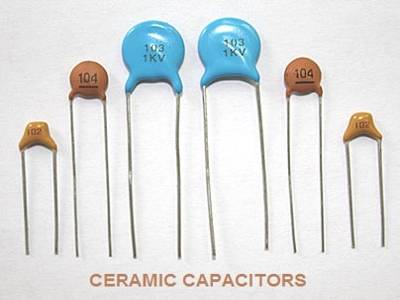

What is ceramic capacitor? The ceramic capacitor is one of the most common types of capacitors used in most electrical instruments due to its high reliability and low cost. In this form, ceramic or porcelain discs are used to make non-polarized capacitors and are used in various industries. The poor conductivity of ceramic materials makes them excellent dielectrics, as well as efficient supporters of electrostatic fields.

Ceramic Capacitor Basics

Ceramic capacitors are fixed-value capacitors made of ceramic material as the dielectric. It is made up of two or more layers of ceramic and a layer of metal acting as electrodes. Electrical behavior and therefore applications of ceramic materials are determined by the composition of the ceramic material. Ceramics are inorganic, non-metallic, crystalline oxide, nitride, or carbide compounds such as carbon and silicon. A ceramic capacitor, especially a multilayer ceramic capacitor (MLCC), is one of today’s most common electrical components.

Ceramic capacitors typically have a capacitance range of 10 pF to 0.1 μF.

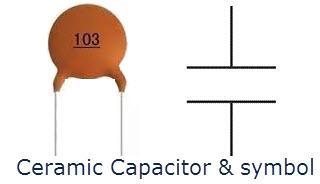

The following figure shows the symbol for a ceramic capacitor:

The ceramic capacitor with three digits, 101, 102, 103, etc., indicates that it is measured in Pico-farads. However, when the same capacitor uses alphabets instead of digits, the value is AB x 10C Picofarad.

Types of Ceramic Capacitors

There are four main types of ceramic capacitors:

Class 1 Ceramic Capacitors

These capacitors are highly stable and have low losses in resonant circuits. Due to their low loss, they can be used in oscillators and filters. Their stable temperature coefficients make them suitable for high tolerance capacitors.

Class 2 Ceramic Capacitors

Based on the applied voltage, capacitors have a certain capacitance. The temperature coefficient of class 2 dielectrics is non-linear. Applications of these capacitors include coupling and decoupling.

Class 3 Ceramic Capacitors

Class 3 dielectrics have permittivity values that are up to 50,000 times greater than class 2 dielectrics. The capacitors are voltage-dependent and have high losses.

Class 4 Ceramic Capacitors

Class 4 capacitors are also called barrier layer capacitors.

The polarity of Ceramic Capacitors

The polarity of a capacitor is one of the most important considerations when connecting capacitors in an electric circuit. On the basis of their polarity, capacitors can be divided into two groups:

Polarized Capacitors

Polarized capacitors have two terminals, known as the anode and cathode.

Non-Polarized Capacitors

Unlike polarized capacitors, non-polarized capacitors have a terminal and, therefore, can be used in either direction. Non-polarity device refers to the absence of polarity on the capacitor.

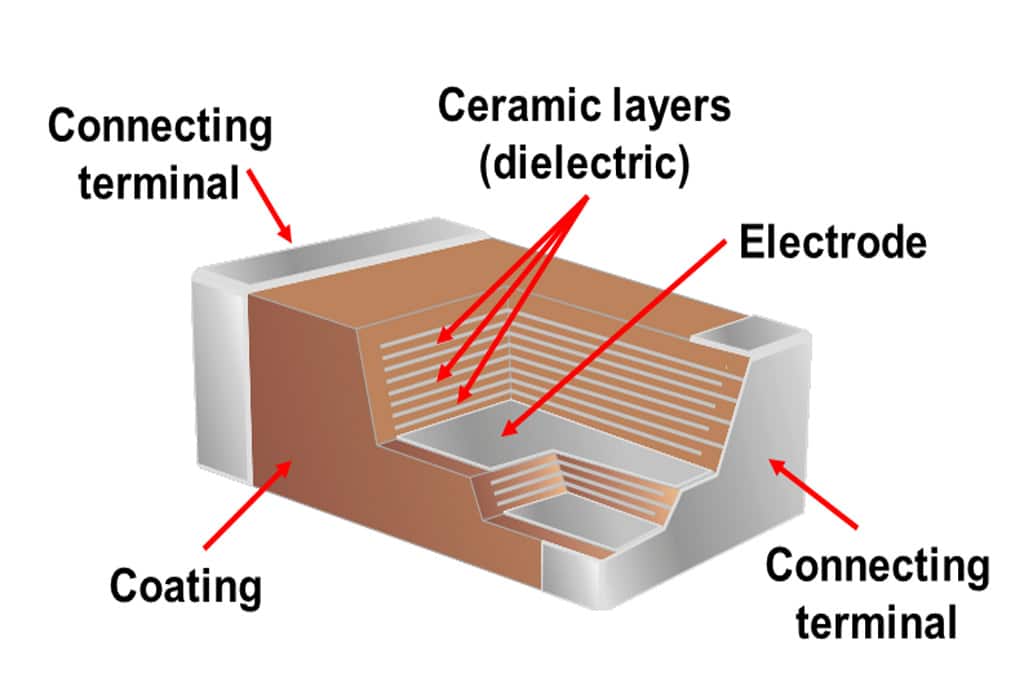

Construction of Ceramic Capacitors

Ceramic capacitors are made up of granules of paraelectric or ferroelectric materials, which are combined with other materials to produce the desired behavior. At high temperatures, these powder mixtures are sintered into ceramics. Dielectric ceramics are used to serve as carriers for metallic electrodes. A ceramic powder grain size determines the minimum thickness of the dielectric layer. For capacitors with higher voltages, the dielectric strength of the capacitor determines the thickness of the dielectric.

