AC and DC generators both use electromagnetic induction for producing alternating and direct currents. The process is different in these generators, while the AC is a periodic sinusoidal current and DC is a constant current in one direction.

How Does an AC Generator Work?

AC generators are devices for converting external input mechanical energy to alternating current and electric energy at the output. As it is clear, a generator does not create any energy by itself and uses the supplied mechanical energy to produce current in the wires, external circuit, and consequently the output systems. An example of AC generator is a power plant, hydro, and wind turbines, which convert the stem and turbine energies to electric power. Modern generators work in the principles of electromagnetic induction and Faraday’s Law.

The EMF is generated in the current conductors that cut the magnetic field directions. There are two types of AC generators based on induction. There are rotary conducting coils and a static magnetic field in the first type. In the second type, we have a rotating magnetic field that includes a static conductor. Stationary coil configuration does not have complex components, and it is easy to draw induced alternating current from a static armature coil.

The strength of the EMF depends on the number of armature coils, magnetic field strength, and the rotating field’s speed. In most of the generators, speed and the magnetic field is constant, and the maximum value for the voltage is constant. The number of coils has an impact on the frequency of the voltage and current. The frequency of the current can be calculated as below:

f=\frac{NP}{120}

N = rotation speed (rpm)

P = number of poles

f = frequency (Hz)

120 = appears in the conversion of rpm to the rotation per sec and using pair of poles as the total number.

What are the Parts of AC Generators

The components of a generator can be classified into the main parts as follows:

