Steam is one of the great sources of energy for our modern age. We have used steam from the very beginning of our first industrial revolution in human history. It provides heat for process heating, sterilization, and many other applications that are increasingly important to industrial facilities, among others. A boiler or steam generator is a device used to create steam by applying heat energy to water. Different types of boilers are available in several sizes and forms and find their use in various applications. The water tube boiler is one of them that is applied widely in industries.

A high-pressure water tube boiler (also called a water tube) pumps water through tubes heated by the fire from the outside. Inside the furnace, fuel is burnt to produce hot gas, which boils water in the steam-generating tubes. The Water Tube Boiler is a vital component of many industrial systems. Water Tube Boilers are available from a variety of Suppliers And Companies, as well as various manufacturers and distributors, and there are several Water Tube Boilers For Sale on Linquip.

There is a comprehensive range of water tube boiler services on the Linquip platform that meets all of your needs. Linquip can connect you with a number of industrial water tube boiler service companies and experts who can help you. Linquip offers a team of Water Tube Boiler specialists who can assist you test your boiler.

In this article, we’re going to have a description of water tube boilers including operation, parts, types, advantages, and disadvantages. Read this new blog on Linquip to find out more.

Water Tube Boilers Features

The water tube boiler represents one of the several pressurized equipment options used to convert water into steam under controlled conditions. A way to rapidly produce steam is to feed the water under pressure into a tube or tubes surrounded by the combustion gases. The earliest example of this was developed by Goldsworthy Gurney in the late 1820s for use in steam road carriages. Modern high capacity boilers are of water tube type. Basically, in this boiler, water will be flown inside the tubes surrounded by flue gases. More steam is generated by using this boiler, so the overall efficiency of the boiler is high. The ability of water tube boilers to be designed without the use of excessively large and thick-walled pressure vessels makes these boilers particularly attractive in applications that require:

- A high steam output (up to 500 kg/s)

- High-pressure steam (up to 160 bar)

- Superheated steam (up to 550°C)

The water tube boiler is common in papermaking, sugar, and other Industries that demand electrical power and steam. Owing to their superb working properties, the use of water tube boilers is highly preferred in the following major areas:

- Variety of process applications in industries

- Chemical processing divisions

- Pulp and Paper manufacturing plants

- The large turbines of utility companies

- Refining units

What Is the Name of a Water Tube Boiler?

Longitudinal Drum Boiler or Horizontal Tubes Boiler are other names for the Babcock-Wilcox boiler. One cylindrical drum is longitudinally positioned above the heating chamber in this sort of boiler. The downcomer tube in the back of the drum is filled, and the riser tube in front of the drum is installed.

What Is the Difference Between a Fire Tube and a Water Tube Boiler?

A firetube boiler produces steam by passing combustion gas through a series of tubes surrounded by water in a vessel, whereas a water tube boiler transfers heat energy and produces steam by sending water through a series of tubes surrounded by combustion gas.

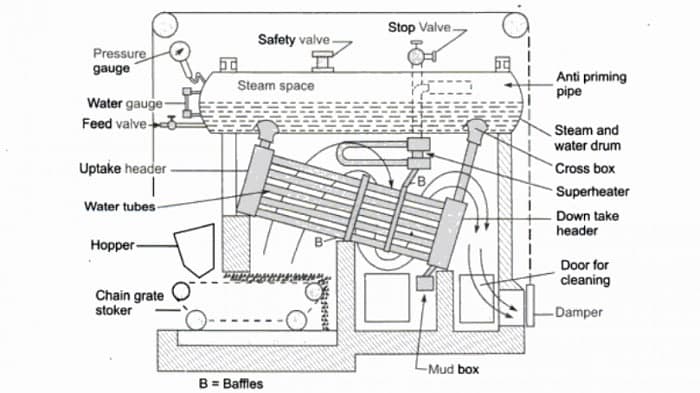

Water Tube Boiler Components

Here is a review of the water tube boiler parts and functions.

- Boiler Shell: This shell is the external cylindrical part of a pressure container.

- Steam drum: It is a collection vessel for steam and water.

- Mud drum: This is a cylindrical formed space at the base of the water space. It will gather impurities like mud, sediment, and others.

- Water walls: It is a tubing arrangement around the furnace to extract heat from fuel to generate steam.

- Furnace: An enclosed space provided for the combustion of fuel.

- Safety valve: It finds a use for stopping the unnecessary force from the construction of a boiler.

- Strainer: This is a type of device as a filter to hold solid elements let a fluid supply.

- Sight glass: A glass tube is utilized on steam type boilers for giving observable signs of the water level in boilers.

- Steam stop valve: It controls the steam flow supply outside.

- Feed check valve: The high-force water flows via this valve, which releases to the boiler simply and supplies the water to the water type boiler.

- Burner: This is one type of device for the beginning of air and fuel into a boiler at the preferred velocity. It is the most crucial apparatus for the firing of gas or oil.

- Economizer: Accessory used to recover the heat of flue gas that leaving the boiler by heating feed water.

- Superheater: It finds use to increase the temperature of the steam.

Working Principle of Water Tube Boilers

Let’s know about the working principle of a water tube boiler, and it will help you to understand its advantages and disadvantages clearly.

