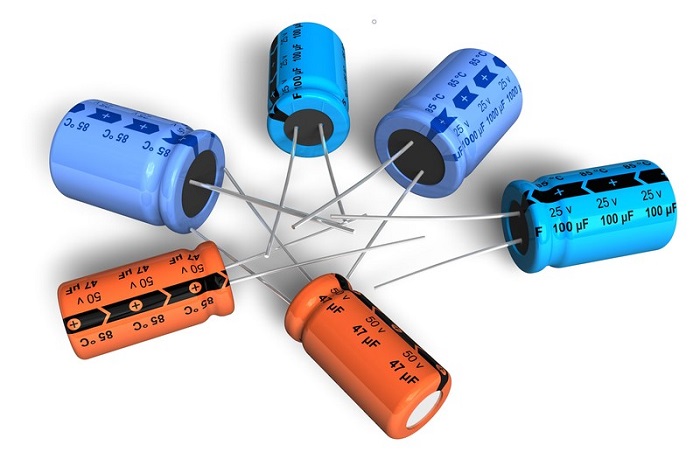

An electrolytic capacitor has one of the highest capacitances when compared to other capacitors. The electrolytic capacitor is the only type of capacitor that is currently in use. Check out this article in Linquip on the electrolytic capacitor fundamentals: if you want to see what it is, how it is constructed, how it works, and where it is used, read our new blog post.

What is an electrolytic capacitor?

An electrolytic capacitor is a type of capacitor that has a higher capacitance than other capacitor types due to the usage of an electrolyte. An electrolyte is a liquid or gel with a high ion concentration. It can provide the same level of low-frequency electric current capacity if no rechargeable batteries are available. Moreover, an electrolytic capacitor is typically employed when a large amount of charge must be stored in a limited amount of space.

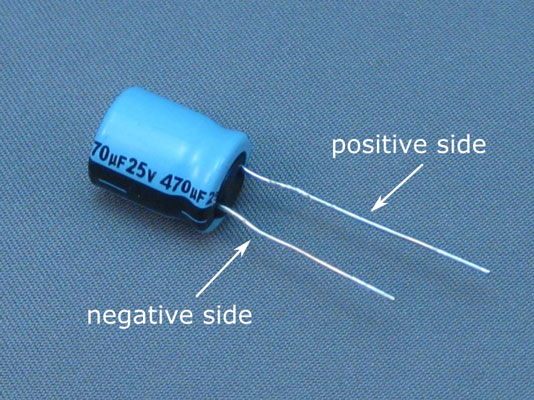

We can also define an electrolytic capacitor as a polarized capacitor, which means that the voltage applied to the terminals must be in the right polarity (positive connected to the positive terminal and negative connected to the negative terminal). If it is connected in the opposite or reverse manner, the capacitor may be short-circuited, which means that a significant electric current flow through the capacitor, which might permanently destroy it.

An electrolytic capacitor aims to utilize an electrolyte to operate with a greater or more positive voltage on the anode than the cathode. As a result, the anode terminal is represented by a positive sign, whereas the cathode is designated by a negative sign.

The electrical conductivity of the electrolytic capacitor improves with increasing temperature and decreases with decreasing temperature. As a result, the capacitance or charge storage of the aluminum electrolytic capacitor increases with increasing temperature and decreases with decreasing temperature. As a result, temperature changes have a substantial impact on the capacitance of the aluminum electrolytic capacitor.

What Characteristics does an Electrolytic Capacitor have?

The capacitance of an electrolytic capacitor wanders from the nominal value with time, and it has significant tolerances, generally 20 percent. This indicates that for example, an aluminum electrolytic capacitor with a nominal capacitance of 47F can be anticipated to have a measured value ranging from 37.6F to 56.4F. Or a Tantalum electrolytic capacitor can be manufactured with finer tolerances, but their maximum working voltage is lower, making them ineffective as a straight replacement.

The electrolytic capacitor must be also forward-biased due to the design and the properties of the electrolyte employed. This means that the positive terminal must always be more charged than the negative terminal. If the capacitor is reverse-biased, the insulating aluminum oxide that functions as a dielectric may be destroyed and begin to operate as a short circuit between the two capacitors’ terminals. Due to the high current flowing through the capacitor, this might cause it to overheat. The electrolyte warms up and spills or even vaporizes when the capacitor overheats, causing the enclosure to rupture. This procedure occurs at reverse voltages of 1 volt or higher. A safety valve is put in the enclosure to preserve safety and prevent the enclosure from bursting owing to high pressures created under overheating circumstances. It is generally created by scoring the upper face of the capacitor, which opens in a controlled manner as the capacitor overheats. Because electrolytes can be poisonous or corrosive, extra precautions should be taken while cleaning up after and replacing an overheated electrolytic capacitor.

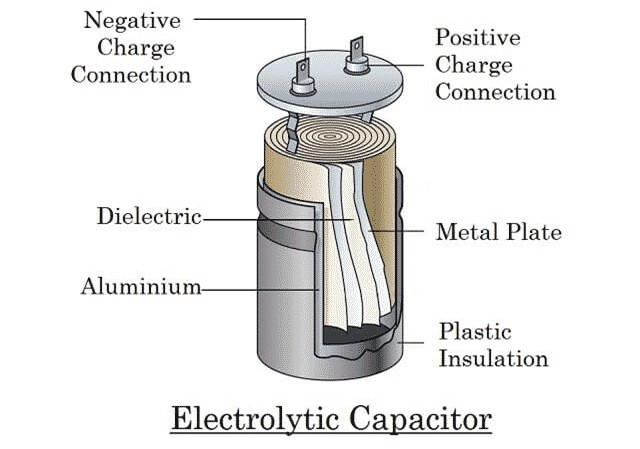

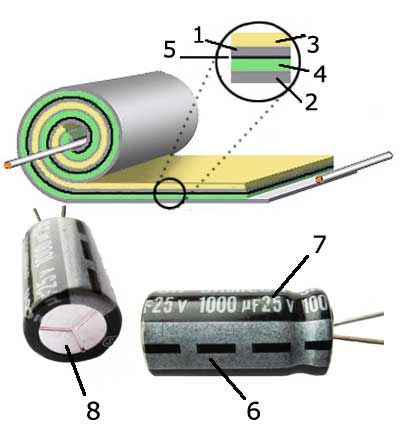

What are the Construction and properties of an electrolytic capacitor?

