A Temperature Sensor is an instrument utilized to measure heat or temperature on the working part of machines. There are various types of temperature sensors. The temperature sensor, such as an electrical thermometer, includes a specific armor and a unit from one or more elements, which can contain, for instance, a neck tube, connection head, hand grip, and thermowell. The sensor part, which is set into the temperature sensor, measures the actual temperature and turns it into an electrical signal. Sensing the temperature is operated by several different instruments. Common examples of temperature sensors are typically a thermocouple, and RTD (Resistance Temperature Detector), which performed the temperature measurement within an electrical signal method.

What does Temperature Sensor mean?

Temperature is an environmental quantity that is simply measured. This is usual, because most chemical, mechanical, electrical, physical, and biological devices are influenced by temperature. Special biological procedures, chemical reactions, and even electronic systems operate best within restricted temperature ranges. Temperature is one of the most customarily measured features, therefore, it is not unusual that there are many methods for sensing it. Sensing the temperature can be operated by direct contact with a near source or without direct contact with the source employing radiated energy.

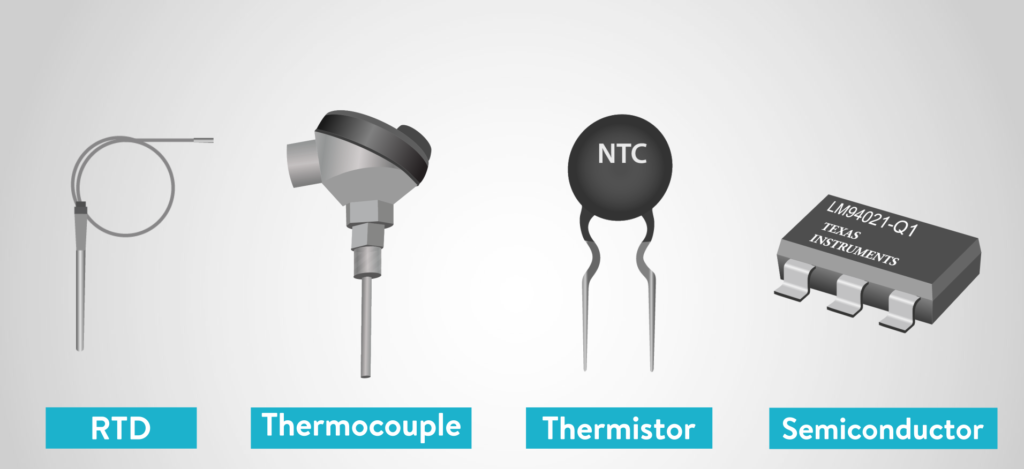

Today, there are many different temperature sensors on the market, such as Thermocouples, RTDs, Semiconductor Sensors, Thermistors, Infrareds, etc. These temperature sensors differ from simple ON/OFF thermostatic systems that monitor a domestic heating system to extremely sensitive types like semiconductors that can control the special procedure of controlling furnace plants.

We recall from our school science textbooks that the motion of molecules and atoms generates kinetic energy as heat forms. The more movement, the more heat is produced. Temperature Sensors can measure the amount of heat energy that is produced by a system or an object, giving us permission to identify or sense any physical modification of temperature generated using an analog or digital output. Click here to see more details about the function of the temperature sensor and its electric output.

Temperature Sensors physical Types

There are many various types of Temperature Sensors available, and all have different features based on their application. A temperature sensor consists of two main physical kinds: Contact and Non-contact Temperature sensors.

Contact Temperature Sensor Types

These types of temperature sensors are needed to be in direct contact with the target being sensed and utilize conduction to control temperature variations. They can be employed to identify liquids, gases, or solids over a wide level of temperatures.

Non-contact Temperature Sensor Types

These types of temperature sensors utilize radiation and convection methods to control variations of temperature. They can be employed to identify liquids and gases that release radiant energy as heat increases in convection streams.

Types of Temperature Sensors

The two principal types of contact and non-contact temperature sensors can also be classified into the following groups of sensors, which are mentioned below. Visit here to explore more about all the different types of these sensors.

Thermocouple

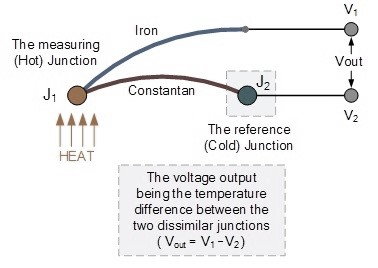

A thermocouple is a common type of temperature sensor, which is constructed by combining the end of two different metals. The connecting end is named the “HOT JUNCTION”. The other end is introduced as the “COLD JUNCTION” or “COLD END”. The cold junction is created in the last part of the thermocouple material. If the temperature of the cold junction and hot junction change, a small voltage is produced. This voltage is the EMF (electro-motive force) and can be measured and utilized to display temperature variations.

