Types of Socket Wrench – As the sockets and attachments on a socket tool or socket wrench are interchangeable, you may use them for a variety of applications. Here are some common parts of a socket and ratchet system that can help you choose the right tool for your job.

On the Linquip website, among the many options available to you, you will find all the information you need to know about the Socket Wrenches, as well as information regarding this marketplace. You can count on Linquip to provide you with as much general and reliable information about this topic, whether you’re a professional or a customer looking for a proper company. We recommend you review a list of all Socket Wrench Products available in Linquip. You can also be encouraged to visit Socket Wrench for Sale and find the most suitable device based on your applications and demands.

What is a Socket Wrench?

A socket wrench, sometimes known as a socket spanner, is a type of wrench that employs a closed socket format rather than the more conventional open wrench or spanner to spin a fastener, most often in the shape of a nut or bolt.

The ratcheting socket wrench, often known as a ratchet, is the most widely used kind. A ratchet features a reverse ratcheting mechanism that eliminates the need to remove and reinstall a wrench in order to spin the socket on the tool.

Pneumatic impact wrenches, hydraulic torque wrenches, torque multipliers, and breaker bars are other typical tools used to drive sockets. Uncommon hybrid drivers include hydraulic impact wrenches and square drive striking wrench equipment (typically powered by on-site hydraulic power such as that present in military tanks and many rail car applications).

The fundamental modern socket shape is hexagonal, sometimes known as “6-point” because of the pointy intersections where its six solid-sided facets converge. Using a male/female square connection fitting, these are connected to the driving tool (called the square drive). There are several common square drive sizes used throughout the world, including 1/4, 3/8, 1/2, 3/4, 1, 1 1/2, 2 1/2, and 3 1/2 in (6.4, 9.5, 12.7, 19.1, 25.4, 38.1, and 88.9 mm) square drive sizes. Less common square drive sizes include a 5/8-inch square drive and both No. 4 and No. 5 spline drives that are specified in ANSI B107 specifications. Due to the vast range of available square drive diameters, a wide range of socket types and sizes are available to accommodate small to extremely large nuts and bolts. Certain square drivers contain a through hole to allow the socket to be attached to the driver using a locking pin, friction ball, or retaining ring with an O-ring and pin (or single-piece molded retention rings). For rapid socket release of smaller sockets, certain standard hand ratchets have a quick release button on top. The socket wrench is driven by a tool that eventually gives the user the mechanical advantage they need to apply the torque necessary to either loosen or tighten the fastener as necessary. More torque often requires larger drivers, whereas smaller drivers are more practical in smaller, low-torque applications. Given the limitations of human strength and tiredness, torque beyond 800 Nm (600 lb-ft) would typically require some sort of power assistance rather than the operator just pulling on a wrench’s handle. To provide torque, very large sockets and drivers are often driven by hydraulics.

Male drivers, often known as Allen drivers (a trademark) or male bit drivers in general, are also made for use with socket head cap screws.

The main benefit of interchangeable sockets is that just individual sockets are required for each size and kind of fastener, as opposed to requiring a different wrench for each. Almost all screw and bolt types now have sockets of various sorts produced to accommodate their bolts or nuts due to their adaptability. To accommodate the heads of various-sized fasteners, sockets sometimes come in “socket sets” that include a variety of sizes and types of sockets. With socket sets, a ratchet of the “set size” is frequently provided. Sockets are frequently offered in metric and fractional inch sizes, as well as short (shallow) and long (deep) variations.

Types of Ratchets

Ratchets are primarily distinguished by their drive, often known as their size. 1/4-inch drive, 3/8-inch drive, and 1/2-inch drive ratchets are the most popular sizes. Moreover, bigger ratchet sizes, like the 3/4-inch drive and the 1-inch drive, are available.

The majority of ratchets used with sockets have a gear system that only permits rotation in one direction. When working in small spaces that don’t leave much room for the handle to move, a ratchet can be made with a gear that has more teeth so that a smaller swing of the handle can make a bigger rotational movement. A gearless ratchet with a roller bearing instead of a gear system works just as well to turn the socket as much as possible with a limited ratchet swing.

