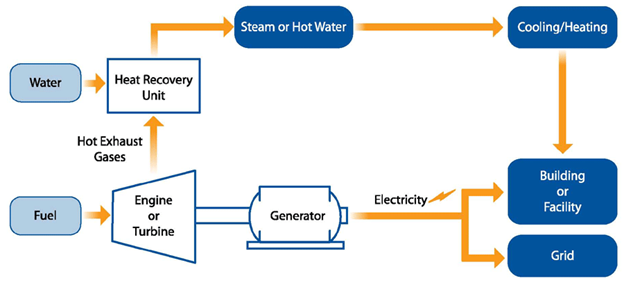

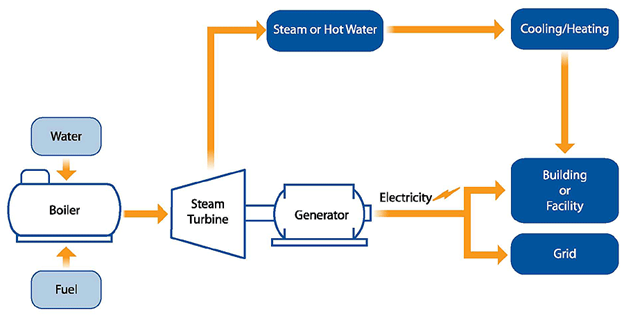

What is CHP? (Combined Heat and Power) – Using various technologies and fuels, CHP is a system that efficiently generates thermal and electrical energy. Losses are reduced thanks to on-site power generation, and heat that would otherwise be lost is used to power facility loads in the form of steam, hot water, or even chilled water for process heating. CHP can be district energy, microgrid, utility resource, or it can be installed at a single building or facility. It can also supply electricity and thermal energy to several end users. In the case of grid failures, CHP equipment can deliver reliable power around the clock, and it may be combined with other dispersed energy technologies like solar photovoltaics (PV) and energy storage.

On the Linquip website, among the many options available to you, you will find all the information you need to know about Power Plants, as well as information regarding this marketplace. You can count on Linquip to provide you with as much general and reliable information about this topic, whether you’re a professional or a customer looking for a proper company. We recommend you review a list of all Industry Directories available in Linquip.

We would be delighted to provide you with more information on how we can help you generate revenue within your industry. Don’t hesitate to contact us if you have any questions! With Linquip’s Solutions for Each Company Level, you will be able to upgrade the capabilities of your organization in order to gain a competitive edge by taking advantage of a wide range of options to enhance your organization’s performance. If you are looking for the simplest or the most sophisticated marketing and advertising package for your business, we can help you ensure that your company gets as many customers as possible to grow your business.

What is CHP?

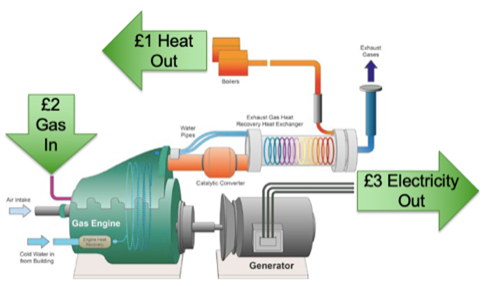

A well-known system called combined heat and power (CHP), or cogeneration (Cogen) concurrently produces electricity and heat from a fuel input.

When compared to buying gas and electricity separately to fuel on-site boilers, cogeneration can reduce primary energy expenditures by up to 30%.

CHP has been utilized for a long time in a variety of sectors and around the world (steam boilers and steam turbines, steam boilers and steam turbines, gas turbines, reciprocating engines and heat recovery systems). The fuel source, market sector, and size that are accessible are typically indicators of the arrangements chosen.

CHP increased quickly in the industry with the installation of gas turbines and steam boiler plants, as well as within the commercial sector and hospitals with the installation of gas engine plants after the privatization of British Gas in 1986 and the hunt for gas in the 1990s. Due to the need for more operational flexibility and the reduction in plant size, gas engine CHP is now the most popular technology.

All of the main manufacturers have biogas and biomethane green gas engine variations as part of the push towards a sustainable, carbon-free economy, and they are also future-proofing their technology to utilize hydrogen (mixed or pure).

