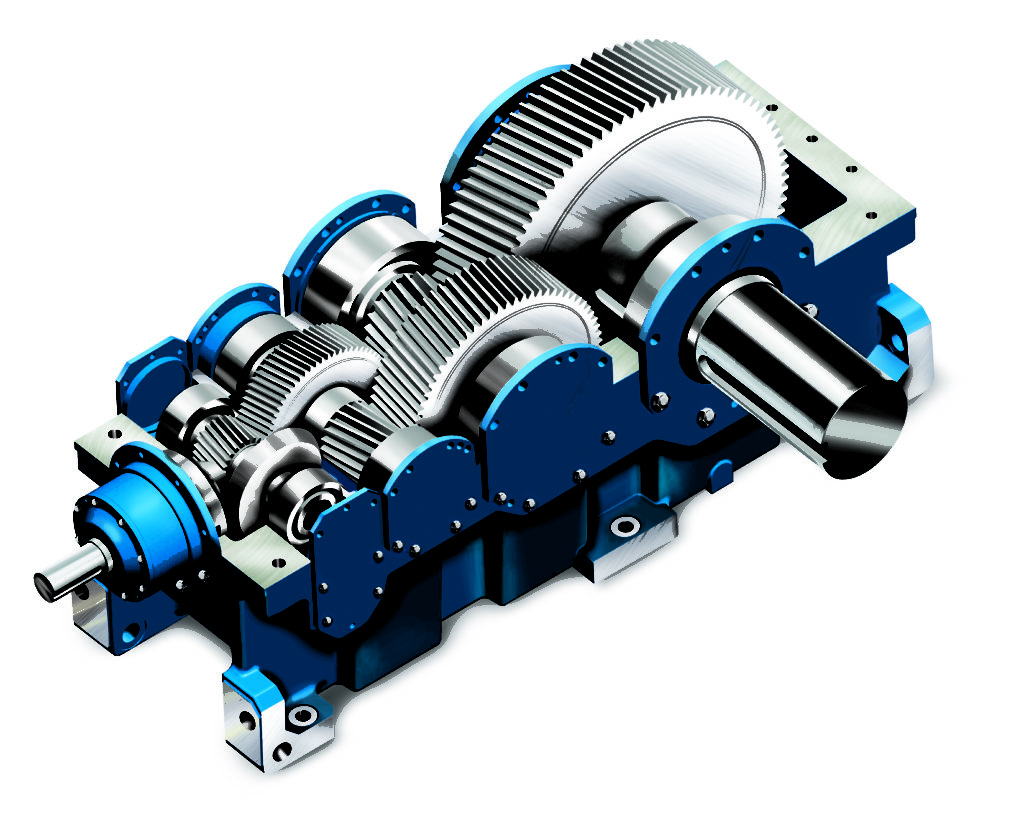

What is a Helical Gearbox? Industrial Gearboxes are employed in different small-scale and large-scale industries and find a broad range of applications. There are some professional leading industrial gearbox constructors around the world. They specialize in the production of different industrial gearboxes such as Helical Gearboxes, Worm Gearbox, Planetary Gearboxes, and Geared Motors. In this post, we will discuss the helical gearbox and its working principle, efficiency, and applications in more detail.

Linquip’s website contains a wealth of information on gearboxes, and we strive to offer you as much information as possible to help you choose a product that will work well for your application. Linquip is the best option if you have questions regarding helical gearboxes. Any questions you have about these devices or equipment can be answered by a Linquip expert at any time. We recommend you take some time to read Linquip’s article entitled, “What is Gearbox?“.

The Linquip platform consists of several components, and to use them to the fullest, Linquip Expert registration is required. If you create an account on Linquip, you will be able to showcase your capabilities that are related to industrial equipment in a way that is tailored to the needs of the industry. Would you be willing to participate in writing a guest post for Linquip? Do you think this is something you would like to contribute to? Guest Posting is a feature of the Linquip platform that lets you post your content directly to the site.