- Alternator

- Engine

- Voltage Regulator

- Fuel System

- Battery Charger

- Cooling and Exhaust Systems

- Lubrication System

- Control Panel

- Main Assembly / Frame

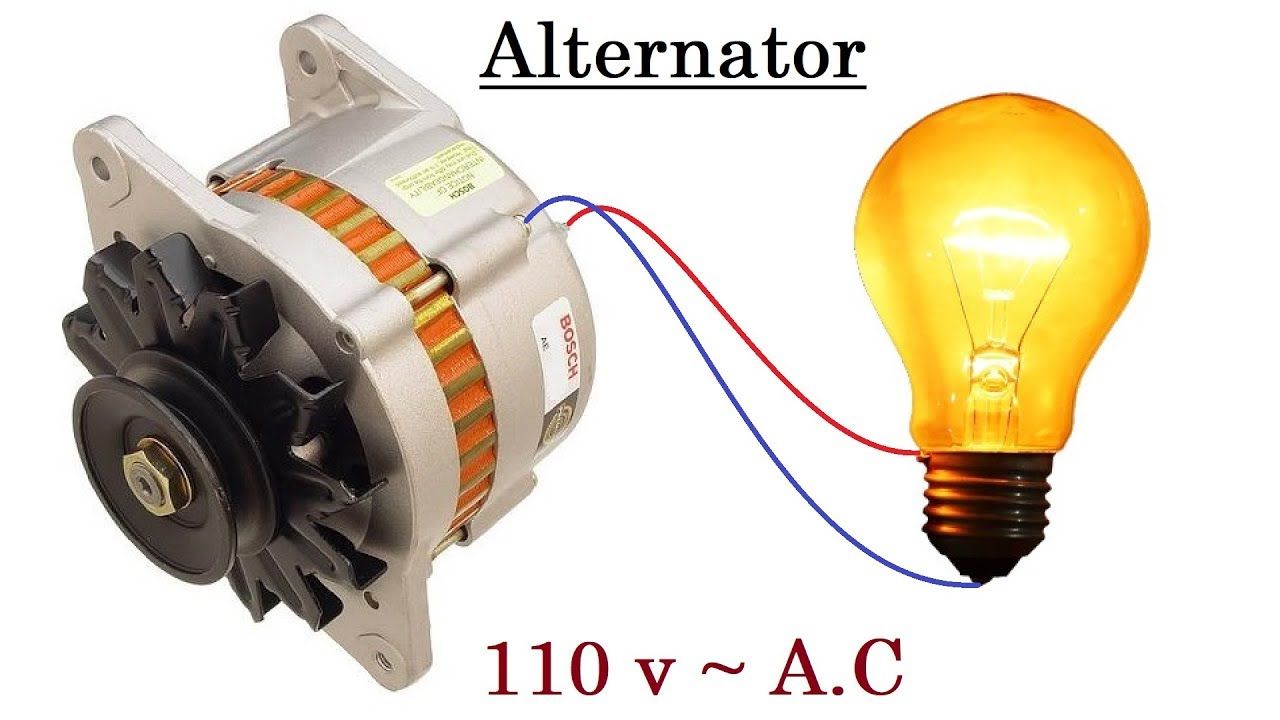

Alternator

This part of the generator that produces electric current from the external mechanical power is called an alternator. An alternator consists of a stationary and rotating part encased in a housing. All the rotating and static parts work together to generate electric power using magnetic and electric fields.

What Should You Know About the Alternators?

It would help if you keep in mind these factors while assessing an alternating generator:

- There are two types of metal and plastic housing. The metal design is durable and the best choice. Plastic housings get deformed easily and cause danger for the users by exposed rotating parts.

- There are ball bearings and needle bearings for the generators. Ball bearings last longer and are preferred to needle bearings.

- A Brushless design is the better choice for you due to the less maintenance and more clear power.

Parts of alternators

Different parts of the alternator are described below.

Armature

The armature is part of the alternating, in which voltage is generated and consists of coils that can carry the full load current in the generator.

Field

The part of creating magnetic flux is called the field. The magnetic flux cuts the armature and current generates in the wires. There are three types of magnetic fields in the alternators.

Prime Mover

Engine diesel, motors, or turbines are the source of the power in alternators and are called prime movers.

Slip Rings

The generators’ electric connections are slip rings that conduct the current from the stationary part to the rotating part.

Stator

The stationary part of the generator is the stator and would be the field if the EMF is generated there and it can be the armature if the excitation of the field is there. It is usually a set of conductors wound in coils over a core of iron.

Rotor

The rotating part of the generator is called the rotor and produces a magnetic field in the generator. The rotating part can be the armature or the magnetic field. The rotor would be the field if the excitation of the field is there, and it can be the armature if the EMF is generated there.

Can We Name the Engine in Parts of AC Generators

The source of the mechanical power can be the engine, and the size of this part is the base of designing for other parts, and it is proportional to the demanding power for the section. Whether the power source and the engine are big or small, the other parts are designed to get the maximum power that can be reached. We should know the specification of the engine and maintenance schedules. There are other types of source power for generators too, but here we describe the parts of a generator using an engine.

Voltage Regulator

As the name implies, this part of the generator regulates the output current and the voltage. The process is as follows:

Voltage Regulator: In this part, the conversion of AC Voltage to DC Current happens. The voltage regulator uses a small portion of the output of AC voltage and converts it into DC. This DC is fed to a set of secondary windings in the stator called exciter windings.

Exciter Windings: In this part, the conversion of direct current to alternating current happens. The exciter windings are similar to the primary stator windings and produce a small alternating current. The exciter windings are connected to units called rotating rectifiers.

Rotating Rectifiers: In this part, the conversion of AC to DC happens. To create an extra electromagnetic field rather than the rotating magnetic field of the rotor/armature, DC is fed to the rotor/armature.

Rotor/Armature: We have a production of AC Voltage in this part. The armature/rotor now induces a larger amount of AC voltage across the windings in the stator, and as a result, the generator produces a larger amount of AC voltage.

All the cycles described here continue until it reaches the voltage for operation capacity.

By an increase in the output, the voltage regulator generates less DC, and as the generator reaches full capacity, the voltage produces just enough DC to be able to fulfill the operating level. By adding a load to the system, there is a dip in the voltage, and the cycle begins again and continues to reach the operating capacity again.

