An ECM motor, known as Electrically Commutated Motors, is the fastest it has ever been, with unparalleled airflow delivery to meet the necessity of a heating or cooling system. It can be used in hundreds of different applications. It is a self-regulating motor that do not need the assistance of any other system to operate. But what causes an ECM motor to work? How does the motor know when to speed up and when to slow down without external sensors to track pressure, temperature, or something else? Let us take an honest look at the topic in this new article at Linquip.

What is an ECM Motor?

HVAC (Heating, Ventilation, and Air Conditioning) devices are those that heat or cool a certain area. They are particularly critical when constructing large office buildings or climate-controlled settings. One of the primary aims of current HVAC research is to identify ways to improve machine energy quality. Energy savings are not only a good way for homeowners and business owners to save money, but they are also good for the world. An ECM engine, also known as a variable speed motor, is a significant advancement for air conditioners and furnaces. In layman’s words, an ECM motor reduces the overall electrical consumption of an AC or furnace while still assisting the maintenance of sufficient air flow through the device.

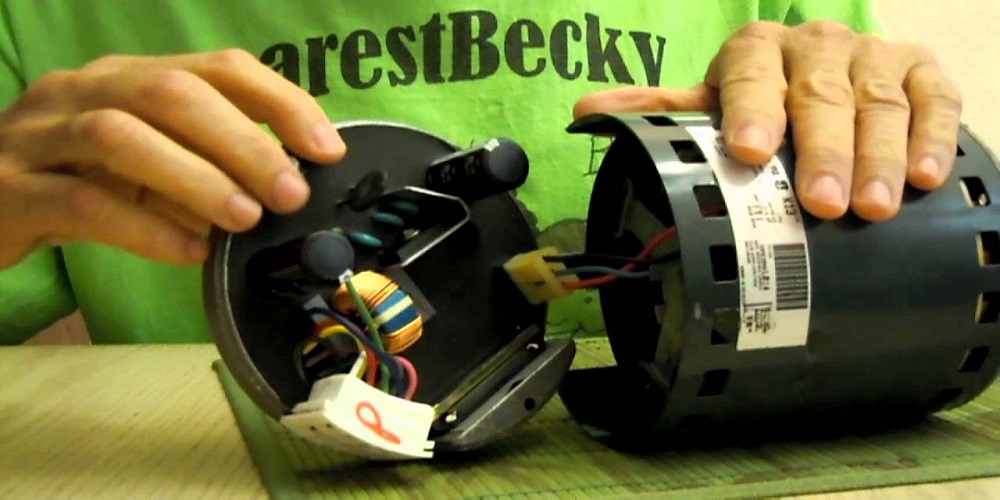

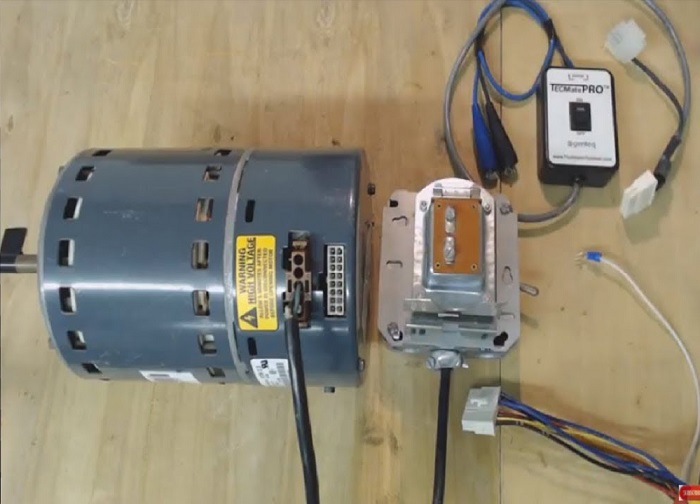

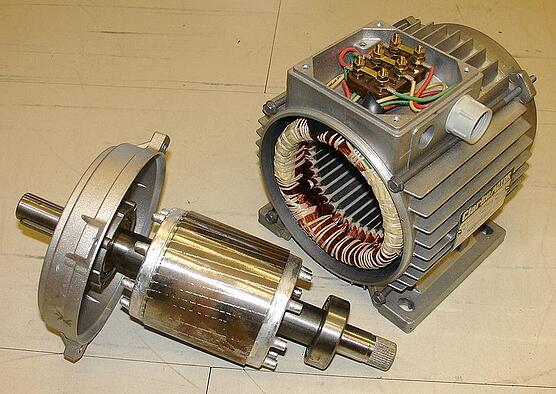

ECM motor has a microprocessor which is a crucial factor in its ability to have higher performance. The microprocessor is used to sequentially energize and de-energize each winding of the stator, generating an electrical current. The processor-based pulse control generates a magnetic field, which allows the rotor inside this ring of magnets to spin. The microprocessor employs a closed-loop feedback system to more accurately regulate the magnetic fields, thus reducing the eddy currents and losses experienced by conventional mechanically commutated motors. This also allows for the use of a brushless motor, which reduces points of physical contact within the motor’s moving parts and makes them more durable.

The most significant feature of the ECM motor is its low energy consumption. The most significant drawback of this motor is its complexity. Failures in these motors are much more likely due to the electronics used in them. Let’s continue reading how an ECM motor works, where it is used, and the pros and cons briefly.

The Use of ECM Motor

The use of ECM motor is increasingly expanding. Today, all motors used in residential and light commercial HVAC (indoor and outdoor) and commercial refrigeration (evaporator and condenser) have an ECM application. This provides improved electrical efficiency as well as the ability to program more accurate and regulated motor operation over a broad variety of HVAC system output needs to improve user comfort.

How does an ECM Motor work?

The motor torque and airflow should remain constant until the settings are programmed into the microprocessor and the control board dip switches are set in the area. What WILL shift is the motor’s rpm. Depending on the machine conditions, the motor can need to turn faster or slower to maintain constant torque and airflow. As the load or demand on the device rises, for example, when it is very hot outside, higher static pressure is present.

