Electrical transducers are such a device for converting different physical quantities to electrical quantities and there are many types of transducers in the market. They should be used in most measurement devices so that the data would observe and recorded consequently. The electrical output is usable voltage or electric current and is equivalent to the measured quantity. Pressure, temperature, displacement, etc., would be measured, and the output signal and data can be displayed and recorded by the transducer for analysis and post-processing. For example, a pressure transducer is converting certain pressure in a system to a specific electric quantity.

An electric transducer is one of the most important parts of each instrumentation and industry application. It should be mentioned that a transducer is a device that converts one energy to another, and its nature is not essential. For example, speaker and piezoelectric devices convert an electric signal to physical displacement and pressure waves. By the way, an electric transducer is a system for converting physical quantities to an electric signal.

Which type of transducers should you buy?

Many different parameters make a transducer excellent and useful for the customer. While you want to choose a transducer, be careful, and keep these points in mind:

- Loading effect is not much in low output impedance and high input impedance transducers

- It should have a fair resolution in the entire range.

- Try to buy a highly sensitive one with fewer unwanted signals.

- It is better to buy a small size and weight transducer.

- Keep in mind the working situation, for example, the humid or corrosive environment.

- Resistance to vibration, pressure, shock, temperature, etc., may be important.

- Good repeatability and accuracy are necessary for transducers

Differences between sensors and transducers

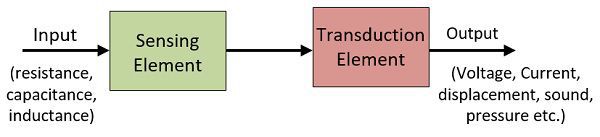

Sensors are getting the physical changes in the system, while transducers convert these physical and non-electric changes into electric signals, which is the big difference between them. Here, as shown in the figure, the sensor measures the quantity, and the conditioning device filters, modifies, or attenuates the signal to be accepted readily by the output devices.

Types of Transducers

Transducers can be categorized based on different aspects described below, and a wide range of them are available in the market. Choosing a transducer is dependent on the application, and you should know which type is suited for your application and demand.

transduction phenomenon (Transducers and inverse transducers)

A transducer is an instrument for converting a non-electrical (usually physical) input and quantity to an electrical output and quantity. On the other hand, the inverse transducer is converting electric input to physical output. To be clear about this classification, we should know that the transducer’s output is an electrical quantity, and the output of the inverse transducer is always physical output and non-electrical quantity. The output in these types of transducers such as thermocouples, and photoconductive cells, the pressure gauge is an electrical signal, and the piezoelectric transducer converts electric input to the strain in the output.

Types of Transducers based on the Operation Principle

Transducers work on different bases depending on the measured physical quantity and conversion of the physical parameter to the electric current and voltage stands on various principles. Some of them are listed here:

- Piezoelectric transducer

- Photoconductors

- Chemical

- Electromagnetic

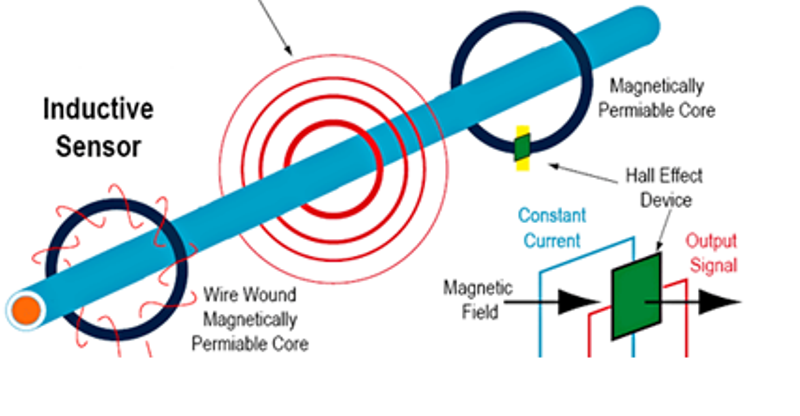

- Mutual induction

- Hall effect

- Photovoltaic (e.g. a solar cell)

The requirement for External Power Source

Basically, types of transducers can be divided into active and passive ones depending on the power source in them. An active transducer is free of the external power source, while the passive one needs a power source to work correctly.

Active transducer

Some transducers do not need any power source for their operation and are called active transducers or self-generating transducers. These types of transducers supply their own electric signal proportional to the physical parameter and quantity measured. Thermocouples or Piezoelectric transducers is one of the active transducers, and they are based on energy conservation principles.

Passive Transducers

Passive transducers require an external power source to perform. Photocell (LDR), thermistor, and differential transformer photomultiplier tubes are examples of these types. Internal parameters like resistance, capacitance, and inductance change when we have the input signal in the passive transducer.