Type of Fuel Used

There are different engines and different fuels for them. Propane (in liquefied or gaseous form), diesel, gasoline, or natural gas can be used for engines. Small engines use diesel, and larger ones use other fuels. In some cases, some types work with both diesel and gas or use biofuels.

Overhead Valve (OHV) Engines versus non-OHV Engines

OHV engine differs from other engines in that the engine’s intake and exhaust valves are located in the head of the engine’s cylinder and not on the engine block. Overhead Valve engines have several advantages over other engines while there are more expensive:

- Simpler operation mechanism

- Compact design

- Durability

- Low noise during operations

- Low emission levels

- User-friendly in operations

Cast Iron Sleeve (CIS) in Engine Cylinder

The CIS reduces wear and tear and ensures the durability of the engine. Most of the OHV engines are equipped with CIS, but it is vital to check this feature in the engine of a generator. Using CIS is not expensive, but it plays a key role in engine durability when you need to use your generator often.

Fuel System

We use a fuel tank to ensure proper engine work, and as the tank capacity increases, we have a long operation duration. In the small generators, the fuel tank is in the generator, but we need to install a tank to the system in a larger application.

Usually, components of the fuel systems are:

Pipe Connection from the Fuel Tank to the Engine

We need supply lines to direct fuel from the tank to the engine and return lines to lead fuel from the engine to the tank.

Overflow Connection from the Fuel Tank to the Drainpipe

This part is required to not allow spillage of the liquid on the generator set in any overflow during the refilling of the tank.

Fuel Pump

The pump transfers fuel to the day tank from the main storage tank.

Fuel Separator / Fuel Filter

For preventing corrosion and contamination in the generator, we use a separator.

Fuel Injector

The injector atomizes the liquid fuel by spraying the desired amount of fuel into the combustion chamber.