A high temperature is applied after layering, and the material is sintered, resulting in ceramic material with the desired properties. As a result, a capacitor is formed by connecting many smaller capacitors in parallel, which results in an increase in capacitance.

A ceramic capacitor comes in three basic forms although other types exist:

Leaded Disc Ceramic Capacitors

They are resin-coated for through-hole mounting. The ceramic discs are coated on both sides with silver contacts. Disc capacitors have capacitance values between 10pF and 100μF with voltage ratings ranging from 16V to 15KV. The devices can be made up of multiple layers to gain higher capacitances.

Disc type of ceramic capacitor consists of two conductive discs on either side of the ceramic insulator. These plates are coated in a ceramic composition that is waterproof, to which the leads are attached. This type of ceramic capacitor is available up to the value of 0.01 F. They can withstand a DC voltage of 750 volts and an AC voltage of 350 volts.

Multi-Layer Ceramic Capacitors (MLCC)

MLCCs are rectangular blocks composed of a blend of paraelectric and ferroelectric components layered with metal contacts and designed for surface mounting. More than 500 layers are present in the MLCCs, with a minimum layer thickness of about 0.5 microns. It is technologically possible to decrease the layer thickness while increasing capacitance in the same volume.

MLCC capacitors have a capacitance (C) that uses a plate capacitor formula with the number of layers increased.

C=\varepsilon \frac{nA}{d}

In the equation above, ε represents dielectric permittivity; A stands for electrode surface area; n is the number of layers, and d shows the distance between the electrodes.

Lead-less Disc Ceramic Capacitors

Specially designed microwave ceramic capacitors fit in slots on PCBs.

Ceramic Dielectric Types

Contrary to tantalum and electrolytic capacitors, ceramic capacitors can be made from a variety of dielectric materials. Different dielectrics impart very different properties to capacitors. So, apart from selecting a ceramic capacitor, a second decision may also be required concerning which type of dielectric to use. Many ceramic capacitor dielectrics are mentioned in distributors’ lists, including C0G, NP0, X7R, Y5V, Z5U, and many more. The best type, however, needs further investigation.

Applications of Ceramic Capacitors

Ceramic capacitors have numerous applications, including:

- In transmitter stations in the resonant circuit

- In High voltage laser power supplies

- Induction furnaces

- Power circuit breakers

- Printed circuit boards

- High-density applications

- These capacitors can also be used as general-purpose capacitors and as brushes for DC motors to reduce RF noise.

Advantages of Ceramic Capacitors

Ceramic capacitors have the following advantages:

- It is reliable and has good frequency response characteristics even when operating at higher frequencies.

- They can withstand higher voltages of up to 100 volts.

- They weigh less than other capacitors.

- Costs are low for these items.

- A variety of shapes and sizes are available.

- They have low ESR (Effective Series Resistance), and low ESL (Effective Series Inductance) compared to other capacitors.

Disadvantages of Ceramic Capacitors

Below are some of the disadvantages of ceramic capacitors:

- With its design, it’s not possible to build capacitors of higher values. There is a maximum capacitance value of 150 µF.

- Ceramic capacitors with constructions similar to the above are not available in higher voltages. Power ceramic capacitors are built with larger shapes and sizes. They can handle voltages from 2 kV to 100 kV.

- They have a higher temperature coefficient.

- The tolerance values of ceramic capacitors are higher.

- Some power supply circuits can have problems with ceramic capacitors as output capacitors.

- A series of smaller capacitors are used in parallel because larger units crack with PCB flexing.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

-

- What is a Paper Capacitor?

- What is a Polarized Capacitor

- Types of Capacitors: All You Need to Know

- Difference Between Condenser and Capacitor in a nutshell 2022

- What is Mica Capacitor Used for?

- What is an Electrolytic Capacitor? Usage & Application

- What is Film Capacitor & What is it used for?

- What is Capacitor and How Does it Work?

- 7 Types of Capacitors and Their Uses

- What is Ceramic Capacitor Used for?

- What are Mica Capacitors? Comprehensive Overview

- What is an Electrolytic Capacitor?

- What is a Polarized Capacitor? Function and Applications

- What is Capacitive Circuit? Formula & Function

- What is Film Capacitor? Different Types & Working

- What is Ceramic Capacitor? A-Basics Description

- Types of Capacitors: All You Need to Know

- Difference between Capacitor and Inductor- Capacitor vs. Inductor