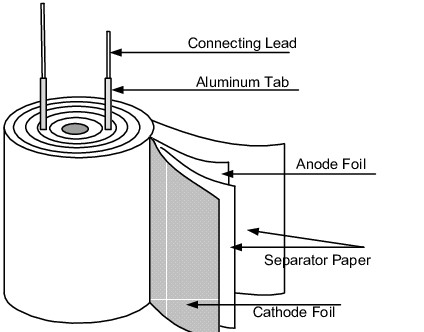

The electrolytic capacitor is made up of two thin layers of aluminum foil – plain foil and etched foil. It is built between two plates separated by an electrolyte. It is made up of two terminals termed ‘Anode’ and ‘Cathode.’ The ‘Oxidized Layer’ is applied to certain metals. This layer is the component’s insulating material. To establish the polarity of the two foils, they are anodized, which involves chemically developing a thin coating of aluminum oxide to produce the anode and distinguish it from the cathode. The cathode and anodized anode are created during the electrolytic capacitor manufacturing process, which is separated by an electrolyte (paper soaked with electrolyte).

During normal operation, the anode is maintained positive about the cathode, therefore, the cathode is marked on the capacitor’s body with a negative (-) symbol. Because aluminum is a polarized material, delivering a reverse voltage to these terminals would cause the insulation in the capacitor to fail, causing the capacitor to fail.

The Function and Working Principle of an Electrolytic Capacitor

Because the electrolytic capacitor is built asymmetrically, it contains polarized components. This structure owes to its higher voltage functioning, in which one side gets more power than the other. It features a metal or aluminum anode with an oxidized cover layer that acts as a dielectric and serves as the capacitor’s positive electrode. This side gets the majority of the input voltage.

The cathode, which includes aluminum foil and a liquid electrolyte, serves as the negative electrode. This liquid is typically made up of water and sodium borate or boric acid. A few sugars are also added to avoid evaporation. Aluminum oxide is responsible for the polarity of electrolytic capacitors. It is held in place by the electric field. When direct current (DC) voltage is applied to an electrolytic capacitor, the correct polarity must be present. This necessitates connecting the positive lead and positive terminal, as well as the negative lead and negative terminal. If this is not done correctly, the capacitor will be ruined.

Warning: Make sure you don’t get the liquid in your eyes, mouth, or skin since it’s extremely harmful to your health. If the liquid comes into contact with any area of your body, wash it off right away.

What are the Applications of electrolytic capacitors?

The following are some examples of electrolytic capacitor applications:

An electrolytic capacitor may be used in a variety of filtering applications to minimize the amount of voltage ripple. In practice, this is done in audio amplification circuits to decrease hums in the circuit.

An electrolytic capacitor may also be utilized as a low pass filter in input and output smoothing if the signal is a DC signal with a faint AC component. However, due to the power wasted at the parasitic internal resistance known as equivalent series resistance, electrolytic capacitors do not perform well with big amplitude and high-frequency signals (ESR). Low-ESR capacitors must be used in such applications to decrease losses and avoid overheating.

An electrolytic capacitor also exhibits polarity effect and overheat situations. This does not work well with high-frequency transmissions. It is influenced by the resistance that is there in it. Equivalent series resistance is the name given to this type of resistance. The primary cause of this is power dissipation.

Does an Electrolytic capacitor have ant Disadvantage?

Electrolytic capacitor is not without flaws. The advantage of high capacitance in an electrolytic capacitor is accompanied by several disadvantages, such as value tolerances, comparable series resistance, and a restricted lifetime.

It may also fail to fulfill its function, resulting in leakage and bulkage. When utilizing an electrolytic capacitor, most electrical devices have a low Equivalent Series Resistance (ESR), therefore a high ESR is one failure mode. However, the failure may occasionally be due to the capacitor, not opening, which implies that the electric flow cannot be distributed properly to the circuits.

Summary

By reading the post, we can say that an electrolytic capacitor is polarized, almost all, which implies that the positive terminal voltage must always be larger than the negative terminal voltage. The capacitance of a component increases with increasing surface area and decreasing distance between the anode and cathode. To produce a considerably greater capacitance per unit volume, an electrolytic capacitor employs an electrolyte, which can be solid, liquid, or gel, as the cathode or negative plate. Yet there might be some other fundamentals you want to discover. So, feel free to leave your comments; but before that do not forget to register in Linquip first.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- What is a Non-Polarized Capacitor? Types & Function

- Difference between Capacitor and Inductor- Capacitor vs. Inductor

- What is a Paper Capacitor?

- What is Paper Capacitor Used for?

- What is Mica Capacitor Used for?

- What is Film Capacitor & What is it used for?

- What is Capacitor and How Does it Work?

- 7 Types of Capacitors and Their Uses

- What is Ceramic Capacitor Used for?

- What are Mica Capacitors? Comprehensive Overview

- What is Electrolytic Capacitor?

- What is Film Capacitor? Different Types & Working

- What is Ceramic Capacitor? A Basic Description

- Types of Capacitors: All You Need to Know

- Difference Between Condenser and Capacitor in a nutshell 2022