Types of thermistors are various but they all operate on the same phenomenon: variation of resistance based on temperature change. There are fundamentally two types of thermistor of which all types are classified based on them; NTC (Negative Temperature Coefficient) and PTC (Positive Temperature Coefficient) thermistors. You may require one thermistor or more depending on your special application.

Types of Thermistor

We presented what is a thermistor and how it works in our last posts. We also explore about transducers because a thermistor is practically a special type of resistor-transducers. Now, we want to look a little deeper into various types of thermistor, their production, and what kinds of applications they are usable. If you want to explore more about them, first check out the “What is a Thermistor” post, and then visit here to know clearly this special type of temperature sensors.

Thermistor basics

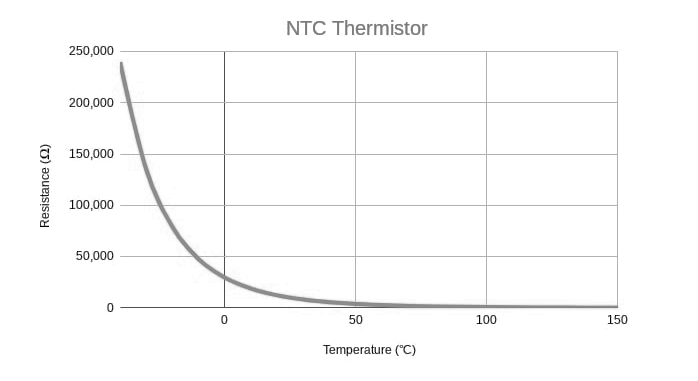

As discussed before, a thermistor resists the electrical values. It changes based on the resistor because a thermistor influences the current due to the temperature variations. Let’s look at the diagram to help understand the relation between resistance and temperature.

We can see the resistance of the thermistor reduces with the temperature change. However, if this was a resistor diagram, the “curve” would normally be vertical and the resistance doesn’t modify based on the temperature.

Thermistor definition

A thermistor is a resistor whose resistance varies immediately with a temperature modification. They are ceramic semiconductors and are constructed from metal oxides, which are utilized to gain the suitable application. The forms of oxides and additional materials identify the particular behavior of special types of thermistor. Iron, nickel, cobalt, copper, or manganese are usual oxides for NTCs, and strontium, barium, or lead titanates are usually employed for PTCs.

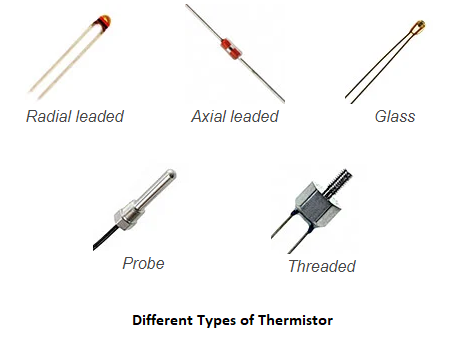

Different Types of Thermistor

Different types of thermistor are suitable for various applications. Thermistors are a practical part of our temperature products because they are a precise method for sensing temperature.

NTC and PTC Thermistors

Two main types of thermistor are NTCs and PTCs. These thermistors sense the temperature by applying resistance variation.

What are NTC thermistors?

NTC thermistors are resistors which have a negative temperature coefficient. It means that the resistance is reduced based on increasing temperature. They are typically introduced as resistive temperature transducers and current-limiting systems. The sensitivity of their coefficient is approximately five times greater than silicon temperature sensors (silistors) and ten times larger than RTDs (Resistance Temperature Detectors).

NTC sensors are commonly employed between −55 to 200°C; however, they can be particularly constructed to sense much lower temperatures. Their popularity is based on their immediate response, stability, and low cost. These instruments are utilized widely in the transportation, HVAC industries, and many other systems.

The non-linearity between temperature and resistance provided by NTC resistors caused a major difficulty when utilizing analog circuits to detect the temperature. However, the development of digital systems removes the problem and enables systems to supply accurate values by using equations providing a particular NTC curve.

Characteristics of NTC thermistors

NTC thermistors are usually constructed from polymers or ceramics, unlike RTDs which are commonly produced from metals. Different substances utilized in various temperature ranges provide several responses more important than other features.