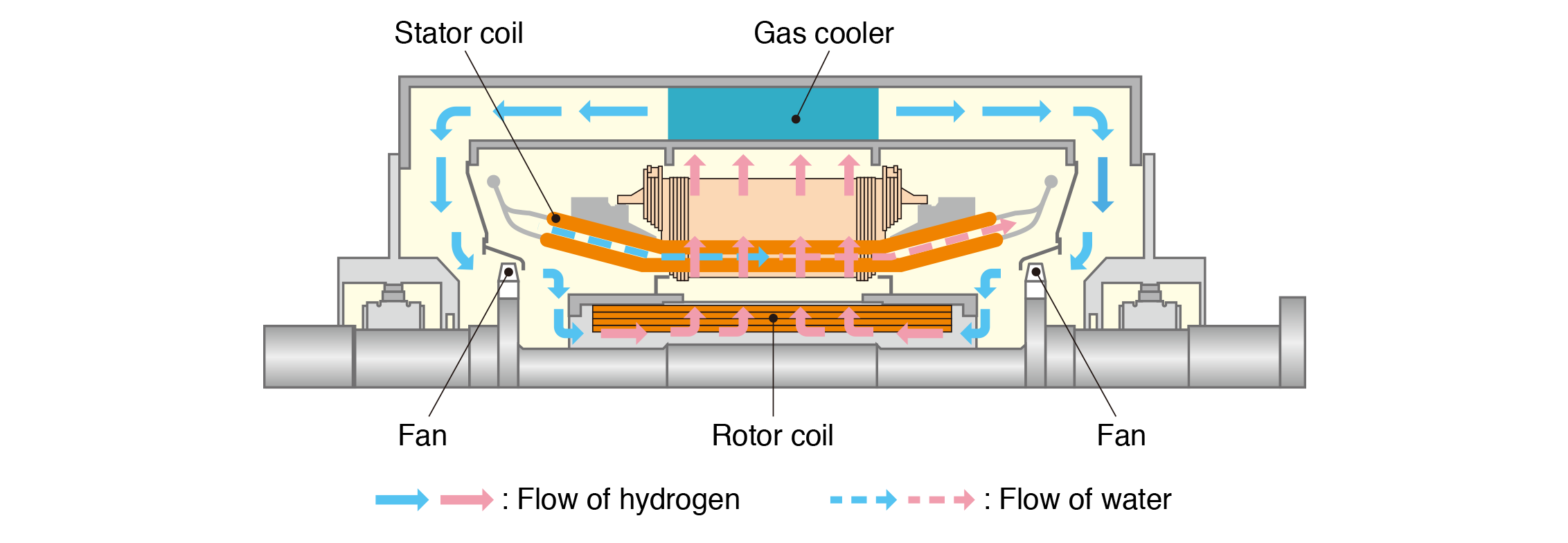

Cooling System

Generators are used days and nights, and it shows itself by producing heat in the system. It is very important to use a cooling and ventilation part in the system to remove generated heat. For common generators, radiators and fans are used as primary cooling systems. Water is used in specific applications and generators such as city applications or over 2250 kW. Hydrogen cooling systems are used in generators as hydrogen is efficient in absorbing heat.

Daily checking of the coolant level is essential, and the heat exchanger should be cleaned every 2,400 hours of the generator working. Also, raw water in the cooling system should be flushed every 600 hours. The National Electric Code (NEC) implies that a minimum space of 3 ft should be prepared on all sides of the generator to be ensured flowing cooling air, so the generator should be placed in an open and ventilating space.

Exhaust System

The engine of the generator emits fumes and exhaust gases just the same as the other diesel and gasoline engines. These toxic chemical materials should be managed and disposed of in the system with an adequate exhaust system. Just to emphasize the importance of this system, we can mention carbon monoxide poisoning, which is the most common cause of casualties in the world, and people should be safe around the generator.

Exhaust pipes are made of wrought iron, cast iron, or steel and need to be freestanding, and should not be supported by the generator or the engine. Exhaust pipes are generally attached to the engine by using flexible connectors to minimize vibrations and prevent damage to the generator’s exhaust system. We must ensure that the exhaust system of the generator is not connected to any other types of equipment. Also, you should consult if you will need to obtain approval from the local authorities or not because of conforming laws.

Lubricating System

As we have moving and rotary parts in the system, the generator needs lubrication to ensure smooth operations and durability for a long period. The engine is lubricated by oil, and a pump and checking the level of lubricating oil every 8 hours is necessary. Inspecting and checking for any leakages and changing the lubricating oil every 500 hours shouldn’t be forgotten.

Battery Charger

Starting the generator is battery-operated. The charger keeps the generator battery full by supplying it with an accurate ‘float’ voltage, and if the float voltage is low, the battery will remain undercharged. On the other hand, if the float voltage is high, it will shorten the life of the battery. For preventing corrosion, battery chargers are usually made of stainless steel. 2.33 Volts per cell is set for the DC output voltage of the battery charger, which is the exact float voltage for lead-acid batteries.

Control Panel

The user interface of the generator, which contains provisions for electrical outlets and controls, is a control panel. Different manufacturers and companies present varied features to offer in the control panels. Usually, these features are presented in all control panels:

Electric start and shut-down: Autostart control panels automatically start generators during a power outage, inspect the generator in operation, and shut down the unit when no longer required automatically.

Engine gauges: Indicate important parameters in different gauges such as the temperature of the coolants, oil pressure, battery voltage, duration of operation, and engine rotation speed.

Generator gauges: Output current and voltage, and operating frequency are measured and displayed.

Other controls: Frequency switch, Phase selector switch, manual mode, and auto mode.

Main Assembly/Frame

Portable or stationary generators include customized housings for providing structural base support. Also, generated is earthed for safety by using a frame.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- A Clear Classification of DC Generators

- The Best Diesel Generator of 2022

- The 10 Best Solar Generator

- Best Dual Fuel Generator of 2022

- The 8 Best Standby Generator of 2022

- Applications of AC Generators: 2022 Ultimate Guide

- The 5 Best Gasoline Generators of 2022

- Working Principle of AC Generator

- What are The Electric Generator Parts?

The way you share the information is really amazing. Thanks for sharing such an informative blog.

Dear Friend

Thanks for your attention.