The Thermocouple is the most frequent type of temperature sensor. Thermocouples are common according to their user-friendliness, simplicity, and their speed of response to modification in temperature. Thermocouples also have the greatest temperature level of all the temperature sensors, from lower than -200oC to more than 2000oC.

Thermocouples are existing in several compositions of metals or calibrations. The most usual kinds of thermocouples are base metal thermocouples; however, noble metal thermocouples are utilized in high-temperature applications. Each calibration has a specific temperature level and environment, while the maximum temperature modifies with the diameter of the wire employed in the thermocouple.

Thermocouples fundamentally include two different metals, such as constantan and copper, that are crimped together. One junction is maintained at a constant temperature and introduced as the reference junction, whereas the other is the measuring junction. When the temperature of the two junctions varies, a voltage is produced across the junction, which is utilized to sense the temperature.

Thermocouple applications

A thermocouple can be employed in several applications, including:

- Flame sensors in safety machines for gas-powered systems.

- Temperature sensors in thermostats for home instruments.

- Temperature measurement for industrial procedures such as gas turbine exhaust, and diesel engines.

Thermocouple Construction

The working principle of a thermocouple is very basic and simple. When the junction of the two different metals such as copper and constantan fused, they generate a “thermo-electric” result, which provides a few millivolts (mV), constant potential difference, between them. The voltage difference between them is named the “Seebeck effect” as a temperature difference is produced along the conducting wires making an EMF Then the external voltage from a thermocouple is an operation of the temperature variations.

If both parts are at the same temperature, the potential difference in the junctions is zero. In other words, we have no output voltage, and V1 = V2. Nevertheless, when the joints are connected to a circuit and have different temperatures, an output voltage will be identified compared to the difference in temperature between them, V1 – V2. This variation in voltage will rise according to the temperature until the joint’s peak voltage rate is obtained. This is specified by the features of the two different metals utilized.

The three usual thermocouple substances employed for general temperature sensors are Iron-Constantan, Nickel-Chromium, and Copper-Constantan. The output voltage of a thermocouple is very low, for instance, only a few millivolts (mV) for a 10oC variation in temperature. Because of this low output voltage, some solutions like amplification is usually needed.

Thermocouple Amplification

The type of amplifier, either operational or discrete, requires to be attentively chosen because appropriate stability is needed to stop the recalibration of the thermocouple at repeated intervals. Therefore, the chopper and instrumentation type of amplifier is the perfect option for most temperature sensors in different applications.

The RTD

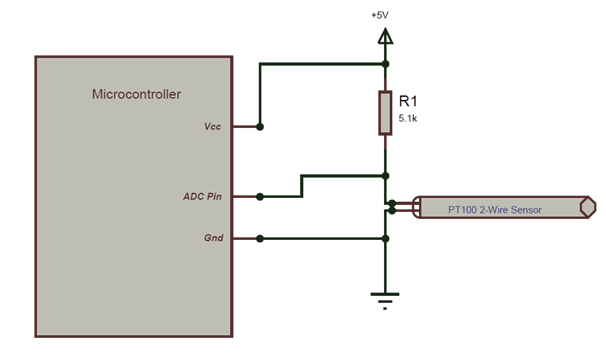

Resistance Temperature Detector or RTD is a temperature sensor whose resistance varies directly with temperature. It is usually built from platinum, while those constructed from nickel or copper are not unusual, RTDs can be made in many different forms, such as thin film or wire wound. The problem is that Platinum is too expensive, and one of the practical disadvantages of using this type of instrument is its cost. Applying a constant current, measuring the output voltage, and determining the resistance of RTD are simple methods to measure the temperature in an RTD.

RTDs approximately display linear resistance to temperature diagrams over their working parts. For instance, the PT100 RTD evaluation board utilizes plain mount RTD to measure temperature (PT100 has a standard resistance range of 100Ω at 0oC). An external 2, or more-wire PT100, can also be used to measure temperature in remote sections. The current magnitude is always low to decrease self-heat according to power dissipation. The circuit presented in the figure is the constant current condition that utilizes an amplifier, a reference voltage, and a PNP transistor.

