Types of Thermowell_ Thermowells are applied to protect temperature sensors such as thermistors, thermocouples, and bimetal thermometers against excessive pressure, material velocity, and corrosion. Installing them in a system also increases the sensor’s longevity, allows sensor replacement without draining the system, and reduces the probability of contamination. Thermowells produced for high-pressure applications are usually machined from bar stock to guarantee integrity. Smaller thermowells for low-pressure environments may be built from tubing with one end welded.

What are Thermowells?

Thermowells are cylindrical fittings used to shield installed temperature sensors in industrial processes. A thermowell consists of a closed-end tube and is positioned in the process stream. A temperature sensor such as a thermocouple, thermometer, or resistance temperature detector is implanted in the open end of the tube, which is generally in the open air outside the process vessel or piping and any thermal insulation. Thermodynamically, the process fluid gives heat to the thermowell wall, which transfers heat to the temperature sensors. As the extra sensor-well assembly has extra mass compared to a probe directly immersed in the process, the response of the sensor to process temperature fluctuations is reduced by the addition of the well.

If the sensor does not operate properly, it can be easily replaced without any change in the vessel or piping. As discussed before, sensor responsiveness and accuracy are reduced by the addition of a thermowell, As the mass of the thermowell needs to be heated to the process temperature first.

In the past, the thermowell length was based on the degree of insertion related to pipe wall diameter. This tradition is not acceptable anymore as it can endanger the thermowell to the risk of fatigue failure because of flow-induced vibration. When measurement error calculations are investigated for the installation in insulated piping or ambient fluid temperatures, excluding thermal radiation consequences, conduction deviation is less than one percent as long as the tip is exposed to fluid, even in flanged fixed installations.

The response time of the fixed sensor is primarily governed by the fluid velocity and is considerably more significant than the response time of the sensor itself. This results from the thermowell tip’s thermal mass and the heat transfer coefficient between the fluid and the thermowell.

Discussions for more extended designs are based on notions and principles are rarely justified. Long thermowells are used in low-velocity services or in circumstances where historical experience confirmed their use. In high-strength piping and high fluid velocities, we must examine each installation carefully, especially in situations where acoustic resonances in the process are concerned.

A typical type of thermowell is machined from drilled bar stock to guarantee a proper sensor fit (for instance, a 0.260-inch bore is a good match for a 0.250-inch sensor). A thermowell is typically installed into the process stream through a sanitary cap, threaded, welded, or flange process connection. The temperature sensors such as a thermocouple, thermometer, or resistance temperature detector are fixed in the open end of the thermowell and usually spring-loaded to ensure that the outer tip of the temperature sensor is in metal-metal contact with the inner tip of the thermowell. The application of welded sections for long designs is not suggested due to fatigue and corrosion risks.

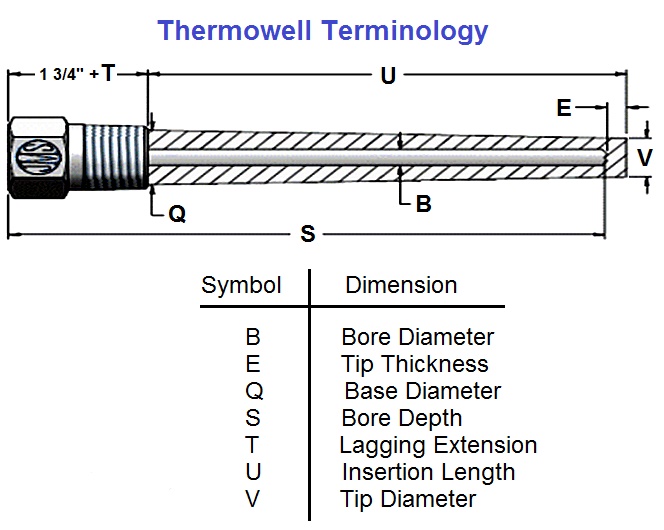

Thermowell Specifications

We should know the thermowell Specifications to understand and choose the suitable one for our applications.