CHP is a tested technology that uses low-carbon natural gas as a fuel source to produce electricity at up to 95% efficiency. The carbon profile of CHP will decrease when gas networks go green. However, CHP may offer zero or a negative carbon position directly using zero-carbon fuels.

Businesses should always take into account CHP or trigeneration, commonly referred to as combined cooling, heat, and power (CHP), while planning the construction of new facilities or upgrades to existing ones (CCHP). CHP may be a useful tool for helping businesses provide a secure, reliable, and flexible energy supply.

Working Principle of CHP Plant

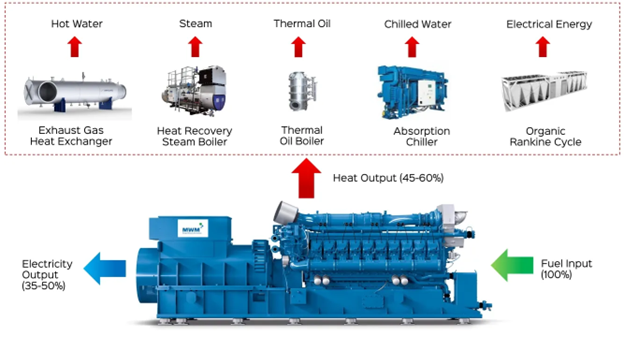

Burning a fuel source—fossil or renewable—produces energy that powers a prime mover, such as a reciprocating engine or gas turbine, which generates both mechanical power and heat. An alternator transforms the mechanical power into electricity, and the heat may either be used immediately or transformed to satisfy the site’s needs.

The energy efficiency of a CHP system may reach up to 95% for particular applications, while generally, they meet between 70 and 80%, which is a major increase over importing grid power and producing heat the old-fashioned way. The cost of manufacturing is reduced by increased energy production efficiency, and if carbon fuels are utilized as fuel, the amount of carbon released into the atmosphere per unit of energy generated is reduced.

Because the cogenerated energy and heat are generated and used locally rather than being transported from distant producers to consumers, which results in transmission losses of about 7.5%, further power efficiencies are attained.

CHP may enhance the energy efficiency, reduce energy costs, and improve the carbon footprint of a site based on the price difference and site-specific requirements. CHP can provide a carbon neutral or negative position depending on the fuel sources employed (for example, biogas and hydrogen).

Advantages of a CHP System

CHP, Trigeneration, or Quad-generation should be taken into account as components of an energy plan if your organization uses electricity, heat, steam, cooling, and CO2 in its operations and activities. Although it doesn’t work for every organization, CHP can provide significant advantages like:

- Decrease or control energy costs

- Reduction in carbon footprint

- Operational flexibility aids in managing energy demand and supply

- Enhanced energy resilience

- Protecting your facility from unpredictable external energy issues in the future

- Generating both heat and power using the same fuel

The advantages of CHP over conventional methods of producing electricity and heat separately are numerous, and the ones mentioned above are only a few.

Common CHP Configurations

The following are the top two arrangements for CHP systems:

- Reciprocating engine or combustion turbine with the heat recovery unit

- A steam turbine and a steam boiler

Reciprocating Engine Or Combustion Turbine With The Heat Recovery Unit

A reciprocating engine or a combustion turbine CHP systems employ heat recovery devices to collect the heat from the turbine or engine while burning fuel (natural gas, oil, or biogas) to spin generators that create electricity. In most cases, steam or hot water is produced as a result of the conversion of this heat into usable thermal energy.

A Steam Turbine And A Steam Boiler

When using steam turbines, the procedure starts with the creation of steam in a boiler. The steam is then utilized to drive a turbine that powers an electricity-generating generator. It is possible to generate usable thermal energy from the steam that exits the turbine. These systems may run on a range of fuels, including coal, biomass, natural gas, and oil.

- The Catalog of CHP Technologies contains a detailed list of CHP technologies along with details on their performance and cost parameters.

- A comprehensive technical analysis of biomass CHP systems may be found in the Biomass CHP Catalog of Technologies.

