An induction motor is an AC electric motor in which the electric current in the rotor needed to produce torque is obtained by electromagnetic induction from the magnetic field of the stator winding. This article will take a closer look at a type of single-phase induction motor, called Capacitor start induction motor. Read this new blog in Liquip to find out what is capacitor start induction motor and its working principle.

What Is Capacitor Start Induction Motor?

A Capacitor Start Motors is a single phase Induction Motor that employs a capacitor in the auxiliary winding circuit to produce a greater phase difference between the current in the main and the auxiliary windings. The name suggests that the motor uses a capacitor to start.

Capacitor Start Motors are single-phase induction motors with a capacitor in the auxiliary winding circuit to increase the phase difference between the main and auxiliary winding currents. The word capacitor begins implies that the motor starts with the help of a capacitor. Capacitor start induction motors are available from a variety of Suppliers and Companies, as well as other manufacturers and distributors, and there are various Capacitor Start Induction Motors for Sale on Linquip.

There is a complete list of capacitor start induction motor services on the Linquip platform that covers all OEM fleets. Linquip vendors can assist you with this. Please contact Capacitor Start Induction Motor Experts to learn more about how to connect with a diverse group of Service Providers who consistently deliver high-quality products.

What Is Capacitor Start and Capacitor Run Induction Motor?

The squirrel cage rotor of the capacitor-start capacitor-run induction motor contains two windings: the beginning or auxiliary winding and the main or running winding. In the space, the two windings are separated by a 90° angle.

What Is the Difference Between a Run and Start Capacitor?

In the motor’s distinct start windings, the start capacitor causes a current to voltage lag. The current gradually builds up, giving the armature the opportunity to begin rotating with the current field. A run capacitor boosts the current that powers the motor by using the charge in the dielectric.

Capacitor Start Induction Motor Construction

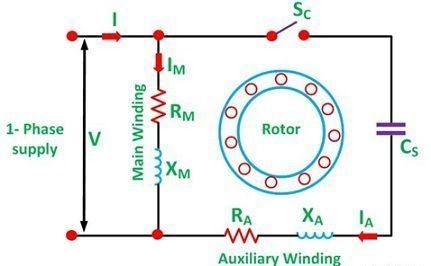

The capacitor start motor has a cage rotor and has two windings on the stator. They are known as the main winding and the auxiliary or the starting winding. The two windings are placed 90 degrees apart. A capacitor CS is connected in series with the starting winding. A centrifugal switch SC is also connected to the circuit.

The connection diagram of the capacitor start induction motor is shown in the figure below.

Capacitor Start Induction Motor Working Principle

- When the stator windings are energized from a 1-phase supply, the main winding and the starting winding, carry two different currents. There is a 90° time-phase difference and 90° space difference between the two currents. These two currents produce a rotating magnetic field that starts the motor.

- The main and auxiliary windings are connected in parallel during motor starting. A start capacitor stays in the circuit long enough to rapidly bring the motor up to a predetermined speed, which is usually about 70 to 80 % of the full speed.

- Then the auxiliary winding is disconnected from the supply often by a centrifugal switch and the motor remains powered by a single winding creating a pulsating magnetic field. In this sense, the auxiliary winding in this design can be regarded as a starting winding, since it is only used during motor startup.

- Note that the motor will not work properly if the centrifugal switch is broken. If the switch is always open, the start capacitor is not part of the circuit, so the motor does not start. If the switch is always closed, the start capacitor is always in the circuit, so the motor windings will likely burn out. If a motor does not start, the capacitor is far more likely the problem than the switch.

Capacitor Start Induction Motor Features

- The starting winding of a capacitor starts motor heats up less quickly and is well suited to applications involving either frequent or prolonged starting periods.

- The power rating of such motors lies between 120 W and 7-5 kW.

- The capacitor starts motor develops a much higher starting torque of about 3 to 4.5 times of the full load torque. To obtain a high starting torque, the two conditions are essential that are as follows:

- The Starting capacitor value must be large.

- The valve of the starting winding resistance must be low.

Capacitor Start Induction Motor Advantages

Several advantages of capacitor start induction motors are mentioned below.

- Because of high starting torque and low starting current, capacitor start induction motors have a wide range of applications.

- The capacitor is in series with the start circuit, so it creates more starting torque, typically 200 to 400% of rated load. And starting current, usually 450 to 575% of rated current, is much lower than that of the split-phase types due to the larger wire in the start circuit. This allows higher cycle rates and reliable thermal protection.

- The start capacitor generally has more capacitance than a run capacitor induction motor type, the 7- to the 9-microFarad capacitor, which improves the motor’s performance after it has begun running.

- This motor configuration works so well that it is available in multi-horsepower (multi-kilowatt) sizes.

Capacitor Start Induction Motor Application

- These motors are used for the loads of higher inertia where frequent starting is required.

- They are used on a wide range of belt-drive applications like small conveyors, large blowers, and machine tools.

- They are used in pumps and compressors.

- They are used in the refrigerator and air conditioner compressors.

- They are also used for many direct-drive or geared applications.

Now that you know the answer to the question of What is capacitor start induction motor, how about sharing your thoughts and comments on the subject with us? Comment below and let us know what you think! And if you have any questions about the capillary tubes, sign up on Linquip right now and we’ll help you in the blink of an eye!

Download Capacitor Start Induction Motor PDF

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What Are Shaded Pole Induction Motors? 2021 Ultimate Guide

- Types of Induction Motor: A Concise and Useful Guild

- Single-Phase Induction Motor: All You Need to Know About It

- Working Principle of Induction Motor: 2022 Full Guide

- Efficiency of Induction Motor: Calculation & Equation

- What is Capacitor Start Induction Motor: A Complete Guide

- What Is Split Phase Induction Motors? 2022 Ultimate Guide

- Working Principle Of DC Motor: 2022 Complete Guide

- What is Gear Shaft? Clear Principle & Advantages

- What is a Reduction Gearbox?

- Efficiency of Electric Motor: A Simple Guide

- A Full Explanation on Types of Servo Motors

- What is Helical Gearbox?

I was curious an out AC history.

I am familiar with DC motors but AC motors

are not familiar to me.

I was researching Tesla’s history recently.

the advent of AC power was interesting to me.

So motor design was very interesting….

this helps me very well, thank you for the explanation

Thanks for visiting our website and leaving your comment. You are encouraged to visit Linquip Tech News, where you can find similar posts.