Temperature Response

Most NTC types of thermistor are normally desirable for a temperature range between −55 and 200°C, where they present the most exact outputs. Nevertheless, particular types of NTC thermistors can be utilized at temperatures close to absolute zero, also some of them are specifically constructed for above 150°C.

The sensitivity of an NTC transducer is known as “percentage variation per degree”. The practical values of temperature sensitivities are between -3 to -6% per °C based on the substances employed and the characteristics of the construction procedure.

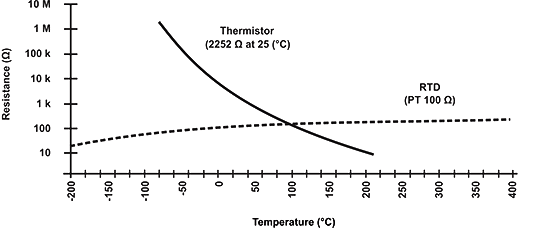

As demonstrated in the figure, the NTCs have a much faster temperature-resistance diagram in comparison with the platinum alloy of RTDs, which means the best temperature sensitivity. RTDs have accuracy about ±0.5% of the detected temperature, and they are applicable in the temperatures between -200°C and 800°C, which is a much greater range than that of NTC types of thermistor.

Comparison to other Temperature Sensors

The NTCs have a little size, quick response, higher resistance to vibration, and a lower cost in comparison with RTDs. The accuracy gained from them is similar to thermocouples; however, thermocouples can tolerate high temperatures close to 600°C and are employed in particular applications instead of NTCs.

Nevertheless, NTC types of thermistor present higher sensitivity, reliability, and precision than thermocouples at lower ranges of temperature and can be used at a lower whole price. This total cost can be reduced by the lack of requirement for signal processing systems like amplifiers that are typically needed by using RTDs or thermocouples.

Self – heating effect

The self-heating effect is a process that happens while there is a flow-current in the NTC types of thermistor. The thermistor is fundamentally a resistor, so it reduces power as heat through it. This heat is produced in the center of the thermistor and influences the accuracy of the detection. The effect of this phenomenon is determined by the amount of flow-current, the temperature coefficient, the liquid or gas environment, and the thermistor’s total surface.

Heat capacity

The heat capacity is known as the amount of heat needed to rise up the temperature of the thermistor and is normally presented in mJ/°C. The exact heat capacity of NTC types of thermistor is too important in using them because it specifies the response rate of the NTC.

Curve Selection and Calculation

The appropriate choice includes important parameters such as resistance variation, thermistor dissipation, thermal time coefficient, resistance-temperature diagram, and particular tolerances. Nevertheless, special considerations should be applied in practical systems due to the nonlinear relationship between resistance and temperature. But first, we must answer the next question.

What are the Thermistor Curves and Ranges?

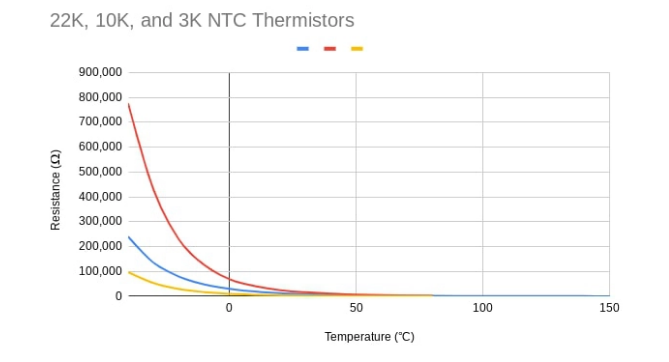

Types of thermistor vary by curve and range regardless of the particular classes of NTCs and PTCs. They are generally detected by their resistive capacity at normal temperature. Now we should present the graph of a few different NTC types of thermistor and explore more about significant points.

We can identify the optimal level of a thermistor from these particular curves. It can be seen a large variation in resistance below 0℃. This means that each little rising in temperature should be accurately detected because the resistance variation is great. However, the resistive sensitivity of many thermistors is not too accurate without particular circuits below temperatures of -50℃.

