You do not have to be a mechanical engineer to realize the fact that condensers’ importance in industry cannot be disregarded. There are many things to consider when it comes to purchasing a condenser. Therefore you need to know what it is and how it works to make the most out of it. Linquip has provided thorough information on water-cooled condensers.. Read on and find out more about them.

What is a water-cooled condenser?

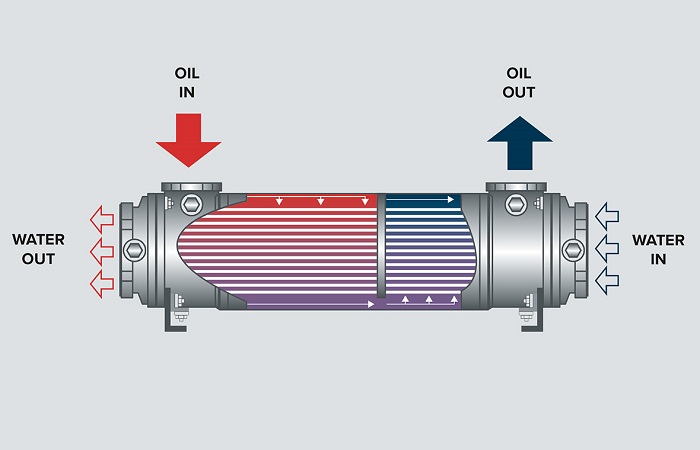

It is a technical heat exchanger used to remove heat from refrigerant vapor and transfer it to the water which runs inside the tube.

How does a water-cooled condenser work?

This type of condenser is developed to transfer heat from a working fluid to a secondary fluid. The vapor normally enters the condenser at a temperature above that of the secondary fluid. When the vapor cools, it reaches the saturation temperature, condenses into liquid and releases large quantities of latent heat; as a result, the quantity of vapor decreases and the quantity of liquid increases; while there will only remain liquid at the outlet of the condenser.

water-cooled condenser types

Commercial water-cooled condensers are of three basic types:

- Shell and coil water-cooled condenser: the shell condenser is a steel tank enclosing copper tubes inserted in the shell. As water flows through the tubing, it condenses hot gases into a fluid and the bottom part of the shell receives the fluid. The benefits of this type of separate condensers include compact design and elimination of fans. Since the coils are completely surrounded by a steel shell, the mechanical cleaning of such coils is almost impossible.

- Tube within a tube (double-tube) water-cooled condenser: the second type of these condensers is double-tube. One tube is put within another one in a way that water flowing through the inside tube cools the refrigerant in the outside tube. The construction of this condenser can be either in the cylindrical spiral or in the rectangular style.

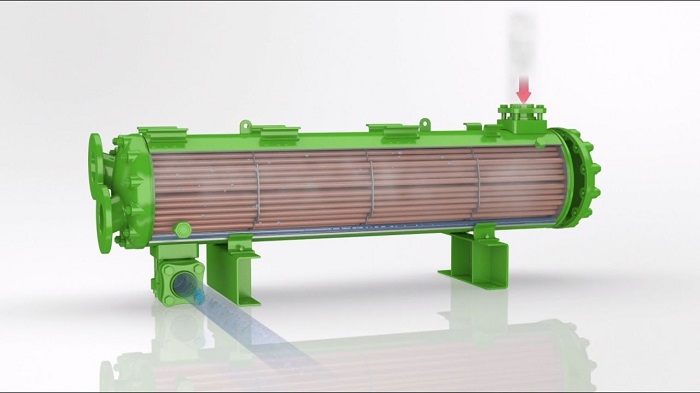

- Shell and tube water-cooled condenser: shell and tube is the most common type of such condensers in chemical processing plants which consists of number of straight water tubes enclosed by a large cylindrical shell. Tube diameters of 15mm to 50mm are common, while the number of tubes in the condenser varies from as few as six or eight to as many as one thousand or more. The end-plates of the condenser are removable to allow mechanical cleaning of the water tubes.

Advantages of a Water-Cooled Condenser

- Where there is restriction for air-cooled condenser, water-cooled condenser is a perfect replacement.

- There is thermal energy recovery to be used in other heating processes.

- This type of condenser can be housed indoors.

- A water-cooled system typically lasts years longer, assuming maintenance is not neglected.

- It has higher heat transfer rate.

- It consumes far less overall energy, which can lead to savings on energy costs and consumption.

- It does not require any external power.

- Since water cooling is more efficient than air cooling, time required for cooling is less.

- Length of the condenser pipe is reduced which decreases the compressor work and thus increases its efficiency.

- With the incorporation of these condensers, the net weight of the system increases.

Disadvantages of a Water-Cooled Condenser

- Using water as a cooling medium might cause corrosion problem.

- Use of water as a cooling medium may result in the formation of scales in the supply line.

- Because of shortages of fresh water around the world, few countries can afford to run water to waste.

- Using water tank makes the system bulky which results in problem during domestic use.

So, this is all you need to know about water-cooled condensers and their application within a system. If you enjoy this article and want to share your experience with different condensers in linquip, let us know what you think by leaving your ideas in the comment section. Is there any question we can help you with? Feel free to sign up on our website where our experts waiting to give you the professional advise you need.

Thank you very much for the brilliant write up.

Dear Clover

Thanks for your attention.

Whenever I see an air conditioner condenser where only the compressor is running but the fan is not running, and in the case of a water cooled condenser, when only the compressor is running, but neither the water or fans are running, it makes my sexually aroused enough to ejaculate because it reminds me of women touching my butt crack with their fingers and then touching my pancakes.