Thermowell Root Dimension (Q)

The “Q” parameter of a thermowell is the thickest section of the thermowell that is on the temperature control side of the process connection or flange. The thermowell Q dimension is related to the bore dimension of the thermowell and also the process connection size.

Thermowell Immersion (“U”) Length

Thermowell immersion lengths are regularly called the “U” length. The U length is the distance from the base of the process connection to the tip of the thermowell. The U length of a thermowell shows the length of the Thermowell that is really in the process of being measured.

Thermowell Bore Size

Bore size is known as the inside diameter of a thermowell.

The usual thermowell bore sizes are 0.260″ and 0.385″. These sizes are intended to accept a 0.25 or 0.38 inch diameter sensor.

Thermowell Lagging Extension (“T”) Length

The thermowell’s “T” length is a name that refers to the lagging extension of a thermowell. The lagging extension or T length is determined on the cold head of the process connection and is regularly an extension of the hex length of the Thermowell. Generally, the T length allows the probe and thermowell to extend through insulation or walls.

Types of Thermowells

Thermowells are ready to use with all Temperature Instrumentation and control products, including RTDs, Temperature Recorders, Thermometers, Thermocouples, and Temperature Controllers.

Connections

Thermowells are prepared in a variety of process connection styles. The most widely specified Threaded connections are 1/2, 3/4 and, 1 NPT. Socket weld, raised face flanged, and weld-in connection styles are also available. Bimetal thermowells are produced with a 1/2 NPSM instrument connection to provide pressure relief within the thermowell.