There is little modification in resistance at the other part of the chart above 50℃. The curve is approximately flat and this means it is simple to have inaccurate temperature outputs due to the small resistance changes. Only particular types of thermistor can work appropriately above 100℃.

First-order approximation

The first-order approximation is the simplest method to employ and is based on ΔR= k ΔT Where k is the negative constant, ΔT is the temperature variation, and ΔR is the resistance modification depending upon the temperature change.

However, this method is only valid for a few temperature ranges, and should only be utilized for conditions where k is approximately constant throughout the total temperature state.

Beta formula

This formula is another equation that can give suitable results and has accuracy near ±1°C in the range of 0 to 100°C. It is based on a single substance constant β which can be gained by particular experiments.

The formula can be presented as R(T)= R(T0). eβ (1/T – 1/ T0) Where R(T) is the resistance at the particular temperature, and R(T0) is the reference. This equation needs a two-point calibration and is usually not more exact than ±5°C in the range of the NTC types of thermistor.

Steinhart-Hart equation

The most appropriate equation has been introduced is the Steinhart-Hart formula, presented in 1968 as:

1/T = A (ln R) + B (ln R)3 + C

Where (ln R) is the logarithm of the resistance at a particular temperature, and A, B, and C are special constants evaluated from experiments. These coefficients are normally presented in the thermistor’s datasheet. The Steinhart-Hart equation is usually precise close to ±0.15°C between -50 to +150°C, which is useful for most applications.

Choosing the right approximation

The selection of the equation applied to evaluate the temperature from the resistance sensing requires practical tolerances and calibrations. The first-order equation is more than enough in some systems, while in others the Steinhart-Hart one doesn’t provide full requirements, and the thermistor must be calibrated point by point.

Construction and Properties of NTC Thermistors

Materials usually used in the construction of NTC types of thermistors are nickel, platinum, iron, cobalt, and oxides of silicon. NTCs can be categorized into three kinds, based on their construction procedure.

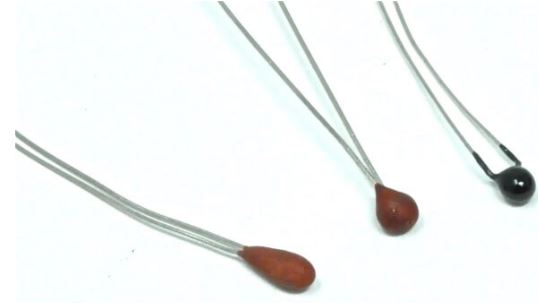

Bead Thermistors

These NTC types of thermistor are constructed from platinum alloy. Also, lead wires are straightly combined with their ceramic body. They usually provide fast responses and proper stability, and permit working at high temperatures than other NTC sensors.

It is usual to seal them in glass to protect them from environmental problems during construction, and to increase their sensing stability. The common size range of them is between 0.075 to 5mm.

Disk and Chip Thermistors

These NTC types of thermistor have a metalized plane in direct contact. They are larger than other types, so have slower responses than bead resistors. They can monitor high currents more appropriate than bead thermistors because of their size.

Disk thermistors are produced by compressing a blend of oxide covers into a round surface, then constructed at high temperatures. Chips are usually manufactured by a tape-casting procedure where a film of substance is covered as a thick layer, and cut into particular shapes. The popular sizes of them are between 0.25 to 25mm in diameter.

Glass encapsulated NTC thermistors

They are covered with a sealed glass bubble and designed to employ in temperatures above 150°C, or for particular circuit boards. Sealing a thermistor in glass increases the accuracy of the sensor, and protecting the device from damages. The useful sizes are from 0.4-10 mm in diameter.

Typical Applications

NTC types of thermistor are utilized in many applications. They are typically used to monitor and control the temperature. They can also be employed to identify the presence or absence of fluid in power supply circuits and automotive applications. Their application can be classified into three groups, based on the electrical features in different devices.

Resistance-Temperature Features

There are various applications of resistance-time features such as temperature sensing, control, and compensation. These also contain conditions in which an NTC thermistor is employed so that the temperature of the NTC is proportional to some other physical properties. This type of application must be used in a zero-power condition, which means that the current should be kept as low as possible.

Current-Time Features

These applications are based on current-time features like inrush current limiting, time delay, and surge systems for suppression. These properties are the heat capacity and dissipation coefficient of the thermistor. The system generally relies on the heating up of the thermistor based on the current passing.

Voltage-Current Features

There are some applications based on the voltage-current features of a thermistor like circuit variations which cause some modifications in the operating process of the circuit. These features can be utilized for various applications such as current monitoring, or temperature compensation.

What are PTC thermistors?

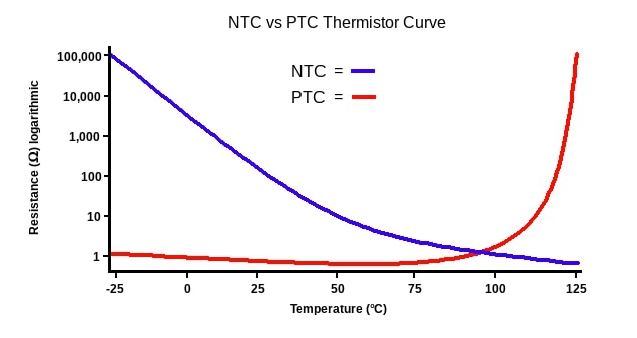

PTC types of thermistor are instruments with a positive temperature coefficient. They operate in the opposite method of an NTC thermistor which means that the resistance improves with an increase in temperature. They are typically not common but can provide a particular niche function like using in a safety fuse. The next diagram presents the opposing curves of PTCs and NTCs.

PTC thermistors are categorized into two types, according to their materials, structure, and the construction process. The first type of PTCs is silistors, which apply silicon as the semiconductive substance. They are utilized as temperature sensors due to their linear diagram.

The second type is the switching thermistor which is more useful in various applications. This type of PTCs is generally used in heaters. Polymer thermistors, constructed from a specific plastic, are also in this group, often applied in resettable fuses. They have a highly nonlinear curve. When the thermistor is warmed, the resistance primary begins to decrease, until a certain critical temperature known as “Curie temperature”. As the temperature is more increased above that value, the resistance increases significantly. The most usual switching temperatures are between 60 to 120°C. They are typically employed for self-regulating systems and self-resetting protection devices.

Characteristics of PTC thermistors

Switching PTC types of thermistor are typically constructed of poly-crystalline ceramic that are significantly resistive in their basic state. Particular applications force designers to construct them to work in temperatures lower than 0°C or higher than 200°C.

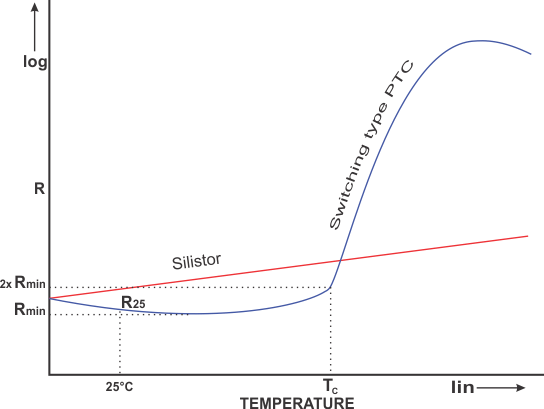

Silistors have a linear curve, with a small slope in their operational state. They may provide a negative constant at temperatures more than 150 °C.

Minimum resistance (Rmin)

It is the minimum resistance that can be sensed in a switched thermistor, as presented on the R-T diagram. This is the point on the diagram which the temperature constant turns positive after it.

Rated resistance (R25)

This is usually known as the resistance at 25°C. It can categorize the thermistors according to their resistance. It is detected with a little current that does not warm the thermistor.

Dissipation constant

This constant demonstrates the relationship between power and the body temperature due to the self-heating effect. Contact wire substances, way of mounting, absolute temperature, and the conduction paths between the instrument and its surroundings can affect this constant.

Maximum rated current

It presents the maximum current that can pass through a PTC thermistor at particular conditions. Its value is based on the R-T diagram and the dissipation constant.

Maximum rated voltage

It provides the highest voltage that can be applied to the thermistor like the maximum rated current.

Modes of operation

PTC types of thermistor can be used in different modes of operation based on the application. The two common modes are self-heated and sensing (zero-power) mode.

Self-heated mode

Self-heated applications use the applied voltage to a thermistor and flow-current through it. Close to the Curie temperature, the resistance increases, permitting less current to pass. The current will fix at a particular value if the voltage remains constant. The final temperature is based on the voltage applied, and the dissipation factor of the thermistor.

Sensing (zero-power) mode

The power of the thermistor is too small in this mode of operation. Therefore, it has a negligible influence on the thermistor’s temperature, unlike the self-heated mode. The sensing mode is generally utilized when the R-T curve is the reference for measuring the temperature.

Construction and Properties

Switching groups, which are the most common PTC types of thermistors, are often constructed by using titanium oxide, barium carbonate, and additional materials like tantalum, manganese, and silica. The materials are mixed and pressed into disk shapes and eventually coated. Few contaminations in the manufacturing process can cause major problems in the thermal and electrical features of them.

Typical applications for PTC thermistors

Self-Regulating Heaters

These thermistors will be fixed at a certain temperature if there is a passing current through the switching part. The PTCs can reach a point where the power is usually independent of the voltage.

These PTC thermistors are usually constructed from particular ceramics in different shapes and sizes. They are an appropriate selection for monitoring electrical heat.

Over-Current Protection

Switched PTC thermistors are utilized in application to limit the over-current like resettable fuses. In this case, the thermistor temperature immediately reaches the Curie temperature. and limits the current in the system. It is known as an automatic resettable fuse.

Polymer thermistors are also employed for this application. They are introduced as polyswitch or polyfuse.

Time delay

This is the time required for a PTC thermistor to warm up enough based on the size, normal temperature, and external voltage. Their usage in fluorescent lamps is a common example of time delay. When the Curie temperature is obtained, the PTC will change, and the lamp will start normal working.

Motor starting

In some electrical motors which have a dual startup, we may employ the self-heating phenomenon of a PTC thermistor. When the circuit is utilized, the PTC thermistor has a particular resistance, permitting current to flow through it. The thermistor warms up as the motor begins to operate. The time required for this effect is estimated according to the motor startup time.

Liquid level sensing

Some systems are based on the variation in the dissipation constant. This change in the dissipation constant depends on the contact between the instrument and fluid passing around it. As a result, the improved power can be sensed and determines the particular circuit for the thermistor.

Other Types of Thermistor

Thermistors can be introduced with some other factors as described below:

Resistance

Thermistors will usually be introduced by their resistance value like a 10K or a 5K thermistor. This number provides the resistance value in Ohms. It is a popular way to specify which thermistor is appropriate for special applications.

Axial, Radial, or Chip

Thermistors have various styles and the most common of them are radial and axial. Radial thermistors are constructed from two wires leaving the main part in the same direction., while Axial thermistors have one wire connecting the top and the middle section.

Glass or Epoxy

The main part of thermistors is typically produced from epoxy or glass. Epoxy thermistors are more suitable for lower temperatures, whereas glass ones are desirable for higher temperature applications.

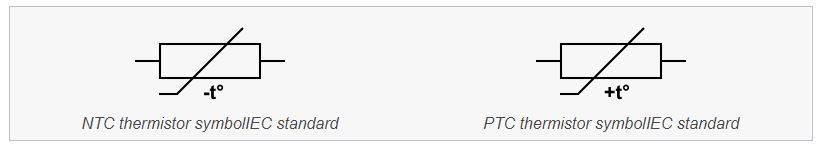

Thermistor symbols

The following symbols are applied to the thermistors due to the IEC standard.

And That’s the Types of Thermistor in a Nutshell

By and large, temperature sensing is a common requirement in various industries and thermistors are an accessible choice for some of them. Generally, there are different types of thermistor available in the market, each with their own advantages and disadvantages. You must explore completely about all of them to choose the best type for your particular application of controlling temperature.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What is the core difference between Thermistor and RTD?

- What are the Different Types of Actuators?

- What is a Thermistor and How its Working?

- Difference Between Thermistor and Thermostat: which one outperforms the other?

- What is PTC Thermistor? (Applications & Advantages)

- What is NTC Thermistor? (Types, Applications & Advantages)