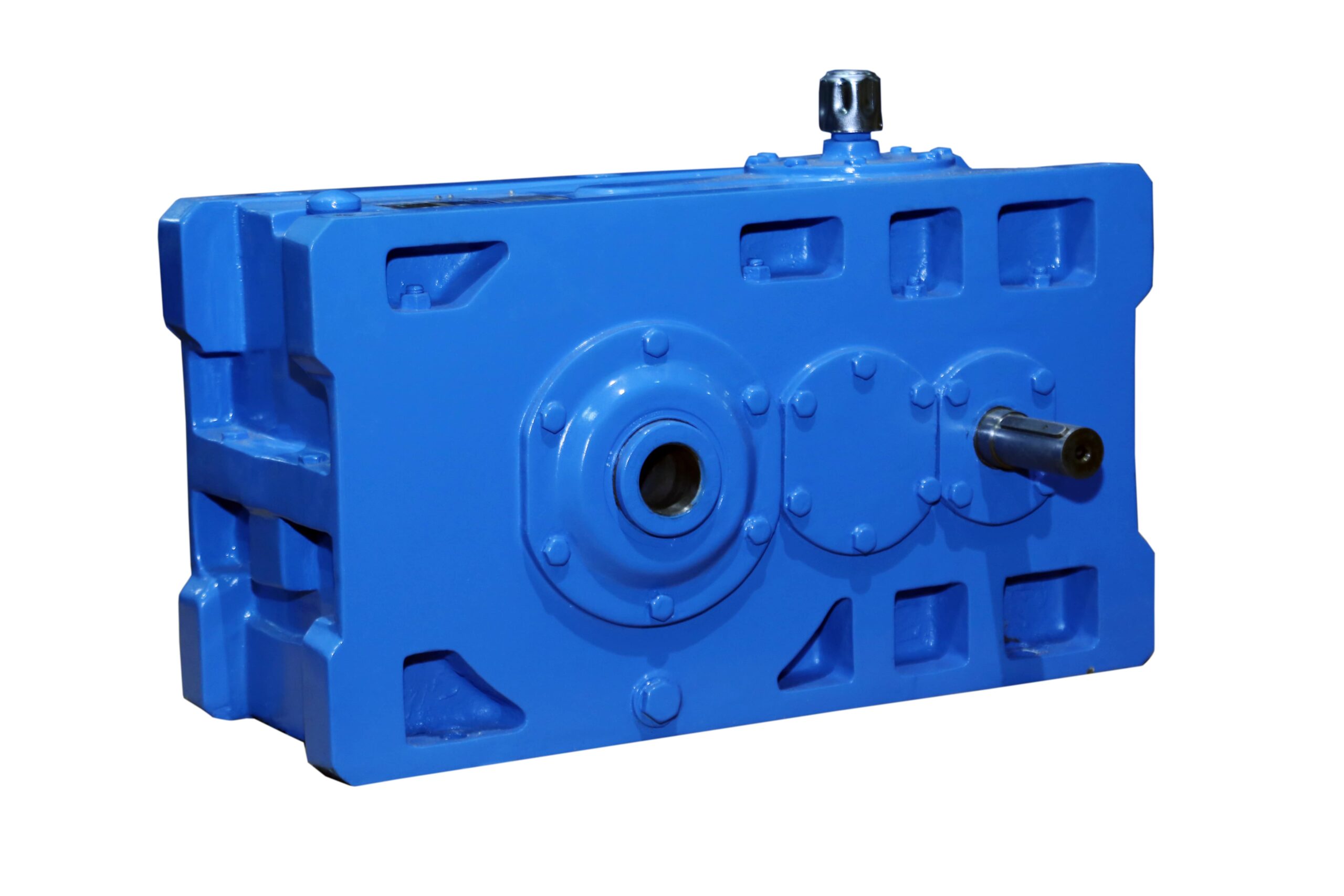

What is a Helical Gearbox?

