Welcome to Linquip Blog. Today and in this article, we are going to answer the question “What is a Fluid Coupling?”. The information in this article gives a significant collection of technical data about working principles, operations, size and dimension specification, and privileges of jaw couplings.

Our team gathered all of the necessary information on this topic to eliminate the need for reading diverse content on other websites. Stay with us until the end to find the answer to your question on this topic. We have a long journey ahead of us, so take a deep breath, sit back, and keep reading this article until the end.

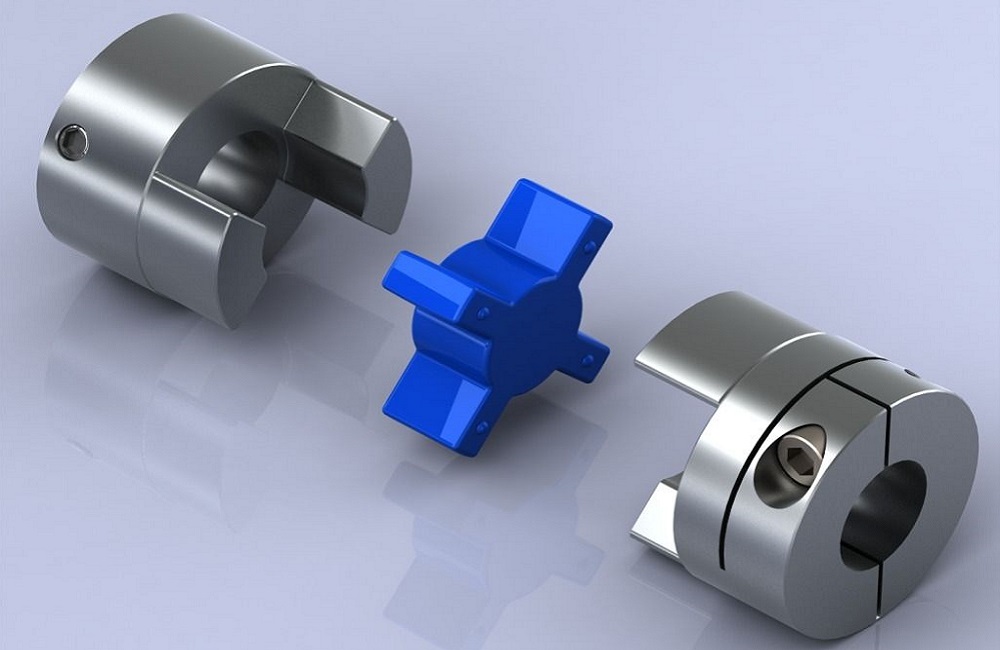

An Introduction to the Jaw Couplings & Their Parts

Jaw couplings are a general, all-purpose industrial power transmission device that operates in a range of temperatures, handles angular misalignment and the accompanying reactionary loads, resists chemicals, and has good speed and dampening capabilities. A basic jaw coupling is made of three parts: two hubs, generally bored to a clearance fit tolerance, and an elastomeric insert. These inserts sometimes referred to as spiders, are designed to last a long time, but do eventually need to be replaced.

When the inserts fail, the coupling’s fail-safe design comes into play. The hubs will interlock and continue to carry the load, but without the dampening capability that the insert provided, allowing an operator to quickly shut down a system. Once an insert fails, replace the insert and the two hubs as soon as possible, as the hubs will have worn on each other and no longer be useable.

The Working Principle of Jaw Coupling

So far, we are somewhat familiar with jaw couplings and know what they are basically used for. Let’s take a closer look at how jaw couplings work.

All elastomeric couplings are classified according to how their elastomeric elements transmit torque between driving and driven hubs – the element is either in compression or shear.

In jaw couplings, the element is loaded in compression between the jaws of mating hubs. These jaws operate in the same plane, with the driving hub jaws pushing towards the driven hub jaws. Legs of the elastomeric spider transmit and cushion the force between the driving and driven jaws by being compressed between them.

This contrasts to shear-type couplings, in which driving and driven hubs operate in separate planes, with the driving hub pulling the driven hub through an elastomeric element suspended between them. Here, the element transmits and cushions the force between hubs by being stretched between them.