RTD’s are exact temperature sensors constructed from high-purity conducting metals similar to that of the thermistor. These instruments have a thin film of platinum entrusted on a white ceramic surface. RTDs have positive temperature coefficients (PTC), but dissimilar to the thermistor, their external voltage is extremely linear, generating very accurate measurements between temperature sensors. Nevertheless, they have very low thermal sensitivity, which is a temperature modification only generates a very low output change, for example, 1Ω/oC.

RTD’s are passive resistive systems like thermistors. They pass a constant current in the temperature sensor to gain an output voltage that rises linearly with temperature. A normal RTD has a resistance of about 100Ω at 0oC, rising to 140Ω at 100oC with a working temperature range of between -200 to +600oC.

The RTD is a resistive instrument, so we need to pass a constant current in them and control the output voltage. However, any modification in resistance, according to I2R (Ohms Law), causes a change in the readings. The RTD is typically connected to a Wheatstone Bridge network with extra connecting wires to avoid this problem.

Thermistors

The thermistor is a temperature sensor whose resistance varies with temperature, similar to the RTDs. However, thermistors are constructed from semiconductor substances. Their name is included from the term: THERM-ally sensitive res-ISTOR. A thermistor has a particular type of resistor, which modifies its physical resistance greater than other temperature sensors.

Their resistance is specified like the RTDs, but thermistors present a nonlinear resistance-temperature diagram. As a result, it can supply a large resistance variation for a very small temperature modification in the working range. This makes it a highly sensitive instrument, ideal for high-tech and set-point applications.

Thermistors are usually made from ceramic substances like oxides of manganese, nickel, or cobalt covered in particular glasses surface. Their special advantages over other types are accuracy, repeatability, and quick response to variations in temperature.

Most kinds of thermistors have a Negative Temperature Coefficient of resistance (NTC); that is, their resistance decreases when the temperature increases. However, there are a few types of them that have a Positive Temperature Coefficient (PTC).

Thermistors are evaluated by their timely response to react to temperature variation, their resistive range at room temperature, and their power rating according to the current through them. Thermistors are available with different resistance values from a few Ohms to MΩ ranges, but for sensing applications, those types with kilo-ohms ranges are usually utilized.

The Thermostat

The Thermostat is a contact kind of electro-mechanical temperature sensor that fundamentally includes two different metals such as copper, tungsten, nickel, or aluminum. They are combined to create a Bi-metallic part. The linear expansion state of the two different metals changes and generates mechanical bending when the part is heated.

The Bi-metallic Thermostat principle

The bi-metallic device can be used as an electrical switch or as a mechanical method of working an electrical switch in thermostatic monitoring. They are employed to control the heating elements in furnaces, hot water storage sources, boilers, and in the cooling system of vehicle radiators.

There are two special kinds of bi-metallic thermostats classified by their moving situation. First is the “snap-action” that generates an immediate “ON/OFF” response on the electrical switches at a set point. Snap-action thermostats are usually used in homes for monitoring the temperature point of immersion hot water sources, ovens, and irons, and they can also be found on walls to monitor the heating system of the house.

The other is the slower “creep-action” that changes their state slowly as the temperature varies. This makes them ideal for sensing temperature gauges and dials. Snap-actions are very cheap and available at a wide working level, but one basic disadvantage is that they have a large hysteresis range in their open-close loops. For instance, it may present 20oC, but it actually varies between 18 to 22oC.

Semiconductors

Semiconductors consist of different types, such as Current output, Digital output, Voltage output, Resistance output silicon, and Diode temperature sensors. New semiconductor temperature sensors provide high accuracy. They also offer high linearity in their operating range between 55 to 150°C. Using internal amplifiers can scale the output to perfect amounts like 10mV/°C. They are also effective in cold-junction circuits for high-temperature states of thermocouples.

Digital Temperature Sensors

Digital temperature sensors remove the requirements for additional parts like the A/D converter, and there is no demand to calibrate devices or the systems at particular temperatures as required when using thermistors. These sensors are used with everything. They can empower the main system temperature and monitor the function to be made plainer.

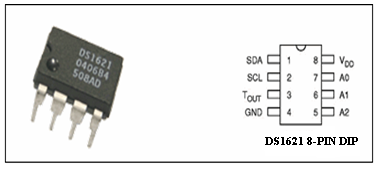

The principal advantage of a digital temperature sensor is its precision output temperature range. The sensor output is balanced. This doesn’t need other devices, such as an analog-to-digital converter. So, it is much easier to employ than a thermistor, which displays a nonlinear resistance-temperature diagram. An appropriate example of these sensors is DS1621, which presents a 9-bit reading of temperature.

