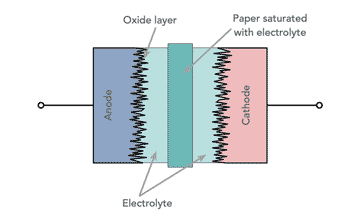

To give a short answer to the question “What is electrolytic capacitor?” we can say that it refers to a polarized capacitor that consists of an anode or positive plate made of metal, forming an insulating oxide layer by anodization. The oxide layer serves as the dielectric of the capacitor. A liquid, solid, or gel electrolyte covers the oxide layer surface as the cathode or negative plate of the capacitor. Electrolytic capacitors have a much larger capacitance-voltage (CV) product per volume than ceramic or film capacitors because of their very thin dielectric oxide layer and enlarged anode surface. These capacitors can be divided into three main groups:

- aluminum electrolytic capacitors.

- tantalum electrolytic capacitors.

- niobium electrolytic capacitors.

In these three capacitor families, both non-solid and solid manganese dioxide or solid polymer electrolytes are used, which means there is a wide range of anode materials and non-solid or solid electrolytes that can be used.

Electrolytic capacitors have a large capacitance, making them ideal to passing or bypassing low-frequency signals, as well as storing large quantities of energy. For instance, they can be used to decouple or filter noise in power supplies and DC link circuits for variable-frequency drives, couple signals between amplifier stages, or store energy as in flashlamps.

Electrolytic capacitors have polarized construction due to their asymmetrical design and must always be used with a higher voltage (positive) on the anode than on the cathode. In order to differentiate between these two terminals, the anode terminal is marked with a plus sign, while the cathode is marked with a minus sign.

Reversing the polarity of the capacitor or applying a voltage higher than the maximum rated working voltage of 1 to 1.5 volts can cause the dielectric to be destroyed and thus damage the capacitor. Electrolytic capacitors can be hazardous if they break down, resulting in a fire or explosion.

Also available are bipolar electrolytic capacitors, which can operate with either polarity and have two anodes that are connected in series. The formation of a bipolar electrolytic capacitor is possible by connecting two standard electrolytic capacitors, anode-to-anode or cathode-to-cathode.

Electrolyte

Electrolytes are liquid electric conductors in which moving ions carry current. Electrolytes or minerals in our blood, for example, carry an electric charge. Sodium, potassium, chloride, calcium, and phosphorus are some of the most common electrolytes.

In electrolytes, ions are either anions (-) or cations (+). An anion refers to an ion that contains more electrons than protons. The electron is negatively charged, whereas the proton is positively charged. As a result of having more electrons than protons, the overall charge of the anion becomes negative. Anions are, therefore, negatively charged ions that move negative charge.

Cations, on the other hand, have fewer electrons than protons. As the cation has fewer electrons than protons, its charge is positive. Cations are therefore positively charged ions. The positive charge is carried by these cations.

Applications of Electrolytic Capacitors

When large capacitance values are needed, electrolytic capacitors are commonly used. An electrolyte solution in the form of jelly or paste is used instead of a very thin metallic film for one of the electrodes (usually the cathode).

Dielectrics are made from a thin oxide layer that grows electro-chemically, achieving a thickness of fewer than ten microns. The insulating layer is so thin that small capacitors can be made with a very large capacitance but with a very small physical size due to the small distance between the plates.

Capacitors with large capacitances and small sizes are used for reducing ripple voltages or for coupling and decoupling applications in DC power supplies. Since electrolytic capacitors have relatively low voltage ratings and the fact that they are polarized, they must not be used with AC supplies.

As an example, electrolytic capacitors are commonly used as filters in audio amplifiers for the purpose of reducing mains hum. Typical mains hum consists of 50Hz or 60Hz from the mains electrical noise that would be audible if amplified.

Types of Electrolytic Capacitors

Depending on the material used to construct the dielectric, electrolytic capacitors can be classified into three types:

- Aluminum electrolytic capacitors

- Tantalum electrolytic capacitors

- Niobium electrolytic capacitors

Electrolytic capacitors of all types operate similarly. Electrodes, however, are made of a different type of material.

Aluminum Electrolytic Capacitors

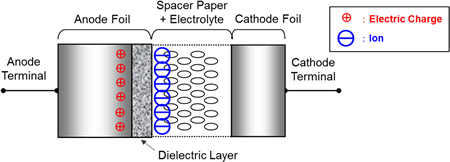

An aluminum capacitor is an electrolytic capacitor that has an anode electrode (+) made of pure aluminum foil with an etched surface. The aluminum forms an extremely thin insulating layer of aluminum oxide by anodizing, which functions as the capacitor dielectric. In principle, the oxide layer is a second electrode (cation) (-) of the capacitor, which is covered with a non-solid electrolyte. The negative terminal of the capacitor is connected to the electrolyte through a second aluminum foil called “cathode foil.”