Temperature Range of Operation, Sizes, Dimensions & Materials

Jaw couplings are commonly employed on large, industrial machines such as pumps, blowers, compressors, mixers, etc. They are also used in smaller motion control systems. For standard power transmission applications, jaw couplings are available in a broad range of shaft sizes and torque capacities, with typical bore diameters from 1/8 to 7 in. and torques from 3-1/2 to 170,000 in.-lbs. available.

Couplings are designed to operate without lubricant in many instances and function well in the presence of dirt and other particulates. Jaws can be manufactured in steel, aluminum, and stainless steel and often in bronze, ductile iron, and powdered metal. Spiders may be made of polyurethane, natural rubber, urethane, hytrel, and in special cases, soft metals such as bronze for low speed, high torque applications.

There is a chart below to show the characteristics of each material commonly used for jaw couplings:

| Properties | Buna-N (N) | Urethane | Hytrel (H) | Bronze (B) |

| Oil Resistance | Good | Good | Excellent | Excellent |

| Chemical Resistance | Poor | Good | Excellent | Excellent |

| Flexibility | Excellent | Good | Fair | Poor |

| Temperature F | -40 to +212 | -30 to +160 | -60 to +250 | -40 to +450 |

| Range C | -40 to +100 | -34 to +71 | -51 to +121 | -40 to +232 |

| Torsional Stiffness | Full Soft | Medium Soft | Hard | Hard |

| Average Hardness (Shore Number) | 80A | 90A | 55D | – |

| Max. Misalignment | ||||

| • Angular | 1° | 1° | 1/2° | 1/2° |

| • Parallel | 0.15″ | 0.15″ | 0.15″ | 0.10″ |

| Color | Black | Orange | White | Bronze |

| Cost | Lowest | Moderate | Higher | Highest |

Jaw Coupling Privileges

First and foremost, jaw couplings are popular because they are versatile & robust. They truly are and make for an excellent general all-purpose industrial power transmission coupling. They operate in a wide band of temperatures, can handle angular misalignment, can handle reactionary loads due to misalignment, have good torque to outside diameter capability, have good speed capability, good chemical resistance (spider dependent), and decent dampening capability.

They are easy and straightforward to install. A basic jaw coupling is comprised of only 3 main parts. Two hubs, and an elastomeric spider or insert. Jaw couplings are fail-safe. While you should periodically check your jaw coupling spiders for wear and replace them inevitably, someone will forget to check or service a jaw coupling and the spider will wear out or fail. In this case, the coupling hubs will interlock and continue carrying the load though without any dampening capability or other benefits that the spider provided allowing an operator to quickly shut down a system.

In addition to jaw couplings being considered fail-safe and all the other benefits already discussed above, jaw couplings are also considered maintenance-free as they require no lubrication. Unlike gear, grid, or chain couplings that require periodic reapplication of grease… as long as the spider remains intact, a jaw coupling will continue to work without additional maintenance required.

What Is a Sleeve Coupling? Everything You Need to Know

Conclusion

The present article was an attempt to deal with the question “What Is a Jaw Coupling?” and deliver all the essential information about how it works and where it is used. Jaw couplings are a general, all-purpose industrial power transmission device that operates in a range of temperatures, handles angular misalignment and the accompanying reactionary loads, resists chemicals, and has good speed and dampening capabilities.

If you have any experience of using Fluid Couplings, we will be very glad to have your opinions about their performance in the comments on our website Linquip. Moreover, if you have any questions about this topic, you can sign up on our website and wait for our experts to answer your questions. Hope you enjoyed reading this article.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- The Practical Guide To Types of Coupling in 2021

- What is Grid Coupling? Essential Details You Need To Know

- A Cheat Sheet For The Types of Pump Couplings

- Advanced Guide: Types of Rigid Couplings

- The Quick Guide To The Types of PVC Couplings

- Types of Shaft Couplings: A Simple Guide to The Types

- What is Disc Coupling: A Complete Guide

- The Complete Library of Types of Flexible Coupling

- Types of Gear Coupling: a Basic Yet Crucial Description of the Types

- What Is a Fluid Coupling? Diagram + Parts

- Flange Coupling Adaptor: Working Principle and Applications

- What Is a Sleeve Coupling? Everything You Need to Know