Helical gearboxes are one of the most widely used gearboxes and they are more effective than any other gearbox. Their configuration facilitates many performances.

Helical Gears Definition

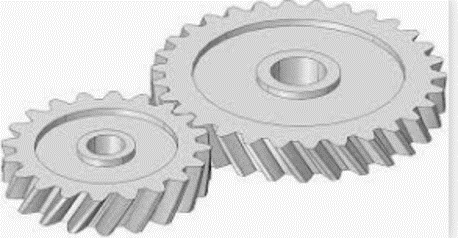

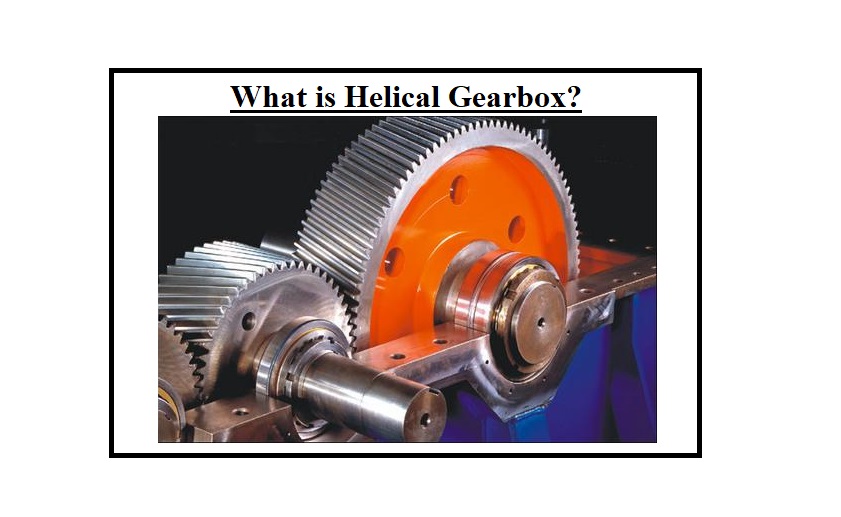

Helical gears are power transmission instruments primarily utilized to reduce speed and increase torque between turning shafts. Fundamentally, they can be divided into two forms, those that transmit energy between parallel parts and those that transfer power between non-parallel components, typically introduced as cross-axis gears. While a helical gear in section view has the identical involute tooth shape like spur gear, it is cut at an angle to the circulation of the gear blank. This angle is introduced as the helix angle. Helical gears are explained below, along with a discussion of their performance and usual applications.

Helical gears contain special teeth that are placed at a particular angle to the shaft. This leads to more than one tooth being in touch during the function, making the gear capable of tolerating more load. This configuration also allows helical gears to perform quieter and smoother than spur gears because of the load sharing between teeth.

The modular model and production of the helical gearbox provide several engineering and performance advantages, containing a high degree of interchangeability of components and sub-assemblies. This offers economical construction while keeping the best standard of component integrity.

Helical Gearbox Working Principle

A helical gearbox includes a set of helical gears. Helical gears are one kind of cylindrical gear with the slanted form of tooth trace. In comparison with spur gears, they have a higher contact level, less vibration, excel in quietness, and can transfer larger loads. A set of helical gears has an identical helix angle, but the helix hand is on the opposite side. Visit here to explore more about the helical gearbox.

When the reference part of the gear is in the standard form, by tilting the hobbing instrument, the spur gear hobbing tool and hobbing machine can be employed to create helical gears. Due to the twist of teeth, their production has the disadvantage of more problematic construction.

As discussed before, the helical gears can be categorized into two forms by the reference section of the gears being in the turning plane (transverse module) and the standard plane (normal module). If the reference component is in the turning plane, the center gap is as same as the spur gears as long as they have the identical module and number of teeth. This permits simple swapping with spur gears.