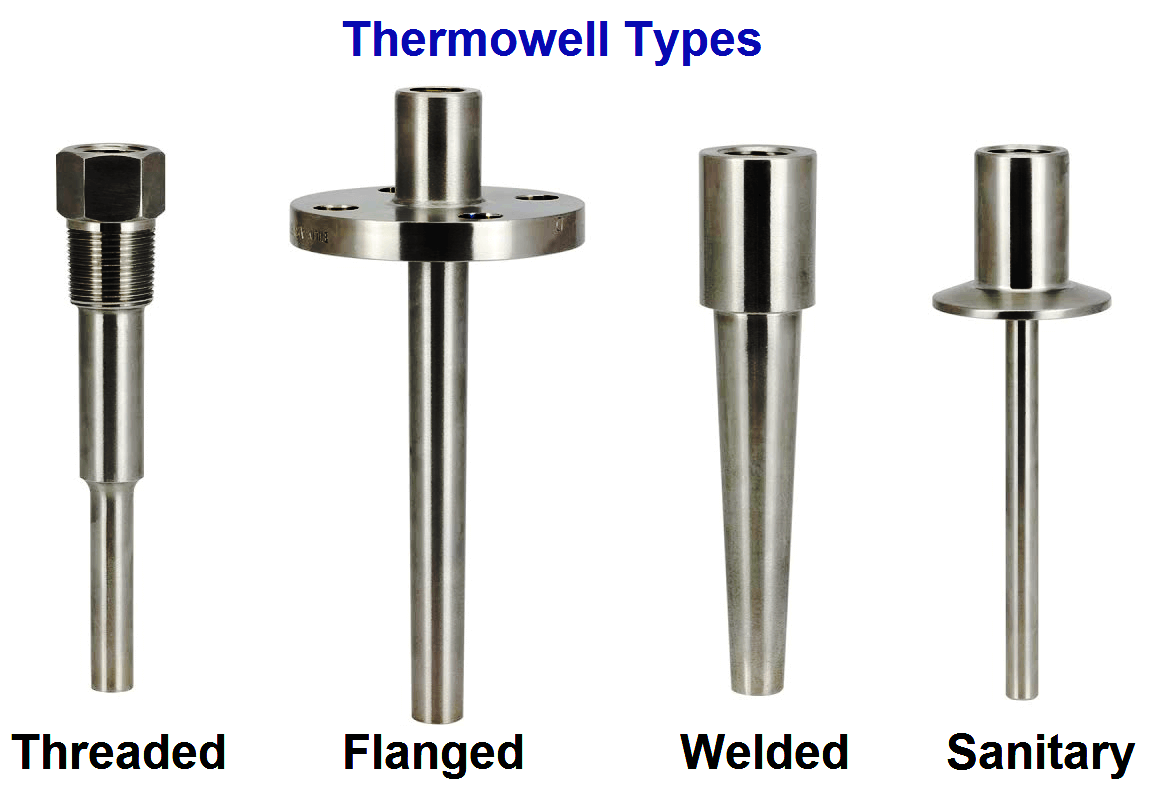

Different Types of Thermowells based on the connection

Thermowells can be distinguished based on their process connection or the design of their stem. Here are some popular types of thermowells available across various industries.

- Threaded Thermowells: As the name implies, these thermowells are screwed into a thermowell threadolet directly or into the tapped pipe wall.

- Flanged Thermowells: A flanged thermowell features a flange collar, which is placed on the mating flange. This mating flange is connected with a piping nozzle.

- Weld-in Thermowells: These types of thermowells are welded into the piping or a process vessel directly.

- Socket Weld Thermowells: These thermowells may be welded into the socket of the weldolet directly. Alternatively, these tools may be welded into the pipe wall.

U-Length

The U-length (insertion length) of a thermowell shows its insertion depth into a process piping system or vessel and is measured from the tip of the thermowell to the root of the threads. The U-length must exceed or be equal to the length of the sensitive part of the temperature instrument’s stem or bulb.

Shank

Thermowells are available in tapered, stepped, and straight shank configurations. Tapered shank thermowells are designed to be installed on heavy-duty applications. Stepped shank thermowells are typically utilized on standard duty applications. Straight shank thermowells are designed to be coupled with instruments that have short stem lengths or wide stem diameters.

Construction of Shank Thermowell

The most typical shank types for thermowells are straight, step, and tapered. A straight shank thermowell has an equal size along the immersion length of the Thermowell. Step shank thermowells have a different outer diameter at the end of the thermowell immersion length to respond quicker. In a tapered thermowell, the outer diameter of the thermowell lowers gradually along the immersion length of the thermowell. A heavy-duty tapered thermowell is generally used for high-velocity applications because of the tapered thermowell shank specification in the old ASME PTC 19.3 (1974) thermowell standard. However, where the inner nozzle diameter is a design limitation, the straight shank thermowell type is often the best choice for resistance to velocity-induced resonance.

Lagging Extension

Lagging extension thermowells are applied to applications where we use insulation to cover the vessel or piping system. The extension length (T-length) is the distance between the thermowell’s instrument connection and the process connection.

What You Should Care Before Thermowell Selection

Three Thermowell criteria are essential when selecting a Thermowell: immersion length, the potential for vibration, and material.

Thermowell Immersion Length

All types of thermowell encase temperature sensors. It is crucial to remember that thermowells are expected to assist in providing secure temperature measurements. Accordingly, the thermowell U size is vital to the precision of a temperature reading. Typically, the smallest U dimension of a thermowell in a fluid process is a length equivalent to five times the outside diameter of the thermowell. For a process including gas or air, the minimum U size of a thermowell is equivalent to ten times the outside diameter of the thermowell.

Possible Vibrations of the Thermowell

Thermowells sometimes fail due to the consequences of vibration. The common cause of vibration is the flow of media in the section of the process as the temperature is being measured. As the media of a process passes through a thermowell, it creates a turbulent wake that induces vibration in proportion to the flow of the fluid and the diameter of the well.

in order to reduce and avoid vibration, this tool must have enough stiffness so that the wake frequency will never be equal to the natural frequency of the structure itself. Many engineers prefer a tapered thermowell design as this form offers greater stiffness without losing the temperature sensitivity of a straight thermowell. The ASME PT 19.3TW organization has developed a standard (ASME/ANSI PTC 19.3TW-2010 Thermowells) that specifies the design criteria for thermowells.

