We need to breathe in clean air to remain healthy. As we spend most of our time in close buildings, proper ventilation design is crucial. Stemming from this fact, the question which may arise here is how to design an efficient ventilation system. On the other hand, ventilation design has a direct relationship with energy bills. So, it increases the importance of paying more attention to it.

It is time to pay more attention to ventilation design. Here we have some considerations that should be kept in mind.

4 steps to guide ventilation design

In this part, we are going to help you design the ventilation system in just four steps:

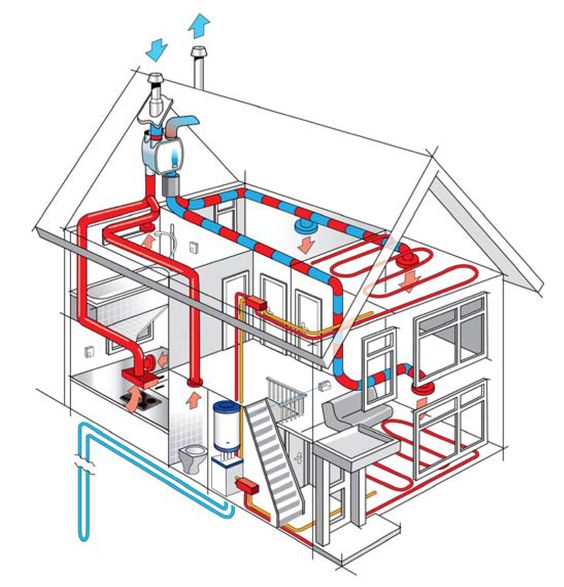

Step1: Choose where you want to ventilate

Decide which places of your building need ventilation. Typically, these areas in the house contain the living room, subfloor, and roof space.

Suppose you are going to design an efficient ventilation system and make the duct more effective. In that case, you should ventilate the roof space to reduce the temperature. On hot days, your roof can heat up like a stove and direct conditioned air through the heat to the house. So, the air temperature will increase before reaching your living space.

Furthermore, you can install a whole-home ventilator to diminish your reliance on air conditioners. The whole home ventilator continuously removes heat from your living space and the roof during the day and night. It helps you regulate the temperature of your home and prevent extreme heat or cold during the year.

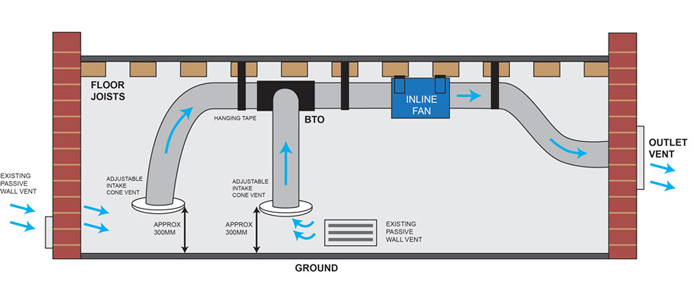

Additionally, another concern that should be noticed in ventilation design for cooling a house is humidity inside the room. While using air conditioning, the damp may rise in under-floor areas. Thus, the moisture in the subfloor must be removed using the ventilation system to reduce the risk of structural damage and other probable risks.

Step2: Determine the equipment you may need in ventilation design

- The roof space: The roof ventilator is essential. You can choose mechanical ventilation or a natural wind-driven system here. Smart vents have up to 6 times better performance compared with wind-driven vent.

- The subfloor: a subfloor ventilator is needed in this situation. A twin system, one to exhaust hot, humid air, and the other to draw in fresh dry air, can be useful.

- The living area: a whole-home ventilator is needed here. Suppose you are ventilating a specific room like a bathroom or laundry. In that case, you can use a roof ventilator with ducting and ceiling grilles. However, if you are ventilating a damp area like a bathroom or laundry, you should duct these rooms directly outside, i.e., not into the roof space.

Step 3: Calculate how many vents you need.

You should determine the number of vents that may be employed in ventilation design. Roughly speaking, we can say:

- Each 87 m2 area needs 1 smart vent or 1-2 wind-driven vents for ventilation of roof space.

- The ventilation of a roof and living space with an area up to 150 m2 needs 1 whole ventilation system.

- The ventilation of the subfloor needs 2 subfloor ventilators.

These factors can be considered in ventilation design roughly. However, to access a proper, efficient design with an accurate number of components, you should contact one expert in this field.

Step 4: Paying attention to the make-up air flow rate

make sure to provide sufficient make-up air into the ventilated area. To optimize the ventilation design, you should provide an inlet for cold fresh air coming from outside, known as make-up air. It is necessary to remove the polluted air and replace it with a ventilated one. Regarding this fact, you should notice the following hints in ventilation design:

- You can install eave vents into the overhang of the roof to prepare make-up air into the roof space.

- In the living space, you can prepare the fresh air by just opening the windows.

- In the subfloor, a twin ventilation system is essential to create enough make-up air. In this way, one vent will be set to pull outside air into the indoor area.

Ventilation Design Procedure

The procedure mentioned below can be employed for ventilation design:

- Calculate heat or cooling load, containing both sensible and latent heat.