However, in this application, they need special grinding stones and hobbing cutters, leading to higher construction prices. Otherwise, if the reference part is in the standard plane, it is feasible to use spur gear hobbing tools and grinding stones. However, the identification module and number of teeth in spur gears no longer match the center gap of helical gears, and swapping becomes very problematic. Besides, the center gap is commonly not an integer.

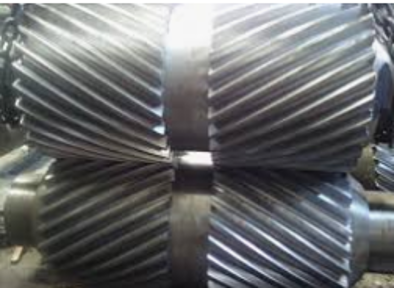

Although spur gears do not create axial thrust loads, due to the twist in the tooth trace, helical gears generate axial thrust force. As a result, it is suitable to utilize thrust bearings to absorb this load. However, combining left-hand and right-hand helical gears and making double-helical gears will remove the thrust force.

Helical gears are typically used in automotive transmission applications by replacing spur gears. Unlike spur types, helical gears, and helical gearboxes both have the potential to conduct a smooth performance. The teeth on a helical gear are cut at a special angle based on the face of the gear. So, during the operation, when two of the teeth begin to engage, the contact is gradually starting at one section of the tooth and keeping the contact on as the gear turns into full engagement. When it comes to transferring, the helical type is the most typically used gear, and it even creates large amounts of thrust.

Fundamentals of Helical Gearbox Operation

A helical gearbox is technically a spur gear set with a 0° helix angle. For helical types, helix angles mostly run between 15° and 30°. The normal gear tooth form is detected as the 20° involute spur. Simultaneously, 14-1/2° involute spur gears were usual, but this is no longer so. These latter-degree specifications are known as the pressure angle of the tooth. The line of touching the two teeth follow as they come into and out of the main mesh.

The pressure angle will remain the same throughout the meshing just for the involute gears of individual teeth. The genius behind the main tooth form is that it presents theoretically fixed velocity ratios even when the center gaps are not completely set. This requirement for a fixed velocity ratio is occasionally called the fundamental rule of gearing.

The best method to understand a helical gearbox is to imagine many same spur gears cut from paper and joined together such that each successive section progresses gradually forward of the one before it. For such a configuration to operate, the mating gear would require to stagger its sections in the opposite direction. Therefore, mating helical gears on parallel shafts is undoubtedly left-handed and right-handed.

Handedness leads to thrust forces, something not produced by mating spur gears. Models employing helical gears should deal with this thrust loading with the use of roller or ball bearings capable of managing axial loading.

Advantages of Helical Gearbox

Considering the paper design again, it is simple to see each spur gear layer mating with its match gradually before the next section makes contact, a distinction over spur gears where touching happens at the same moment along the entire teeth face. Since the width of each tooth is greater, more teeth are in touch at any given time as well. Therefore, the helical gearbox transmits loads more smoothly than spur types do. This results in higher load capacity, higher speed potential, and quieter running. Some advantages of helical gearboxes over other types are summarized below:

- Due to the thrust forces and increased sliding friction between components, the helical gearbox performs at lower efficiencies than spur types.

- The angled teeth engage more gradually than spur gear teeth so that they can run more smoothly.

- A helical gearbox, as well as helical gears, is mostly durable and perfect for high-load applications.

- It has the potential to transfer power and motion between either right or parallel-angle shafts.

The Efficiency of Helical Gearbox

The set of helical gearboxes has parallel shaft gears, and its particular mesh is commonly all rolling touch, so its basic efficiency is considerable, ranging between 90% to 99.5%.

Radial Module and Normal Module

For involute helical gearboxes, some types use the normal (perpendicular to teeth) module arrangement, and others are employing radial (perpendicular to the shaft) module configuration, which has differing tooth shape reference sections.

As the standard helical gears, professional constructors offer two line-ups of radial module arrangements series and normal module system types, and we will list the main differences between the two below.

