What do you know about a water chiller system? Do you know what components it consists of? Have you ever been curious to know how it works? We prepared an easy-to-understand guide for you to give you some necessary information about water chiller system. Quite essential data have been gathered by Linquip to assist you to know more about this equipment. In the following sections, we will analyze the parts, functions, uses and applications of this cooling system.

What Is a Water Chiller System?

First of all, by having a look at the name of chiller, it becomes quite obvious that this piece of equipment is used for the act of rejecting the heat from an internal component, environment or more specifically, a liquid in order to drop the temperature. This refrigeration system can be used in many types of machinery. It can be also used in some industrial processes as well. As a matter of fact, we can see that such a system needs to be used in commercial places such as restaurants, hospitals, manufactures and more.

Chillers fall under two categories: vapor absorption and vapor compression. Between these two categories the vapor compression chillers are the most common in use. One kind of categorization put vapor compression chillers into two different categories of air chillers and water chiller systems. Moreover, there is another way of categorization of vapor compression chillers which is based on the type of compressor technology. According to this categorization, we have centrifugal, scroll, reciprocating and screw chillers. If we want to have a very short and brief description of chillers, we have to say that a water chiller system is a device that is used to cool the water temperature down.

Vapor Absorption vs. Vapor Compression Chillers

Let’s get back to the first categorization where we have vapor absorption and vapor compression chiller. The main difference between these two major types of chillers is that the vapor compression ones use a mechanical compressor driven by electricity to force the refrigerant around the system while the vapor absorption ones use heat for this purpose.

As the vapor compression chillers are more commonly used nowadays, in the following section we elaborate the types of this kind and deliver some pieces of information about the components, functions and types of compressor technologies.

Main Types of Vapor Compression Chillers

From here onwards, by water chiller system or simply chiller, we mean any kind of chiller in the vapor compression category. Considering the process in which the refrigerant is cooled, chillers are divided into two categories: air- cooled and water-cooled. The primary distinction between these two types is driven from their names: air-cooled chillers use airflow to remove unwanted heat and water-cooled ones use water for a similar purpose.

The Function of Air/Water-Cooled Chillers

Both of these refrigeration systems have similar parts. Air and water-cooled systems have and evaporator, a compressor, a condenser and an expansion valve. Besides, most of the mechanics of these two systems is processed similarly. The refrigerant cycle inside a water chiller system begins in the compressor. In the next stage, the gas form of refrigerant flows through the coils of the condenser and the heat of the refrigerant is removed in the condenser and the gas begins to be condensed into liquid. The liquid goes through the expansion valve. The expansion valve restricts the flow of the liquid refrigerant and passes it to the evaporator. Evaporation starts in the evaporator and turns the liquid form of refrigerant into gas. In this stage, the gas is very cold and the fluid/ water makes an interaction with the cold refrigerant. The heat of fluid is absorbed by the refrigerant. So, the hot refrigerant enters to the compressor to make the circle complete and the whole process repeats and repeats. This is how a water chiller system works.

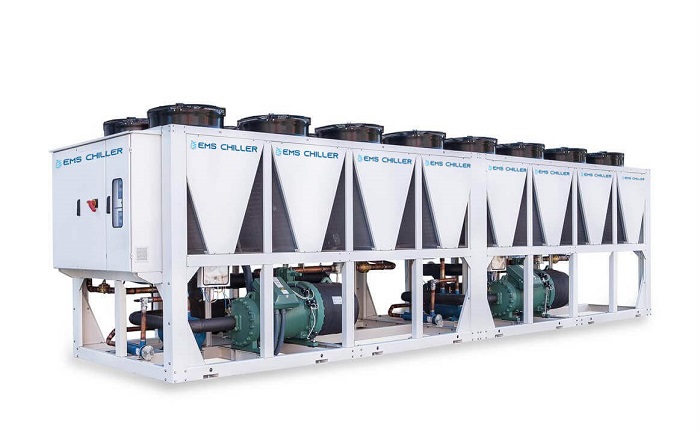

How Does an Air Chiller Works?

There are some fans in the structure of an air-cooled chiller. These fans make a pushing air flow across the exposed coils of the condenser. Air-cooled chillers are easy to install and have to be installed outside a building for maximize the capacity of fans. Compared to water-cooled chillers, air chillers are bigger in size and more likely to experience blockages and re-circulation issues.

