What Is a Water Booster Pump and How Does It Work? – When the pressure and flow rate delivered to individual plumbing fixtures fails to fulfill code requirements, water booster pumps are necessary. However, prior to installing the system, make sure the low pressure isn’t caused by other issues like clogged or undersized piping. When a water booster pump is appropriately designed and fitted with a high-efficiency motor and speed control, it delivers optimal performance.

⇒ View a Comprehensive List of Pumps for Sale and Their Suppliers ⇐

What Is A Booster Pump?

The booster pump is a centrifugal pump since it pumps fluid using centrifugal force and one or more impellers. This pump is a mechanical device that boosts fluid pressure and flow. A pressure pump is another name for a boost pump. It gives you the extra boost you require to get your fluid pressure to where you want it. These pumps can handle both gases and liquids, however the design will vary depending on the fluid. Boosters are capable of transporting high-pressure gas, filling cylinders, increasing gas pressure, and removing gas. Booster pumps are commonly used in low-pollution water systems and services. Many military, municipal, and commercial uses use boost pumps. Pumps like these are used in a range of industries, including food processing, mining, and aerospace.

A water booster pump generates enough pressure to carry water from a storage tank or throughout a home or business. Water pressure is a force that holds water from a water source to a desired destination or system of water supply. The water pressure delivered to the house from the water source is high (head). Friction and other losses in the pipeline might create energy losses as the water moves from the tank to the intended area. This energy loss prevents water from reaching the upper levels of high-rise buildings. The booster pump installation adds some extra pressure to the water and restores the necessary level of pressure. Water can readily reach the required height of the building or house in this manner.

A booster pump is used in conjunction with other pumps. In other words, booster pumps cannot push fluids into the targeted area or position on their own. The primary goal of these pumps is to “just boost” the performance of the existing pumping system.

Booster Pumps for Household Water Pressure

Household water pressure booster pumps are typically basic electrically driven centrifugal pumps with a non-return valve. They could be constant speed pumps, which turn on when pressure falls below the low set-point and turn off when pressure rises over the high set-point, or variable speed pumps, which are adjusted to keep the output pressure constant.

Constant-speed pumps are started by a normally closed low-pressure switch and run until the pressure rises enough to open the high-pressure switch. They’ll cycle anytime there’s enough water to decrease the pressure below the low set point. Cycling will be reduced by using an accumulator in the upstream pipeline.

Pressure feedback is used by variable speed pumps to manage motor speed and maintain a steady discharge pressure. Most applications employ an inverter to adjust motor speed and run on AC mains power.

Water supply systems for high-rise buildings may require boosters at multiple levels in order to maintain sufficient pressure on all floors. In this situation, independent boosters at several levels might be placed, each raising the pressure provided by the lower level below it. It’s also feasible to boost once to the highest pressure required, then drop pressure at each level via a pressure reducer. If there is a holding tank on the roof with gravity feed to the supply system, this method would be used.

Reasons of Low Water Pressure

Water pressure decreases for a variety of causes, including gravity, distance from the water source to the outlets, insufficient local water supply, system additions, and more. In the following paragraphs, we’ll go through some of the major factors.

Gravity

Water flow is either accelerated or slowed by gravity. The more lowering the water pressure, the higher the elevation at which water must be delivered. Consider the weight of a gallon of water, which is almost 8 pounds. Gravity wants to send water back down if it climbs upwards or up multiple floors. Buildings that are lower than their water supply may not be affected in the same way. Skyscrapers, apartment buildings, residences, and companies with multiple stories require a huge booster pump to transport water up many levels.

Distance from the Water Source

The water pressure is affected by the path taken from the water source and the diameter of the water pipes. The water flow may be low before it reaches your home or company if you are at the end of a water supply line. In addition, if your water lines are too small, your devices will receive less water.

Low Pressure from the Local Water Supply

Your house may be located below the water supply, the sewage lines may be clean, but the water pressure remains low. Low water pressure from the local water supply can sometimes cause low water flow.

Add-on Water Systems

Additional water purifying systems or other water devices in your home can bring fresh water into your home, but the water pressure will be reduced. A water booster pump can assist in achieving the desired water pressure.

Plumbing Problems

A water pressure booster can help if low water pressure is caused by gravity, transportation, or other systems. Plumbing issues, on the other hand, may be the reason in some cases. Check your plumbing before purchasing a water pressure booster. It’s possible that the pipes are clogged, or that the pressure lowering valve has to be adjusted.

How Does A Water Pressure Pump Work?

A water booster pump works similarly to a fan. It has an impeller inside that boosts water flow and pressure in the same way as a fan’s blades rotate around to enhance air velocity. A booster pump’s goal is to increase the fluid’s pressure while also increasing the flow rate in some situations. This pump is designed to operate with an existing pump.

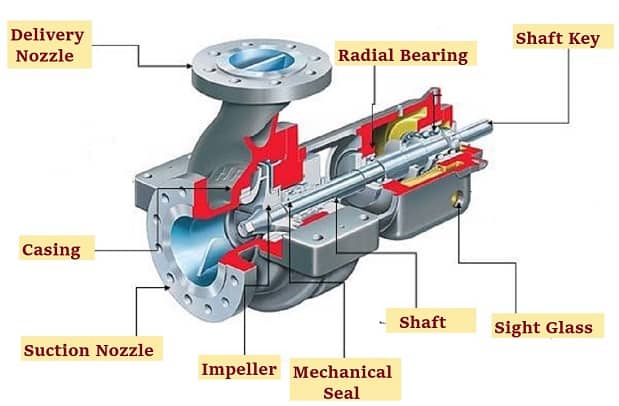

The main components of all water booster pumps, regardless of manufacturer, are the same:

Body

- Motor

- Impeller

- Impeller blades

- Inlet and outlet valve

- Volute Casing

An impeller in a booster pump pushes water that enters via the inlet and exits through the output. The impellers are spun by a motor. Booster pumps differ in the way they take in and push out water. A spinning propeller is used in some water booster pumps, whereas an oscillating diaphragm is used in others. Water is pushed by two oscillating or rotating plates, one with cups and the other with indentations, in pumps with oscillating diaphragms. As the plates collide, the cups are compressed, forcing the water out. More water is pulled in as the plates open.