First, the normal module set of the helical gearbox has the benefit of being capable of employing identical tooth-cutting tools such as grinding and hob stones as spur gears. In other words, in comparison with the new production of later explained radial module form of helical gears, they can be constructed more economically. Otherwise, according to the helix angle, compared to the identical module and number of teeth in spur gears, the pitch circle diameter becomes great, and changing spur gears with the identical module and number of teeth, helical gears cannot be performed without varying the center gap which is a disadvantage of the normal module system.

It is also problematic to keep the center gap to simply manageable integer numbers. The main benefit and merit of the radial type is the reverse of the normal module configuration. The first advantage that can be noted is because the real value of the pitch becomes low in comparison with the normal pitch even with the helix angle, it is feasible to replace them with spur types of the identical module and number of teeth while keeping the same center gap. As for a drawback, since the real radial pitch varies with each helix angle, it becomes essential to gain hobs and grinding wheels for each helix angle which practically leads to a raising in production costs.

Why Should We Use Helical Gearbox?

Helical gearboxes are using a set of cylindrical gears whose teeth are not parallel to the turning axis. The teeth appear as a segment of a helix that makes it transform power between right or parallel angle axes. The basic difference between a helical gearbox and other types is that the teeth create a helix and can operate more quietly. Another advantage of employing these gearboxes is that they have more potential to transmit power between two parallel shafts compared to the equivalent width and similar module of spur gears. And, of course, there will be less tear and wear as the power will be distributed between several teeth.

Based on their requirement for applications in various industries, there are different modifications of a Helical Gearbox.

Single Helical Gear

Single helical gears are the types that are at a particular angle to the axis. We can have the right and left-hand orientation of the gears. The basic features of the gear are getting more surface touching and power carrying capacity.

Double Helical Gear

Double helical types are sub-type of helical gearboxes, in which two helical sections are installed close to each other with a gap dividing them. Each section has similar but opposite helix angles. Using a double-helical arrangement of gears removes thrust forces and provides the possibility of higher tooth overlap and smoother performance. Like the helical type, double helical gears are typically employed in enclosed gear systems.

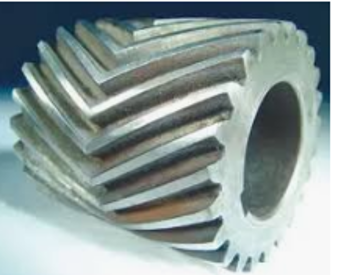

Herringbone Gear

Herringbone types are similar to the double-helical form, but they do not have a distance separating the two helical faces. Herringbone types are commonly smaller and are perfectly suited for high-vibration and shock cases. Herringbone form is not employed very often based on their production difficulties and high price.

Herringbone gears provide a gear-based way of removing thrust. Half the face is cut in one direction while the other half is cut in the opposite direction, beneficially balancing the thrust improved by the gear. According to the production method used to create such double-helical gears, a central gulley may be needed for the teeth may be staggered or for tool clearance.

An exception to handedness is in cross-axis types, where the parts are perpendicular. In these cases, the two gears will be of the same hand. Shafts for helical gearbox can cross at any angle.

Applications of Helical Gearbox

Most of the reputable industrial gearbox manufacturers propose helical gearboxes to operate under heavy power efficiency and, of course, when we require silent performance such as automotive systems. Some of them include:

- Steel, rolling mills, power, and port applications

- Printing industries, fertilizer industries, and earth-moving industries

- Plastic industries, textile industries, food industries, elevators, conveyors, compressors, blowers, oil industries, and cutters

The sound a manual transmission system produces when driven in reverse presents a pretty good illustration of the quietness of helical types. That distinct whine is based on the use of spur forms for reverse (so they may be “changed” – all the other instruments being in constant mesh). Helical gears are employed for the forward velocities and are especially quieter. Some 4-wheel drive transfer systems use spur types for the low range where velocities are slow and the noise is not unpleasant.