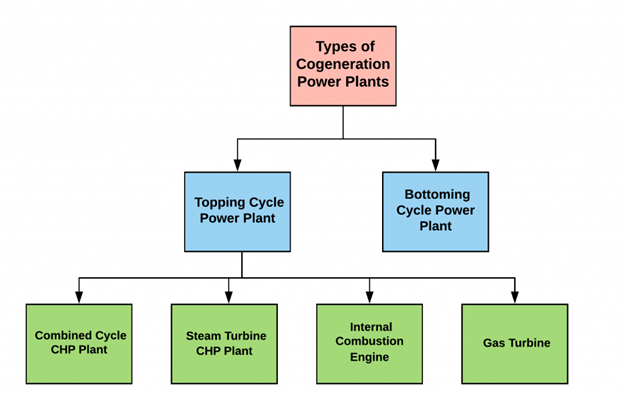

Types of CHP Plants

Steam turbines are the main source of energy production in topping cycle facilities. The partially expanded steam is then condensed at an appropriate temperature, such as for district heating or water desalination, in a heating condenser.

A waste heat recovery boiler then supplies an electricity plant with the high-temperature heat produced by bottoming cycle facilities for industrial activities. Bottoming cycle plants are less prevalent since they are only utilized in industrial processes that demand extremely high temperatures, such as furnaces for the production of glass and metal.

Large cogeneration systems supply electricity and warmth for an industrial site or a full town. Typical forms of CHP plants include:

- Gas turbine CHP facilities that use the waste heat from the gas turbines’ exhaust gas. Natural gas is frequently utilized as fuel.

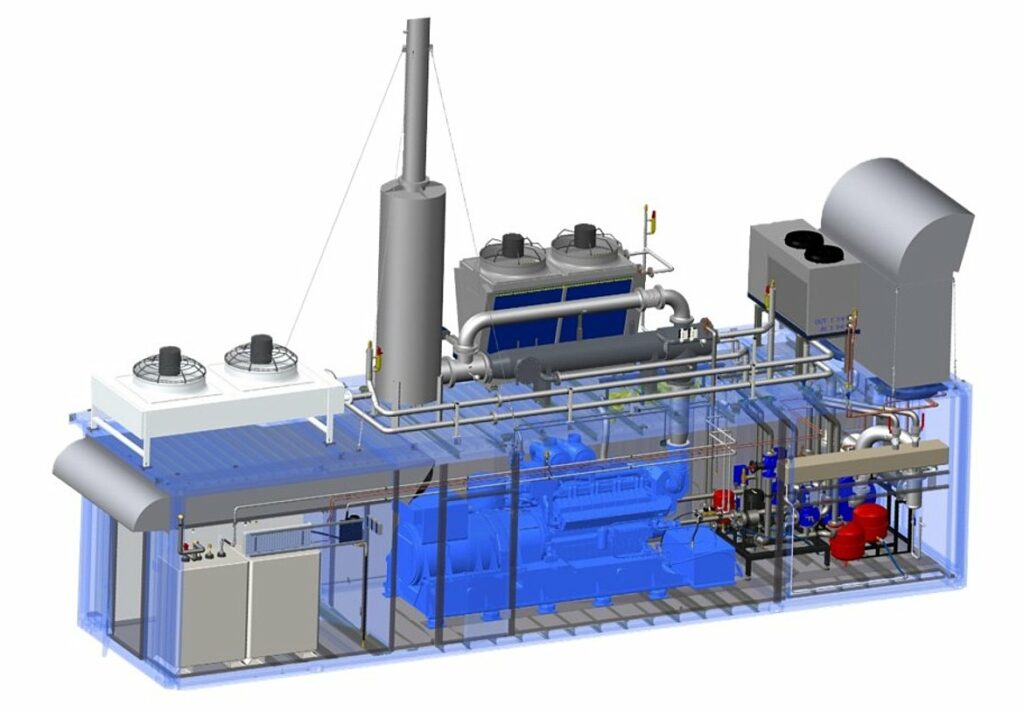

- Gas motor Reciprocating gas engines are used in CHP plants because they are, up to a capacity of 5 MW, more cost-effective than gas turbines. Natural gas is often utilized as the gaseous fuel. These plants are often produced as completely packed units that can be easily connected to the site’s gas supply, electrical distribution network, and heating systems to be put within a plantroom or outside a plant complex.