The anodization principle of aluminum electrolytic capacitors makes them polarized capacitors. The correct polarity of DC voltage is required for the operation of these devices. Short circuits can occur when the capacitor is operated with AC voltage or incorrect polarity. The only exception is the bipolar aluminum electrolytic capacitor with a back-to-back arrangement of two anodes in one case and can be applied for AC purposes.

Because aluminum electrolytic capacitors have relatively high capacitance values, their impedance values are low, even at lower frequencies such as mains frequency. Applications of aluminum electrolytic capacitors include:

- power supplies

- switched-mode power supplies

- DC-DC converters to smooth and buffer rectified DC voltages in many electronic devices

- industrial power supplies

- used as DC link capacitors for drives, photovoltaic inverters, and converters in wind power plants.

- Particular types are also used in strobes and photoflash applications or for signal coupling in audio signals.

During a temperature increase, the conductivity of the electrolytic capacitor increases while its conductivity decreases with a decrease in temperature. Consequently, aluminum electrolytic capacitor capacitance changes dramatically with temperature.

Tantalum Electrolytic Capacitors

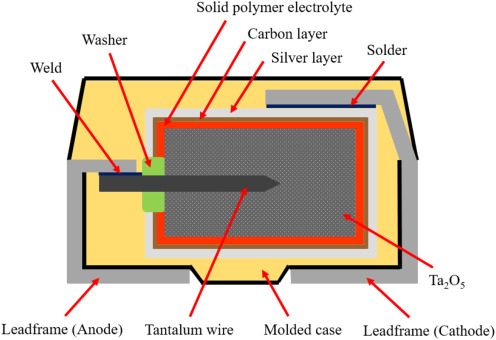

Tantalum electrolytic capacitors are passive components of electronic circuits. This type of electrolytic capacitor has an anode consisting of a pellet of porous tantalum metal, which is covered by an insulating oxide layer and surrounded by a liquid or solid electrolyte as a cathode. Unlike conventional and electrolytic capacitors, the tantalum capacitor has a relatively thin and high permittivity dielectric layer enabling it to have a very high capacitance per volume (high volumetric efficiency) and to be relatively light.

Compared with aluminum electrolytic capacitors, tantalum electrolytic capacitors are much more expensive.

Tantalum capacitors are, by nature, polarized components. The capacitor can be destroyed by reverse voltage. By effectively connecting two polarized capacitors in series, anodes facing opposite directions, non-polar tantalum capacitors are made.

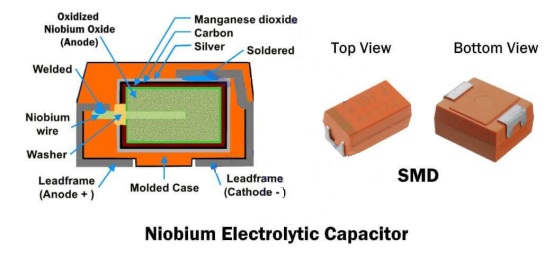

Niobium Electrolytic Capacitors

In a niobium electrolytic capacitor, a polarized capacitor, anode electrode is built of passivated niobium metal or niobium monoxide that an insulating niobium pentoxide layer on that serves as the niobium capacitor dielectric. As the second electrode (cathode), there is a solid electrolyte on the oxide layer surface.

Capacitors made of niobium are polarized components by design, so they can only receive DC voltage in the correct direction. Like the other two types of electrolytic capacitors, reverse voltage or ripple current higher than a certain value can damage the dielectric and thus the capacitor. In order to ensure the safe operation of Niobium capacitors, manufacturers specify specific circuit design rules.

Comparison of Different Types of Electrolytic Capacitors

Aluminum electrolytic capacitors, also called “wet” capacitors, are the cheapest out of all conventional capacitors. In addition to providing the most cost-effective solutions for high capacitance and voltage applications for decoupling and buffering, they are insensitive to low ohmic charging and discharging as well as for low-energy transients. Nearly all electronic devices use non-solid electrolytic capacitors except for military applications.

Surface-mountable capacitors made of tantalum electrolytic with solid electrolyte are commonly used in electronic devices with little space or a low profile. The instruments operate reliably over a wide range of temperatures without large parameter deviations. Tantalum electrolytic capacitors are the only ones that meet military and space requirements.