Industrial gearboxes are provided in both helical- and spur-gear configurations. The debate as to which to apply centers on the particulars of a certain case. Where noise is an issue, helical types make sense particularly if the gear train will be working at medium to high velocities. Where space is restricted or weight is an important matter, spur gearing may be a more suitable method as the requirements for power thrust-carrying bearings are decreased. Spur gears are typically less costly to construct than helical gearboxes, though the difference is just mildly considerable. Costs are added to the model of the more robust shaft bearings/supports required for helical gears.

This discussion considers parallel shafts. The option is no longer between the spur and helical gears for cross-axis shafts but between helical, worm, and bevel gearing. Helical types provide a less expensive method for transmitting power between crossed shafts, but their potential to transmit great loads is diminished compared with their capacities on parallel arrangements. One usual application of crossed-axis helical types is the gear pair employed to run the automobile engine oil pump/distributor shaft.

Bevel gears offer significantly higher capacity than helical gears, albeit at higher prices. Worm gears provide severe reduction levels but need heat management of lubrication based on the immense sliding friction they create.

Speaking of bevel forms, helical tooth types are always employed to generate so-called spiral bevel types. Information on these instruments can be found in our comprehensive post on bevel gears.

Herringbone gears can sometimes be replaced with spur types as direct replacements, but more difficult production makes them more cost-effective. Herringbone gears are typically used in very large transmission applications, such as shipboard basic reduction gears.

Gears are generally constructed of AGMA grade 20 cast iron, with greater grades present for increased strength at increased prices. Steel is always employed as a pinion substance meshing with a cast iron gear to obtain better balance to the component wear. Heat treatment can warp gears, so it is commonly just used with gears made of alloy steel. Grinding after the heat process can refine the tooth profiles. Bronze is applied to create gears as well. Different plastics are also used to produce gears, sometimes as gear that combines with a steel pinion or cast iron.

In addition to the above applications, there are many other usages. The overall application of helical gearboxes and helical gears is widespread. Keep an eye on the space to explore more.

Helical Gearboxes are the most effective devices constructed in the industry and work at 98% efficiency just after Planetary types.

The angled teeth engage more slightly than spur-form teeth so that they can operate more smoothly. Helical gearboxes, as well as helical gears, are the most durable and perfect for high-load cases. It has the potential to transfer power and motion between either parallel or right-angle configurations.

In Addition to the above, they also find applications in extruders, crushers, cranes, coolers, mixers, and conveyors, which are all low-power systems.

Download What is Helical Gearbox PDF

You can download the PDF file of the entire article by clicking on the following link.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- What is a Reduction Gearbox?

- What is a Helical Gearbox?

- What is a Worm Gearbox?

- Types of Bevel Gears

- The Ultimate Guide to the Types of Gearbox

- Industrial Gearbox A Comprehensive Review on Features, Types, and its Usability

- Gearbox Components and Parts: Everything You Need to Know

- The Difference Between Gearbox and Transmission

- The Stages of Reverse Engineering an Industrial Gearbox

- Top 10 Gear Manufacturers and Suppliers in the USA in 2022

- What is Planetary Gearbox and How Does it Work?

What is the extra bore hole for on the helical gear box

The output shaft and bore size must fulfill client specifications for sizing an application. These might include whether the unit has a stainless output, a keyed or keyless shaft, a keyed or keyless hollow bore, or a flanged output in combination with any of the above. Obtaining the suitable bore size on a unit may necessitate the acquisition of a larger gearbox or a different design of gearbox to accommodate the customer’s present shaft. In certain cases, the client can adjust their shaft to employ the most cost-effective unit while still achieving the best results.

I hope that this answer will be helpful for you Julie.

Really great written article, appreciated.

I am here to also helps you about, if you are looking for custom-designed helical gearbox or geared motor then I whould recommand you purchase them from “Rehfuss”. They are capable to develop these products as per your special requirements and deliering worldwide at best price.