An example of a passive transducer is a strain gauge, consisting of wires on a surface. A strain gauge measures stress and pressure, and an external electric source provides voltage to the wires. Any increase and decrease in the strain gauge because of bending, compressing, or tension causing changes in the resistance of the wired equivalent to the difference in the stress.

classification based on the type of output

The type of output is very important in the transducer and is divided into digital and analog types.

Analog transducer

Digital transducers convert the physical input to a continuous function in output and signal. Thermocouples, thermistors, and strain gauges are examples of digital ones.

Digital transducer

These types of transducers that provide pulse in output are known as digital transducers and may work in low or high power.

Primary and Secondary types of Transducers

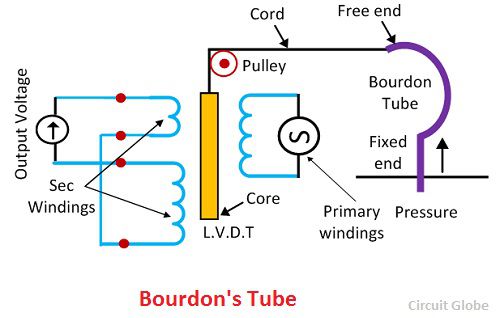

If the conversion is completed in one step, then it is a primary transducer. In case there are two or more transduction stages, then it is called a secondary type.

Primary transducer

Primary transducers consist of mechanical and electrical parts at the same time. The mechanical part provides the mechanical signal by changing a physical input quantity, and as a result, this mechanical device is called a primary transducer.

Secondary transducers

Secondary transducers are just changing the mechanical input to the electric signals based on the quantity of the input parameter. And usually are part of the bigger instruments.

An example to distinguish the secondary and primary types of transducers is a bourdon’s chamber. The free end in the bourdon tube converts the pressure to the linear displacement. In the second part, the displacement transformer (L.V.D.T) provides the electric signal based on the free end displacement proportional to the tube’s pressure. There are two transductions in this system. First, in the primary transducer (tube), the pressure is converted to the displacement, and then the secondary transducer (L.V.D.T) changes it to the electric output.

Types of Transducer based on the measuring quantity

A different parameter can be displayed by using transducers in various applications. When you want to measure a physical quantity, remember to check different transducers from different companies. Some of the important transducers are described below.

Displacement transducers

An electromechanical instrument for converting displacement, vibration, and motion to the electric current and voltage is called a displacement transducer. These transducers are categorized based on the energy conversion to electromagnetic, magnetoelectric, electrostatic, and inductive. Linear variable displacement transducers (LVDT) are a famous example of this type of transducer.

Oscillator transducer

An oscillator transducer is measuring force and pressure and provides voltage or current in the output. This kind of transducer is usually working as a secondary transducer and consists of these parts:

- Mechanical linkage

- Oscillator

- Frequency modulator

- Force summing member

Oscillator transducers are measuring dynamic and static parameters and are the best choice for telemetry applications. This transducer has low accuracy and low thermal stability and should be used for poor accuracy measurements.

Pressure transducers

A type of transducer that converts pressure to electric signals is called a pressure transducer, and various types are available; for example, a strain gauge transducer is working by the deformation in the strain gauge bonded to the diaphragm and wired to the bridge. Generally, different sizes, shapes, and ranges of pressures can be found, but the technology about them are:

- Strain Gauge Pressure Transducers

- Potentiometric Pressure Transducers

- Capacitance Pressure Transducers

- Resonant Wire Pressure Transducers

Flow transducers

Flow transducer measures the volume, mass, or velocity of the liquid, gas, or steam in the different systems. There are many kinds of flow meters based on the principles and for different applications. Flowmeters and transducers are the heart of most industries, and obtaining accurate and repeatable flow measurements is their goal.

Temperature transducers

A temperature transducer is employed to measure the temperature of a physical object. Ordinarily, a transducer is nothing but transforming a physical quantity into electrical energy. Thus, a temperature transducer is an instrument used to convert the thermal energy of the substances into electrical form. In other words, it is a piece of electrical equipment applied for automated measuring of temperature. The latest purpose of the temperature transducer is to measure the heat of the material in a readable format. For more information, click here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Temperature Transducer: Definition, Working Principle, and Types

- Photoelectric Transducer

- Resistive Transducer: All you need to know!

- How to Wire Up Piezoelectric Sensor? A Comprehensive Guide

- Active Transducer: All You Should Know About

- Transducer vs. Sensor: Basic Differences & Advantages of Them

- Piezoelectric Transducer and Its Impressive Applications in Electric Circuits

- What are the Main Benefits of an Ultrasonic Transducer?

- Pressure Transducer: Definition, Working Principle, and Types