A lever on the ratchet makes it easy to switch from tightening to releasing a fastener. This is because the ratchet can be turned either clockwise or counterclockwise. On some ratchet versions, to reverse the direction of rotation, the tool must be turned over and the square drive nub inserted into the ratchet.

Most ratchets have a square nub that fits into a socket. This nub often has a locking mechanism built into it. This prevents sockets from falling off the ratchet or becoming loose while it is in use. If you need to, you can quickly take the socket off the ratchet by pressing a button on the ratchet that releases the lock.

There are flexible-head ratchets that have a junction between the ratchet head and the rest of the handle, whereas many ratchets have a fixed head. This feature gives the tool user more freedom so that they may use a socket wrench at various angles to approach the fastener.

Although motorized ratchets are also readily available, the standard ratchet is made for hand-tightening tasks. Compressed air, often known as pneumatics, is a typical driving mechanism that professional mechanics and others utilize when a higher torque is required or when a repeated task needs to be carried out without the use of manual equipment.

Types of Sockets

There are many different kinds of sockets, which can be told apart by things like size, number of points, use, and material. The most typical socket types will be discussed in the sections that follow.

Metric Sockets

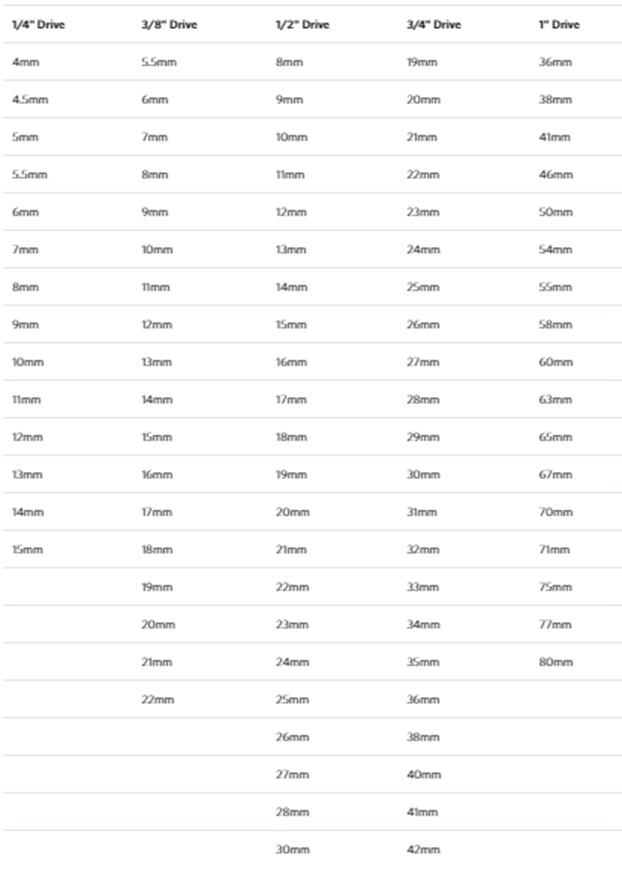

In the US, tools are often offered in standard (imperial) or metric sizes. Metric sockets come in various sizes depending on the size of the drive being used for the ratchet and are used to loosen or tighten metric fasteners. When the drive size and socket size both grow, the socket’s physical dimensions will as well. The most popular metric socket sizes for various ratchet drive diameters are listed in the following figure.

Although there are certain parallels between metric and imperial-sized sockets, caution must be used when using a socket that is near but not exactly the same size as the fastener. Otherwise, the danger of stripping the fastener’s head exists.