The Feed Water is allowed inside the steam drum by a feed check valve. The water travels to the mud drum where any unwanted particles will settle at the bottom of the mud drum. The water circulation is maintained by circulating tubes and steam pressure is maintained by equalizing tubes. The fuel that is burnt in the firebox over the grate produces hot flue gases that travel over the water tubes giving its temperature. For the proper passage of hot flue gases over the water tubes baffle plates are arranged. The heated water generates high-pressure steam used for the production of Electricity. To increase the economy of the boiler, exhaust gases also find use to preheat combustion air blown into the burners and to warm the feed water supply in an economizer.

Types of Water Tube Boilers

Here is a list of water tube boiler types:

- Babcock and Wilcox boiler: Designed by the American firm of Babcock & Wilcox, this boiler finds use in stationary and marine engines. It exclusively finds use when the pressure above 10 bar and steam generating capacity more than 7000 kg/hr is required.

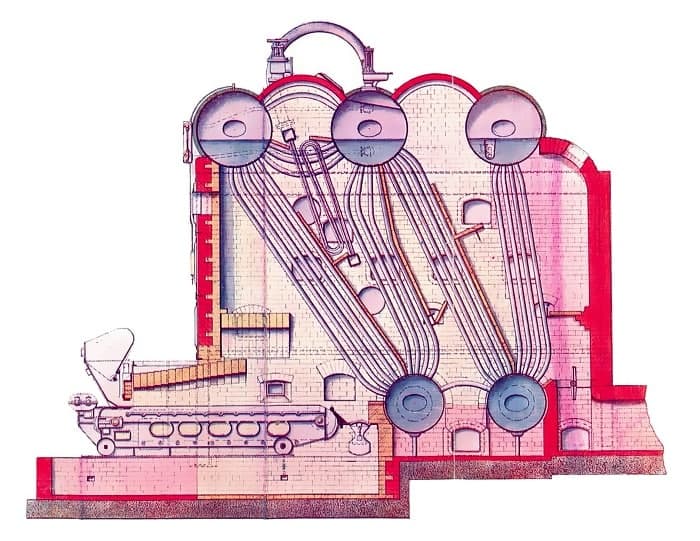

- Stirling boiler: This boiler is an early form of water tube boilers, used to generate steam in large land-based stationary plants. They became widespread in industries that produced combustible waste and required process steam. Stirling boilers are one of the larger arrangements for a water tube boiler.

- Simple vertical boiler: These boilers find use in steam power-driven vehicles as well as mobile machines like railway steam engines, steam tractors, Steam shovels, and steam cranes.

Keep that in mind, contrary to popular belief that a locomotive boiler is a water tube boiler, you better know that it’s a fire tube boiler, and it is not a water tube boiler example.

Water Tube Boilers Pros

Significant advantages of a water tube boiler system include:

- Safe and easy operation

- Fast reaction to steam demand

- Provides highly efficient performance, up to 90% with an economizer

- Rapid heat transmission

- Requires less floor area for a given output

- Can be easily transported

- Easy access to all parts for cleaning, inspecting, and repairing

- Can tolerate high steam pressures

- Large evaporative capacity

Water Tube Boilers Cons

Few limitations associated with the usage of water tube boiler plants include:

- High maintenance cost

- Complicated and time-consuming installation procedure

- Cannot be manufactured in packaged form

- Uneconomical for small industries

Conclusion

So, there you have a useful guide to the water tube boiler. If you have any points to discuss in this article in Linquip, let us know by leaving a reply in the comment section. Is there any question we can help you through? Feel free to sign up on our website to get the most professional advice from our experts.

Download Water Tube Boiler PDF

Read More In Linquip

- Thermocouple for Water Heater: How does it Work?

- Can I Use Water Instead of Coolant in an Emergency?

- Water cooled condenser types : A go-to guide to choosing the right one

- Water Chiller System and the Essential things You Should Know about it

- Condenser water system: An overview of its components and more!

- Water-cooled condensers: facts that will blow your mind!

- Advanced Guide: What Is Tube In Tube Heat Exchangers

- What is u-tube heat exchanger? An undeniable advantageous system

- Types of Shell and Tube Heat Exchanger

- 5 Best Electric Boilers of 2022: A Practical Guide

- Boiler Efficiency: Definition, Formula Caculation

- The 5 Best Regular Boilers of 2022

- The 9 Best Combi Boilers of 2022

- Benson Boiler: A Full Discussion on Structure, Working Principle, Pros and Cons and Applications

- Cochran Boiler : All You Need to Know about Parts, Working Principle, and Features

- Package Boiler: Your go-to guide to learn everything about them

- Locomotive Boiler 101: Your Go-To Guide for Locomotive Boilers

- Lancashire Boiler 101: A go-to guide to know Lancashire Boiler

- Cornish boiler 101: All you need to know about this boiler type

- Types of boilers: Which one is the best?

- How Steam Boiler System Works?

- Parts of Boiler and Their Function in the Boilers

- 5 Best Steam Boilers Worth Buying

Thanks for the lectures, but I want to no more about the furnace

Thank you for your attention

Please refer to other articles on the site