What Is A Demand Pump And How Does It Work? – A demand pump is a small pump that is activated when water is needed and transports it from a storage tank to the point of usage. This sort of pump is a simple, versatile, and cost-effective solution to control water flow in your home, camper, boat or garden. When a pressure drop is detected, such as when a faucet is turned on or a toilet flushes, the demand pump is operated. The demand pump will continue to send water through the open line as long as the faucet is running and consumes water. The demand pump will automatically shut off when the faucet is turned off and the water demand has passed.

Linquip’s website contains a wealth of information on demand pumps, and we make every effort to provide you with as much information to help you choose a product that will work well for your application. The Linquip team is the best choice if you need any information regarding demand pumps. The Linquip experts will be able to offer any assistance you need on this equipment or devices at any time. You may find it useful to spend some time reading Linquip’s article entitled, “Pump: Working Principles, Function & Diagram.”

In order to use the various components to the fullest extent possible, a Linquip Expert registration is required. By creating an account on Linquip, you will be able to demonstrate your capabilities that are related to industrial equipment in an effective way that is tailored to the particular needs of the industry. Would you be interested in writing a guest post for Linquip? You can post your own content directly to the Linquip platform using the Guest Posting feature.

⇒ View a List of Pumps for Sale and Their Suppliers ⇐

What Is A Demand Pump?

Demand pumps, also known as delivery pumps, transfer water from a storage tank to a distribution point. Demand pumps rely on the user to identify a water demand. The user can activate a solenoid to open closed valves in the water line by pressing a button to signal water requests. When the pump detects open valves, it automatically switches on to provide water. When the pump detects pressure rising in the supply line owing to blocked valves, it shuts down.

Demand pumps are built to handle a wide range of fluid transfer tasks. Many frequent applications for demand pumps include transferring water from a non-pressurized tank to a water fountain, boosting water pressure from an under-sink reverse osmosis unit to a refrigerator water dispenser or ice maker, or providing a car wash on a bigger scale.

Users who want to install a demand pump should also think about including a pump tank in their setup. A pump tank guarantees that the proper amount of steady back pressure is provided to the pump’s pressure switch, preventing the pump from cycling on and off to renew pressure. A pump tank provides additional water storage and protects downstream appliances and plumbing from the shock of abrupt pressure spikes.

Demand pumps have two modes of operation: demand and delivery. In most cases, a demand pump will function in demand mode. The pump detects pressure changes in the system and automatically distributes water to the source that requires it in this mode. A built-in pressure switch controls a pump in demand mode. Pumps in delivery mode are controlled by an external switch instead of the pressure switch incorporated within the pump. When water is required, the switch is manually turned on, and the water is delivered by the delivery pump. The water supply from the delivery pump will be turned off when the switch is turned off.

Demand Pump V.S. Bypass Pump

The user can choose between a demand pump and a bypass pump, depending on the application. Demand pumps are perfect for hand-held spray wands because they can transport fluids at a specific flow rate and pressure. While demand pumps turn off when the system’s pressure signals that the fluid demand has been met, bypass pumps keep running regardless of the system’s pressure. Due to its capacity to bypass extra flow when nozzles are turned on or off, a bypass pump may be used with a spray bar that contains multiple separate nozzles that are controlled independently. Neither demand nor bypass pumps should be used to pump gasoline, kerosene oil, or other flammable fluids.

How Does A Demand Pump Work?

Demand pumps detect pressure changes and convey water as a result. A solenoid valve opens when an appliance is turned on, signaling the demand pump that water is needed. Diaphragm pumps are used in on-demand pumps. Demand pumps, unlike rotary vane pumps, move water by oscillation rather than a spinning propeller in a chamber. Water flows into the pump when the diaphragm inside the head of the pump expands. The rubber diaphragms have cups within them that squeeze together as they rotate. This causes suction, and the water to be released from the pump when the cups are pulled apart and the suction is broken. The draw and push inside the pump are created by the suction and ejection processes.

To aid them in operation, demand pumps have built-in pressure switches. The pump starts moving water when demand is activated. When the demand is met, the pump will keep running until the pressure specified in the pressure switch is reached. If a pump has a 65 psi pressure switch, for example, the motor will run until the pressure in the line reaches the 65 psi shutoff setting. When you switch on a shower or open a faucet, the pressure drops, the pump restarts, and the water starts to flow again. Before turning the motor back on, these pressure switches normally drop 10 to 15 psi. A 65 psi shutdown switch, for example, will not reactivate until the pressure drops to roughly 50 or 45 psi.

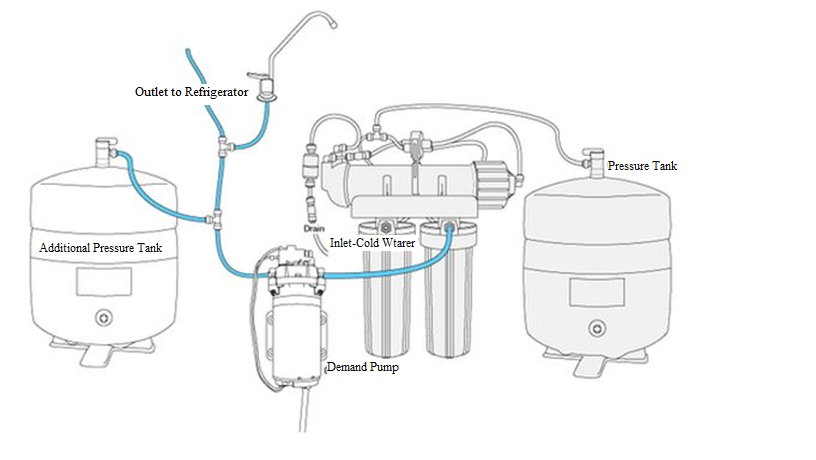

The graphic below depicts a demand pump installation on an under-sink reverse osmosis machine meant to send pressured water to a remote refrigerator. The typical storage tank for the reverse osmosis (RO) unit is the pressure tank on the right. The tank on the left is a “pump tank” that was installed to smooth out the pump’s performance and provide additional storage. The water in the second tank can be used for the kitchen ledge faucet as well as the refrigerator. Water migration back to the RO unit is prevented by a check valve (one-way valve) installed into the pump head.

The Pump Performance Curve

You’ll find a gallon per minute rating on the label of a demand and delivery pump if you look closely. These can be misleading. The gallon output at open discharge is described by the gallon per minute rating on the pumps. That is the pump’s absolute maximum possible output, based on water blowing out of the pump without any tubing or appliances attached. However, once connected to its intended application, the pump will operate at a different pressure. You’ll need to examine the pump curve to figure out what your pump’s actual output will be.

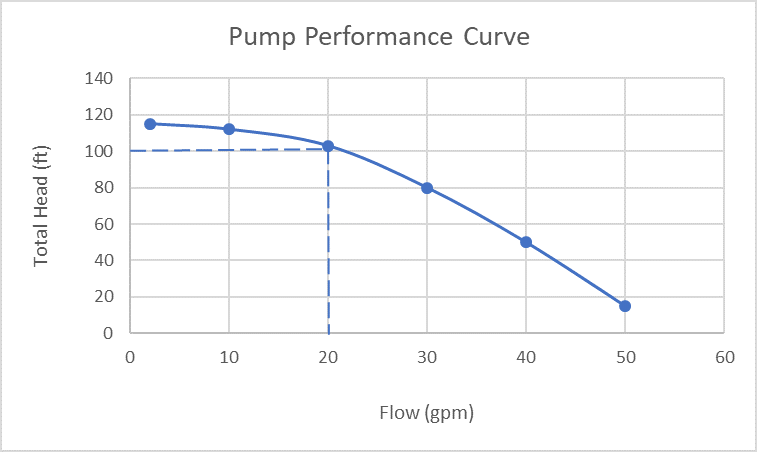

A pump curve is a graph that depicts the discharge pressure (head) generated by a pump at a given flow rate. The greatest height the pump can provide is commonly expressed in units of height, such as meters or feet. Figure below depicts a simplified pump performance curve that highlights the tradeoff between pressure head and flow rate. Lower outlet pressures are associated with higher flow rates. Consider a garden hose. When you turn on a garden hose and let it run freely, you’ll see that it has a high flow rate but low pressure. If you put your thumb over the hose’s end, it will begin to spray at a higher pressure. As you squeeze your thumb over the mouth, the amount of water exiting the hose will decrease, but the spray will reach further and at a higher pressure. Let’s see at the pump curve below again. This pump will supply 100 feet of head if the desired flow rate is 20 gallons per minute. For each pump model, each pump manufacturer offers a pump performance curve.

Note that 2.31 is a mathematical constant that translates a unit of energy against gravity into a unit of force against any other area. A foot of water head is converted to pressure by this constant. Consequently, Pressure in psi equals head in feet of water divided by 2.31.