Increased cooling demand causes condensation on the evaporator coil, which reduces air flow. A clogged filter or dirty coil may also create air flow resistance, which raises static pressure. The higher the load, the greater the torque on the engine. Increased torque essentially means that it takes more “muscle” to drive an engine. Higher pressure effectively causes more resistance on the fan motor’s blades, which is why more “muscle” or torque is needed to turn the motor.

Advantages of ECM Motor

- An ECM motor consumes less wattage than a normal motor.

- The ECM motor’s multiple speeds allow it to reduce the drying effect that can occur during winter heating while still minimizing cold and warm spots in the household.

- The ECM motor can be programmed with several inputs to vary speed and voltages using an internal smart screen.

- ECM-equipped systems, when properly configured, can increase dehumidification, reduce register noise, conserve electricity, and provide trouble-free service.

- A furnace or air handler with an ECM can work flawlessly when mounted on a good vent, coil, and filtration device with static pressures under reasonable design parameters. This is because the motor can provide accurate airflow to balance two-speed condenser designs and multi-stage gas furnace firing speeds to provide silent, draft-free comfort in almost any configuration.

- An ECM motor can only use less energy, to begin with, but its microprocessor controllers may even be designed to further minimize current pull during off-peak hours and maximize energy consumption when running. This results in ECM efficiencies above 90%.

Is ECM Motor Disadvantageous?

- The architecture of an ECM motor is structurally complicated since its stator comprises multiple windings and involves precise timing from some control module to rotate the rotor. On the other hand, although this complexity allows for greater performance, less noise, and improved operating characteristics, maintenance on an EC motor takes longer and is more costly.

- ECM-generated high velocities and pressures on systems with dirty evaporator coils can also blast moisture off the coil surfaces into the supply ductwork. This will reduce the system’s ability to dehumidify and trigger a variety of moisture-related indoor air quality problems.

- When continuously operating in over-amped environments, some older ECM motors will overheat and even malfunction.

- Noise at the registers from higher air velocities is another effect of high static installations. Filter media can be drained out of the rack in serious situations, resulting in filter bypass. In severe situations, filter media will be drawn into the fan, cut up, and blown around the device, causing extensive damage.

This article provided a basic understanding of ECM motor. It defined ECM motor and discussed how it works. This kind of motor conserves energy while improving the efficiency of air flow through your device. Variable speeds are possible with ECM motor, and will lead to the unit’s demand for air flow. You can find out more about ECM motor by consulting our experts in Linquip. Register and contact us. We look forward to helping you.