Thermowell Material

Selection of the proper thermowell material in a process is further essential to preventing thermowell failure. thermowell materials are usually chosen based upon a consideration of the process temperature into which the thermowell is being immersed, the material of construction of the vessel piping, or other structure into which the thermowell is being connected, the corrosion conditions of that process, and the possibility of erosive conditions. You must be aware of these factors before deciding on a particular thermowell material.

Material Selection

Selecting the suitable material is essential to the longevity of a thermowell. The nature of chemical, temperature, and flow rate the thermowell will be connected to should be regarded when specifying the material. The corrosive consequences of chemicals are magnified at higher concentrations and temperatures. In addition, suspended particles in the fluid can cause erosion. The following list includes some of the most frequently adopted materials for the construction of thermowells:

- Stainless Steel

- Carbon steels

- Chromium/molybdenum steels

- Socket Weld

- Incoloy®

- Inconel®

- Monel®

- Titanium

- Hastelloy®

- Haynes® Alloy

Carbon steels have a low resistance to corrosive materials and are limited to low temperature and pressure applications. The most regularly used material for thermowells is stainless steel. A stainless steel thermowell is cost-effective and extremely resistant to corrosion and heat. Also, Chromium/molybdenum steel is a high strength stainless steel utilized in pressurized vessels. The addition of molybdenum increases corrosion resistance. Haynes alloy is composed of nickel, chromium, cobalt, and tungsten. It is most often used for carburizing, sulphidisation, and chlorine-containing environments.

Why Do We Use a Thermowell?

A thermowell works as a protective barrier between a temperature sensor and the process media. Thermowells are often seen in industrial process systems within refineries, chemical and petrochemical plants. In addition to protecting these sensors, thermowells offer easier serviceability and reduce running costs.

Protective Barrier

A thermowell’s primary function is to protect a thermometer from external circumstances, which it prepares by housing the thermometer. With the thermometer safe inside, the thermowell can handle various corrosive or abrasive process media and face turbulent or high-pressure conditions. The thermowell limits the thermometer’s sensing element from being exposed to excessively hot or cold temperatures.

Increased Serviceability

If you need to replace or remove a sensor, thermowells simplify the process by presenting easy access. They are still connected in the piping system while a thermometer is being maintained. As a result, the system continues to work, which means there is no unnecessary downtime, and the media continues to flow without the worry of leaving the system.

Reduced Operational Costs

Thermometers serve longer and do not require to be maintained as often when thermowells are installed to protect them. In effect, thermowells help reduce the total cost of thermometers by minimizing the time wasted maintaining and servicing the instruments. The fact that we do not need to replace thermometers as often or service an extensive list of them will also save money in the end.

Choosing the Right Types of Thermowell

There are various specifications to consider when picking a thermowell, including:

- stem length

- insertion length

- wall thickness

- connection size and type

- style

- media composition and condition

- bore diameter

- type of weld or mount

- Positive Material Identification (PMI)

- Mill Test Reports (MTR)

- Non-destructive Testing (NDT), same as Liquid Penetrant Inspection (LPI), radiography (RT), pressure testing, ultrasonic (UT), and hardness testing

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- What is Thermowell? Types & Working Principles

- The Best USA Thermocouple Manufacturers in 2022

- The Only Guide You’ll Ever Need For Different Type of Industrial Measuring Tools

- What is the Core Difference between Thermistor and RTD?

- Difference Between Thermistor and Thermostat: Which One Outperforms the Other?

- Working Principle of Thermocouple: 2022 Guide + Diagram

- Difference Between Thermopile and Thermocouple

- Thermocouple vs. Thermopile: A Complete Comparison & Advantages of Each Type

- Thermistor vs Thermocouple: Complete Comparison & Practical Selection Guide

- What is a Thermocouple & How Does It Work?

- Thermocouple Types: A Complete Comparison Between Them

- Thermocouple for Water Heater: How does it Work?