Demand Pump Applications

Demand pumps are useful in any application where water must be transported from storage to the point of use. Demand pumps are frequently used in conjunction with the storage tank of a reverse osmosis system to provide filtered water to faucets throughout the house. If you’re storing and distributing distilled water, for people camping or living off the grid, demand pumps can be connected between a water filtration unit and a natural water source such as a river or lake. Furthermore, demand pumps can move water from the RV’s water storage tank to the toilet, shower and kitchen sink.

These pumps are used in hydroponic systems to circulate oxygenated and nutrient-rich water from storage to the plants. Demand pumps are used in food and beverage applications to deliver fluids to ice makers and water dispensers. Fish ponds, irrigation, and car washes can all benefit from demand pumps. A demand pump can be utilized whenever a small amount of water has to be transported. Demand pumps are also commonly used in marine applications such as yachts and fishing boats. Demand pumps can transport water from the ship’s storage tank to the galley or the ship’s plumbing.

It’s critical to understand what fluids demand pumps are made to carry. Demand pumps are designed to transport water. When offering relatively clean water sources, they perform well. Pumping water with a lot of solid trash and organic materials in it is not a good idea. You’ll want to sterilize the system more frequently if you’re pumping water from a well or cycling a nutrient-rich hydroponic solution. Chemical solutions should not be carried by these pumps. If you’re going to pump anything with a lot of chlorine or chemicals via the pump, make sure it’ll operate with Santoprene. Santoprene is a thermoplastic polymer that is used to build the pump. Certain chemical solutions will cause the rubber to degrade, making the pump useless.

How to Select a Demand Pump?

It’s critical to precisely define the jobs, or the types of duties the pump should accomplish, before you can choose a pump that will meet your needs. To get to the answer, consider the following points:

- What are your plans for pumping? You’ll need to know the fluid’s name or formula, as well as its characteristics, temperature, and composition. On demand pumps are commonly used for water, but they can also be utilized for producing beer or wine.

- How long do you want to pump? On-demand pumps are utilized for a shorter period of time although they can run for much longer if properly cooled.

- How far will you pump, and how much pressure will you require at the end of the pressure line? (It can be one feet, or for couple of hundred feet).

Pumps that have been carefully chosen will not only last a long time, but will also be less expensive to maintain. Some helpful hints for choosing your future on-demand water pump:

- What kind of electricity do you have to run the pump?

- What kind of flow or pressure do you require? In most cases, 45 PSI is sufficient for residential use.

- The type of material used to make it. It is preferable to use high-quality plastic or stainless steel. Ceramic bearings are the best choice for a pump with bearings.

- Only relatively clean water reservoirs are suitable for on-demand pumps. Water contaminated with organic waste or solid particles should be avoided.

- It is preferable to have a system that allows for a gradual start.

- Look for devices that offer waterproofing, “dry running,” motor overload, and power surge protection.

- Additional features such as a mud filter, pressure gauges, and a non-return valve are desirable.

Maintenance of Demand Pump

On demand water pumps require maintenance in order to function properly, supply high-quality fluid, and last longer.

-

Sanitizing

Sanitize your pump after lengthy periods of storage or upon purchasing new parts. If your unit has been polluted, you should also do this. This maintenance is being done to guarantee that the water it delivers is clean and that bacteria do not grow inside the pump.

-

Winterizing

The easiest way to avoid freeze damage is to completely drain your pump. Your plumbing may be damaged if there is ice in the system.

You can also watch this nice video to comprehend more about demand pumps’ working principle.

Download What Is A Demand Pump PDF

Using the following link, you can download the entire content of this article in PDF format.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- How to Avoid Pump Cavitation? A Complete Set of Necessary Information about It

- How Does a Heat Pump Work?

- What Is a Water Booster Pump and How Does It Work?

- What is Sump Pump and How Does It Work?

- What is Head of a Pump? A Complete Guide

- What Is a Multistage Centrifugal Pump Used for?

- What is Hydraulic Pump: Learn The Basics, Boost Your Knowledge

- Working Principles of Hydraulic Pump (With Videos)

- Top Dosing Pump Manufacturers and Suppliers in 2022

- Top Water Pump Manufacturers and Suppliers in 2022

- The 7 Best RV Water Pump In 2022 (Clear Guide + Review)

- The 10 Best Electric Air Pump in 2022 (Clear Guide)

- The Best HVAC Vacuum Pump in 2022 (Clear Guide)

- 9 Different Types of Rotary Pumps + PDF

- The 5 Best Well Pump in 2022 (Clear Guide)

- The 10 Best Condensate Pumps of 2022: A Complete Guide

- 13 Parts of Concrete Pump with Name & PDF

- 5 Types of Concrete Pumps + PDF