Standard Sockets

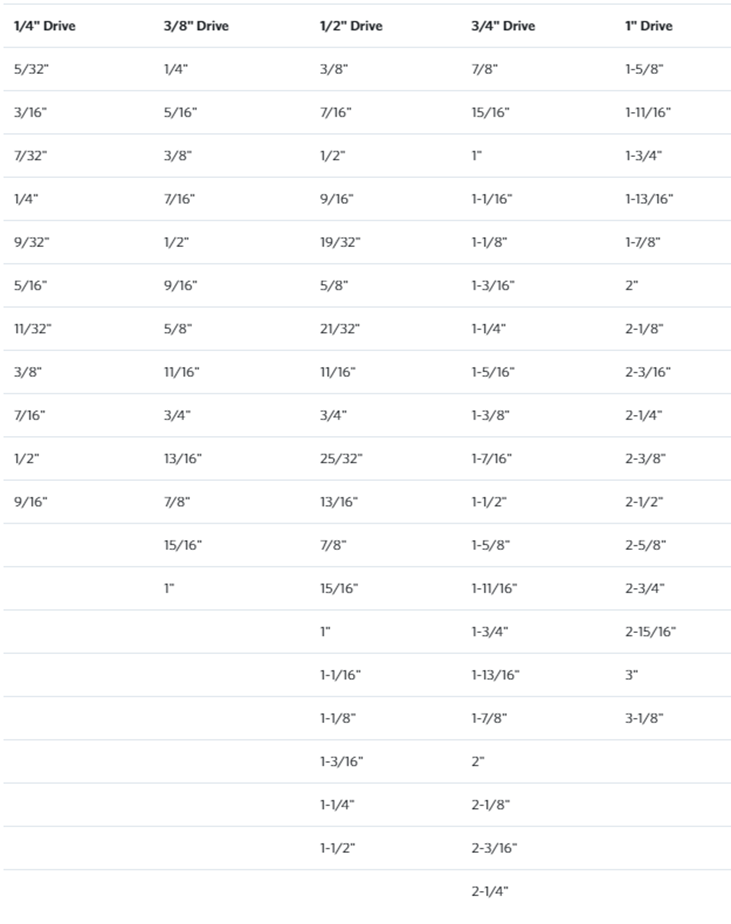

Standard sockets are those with fractional- or inch-sized dimensions. These socket types, often known as imperial sizes or SAE sizes, are the most widely utilized in the United States since so much equipment and systems made here employ imperial fastener sizes. These sockets, like the metric ones, come in several sizes that match the diameters of common fasteners. In general, smaller socket sizes correspond to smaller ratchet drive sizes, while bigger socket sizes are available as the drive size grows. The most popular standard socket sizes for each ratchet drive size are listed in the figure below.

Impact Sockets

Fasteners that are frozen or severely corroded can be removed using impact sockets and impact wrenches. Although electric variants are also available, air-powered impact wrenches are the most common type. The trapped fastener receives a series of percussive hits from the impact wrench’s radially placed hammers, creating significant momentary torque.

Chrome molybdenum, a ductile metal that can better survive the vibration stresses produced by the operation of an impact wrench, is often utilized to make the sockets used with these tools. Standard general-purpose sockets have a chrome finish, whereas impact sockets typically have a black oxide finish. To prevent the socket from being accidentally knocked off the impact wrench, many of these sockets have locking rings and retaining pins. These sockets are often built with a stronger wall to sustain the increased stress and are utilized with high torque applications (1000 ft/lbs and above).

Types Of Socket Point Shapes

The machined geometry of the socket, which is often a dodecagon (also known as a double hexagon) or a hexagon, is referred to as the socket point shape. Both of these forms are frequently referred to as 12-point and 6-point sockets. Although octagons were once popular due to the prevalence of square-shaped bolt and screw heads, their use has recently decreased, and these basic shapes are the ones that are used the most. The double-hexagon form will also line up with hex-shaped fasteners while allowing for several “beginning” positions, while the hexagon shape will precisely match up to a regular hex-head bolt or screw. In small spaces or areas with poor sight owing to recesses, this feature might make it simpler to seat the socket onto the fastener.

There are more socket types that may be used with a socket wrench to handle different forms of fasteners in addition to sockets that suit hex head fasteners. They consist of sockets for common flathead or Phillips screws, recessed-profile hex screws (like AllenTM screws), Torx head screws, and star-head screws. The main distinction is that, unlike dodecagonal or hexagonal sockets, these sockets have a male head on the socket as opposed to a female recessed design.

Since they may be used with an impact driver instead of a typical hand-operated ratchet, these sorts of sockets are frequently referred to as driver sockets.

Socket Length Types

The application requirements should be taken into account while choosing the socket length. Shallow sockets, often known as low-profile sockets, and deep sockets are the two primary socket lengths. Shallow sockets can be used in constrained spaces with minimal clearance above the head of the fastener. Deep sockets provide the ability to reach recessed fasteners and the nut on long bolts with threads that extend over the nut. They are occasionally used for “inverted” ratcheting, which involves screwing a bolt up against gravity.

