What is Isolation Valve? Working Principle & Types – In this post from Linquip, we are going to discuss the operating concept and many types of isolation valves. Fluid handling systems are incomplete without isolation valves. They are specifically made to stop the flow of process media to a specific location. This can be done for a variety of reasons, including both safety and general upkeep.

What is An Isolation Valve?

It’s a fluid handling device that may be used to stop the flow of process media in one spot for maintenance or safety reasons. It’s possible to connect external equipment to a system using these connectors, as well as offer flow logic (choosing one flow channel over another). An isolation valve is categorized as such because of its intended usage in a system, not because of the valve’s specific kind or design. As a result, a wide variety of valves fall within the category of isolation valves.

If you’re having trouble visualizing an isolation valve, picture the valves that are often found beneath a kitchen or bathroom sink. As a general rule, these valves are left open so that the user may adjust how much water flows from a spigot above the sink without having to go below the counter. The isolation valves are closed to stop water from flowing while the spigot is being changed (i.e., the system needs repair). Even the spigot may have the same sort of isolation valve in this setup. However, they are categorized as isolation valves and control valves because of their specific functions. It is common for isolation valves to be made of lower grade globe valves since they are only used in the completely on or fully off positions. For these less-priced models, the stem is threaded straight into the body without the need for a bonnet or seal. A rubber washer and a metal cap resembling a gland nut cover the stem. If the disk is not fully closed and inserted in the right orientation, the top washer will be compressed against the stem and leaks because they do not have a stem seal.

Different Types of Isolation Valves

It is possible to categorize isolation valves depending on how they move or how they are designed. These are the kinds of isolation valves:

- Rotary Movement Valves

- Rocker Style Isolation Valves

- Linear Movement Valves

- Pinch Valves

- Diaphragm Isolation Valves

Rotary Movement Valves

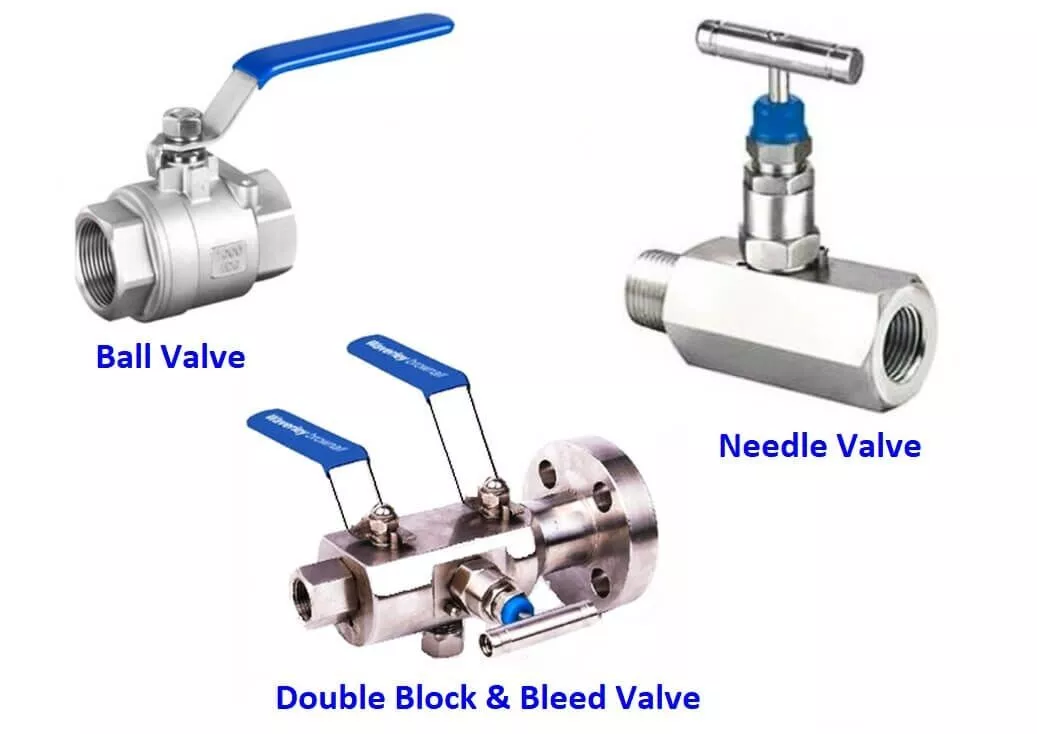

A rotary movement valve is a popular form of the isolation valve. Valves with rotary movement can be rotated. Ball valves and butterfly valves are the two most common types.

Ball valves have a handle that tells you what is going on with them. You can tell if the valve is open or closed by checking the status. These valves are excellent for shutting off a system with a tight seal. A major benefit of ball valves is that they can be cleaned quickly and their upkeep is very simple. There is a lower risk of choking since they can be readily cleaned. Valves must operate slowly to prevent damage to the gauge or diaphragm of the transmitter.