Body or Casing

The water pressure pump’s casing or body is used to keep water from splashing outside the pump. It protects the pump’s internal components from damage if it is subjected to a strong load. The booster pump’s body is made of stainless steel.

Impeller

A revolving component of the pressure booster pump is the impeller. It has a number of fixed blades. With the aid of centrifugal force, this impeller turns the water axially and radially.

Impeller Blades

These blades are found on the pump’s impeller. These rotate in tandem with the impeller. The impeller blades’ primary function is to increase the speed of water or other working fluids.

Inlet & Outlet Valves

The water is drawn into the pump by an inlet valve. The outlet valve, on the other hand, is used to release the pressured water.

Volute Casing

The volute casing’s main goal is to convert the fluid’s speed into pressure and so increase its pressure.

Types of Water Pressure Pump

There are two primary types of water pressure or booster pumps:

- Single-stage Pump

- Multistage Pump

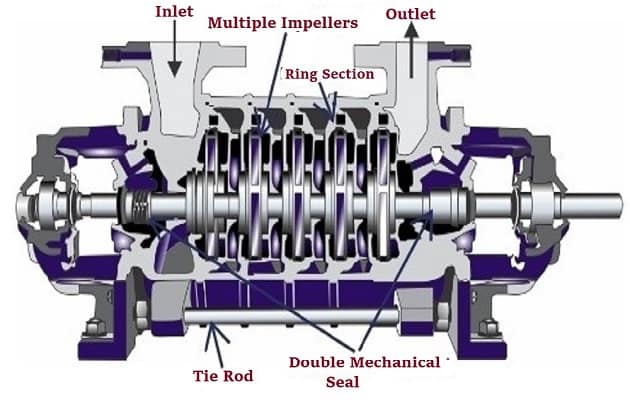

Single-Stage Pump

This pump, as its name implies, simply boosts the pressure of water or other fluid in one stage. The fluid pressure is increased by a single impeller in a one-stage pump. It is less efficient than a multistage pump, but it takes up less space.

Multistage Pump

For pressurizing the fluids, this pump employs many stages. Each stage of this pump has its own impeller. The fluid is pumped through many impellers.

Where to Install a Booster Pump?

A pressure booster pump is installed at the location where the water is to be transferred. For example, if your home has weak water pressure, you must install a pump on the main water pipeline that brings water into your home.

Re-insert the outlet into the piping after installing the inlet.

– There is always a bypass if the pump fails. If the pump isn’t operating and you need to troubleshoot it, you can use the bypass to isolate it. You can still send water into your house through the bypass.

– Before connecting the booster pump to your home, make sure it works. Low flow leaks can cause the pump to cycle in some instances. The cycling results in a fast start and stop of the pumping process.

– The water pressure booster pumps operate on the basis of either pressure or flow, or both. If any leaks are detected, isolate and test the pump to ensure it is working properly. Then figure out what’s causing the leak and repair it.

How to Improve the Efficiency of a Water Booster Pump?

It is to save energy by connecting the booster pump to a variable frequency drive (VFD) for speed control. The following are some reasons why you should install a speed controller with a booster pump:

- Depending on the existing state of the building, the needed boost pressure may vary. If the water pressure requirement is low, for example, the speed controller will not be required.

- Water pressures can be influenced by utility companies as well. Low-pressure issues, for example, can only happen when the distribution system is experiencing peak demand.

- VFDs can also be used to start the water booster pump and avoid inrush currents, which are often 5 to 8 times the rated current. This inrush might create an unexpected voltage drop, which can damage sensitive electronic equipment if there isn’t a soft starting mechanism.

When a speed control unit is connected to a booster pump, you may modify the operation in real time to maximize energy efficiency based on the conditions of the buildings and the water supply. Electronic rectifier motors provide optimal energy economy while also providing integrated speed control for low-power applications.

Criteria for shopping a water booster pump

When shopping for a booster pump, consider the following questions:

- What is the flow rate of my water? Determine the number of gallons of water you obtain every minute, taking into account all fixtures.

- How much water will I require? Think about how much water your family or business needs.

- Is the water supply above the pump or below it? Consider whether your water will have to travel upwards or multiple stories.

- What kind of pressure do I require? When taking a shower, many people prefer high water pressure, but too much pressure can damage piping, fittings, and appliances. To maintain water pressure, most homes have a pressure reducing valve where the water line enters the house. The residential plumbing system is harmed by pressures more than 60 psi.

Depending on how much water you need, the desired pressure, and the location of your water source, you’ll need a booster pump. If you have a large house, a booster pump capable of supplying pressure to the second or third level may be required. Water containing a high total dissolved solids (TDS) or reverse osmosis systems with low feed pressure are some applications which require a lot more pressure.

You are also encouraged to visit Linquip for more information on Booster Pumps and also find various manufacturers and industry experts. Besides, you can watch this video to understand more about the function of booster pumps.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip