What are Coaxial Valves? Working Principles & Types – Coaxial valves are meant to be entirely pressure balanced. The switching behavior is virtually unaffected by the pending medium pressure. Regardless of whether the valves are under vacuum, low pressure, or high pressure, the switching capacity stays constant and the valves switch safely. The pressure levels are limited only by the seal friction at higher pressures. In this post, we discuss the basics of coaxial valves, their working principles and types.

What is A Coaxial Valve?

A coaxial valve functions by using an internal laterally moveable hollow tube that may regulate or redirect the flow of media flowing through the valve. Internal coax tubes are usually made of 316 stainless steel, which has better corrosion, wear, and chemical resistance, making it appropriate for a variety of inert, aggressive, corrosive, polluted, abrasive thick glutinous liquid or gas media.

PTFE, NBR, EPDM, or FKM O ring seals hold the coaxial tube in place, allowing for lateral tube movement while preventing the media from touching any of the valve’s internal elements. When pushed laterally (coaxially) by either an electromagnetic solenoid or an external pneumatic air pilot control, the tube ends will seal against a gasket or seal to either block or allow the passage of media.

Features of Coaxial Valves

Free Flow Path

Coaxial valves are designed for highly viscous fluids because the flow path is relatively free of obstructions. Because of the simple design, they can withstand large flow rates with minimal pressure loss.

Unaffected by Pressure

Coaxial solenoid valves can withstand pressures of up to 400 bar and are unaffected by pressure changes at the inlet or outlet. They can also work in a vacuum or at a zero pressure difference.

Response Time

Coaxial valves are extremely fast-acting when compared to other valves for highly viscous media (motorized ball, gate, butterfly, and globe valves). Other methods might take a long time to activate.

Position Signaling

During the valve manufacturing process, position signaling devices can be added to send open or closed position feedback.

Maintenance

Coax valves have a long cycle life, are durable, and require little upkeep. They can, however, be equipped with manual overrides to make commissioning and maintenance easier.

Types of Coaxial Valves

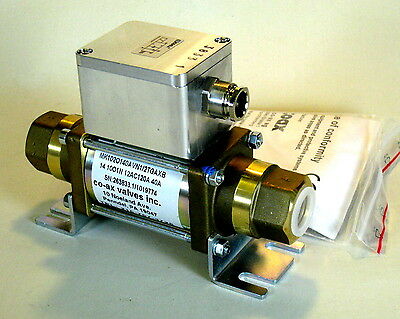

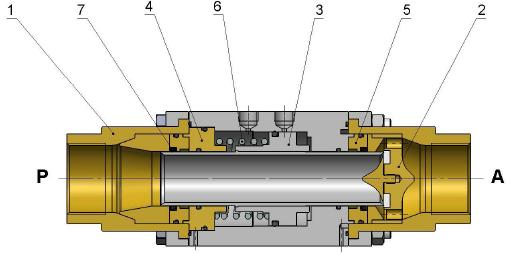

Coaxial Solenoid Valves

A solenoid-operated 2/2 way, usually closed coaxial valve (two ports P input 1 and A output 1) is shown on the right, with the flow route running via a central core tube (3), which is the tube. When an electrical signal is supplied to the connection (5), the coil (4) creates a magnetic field that pulls the tube (3) laterally towards it (left to right), revealing a flow channel through the valve. When the power is turned off, the spring returns the armature to its closed rest position. Coaxial valves are also available in 2/2 way typically open configurations, which are spring open with power to shut.

3/2 way coaxial solenoid controlled valves are also available, with 3 ports and 2 positions. This is a third port (R) or exhaust port that is at 90 degrees to port P (essentially when diagram item 1 points) and is either open when port A is closed (tube to the left exposing R) or closed when port A is open (tube to the right covering R).

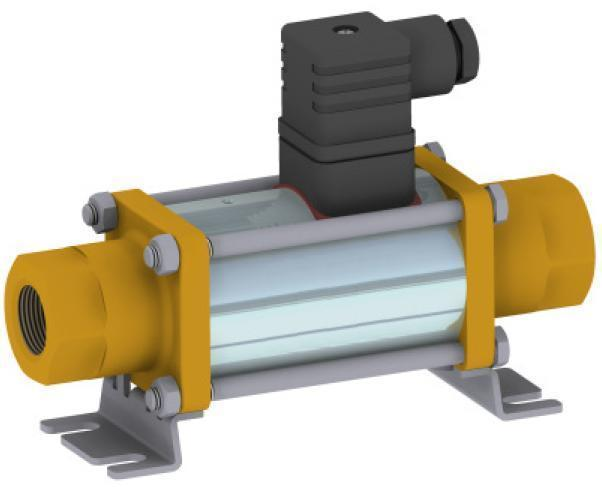

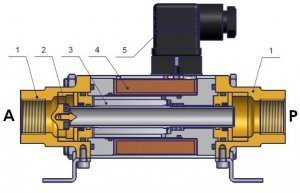

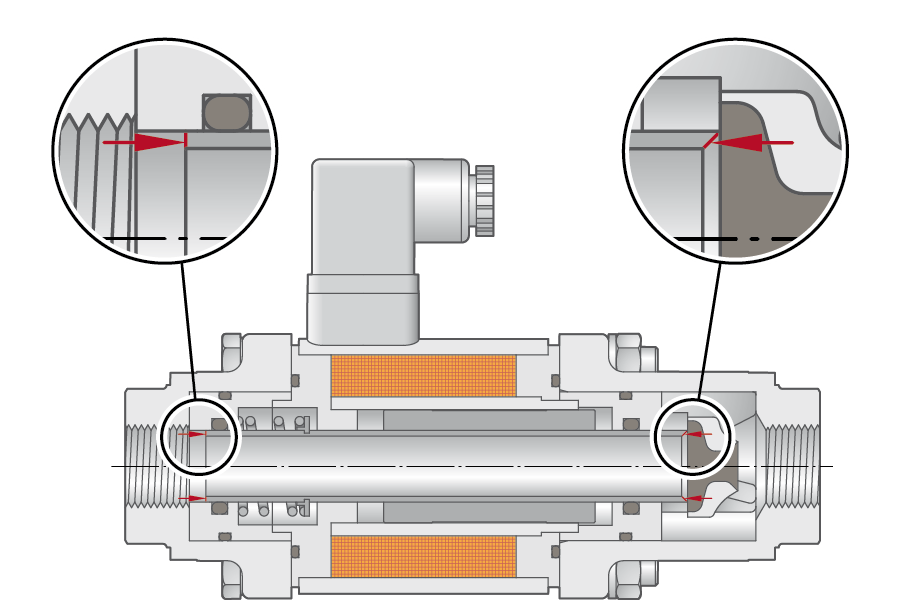

Coaxial Pneumatic Valves

The image on the right shows an externally compressed air pilot controlled 2/2 way normally closed coax valve, in which the solenoid coil has been replaced by a pneumatic piston (3) and the connector has been replaced by two air control inlet pilot holes (6), which are generally surrounded by four namur mounting holes so that 5/2 way namur interface solenoid controllers can be straightforwardly mounted to the valve body to control the compressed air supply. Because the tube (3) is resting on the sealing face, a normally closed valve with intake port P (1) and output port A at rest will restrict passage from P to A. (2). When compressed air is injected into the pilot hole (6) of the air coax valve, the piston slides laterally (coaxially) away from the sealing face (2), enabling flow. When the pressurized air is withdrawn, the internal spring pushes the tube back to its resting position, sealing (2) the valve and prohibiting flow. These valves can be provided 2/2 way typically open, with the spring holding the valve open until compressed air is applied to close it.

3/2 way coaxial air operated valves are also available, with 3 ports and 2 positions. This is a third port (R) or exhaust port that is 90 degrees to port P (essentially when diagram item 1 points) and is either open when port A is closed (tube to the right revealing R) or closed when port A is open (tube to the left obscuring R).

Is a Coaxial Solenoid Valve the Right Fit for Your Needs?

Compared to general-purpose solenoid valves, a coax valve has a number of benefits. If any of the following apply to your application, these valves could be a good fit:

- High flow rates and little pressure loss are required by your system.

- Your medium has high viscosity (more than 50 CST)

- Your medium is gas or liquid that is aggressive, abrasive, mildly polluted, or sensitive.

- There is a lot of back pressure (up to 400 bars) or pressure fluctuations.

- Your system necessitates rapid reaction times.

- Up to 10-4 mbar vacuum is present in your medium.

- There is no pressure difference in your system.