Other Types of Sockets and Ratchets

There are specialty sockets and ratchets that are made for particularly specific uses in addition to the typical varieties already listed. Here is a list of these categories:

- Pass-through sockets have a through-hole in the socket wrench that allows it to fit over a long bolt and are intended to be used with a ratchet that has been particularly built for them. These socket wrenches are utilized to tighten or loosen nuts that are too far down a long bolt’s thread to be reached by a deep socket.

- Spark plug sockets are made particularly to fit over a conventional spark plug body. Some spark plug sockets even come with an interior rubber boot that helps hold the spark plug in place while it is being loosened, making it easier to remove from the engine. Spark plug sockets come in metric and imperial (standard) sizes.

- In order to turn a fastener that is stuck, rounded off, or rusty and cannot be turned with a regular socket, bolt extraction sockets have a set of internal grooves. When used manually, they are meant to be utilized with a breaker bar to offer more leverage and more torque.

- When it’s required to tighten or loosen fasteners close to active electrical circuits, insulated sockets offer protection against electrical shock risks. These sockets can prevent electrical shock to the tool user as well as unintentional arcing or short circuits that can harm equipment when used with a similarly insulated ratchet or breaker bar.

- Other nonferrous materials are used to create non-sparking plugs (ones that do not contain iron). By using this material, there is a far lower chance that the tool may unintentionally drop or hit something, creating sparks. In situations where an explosive environment, such as flammable gasses, liquids, vapors, or other particles, may be present, non-sparking sockets and ratchets are utilized to stop fire and explosion.

- Flex sockets include a hinged joint that permits the socket angle to deviate from the standard 90° angle with respect to the ratchet axis. When a straight-on approach is impeded by other objects, these kinds of sockets offer a better ability to access fasteners from various angles.

FAQs about Types of Socket Wrench

What features does a socket wrench have?

A common hand tool for quick tightening and loosening of fasteners, usually nuts and bolts, is the socket wrench. They function similarly to traditional spanners and wrenches, but their ratcheting construction makes it easier and less taxing for the user to apply torque.

What type of sockets are most commonly used?

A 6-point socket set, commonly known as a hex socket set, is made to fit over a typical nut or bolt head with six sides. The most typical kind of socket is this one.

Does a socket wrench fit all sockets?

To tighten different size fasteners, different size sockets can be added to the long handle of a socket wrench. You risk harming the tool and your hands if you select a socket that is too big. As a result, it’s crucial to select the exact socket size for the given fastener.

Conclusion

You may acquire all the details you want about the Socket Wrenches and details about this market on the Linquip website, one of the numerous possibilities available to you. Whether you’re a professional or a client seeking for a reputable business, you can rely on Linquip to give you as much basic and trustworthy information on this subject. We advise you to look through the whole range of Socket Wrench Experts and take advice from our professionals. If you need any services required for your product, you can count on Linquip and visit Socket Wrench Services.

Download PDF for Types of Socket Wrench

You can download the PDF format of this post from the link provided here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- 42 Types of Wrenches + Guide for Choosing a Wrench

- 12 Types of Industrial Sewing Machine + Advantages

- 13 Types of Adjustable Wrench: Clear Guide

- 15 Types of Wrench Sets and Their Features

- 17 Types of Ratcheting Wrenches + Their Characteristics & Usages

- 6 Types of Pipe Wrenches + Images: Clear Guide

- 27 Types of Plumbing Tools + Table of Characteristic & Usage

- How to Use a Socket Wrench? A Complete Guide

- How to Use a Torque Wrench? (Working Principle & Types)

- The 10 Best Torque Wrenches + PDF & Buying Guide

- The 9 Best Cordless Impact Wrenches

- Different Types of Bolt Heads + Benefit of Bolts and Nuts

- Different 5 Types of Fasteners: A Practical Guide

- 11 Types of Industrial Chains + Their Features and Applications

- 8 Types of Scissors + Table of Characteristics and Usage

- 11 Types of Hand Tools And Their Usage

- 13 Types of Socket Sets + Characteristic & Usage (Clear Guide)

- 8 Types of Abrasives + Benefits & Usage

- 8 Types of Impact Sockets + Their Characteristics