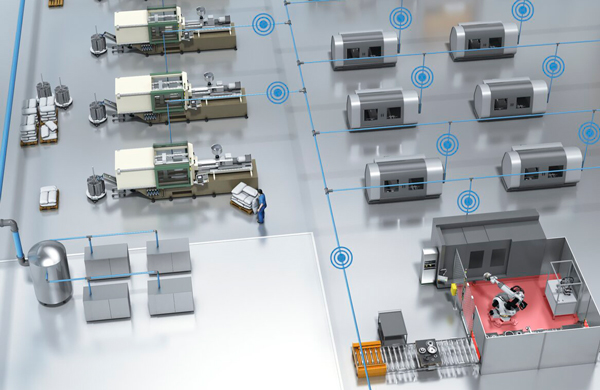

The core of industrial applications is instrumentation. The art and science of measuring and managing various variables such as flow, level, temperature, angle, displacement, and so on is known as instrumentation. A simple instrumentation system is made up of many devices. A transducer is one of these different devices. A transducer is an essential component of any instrumentation system.

It is important to note that a transducer is any device that can transform one type of energy into another. A speaker, for example, can be considered a transducer since it translates electrical signals to pressure waves (sound). An electrical transducer, on the other hand, will transform a physical amount to an electrical quantity.

Different Types of Transducer

There are many different sorts of transducers, and they may be categorized according to various criteria, such as:

- Types of Transducer based on Quantity to be Measured

- Temperature transducers (e.g. a thermocouple)

- Inductive transducer

- Pressure transducers (e.g. a diaphragm)

- Displacement transducers (e.g. LVDT)

- Oscillator transducer

- Flow transducers

- Types of Transducer based on the Operation Principle

- Photovoltaic (e.g. a solar cell)

- Mutual induction

- Electromagnetic

- Chemical

- Hall effect

- Piezoelectric transducer

- Photoconductors

- Types of Transducer based on Whether an External Power Source Is Required or Not

- Active Transducer

- Passive Transducers

Active Transducers

Active transducers are ones that do not require a power source to function. They operate on the concept of energy conversion. They create an electrical signal that is proportional to the input (physical quantity). A thermocouple, for example, is an active transducer.

Passive Transducers

Passive transducers are those that require an external power source to operate. They produce an output signal in the form of a fluctuation in resistance, capacitance, or any other electrical feature, which must then be translated to an equivalent current or voltage signal. A photocell (LDR) is an example of a passive transducer that changes its resistance when exposed to light. A bridge circuit converts the resistance change to a proportional signal. As a result, a photocell may be used to quantify the intensity of light.

A bonded strain gauge, which is a passive transducer employed to monitor stress or pressure, is seen above. As the strain gauge’s stress increases or reduces, it bends or compresses, causing the resistance of the wire linked to it to increase or decrease. A bridge is used to assess the change in resistance that corresponds to the change in stress. As a result, stress is measured.

Common Types of Sensors/Detectors/Transducers

Vision and Imaging Sensors

Imaging and Vision Sensors/Detectors are electrical devices that detect the presence of objects or colors inside their fields of view and convert this information into a visual image for display. Key characteristics include sensor type and intended use, as well as any special transducer properties.

Temperature Sensors

Temperature Sensors/Detectors/Transducers are electronic devices that detect thermal characteristics and provide signals to control and display devices’ inputs. An RTD or thermistor is often used in temperature sensors to measure temperature and convert it to an output voltage. Key characteristics include sensor/detector type, maximum and minimum measured temperatures, and diameter and length dimensions. Temperature sensors are used in various process industries to detect the thermal properties of gasses, liquids, and solids. They are available in general-purpose and special-purpose configurations.

Radiation Sensors

Radiation sensors and detectors are electronic devices that detect the presence of alpha, beta, or gamma rays and provide signals to counters and displays. Sensor type, as well as minimum and maximum detectable energies, are important parameters. Radiation detectors are employed in surveys and sample counting.

Pressure Sensors

Pressure sensors are commonly divided into two types: pressure transducers and pressure switches. The key distinction is that pressure transducers provide precise real-time pressure feedback, whereas pressure switches have a set limit that causes them to switch. To detect pressure, both pressure switches and pressure transducers employ mechanisms that employ the formula – Pressure Equals force divided by area.

Pressure sensors are utilized in a variety of industries to detect pressure in gasses, liquids, and solids. Underwater pressure transducers are sometimes known as level meters since the pressure they measure is proportional to the water level.

Proximity Sensors

Proximity Sensors are non-contact electronic sensors that sense the presence of surrounding objects. A proximity sensor detects the presence of items within a few millimeters and send an alternating current (DC) output signal to a controller. Proximity sensors detect the presence of items and machine components in numerous manufacturing procedures. Key properties include sensor type, maximum sensing distance, minimum and maximum operating temperatures, and diameter and length measurements. Proximity sensors are typically short-range devices, however, variants that can detect things up to several inches away are also available. A capacitive proximity sensor is a type of proximity sensor that is extensively utilized. This device employs the change in capacitance caused by a decrease in the separation distance between the plates of a capacitor, one of which is attached to the item being observed, to determine the motion and position of the object from the sensor.