- Calculate the number of air changes by taking into account the number and activities of living people.

- Calculate the temperature of inlet air

- Calculate the mass of air which must be circulated in the area

- Calculate the amount of energy and temperature loos in equipment and ducts.

- Calculate the properties that can be achieved as an output of components, such as heaters, washers, humidifiers, coolers, etc.

- Calculate the size of a boiler or heater.

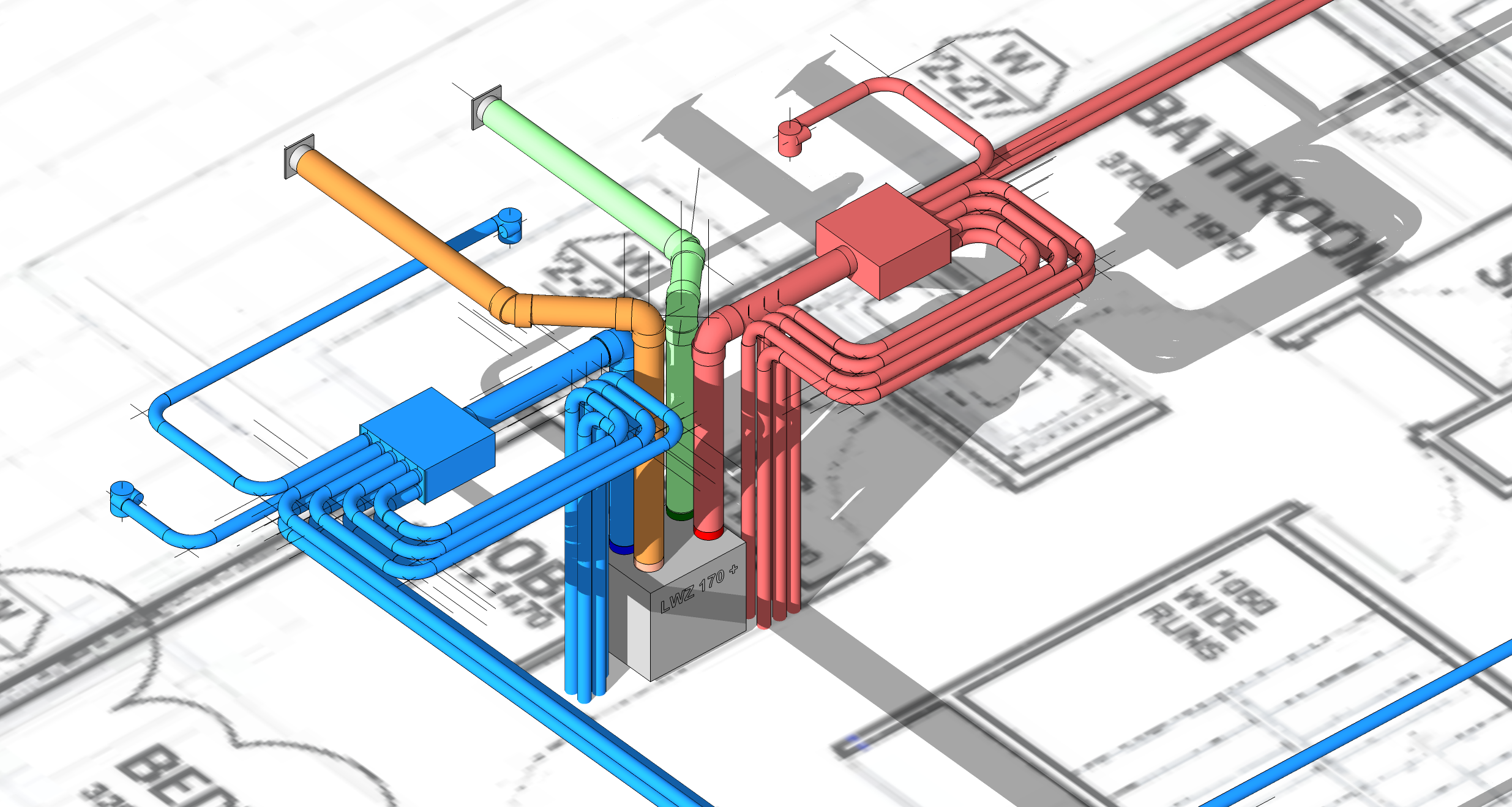

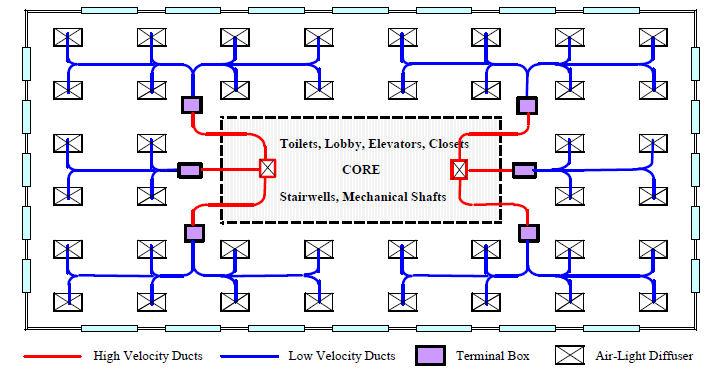

- Design an find the sizing of the duct system

Now each process of ventilation design will be elaborated in more detail.