- A biofuel engine CHP plants are extremely similar in design to gas engine CHP plants and employ a modified reciprocating gas engine or diesel engine, depending on which biofuel is being used. Utilizing biofuel has the benefit of reducing fossil fuel usage and, consequently, carbon emissions. These plants are often produced as completely packed units that can be easily connected to the site’s electrical distribution and heating systems and put inside a plantroom or outside the plant complex. Another option is a wood gasifier CHP plant, which gasifies wood pellets or wood chips as biofuel at high temperatures and with no oxygen before using the generated gas to power a gas engine.

- Combined cycle power plants with CHP conversions

- Both solid oxide fuel cells and molten-carbonate fuel cells have a hot exhaust that is excellent for heating.

- Steam generator CHP systems where the steam condenser for the steam turbine is the heating system

- Nuclear power stations can be equipped with extractions in the turbines to bleed partly expanded steam to a heating system, just as normal steam turbine power plants. For every MW of power loss, it is feasible to extract around 10 MW of heat at a heating system temperature of 95 °C. At 130 °C, the increase is a little less significant—roughly 7 MW are gained for each MWe lost.

A Stirling engine or a reciprocating engine may be used in smaller cogeneration units. The radiator and exhaust are used to remove heat. Because tiny gas and diesel engines are less expensive than small gas or oil-fired steam-electric plants, the systems are popular at modest capacities.

Some cogeneration facilities use biomass, industrial waste, or municipal solid waste as fuel (see incineration). Some CHP facilities generate heat and electricity using waste gas as fuel. Waste gasses include sewage gas, landfill gas, gas from coal mines, gas from animal waste, and gas from flammable industrial waste.

For added technical and environmental performance, several cogeneration plants combine gas and solar photovoltaic generation. These hybrid systems may be scaled down to the level of a building or even a single residence.

How to Choose a System for Cogeneration?

When choosing the cogeneration system, several considerations are taken into account.

- Matching electrical loads

- Thermal-load synchronization

- Matching the base electrical load

- Matching the base-thermal load

- Heat-to-power conversion

- The needed type of thermal energy

- Install outlines

- Current Fuels

When Should We Take a Look at CHP?

For:

- Designing a new structure

- New boiler plant installation

- Upgrading or replacing the current plant

- Examining the Electrical Supply

- The primary source of fuel

- Supplier of mechanical work to the shaft through the motor element

Conclusion

This concludes our discussion of cogeneration, its various forms, and its applications in power plants, which primarily serve a wide range of industries and sectors, including wastewater treatment, the military, the industrial sector, data centers, the leisure industry, hotels, hospitals, prisons, educational institutions, horticulture, mixed developments, etc.

FAQs about CHP Systems

1. What Is CHP Renewable Energy?

A very effective method for capturing and using the heat produced as a byproduct of producing electricity is called combined heat and power (CHP).

2. Does CHP Need Gas?

When it becomes commercially feasible, CHP may use low-carbon natural gas as well as renewable fuels like biogas, biomethane, syngas, sewage gas, and hydrogen. Both liquid biofuels and solid biomass may be used with other CHP technology.

3. Can CHP be Used for Cooling?

CHP facilities offer a variety of consumers local heat, electricity, and occasionally even cooling.

Download What is CHP? (Combined Heat and Power) PDF

You can download the PDF format of this post from here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- The Essential Intro to Geothermal Heating

- Nuclear Power Plant Diagram: A Complete Guide

- What is Pumped Storage Hydropower?

- What is Osmotic Power? Working Principles With Diagram

- What is Combined Cycle Power Plant? + Efficiency & PDF

- What is a Power Plant? (Clear Guide)

- What is Distributed Generation? (Clear Guide) + PDF

- Cogeneration System: Working Principles, Types & Application

- How Does a Power Plant Work? (Step-by-Step Guide)

- 9 Different Types of Power Plants + PDF

- What is a Power Plant? (Clear Guide)

- Top 10 Diesel Fuel Supplier & Manufacturers in 2022

- Top 10 Solar Panel Companies and Manufacturers in the US in 2022

- More Informtion about Power Plant System

- More Details about Power Plant Generator

- More Details about Thermal Power Plant Generators

- Read More Information about Steam Power Plant Generators

- More Information about Nuclear Power Plant Generators

- Read More Information about Hydro Power Plant Generators

- See List of Siemens Generators Products