Position Sensors

Position Sensors/Detectors/Transducers are electronic devices that sense the positions of valves, doors, throttles, and other similar devices and give signals to the inputs of control or display devices. The sensor type, sensor function, measurement range, and characteristics specific to the sensor type are important criteria.

The distance between two places, such as the distance traveled or moved away from a fixed point, or the “rotation” (angular movement) of an object are two ways to determine a position. A robot’s wheel rotation, for instance, may be used to calculate how far it has traveled on the ground. In any case, Rotational Sensors or Linear Sensors may detect an object’s rotational movement or its movement in a straight line.

A string-pot, also known as a string potentiometer, is a typical position transducer.

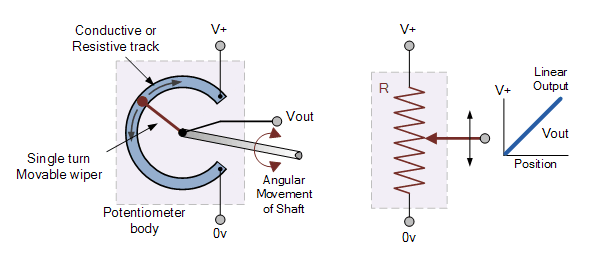

The Potentiometer As a Position Sensor

The potentiometer is the “Position Sensor” that is used the most frequently since it is a cheap and simple device. It makes use of a wiper contact connected to a mechanical shaft that may travel down a track either linearly (slider type) or angularly (rotationally). As a result of this movement, the resistance between the wiper/slider and the two end connections changes, resulting in the output of an electrical signal that is proportionate to the actual location of the wiper on the resistive track. In other words, resistance is proportional to physical position.

Potentiometers are available in a variety of shapes and sizes, including the widely used circular rotating type and the longer, flat linear slider varieties. The moving item is directly attached to the potentiometer’s rotating shaft or slider when being utilized as a position sensor.

The two outside fixed connections that make up the resistive element are subjected to a DC reference voltage. The wiper terminal of the sliding contact, as illustrated below, is where the output voltage signal is obtained.

This configuration generates a potential or voltage divider type circuit output that is proportional to the shaft position. If you applied a voltage of say 10 volts across the resistive element of the potentiometer, the highest output voltage would be equal to the supply voltage at 10 volts, with the minimum output voltage equal to 0 volts. The output signal from the potentiometer wiper will then range from 0 to 10 volts, with 5 volts signifying the wiper or slider’s midpoint or center position.

As the shaft rotates along the resistive track, the center wiper connection provides the potentiometer’s output signal (Vout), which is proportional to the shaft’s angular position.

Photoelectric Sensors

Electrical photoelectric sensors are capable of detecting color, cleanliness, and position if necessary. They detect items moving via their field of detection. These sensors rely on an emitter and a receiver to measure changes in the light they emit. For tasks like counting, robotic picking, and automatic doors and gates, they are frequently used in manufacturing and material handling automation.

Piezoelectric Sensors

This device is a type of transducer whose primary function is to convert mechanical energy into electrical energy. Similarly, electrical energy may be converted into mechanical energy. This transducer is mostly used to detect the impact of the stick drummer on electronic drum pads. Also used to detect muscle movement, which is known as acceleromyography. The engine load may be calculated by calculating various absolute pressures, which can be accomplished by employing these transducers as the MAP sensor in fuel injection systems. Additionally, this can be used as a knock sensor in automobile engine management systems to detect engine knock.

Particle Sensors

Particle Sensors/Detectors are electronic devices that detect dust and other airborne particles and send signals to control or display devices’ inputs. Monitoring of bins and baghouses frequently uses particle sensors. The transducer type, smallest detectable particle size, operating temperature range, sample volume, and response time are important criteria. Radiation detectors are the name given to particle detectors used in nuclear engineering.

Motion Sensors

Electronic devices called motion sensors, detectors, or transducers may detect the movement or immobility of objects, people, or other moving parts, and they can send signals to the inputs of control or display systems. Typical motion detection applications include detecting conveyor stopping and bearing seizing. The intended application, sensor function sensor type, and minimum and maximum speeds are among the key requirements.

Metal Sensors

Metal detectors are electrical or electromechanical devices that detect the presence of metal in a number of circumstances ranging from packages to people. Metal detectors use a variety of sensing methods, with electromagnetics being a prominent choice. They can be stationary or mobile. The intended application, the maximum sensing distance, and particular feature selections like handheld and fixed systems are important characteristics. Metal can be specifically detected by metal detectors during specialized industrial processes, including sawing or injection molding.

Level Sensors

The height of gasses, liquids, or solids in tanks or bins can be determined using level sensors/detectors, which are electrical or electro-mechanical devices that provide signals to the inputs of control or display systems. Standard level sensors measure the height of the product using ultrasonic, vibratory, capacitance, or mechanical methods. Sensor type and function, and maximum sensing distance are important parameters. There are two types of level sensors/detectors: contacting and non-contacting.

Leak Sensors

Leak Sensors/Detectors are electrical devices that detect or monitor the unplanned release of liquids or gasses. For example, some leak detectors use ultrasonic technology to find air leaks. Other leak detectors evaluate the integrity of pipe couplings using straightforward foaming agents. However, different leak detectors are also used to gauge how well vacuum package seals work.

Humidity Sensors

The quantity of water in the air is measured by humidity sensors, detectors, and transducers, which then turn the measurements into signals that may be utilized as inputs to control or display devices. The maximum response time and the lowest and maximum working temperatures are important requirements.

Gas and Chemical Sensors

The presence and characteristics of various gasses and chemicals are sensed by fixed or portable gas and chemical sensors/detectors, which then transmit signals to the inputs of controllers or visual displays. The desired application, sensor/detector type, measurement range, and characteristics are important parameters. The capacity to detect numerous gasses and chemicals is typically included into gas and chemical sensors and detectors that are used for confined space monitoring, leak detection, analytical instrumentation, etc.

Force Sensors

Force Sensors/Transducers are electronic devices that measure different characteristics related to forces such as weight, torque, load, and so on and deliver signals to control or display devices’ inputs. A load cell, as a piezoelectric device whose resistance changes under deforming stresses, is often the foundation of a force sensor. Torque and strain can also be measured by using other techniques. The sensor’s purpose, the number of axes, the minimum and maximum loads (or torques), the minimum and maximum working temperatures, and the sensor’s physical dimensions are some of the most important criteria. All types of load measurement applications, such as truck scales and bolt tensioning equipment, require force sensors.

Flow Sensors

The movement of gasses, liquids, or solids can be detected by flow sensors, which are electrical or electro-mechanical devices that provide signals to the inputs of control or display devices. A flow sensor can be entirely electrical, such as when it uses ultrasonic detection from outside a pipeline, or somewhat mechanical, such as a paddlewheel that sits and spins within the flow stream itself. The kind of sensor/detector, the purpose of the sensor, the maximum flow rate, the maximum working pressure, and the min and max operating temperatures are important requirements. The processing industries make considerable use of flow sensors. Some panel mounting styles enable process operators to see flow conditions quickly.

Flaw Sensors

Flaw Sensors/Detectors are electronic devices that are used in a number of industrial processes to detect flaws on surfaces or in underlying materials such as welds. Flaw detectors, which can be portable or fixed installations, employ ultrasonic, acoustic, or other methods to find flaws in materials. Sensor type, detectable flaw or thickness range, and intended application are important criteria.

Flame Sensors

Flame detectors are optoelectronic devices used to detect the presence and intensity of fire and provide signals to the inputs of control devices. In many combustion control applications, such as burners, a flame detector is used to detect the existence of flame using UV or infrared light. The detector type is a vital criterion. Flame detectors are used in safety applications as well, for as in engine compartment fire suppression systems.

Electrical Sensors

Electrical Sensors/Detectors/Transducers are electrical devices that detect current, voltage, and other parameters and send signals to control devices or visual displays. Hall effect detection is a common technique used in electrical sensors, however there are additional approaches. The operational temperature range, minimum and maximum measurement ranges, sensor type, and sensor function are some important criteria. Electrical sensors are utilized anywhere information about the condition of an electrical system is required, in anything from railway systems to the monitoring of fans, pumps, and heaters.

Download Types of Sensors Detectors/Transducers PDF

There is an option to download the article in PDF format if you find that to be more convenient for you. You can download the file by clicking on the following link.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Types of Circuit Breaker: A Basic Guide to Know Different Classifications

- 15 Types of Electrical Power Connectors (Clear Guide) + PDF

- Types of Thermometers: All You Need to Know

- Types of Electric Circuits: All Classification with Application

- 5 Types of Proximity Sensors (Application and Advantages)

- 3 Main Types of Pneumatic Cylinders With Application

- Types of Resistor: Classification, Application, and Finally Clarification

- 7 Types of Capacitors and Their Uses

- 3 Different Types of Hygrometers and Their Applications

- All Types of Pneumatic Fittings: Specifications and Applications

- 4 Types of Thermowell: Application and Duty

- 10 Types of CNC Machine + Applications & PDF

- Temperature Sensors: Types, working principle & Practical Applications

- Temperature and Humidity Sensors: An Ultimate Guide

- What is Humidity Sensor: Your go-to Guide on humidity Sensors!

- Types of Humidity Sensors: A Full Explanation on The Most Common Types

- Important Detailed Information About The Types of Transducers

- How to Wire Up Piezoelectric Sensor? A Comprehensive Guide