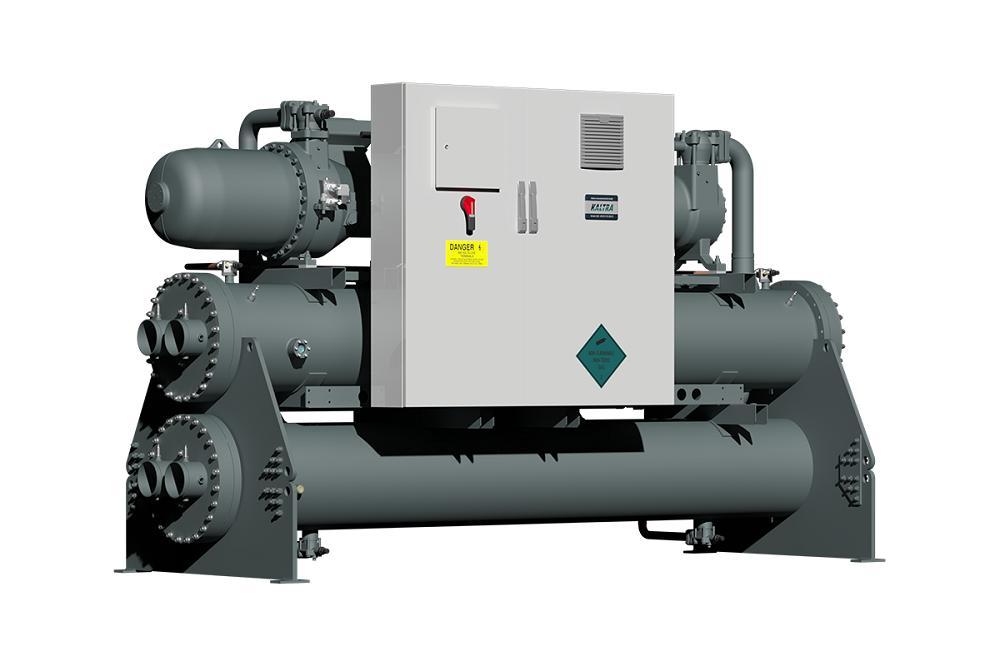

Water Chillers

The overall process of cooling refrigerant in water-cooled chillers is similar to air-cooled ones but there are two more excessive steps: first, the heat of refrigerant is transferred to the condenser water and then to accomplish the process, the warm condenser water is pumped to cooling water to disperse the heat into the ambient air. Because of Water-cooled chillers are typically more efficient. Using water to reject heat utilizes significantly less energy and is more effective (thanks to the water’s high heat capacity) than blowing air across a hot surface. In addition, water-cooled chillers are prone to last longer than air-cooled chillers.

Types of Water Chiller Systems based on Compressor Technology

In previous sections when we delivered some information about what generally a chiller is, we mentioned that vapor compression chillers are divided by their compressor technology into 4 categories. In the next sections, we intend to deal comprehensively with these four categories of chillers.

Centrifugal Chillers

Centrifugal chillers are mainly designed in the scale of water-cooled chiller system. It’s extremely rare to find a centrifugal system in air-cooled chillers. Centrifugal chillers are often available from 150 up to 6,000 tons of refrigeration. Although this system has a compact design, it offers high cooling capacity. One of the main components of this kind of chillers are rotating impellers whose job is to compress the refrigerant and force it around the chiller.

Reciprocating Chillers

The main parts of this type of chillers are a piston and a chamber whose job is to compress the refrigerant.

Scroll Compressor Chillers

Scroll compressors are used in both air-cooled and water-cooled chillers. These chillers operate by using a stationary and a rotating spiral plate to compress the refrigerant.

Screw Driven Chillers

This type is also designed in both water-cooled and air-cooled chillers and are the best choice for small to medium cooling loads. These chillers are usually accessible in 70 to 600 tons. Two interlocking rotating rotors work together to compress the refrigerant.

Conclusion

What you read in this article was information on water chiller system. We analyzed this cooling equipment from different aspects to make it clear for you how each one of the members of this huge family works and what components are they consist of. It is vital to understand the differences between obtainable options we have to select the best. We want you to know that if there are still some ambiguities on this topic for you, you can share your questions with our experts in Linquip. All you need to do is to sign up now. our experts are ready to answer your questions and give you advice. Moreover, if you have any experiences of using any types of chillers, or have opinions on this topic, you can share them with us in the comments. Hope you enjoyed reading this article.

Thanks for providing complete details about the water chiller system and other essential things. This blog is very helpful for me. Keep posting blogs.

Thanks for visiting our website and leaving your comment! We hope to hear from you again in our other posts.

Thank you for sharing valuable information about chiller gas.

Thank you for sharing your valuable information about industrial chiller.

Thanks for visiting our website. You can visit our Industrial Equipment page, where you can find various Chillers based on your application and demand.