Working Principles of Coaxial Valves

These valves operate on a fairly basic concept. The main seal is mounted on one end of the valve’s moving element; when unpowered (or in the absence of a pneumatic signal), the main seal closes the valve’s orifice, which is held in place by the return spring. The moveable element moves when the valve is turned on (either pneumatically or electrically), compressing the return spring and allowing fluid to flow through the orifice to the application. The inlet and outlet connections are oriented on the same axis, making installation on a pipe run easier. To find out more about the working principle of Coaxial Valves, watch this nice video.

Applications of Coaxial Valves

In mechanical and plant engineering, coaxial valves are especially well suited to lubricants. Vacuum and gas technology, test bench building, ship and rail engines, and filling and dosing technology are all viable applications. Both gaseous and liquid, unclean or gelatinous media, such as oils, emulsions, coolants, and lubricants, can be employed with appropriate sealing.

Advantages of Coaxial Valves

Pressure Balanced Design

Regardless of system pressure and pressure differences, the coaxial design balances forces within the valve. Whether it’s regulating vacuum or high pressure, the results are always exact and consistent. Coaxial valves, unlike conventional valves, do not require a minimum pressure differential to work.

Back Pressure Tight

When the valve is closed, the pressure at the exit can be higher without causing any leaks.

Maintenance Free and Resistant to Dirt

Even in the presence of heavily polluted media, the innovative coaxial valve design reduces valve seat wear. Coaxial valves require minimal maintenance because they just have one moving part, no stem seal, and no external actuator/operator. Coaxial valves have up to ten times the lifetime of ordinary valves, even under harshest environments.

Fast Actuation

Coaxial valves are some of the quickest valves you may specify because of their pressure-balanced design, which allows for fast, repeatable operation in less than 30 milliseconds.

Bi-Directional Operation

The valve’s design allows the medium to flow in both directions, obviating the need for further valves.

Compact Size

The coaxial valve design allows for a more compact packaging by obviating the need for large actuators.

Conclusion

In this post, we have described the basics of coaxial valves along with their working principle, types, applications, and their advantages. At Linquip, you can find numerous Valve Companies, along with various Service Providers and Distributors.

FAQs about Coaxial Valves

1. How does a coaxial valve work?

A coaxial solenoid valve is a direct-acting solenoid valve with an unobstructed flow route for very viscous media or high-pressure applications. These valves have a one-of-a-kind design that makes them ideal for systems with high flow rates and minimum pressure loss over the valve.

2. What are the selection criteria for coaxial solenoid valves?

The major selection criteria for coaxial solenoid valves are the differential pressure parameters at the ports, the KV value, and the valve orifice. To avoid corrosion and ensure adequate valve life, the construction material, namely the body and seal material, must be compatible with the medium.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Provider

Read More in Linquip

- How to Prevent Sewer Backflow Valve Problems?

- What is Pilot Valve? Working Principle & Types (Complete Guide)

- What is Poppet Valve? Working Principle, Types & PDF

- 6 Different Shower Valve Types + Pictures: Your 101 Guide!

- The 9 Best Ball Valves: Top Rated Models (2022 Reviews)

- 6 Parts of Butterfly Valve + Function: A complete guide!

- Types of Pressure Relief Valve: All you need to know about PRVs

- 6 Main Types of Plumbing Valves: Complete Guide

- Air Release Valve Installation Costs in 2022 (Ultimate Guide) + PDF

- Angle Valve Installation Costs: Practical Factors in 2022

- Globe Valve Installation Costs in 2022 (Clear Guide) + PDF

- Gate Valve Installation Costs and Maintenance in 2022 (Clear Guide)

- 6 Main Types of Expansion Valves: an Easy to Understand Guide

- Angle Valve: The Most Essential Tips of Features, Functions & Applications

- Globe valve parts 101: All you need to know in one place

- The 10 Best Sprinkler Valves in 2022

- What is Automatic Expansion Valve: A Basic Guide

- What is Solenoid Valve and How Does It Work? 2022 Guideline

- What is Block Valve? Working Principle & Types

- Types Of Solenoid Valves: Everything You Need To Know

- Types of Pneumatic Valves: Specifications and Working Principles

- Best Check Valve for Sump Pump: 9 of the Best Models

- Best Pressure Reducing Valves of 2022

- The Best Blow off Valves of 2022

- The 10 Best Shower Valves (2022 Reviews)