1.Calculation of cooling and heating load:

In this part, you need to calculate the indoor heating and cooling loads, in addition to surrounding loads, to achieve the exact loads you need to come up with for ventilating the area.

2.Number of air exchange

Based on the number of occupants in a place, and the time and type of activities they may have in that area, you can find how many pollutants are emitted there. So, the fresh air, which is essential to be provided through ventilation design, can be calculated. Then, you can calculate the critical air shifts to ensure the healthy air is handy.

3.Air supply temperature

There are some standard guidelines to calculate the temperature of the supply air. One of -which is written here:

- The temperature between 38 to 50 degrees Celsius (100- 120 oF) is suitable for heating the space.

- When you are going to cool down an area where the zone is near the inlets, the inlet temperature should be adjusted 6 to 8oC below the area temperature.

- For cooling with high-velocity diffuse jets, the inlet air temperature should be set 17oC below the room temperature.

4. Air Quantity

If we are going to heat the room, the expression from which you can find the air volume is

qh = Qh / (ρ cp (Ts – Tr))

where

qh = volume of air for heating (m3/s)

Qh = heat load (W)

ρ= density of air (kg/m3)

cp = specific heat air (J/kg K)

Ts = supply temperature (oC)

Tr= room temperature (oC)

For the calculation of cooling load, we have:

qc = Qc / (ρ cp (To – Tr))

in which

qc = volume of air for heating (m3/s)

Qc= heat load (W)

ρ = density of air (kg/m3)

cp = specific heat air (J/kg K)

To= Outside temperature (oC)

Tr= room temperature (oC)

5.Temperature loss in ducts

Another parameter in ventilation design is the temperature loss in the ducts. The amount of heat loss from a duct is calculated from the duct walls, the initial and final temperature in the duct, the temperature around the duct, and the heat loss coefficient. The heat loss coefficient is different for each substance. For example, it is 5.68 W/m2 K for sheet metal ducts and 2.3 W/m2 K for insulated ducts. The equation from which the heat loss of the duct is calculated is

H = k A((T1 + T2) / 2 – Tr )

where

H = heat loss (W),

A = area of duct walls (m2),

T1 = initial temperature in duct (oC),

T2 = final temperature in duct (oC),

and

Tr = surrounding room temperature (oC).

After finding heat losses, air heat loss can be found from

H = 1000 q cp (T1 – T2)

where

q = mass of air flowing (kg/s)

and

cp = specific heat air (kJ/kg K).

So, the temperature loss in ducts is driven out from combining the above equations.

6.Heater, Cooler, Washer, and Humidifier Selection

In calculation design, the proper equipment should be selected based on the air quantity and heating or cooling capacity. For choosing these units, you should search for them in catalogs presented by manufacturers.

7.Calculation of boiler size

Due to the load calculated in, calculation of cooling and heating load, we can size the boiler; but, keep in mind that a margin around 10 to 20% should be added to the calculated load to make sure about the boiler size. It means:

B = Q (1 + x)

where

B = boiler rating (kW),

Q = total heat load of all heater units in system (kW),

x = margin for heating up the system, it is common to use values 0.1 to 0.2.

Finally, the correct boiler with proper rating can be selected from manufacture catalogs.

8.Duct sizing

In order to size the duct in ventilation design, the first step is to find the air velocity in it. Then, the total pressure loss in ducts must be calculated. These pressure losses consist of major pressure loss, minor pressure loss, and minor losses in filters, heaters, and other components. Major pressure loss in ducts is

dpf = R l ,

where

R = duct friction resistance per unit length (Pa, N/m2 per m duct)

and

l = length of the duct (m).

By taking into account the mentioned correlations, the hydraulic diameter of the duct can be calculated from the below

R = f / dh (ρ v2 / 2)

where

f = friction coefficient,

dh = hydraulic diameter.

To understand more about duct sizing in ventilation design, click here.

It’s very good

I need the product fit my house

Please share your contact 8830298484 i need quotation i have 2000 sq feet home with 2 floor’s

I love your page and believe that whenever contacted for a solution you will gladly provide me with the answer. Thank you.

Your kind words are much appreciated! It was a pleasure having you visit us.

very informative and really help me a lot in my design work.

Thanks for visiting our website and leaving your comment, Mario! We hope to hear from you again in our other posts.

Good morning can I ask for the assistance for the ventilation design of 42.6 m x 36 m x 30 m in height, Thank you and God Bless.

Thanks for visiting our website. You can visit our expert page and take advice from hundreds of professionals on your issue.

Sir,

I am asthmatic and want to supply ventilation into my bedroom room from a height of 30 feet for fresh air to avoid pollutants from neighbouring houses. I live on first floor of a double storey house. Can you guide me and with appropriate system for such installation?

Thanks for visiting our website. You can visit our Industrial Equipment page, where you can find various Ventilation Systems based on your application and demand. You can also visit our expert page and take advice from hundreds of professionals on your issue.