Welcome to Linquip Blog. Today and in this article, we are going to deal with the question “What is a Sleeve Coupling?”. The information in this article gives a significant collection of data you need to know about some specifications, and privileges of Sleeve couplings.

Our team gathered all of the necessary information on this topic to eliminate the need for reading diverse content on other websites. Stay with us until the end to find the answer to your question on this topic. We have a long journey ahead of us, so take a deep breath, sit back, and keep reading this article until the end.

An Introduction to the Sleeve Couplings, Their Parts & Materials

Couplings are used to connect two shafts for torque transmission in varied applications. Coupling may be rigid or they may provide flexibility and compensate for misalignment. They may also reduce shock loading and vibration. There are two main types of couplings: Rigid couplings and Flexible couplings. Rigid couplings are used for shafts having no misalignment while flexible couplings can absorb some amount of misalignment in the shafts to be connected.

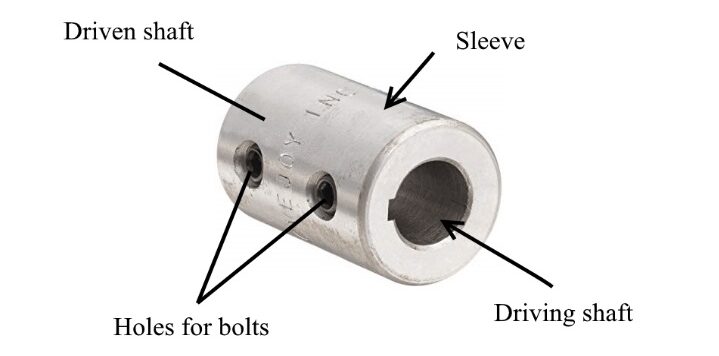

One of the simple types of rigid coupling is a sleeve coupling which consists of a cylindrical sleeve keyed to the shafts to be connected. It is made of cast iron. It consists of a hollow cylinder whose inner diameter is the same as that of the shaft (sleeve). It is fitted over the ends of the two shafts by means of a gib head key. The power is transmitted from one shaft to the other shaft by means of a key and a sleeve.

In other words, a Sleeve coupling is a basic type of couplings including a pipe whose bore is finished to the required tolerance based on the shaft size. Based on the usage of the Sleeve Coupling a keyway is made in the bore in order to transmit the torque by means of the key. Two threaded holes are provided to lock the coupling in position.

Sleeve couplings are known also as Box Couplings. In this case, shaft ends are coupled together and abutted against each other which are enveloped by muff or sleeve. A gib head sunk keys hold the two shafts and sleeves together.

The Structure, Design & Working Principle of Sleeve Coupling

So far, we are somewhat familiar with jaw couplings and know what they are basically used for. Let’s take a closer look at how jaw couplings work.

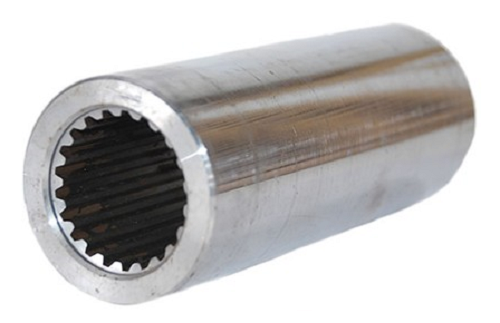

The sleeve coupling transmits low to medium torque between connected equipment in shear through an elastomeric insert with male splines that mate with female hub splines. The insert material is typically EPDM, Neoprene, or Hytrel and the insert can be a one-or-two-piece design.

The muff or sleeve is made into two halves and is bolted together. The halves of the muff are made of cast iron. The shaft ends are made to butt each other. A single key is fitted directly in the keyways of both shafts. One-half of the muff is fixed from below and the other half is placed from above.

Both halves are held together by means of mild steel studs or bolts and nuts. The number of bolts may be two, four, or six. The advantage of this coupling is that the position of the shafts need not be changed for assembling or disassembling of the couplings.

In other words, in sleeve couplings, the shafts are taken and the keys are slid over them. Both the shafts along with the keys are then fitted into the sleeve. In this way, a sleeve coupling is assembled. In the following section, we will meet the advantages and disadvantages of the sleeve, muff, or as it is called box coupling.

Jaw Coupling Applications

Sleeve couplings are nothing but just a sort of thick hollow cylinder/pipe called a sleeve or muff. The sleeve is manufactured keeping the diameter of the shaft in mind so that the shaft fits perfectly into the sleeve. The driver & driven, both shafts are then inserted into each side of the sleeve. Also, two or more threaded holes are provided into the sleeve as well as in both of the shaft’s ends so that they don’t move in the longitudinal direction when the bolts are inserted into them. Also, the keyway and key ensure that the shaft and sleeve don’t slip.

The sleeve coupling is easy to manufacture as there are a few numbers of components.

- used where the shafts don’t require any alignments and load capacity is light to medium duty.

- To transmit power from the driving shaft to the driven shaft.

- To connect or couple 2 components which are manufactured separately for example output motor shaft and generator.

- To introduce extra flexibility while transmitting power in case of space restrictions.

- To introduce protection against overloads.

- To reduce the transmission of shock loads from one shaft to another by using flexible couplings.

Advantages & Disadvantages of Sleeve Couplings

Finally, we reach the last section of this article. In this section, we want to introduce some of the most important advantages and disadvantages of sleeve couplings. Here are the pros and cons of using sleeve couplings:

Advantages

- It is the simplest type of coupling with only a two-part structure

- It is compact in size

- It has no projecting parts which makes it safe for usage

- It cost low to purchase and maintenance

Disadvantages

- It cannot tolerate any misalignment in the axes of the shafts

- It is difficult to assemble or disassemble as the sleeve has to be shifted over a shaft or shaft end.

- It is not able to absorb shocks or variations during power delivery

Conclusion

The present article was an attempt to deal with the question “What Is a Sleeve Coupling?” and deliver all the essential information about how it works and where it is used. A Sleeve coupling is a basic type of couplings including a pipe whose bore is finished to the required tolerance based on the shaft size. Based on the usage of the Sleeve Coupling a keyway is made in the bore in order to transmit the torque by means of the key. Two threaded holes are provided to lock the coupling in position.

If you have any experience of using Sleeve Couplings, we will be very glad to have your opinions about their performance in the comments on our website Linquip. Moreover, if you have any questions about this topic, you can sign up on our website and wait for our experts to answer your questions. Hope you enjoyed reading this article.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What Is a jaw Coupling? With the Focus on the Working Principle, Size & Dimension

- The Practical Guide To Types of Coupling

- What is Grid Coupling? Essential Details You Need To Know

- A Cheat Sheet For The Types of Pump Couplings

- Advanced Guide: Types of Rigid Couplings

- The Quick Guide To The Types of PVC Couplings

- Types of Shaft Couplings: A Simple Guide to The Types

- What is Disc Coupling: A Complete Guide

- The Complete Library of Types of Flexible Coupling

- Types of Gear Coupling: a Basic Yet Crucial Description of the Types

- What Is a Fluid Coupling? Diagram + Parts

- Flange Coupling Adaptor: Working Principle and Applications