Sensor ICs in Common Temperature Sensors

There are too many varieties of temperature sensor ICs that are existing to facilitate the challenges of temperature control. These silicon sensors vary considerably from the common types in some important aspects. The first is the range of work; A temperature sensor IC can use in the range of -55°C to +150°C.

The second main difference is performance; A silicon sensor has an integrated circuit. Therefore, it can contain great signal processing in the package of the sensor. There is no requirement to add circuits for compensation. Some other sensor ICs include analog-sensing systems and digital output to monitor registers and make them a perfect microprocessor system method.

Temperature is measured without interruption and can be detected at any time. The main processor can ask the sensor to control temperature and increase or decrease it desirably if the temperature exits from the determined range. Thus, the digital output voltage can be used for practical temperature control in different high-tech systems.

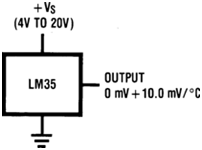

The above temperature sensor contains three terminals and needs a Maximum of 5.5 V power supply. This kind of sensor has a material that works due to temperature to change the resistance. This modification of resistance is detected by the circuit, and it evaluates the temperature. It can apply this operation by using a diode. The sensor can exchange data effectively with low-cost processors without the requirement for A/D converters. A good example of them is LM35. LM35 sensor has an integrated circuit and senses precisely. Its output voltage is proportional to the temperature linearly. The LM35 works at -55 to +120˚C.

How to choose a Temperature Sensor

All kinds of temperature sensors, like Thermocouples or RTDs, must be carefully chosen for particular applications to meet all demands. The information of this section presents a guide to help in making the appropriate selection of the perfect sensor for different applications.

Style

Temperature Sensors are present in different styles. The weatherproofed style with a screw cover presents an electrical connection. The non-threaded style is offered for sensing in open systems. This model is designed with integrated lead-wire and can be covered by Teflon to support the lead-wire in corrosive environments.

Stem (Sheath)

Thermocouples and RTDs are equipped with a 316 stainless steel stem and internal wiring coated with powdered ceramic. The screw head style is existing in two stem kinds: spring-loaded and welded. The spring-loaded stem is made to the bottom of a thermowell, presenting maximum heat sensitivity. The welded stem is desirable for usage in liquid applications.

Insertion (U) Length

The insertion (U) length of a thermocouple or RTD indicates the depth of the procedure. Thermocouples and RTDs are present in lengths from 2″ to 24,” which are standard U-lengths. Other lengths require special orders and consult with constructors.

Measuring (Hot) Junction

Thermocouples are available in different types and use ceramic cover insulation to present the measuring junction. RTDs are a block of platinum, normally a 3-wire model, and are performed with 100Ω to 1000Ω resistance at 0°C.

Connection (Termination)

Thermocouples are typically presented with a mating jack, terminal block, or integrated lead-wire ports. The extension wire should be compatible with the thermocouple type, otherwise, multiple junctions will be produced. This will cause inaccurate temperature identification. RTDs usually have a terminal block or integrated lead-wire connection. An extension wire should be attached to the detector or controller because the connection of the terminal block has no lead-wire.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Types of Thermometers: All You Need to Know

- 5 Types of Proximity Sensors (Application and Advantages)

- 3 Different Types of Hygrometers and Their Applications

- 4 Types of Thermowell: Application and Duty

- Temperature Sensors: Types, working principle & Practical Applications

- Temperature and Humidity Sensors: An Ultimate Guide

- What is Humidity Sensor: Your go-to Guide on humidity Sensors!

- Types of Humidity Sensors: A Full Explanation of The Most Common Types

- How to Wire Up Piezoelectric Sensor? A Comprehensive Guide

- Difference Between Actuator and Sensor: The Ultimate Guide

- Types of Temperature Sensors and Their Application

- Instrument Used to Measure Humidity

- Types of Hygrometers

HELLO

Kindly provide us with your best pricing include weight, freight cost and lead time

Item

Description

Part Number

Unit

Qty

Need By

Unit Price

Extended Amount

1

MONITOR:TEMPERATURE TYPE:IONISATION FLAME MONITOR D-IO SIZE:STD RESOLUTION:STD POWER SOURCE:STD DURAG IGNITION TRANSFORMERS IONISATION FLAME MONITOR D-IO 55, PART NUMBER GST-29AACCD3792R1ZT, MONITORING OF GAS AND OIL BURNERS OF ANY LOAD. TAG: UNIT 50 HEATERS.

QA Code Description

01 – Declaration of Conformity

01A – Certificate of Conformity

Manufacturer Part Number (M) – GST-29AACCD3792R1ZT;