The availability of niobium makes these capacitors directly competitive with tantalum electrolytic capacitors. They are comparable in terms of their properties.

By using polymer electrolytes, aluminum, tantalum, and niobium electrolytic capacitors have significantly improved electrical properties.

The capacitance of Electrolytic Capacitor

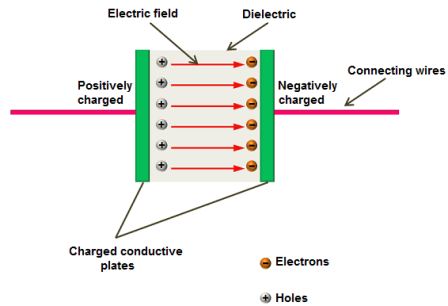

An electrolytic capacitor operates on the principle of a “plate capacitor,” whose capacitance increases as the electrode area A, dielectric permittivity ε, and dielectric thickness (d) increase.

C=\varepsilon \frac{A}{d}

In electrolytic capacitors, the dielectric thickness is very thin, typically in the nanometer range. Meanwhile, this oxide layer has high voltage strengths. Combined with a sufficiently high dielectric strength, this thin dielectric oxide layer allows electrolytic capacitors to achieve high volumetric capacitance. This is why electrolytic capacitors have a higher capacitance value than conventional capacitors.

Compared to a smooth surface of the same volume or area, etched or sintered anodes have a much higher surface area. With non-solid aluminum electrolytic capacitors as well as solid tantalum electrolytic capacitors, that can increase capacitance by a factor of up to 200. Secondly, the large surface area as compared with a smooth one is a factor for the high capacitance values of electrolytic capacitors.

By using the formula of the series connection of two capacitors, we can find the total capacitance of the capacitor:

C_{tot}=\frac{C_aC_c}{C_a+C_c}

In the above equation, Ca and Cc are capacitances of anode and cathode, respectively.

Ripple Current

In continuous operation within a specified temperature range, ripple current is defined as the RMS value of a superimposed AC of any frequency with any waveform. That means:

I_R=\sqrt{i^2_1+i^2_2+i^2_3+i^2_n}

Ripple currents produce heat inside the body of the capacitor. In addition to the ambient temperature and other possible external heat sources, this internally generated heat raises the body temperature of the capacitor against the ambient temperature. This heat is distributed as thermal loss Pth over the capacitor surface A and the thermal resistance β to the ambient.

P_{th}=\mathit{\Delta}T.A.\beta

Internal heat must be distributed to the ambient through thermal radiation, convection, and conduction. A capacitor’s temperature, which is the balance between the heat produced and distributed, must not be higher than its maximum specified temperature.

Symbol of Electrolytic Capacitor

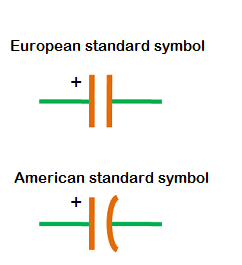

Either two parallel straight lines represent the electrolytic capacitor or one straight line accompanied by a curved line. In the figure below, you can see the symbol for an electrolytic capacitor.

Near any one of the lines is either a plus or a minus sign, indicating whether the terminal is positive or negative (anode or cathode). It is essential to apply the voltage at the correct terminal. If not, the capacitor may be destroyed.

Advantages and Disadvantages of Electrolytic Capacitors

With electrolytic capacitors, a large amount of charge storage is obtained. Another advantage of these devices is their low cost.

Their weaknesses, however, include a large leakage current and a short lifetime.

Conditions That Damage Electrolytic Capacitors

Electrolytic capacitors can have problems working under certain conditions. The following are some of the most important ones.

Over-Voltage

An excessive voltage will result in current leaking through the dielectric, creating a short circuit.

Reversed Polarity

Reversed voltage damages and destroys the oxide layer.

Over-Temperature

Excessive heat can dry out the electrolytic and shorten its life.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- What is a Non-Polarized Capacitor? Types & Function

- Difference between Capacitor and Inductor- Capacitor vs. Inductor

- What is a Paper Capacitor?

- What is Mica Capacitor Used for?

- What is Electrolytic Capacitor? Usage & Application

- What is Film Capacitor & What is it used for?

- What is Capacitor and How Does it Work?

- 7 Types of Capacitors and Their Uses

- What is Ceramic Capacitor Used for?

- What are Mica Capacitors? Comprehensive Overview

- What is Film Capacitor? Different Types & Working

- What is Ceramic Capacitor? A Basic Description

- Types of Capacitors: All You Need to Know

- Difference Between Condenser and Capacitor in a nutshell 2022