Instrument isolation is made simple with needle and ball valves. A hollow sphere with holes drilled into it is what makes up a ball valve. With no impediment, the valve is open and there is no need for a spool to be inserted. The valve closes and prevents fluid flow when the ball is rotated.

The disc in a butterfly valve revolves around a shaft. When the disc is open, the plane of the disc is perpendicular to the direction of fluid flow. When closed, its posture is perpendicular. These valves are ideal for low-pressure applications. Additionally, butterfly valves are small and light. These make excellent use of the little area available because of their design.

Rocker Style Isolation Valves

Solenoid-operated tools, rocker-style isolation valves, are similar to diaphragm isolation valves. These valves employ a rocker mechanism to seal the seat of the valve and prevent fluid from flowing through it. A two-way valve or a multi-port diverter/selector can be used with these devices.

Linear Movement Valves

A linear movement valve is a form of the isolation valve. Linear movement valves are valves that travel in a straight line, which is why they are named so. Gate valves, globe valves, diaphragm valves, and pinch valves are all examples of these valves.

Pinch Valves

A pinch isolation valve can also be employed to open and close the fluid’s flow path. To open or shut the path, they use a disposable, detachable tube that they squeeze.

Diaphragm Isolation Valves

Diaphragm isolation valves are also known as membrane valves. The valve seat is sealed by a diaphragm in these solenoid-operated devices. In this way, the valve is able to separate the fluid flow channel. Alternatively, they can be used as a two-way or three-way on and off system to control the flow of fluid.

Different Types of Isolation Valve: Benefits and Drawbacks

Flow control, the ability to work at high temperatures, and good metal-to-metal sealing are all advantages of gate and piston valves. Their disadvantages include only one-way flow (except for the gate valve) and the possibility of fluid accumulation on the damper depending on the type of fluid, shortening the stroke length.

Ball valves, butterfly valves, and monoblock valves, for example, have advantages like minimal pressure drop, ease of use, perfect sealing, and remote position detection. They have a few drawbacks, such as their heavy weight and the possibility of ruptures from the sealing element during the process. Another drawback is that, due to their design, the opening and closing torque values after a certain nominal diameter are excessive.

However, keep in mind that while different types of isolation valves have their own set of drawbacks, they also have their own benefits. They can aid with flow management and maintenance by utilizing them. As a result, you must pick which one provides the most benefits and is most suited to your needs.

Applications of Isolation Valves

Finding the best fit between a design’s requirements and the valve’s characteristics is key to selecting the best valve for your application. Because so many factors are involved, this isn’t usually an easy task. For example, how much flow is required and what is the medium pressure? Are there any space restrictions, power constraints, or a minimum reaction time or lifetime that must be met? What kind of media is being utilized, and what building materials are suitable for it? Are there any particles in it? Cross-contamination: how serious is it? Is disposable tubing a good idea? The chart below shows some of the distinct properties of these types of valves and may be used as a reference for choosing the correct type of valve for a certain application.

The isolating valve should be located at:

- Each appliance

- A flushing cistern

- A pumping apparatus

- A thermostatic mixing valve

- The outlet of a storage tank

- Each pumping apparatus

- The inlet of a storage tank.

Why Do We Employ Several Isolation Valve Types?

Isolation valves have been developed to block the flow of various fluids. They can make it easier to remove instruments for maintenance. Isolation valves make it easier to halt and redirect process media for various objectives, such as moving the flow to a new area. They can also assist in the shutdown of process facilities in the event of drain or vent lines. They are closed for maintenance or repair, yet they are open under regular conditions.

Conclusion

In this post, we have briefly discussed the working principle, types, and applications of isolation valves. At Linquip, you can find numerous Valve Companies, along with various Service Providers and Distributors.

FAQs about Isolation Valves

1. What is the difference between a check valve and an isolation valve?

Although check valves may efficiently stop the reverse flow, they should never be used to hold live steam in a segment of pipe instead of an isolation valve. Check valves, like isolation valves, come in a variety of designs, each suited to a specific use.

2. Is the isolation valve and gate valve the same?

In a fluid handling system, an isolation valve blocks the flow of process media to a specified point. In a fluid handling system, the isolation gate valve is used to block the flow of the process medium.

3. Do isolation valves restrict flow?

Closing the isolation valves has no effect if you’re using a mains pressure system and the taps aren’t rated properly (you can only obtain taps for gravity-fed systems). It restricts the flow, so when you completely open the taps, the flow is reduced, lowering splashback and other issues.

4. What is the isolation valve in the fire Main?

Isolating valves separate the segment of the fire main within the machinery area holding the main fire pump or pumps from the remainder of the fire main and must be installed outside the machinery spaces in a readily accessible and tenable location.

5. Is a butterfly valve An isolation valve?

Butterfly valves combine full isolation and control in a single device. They are suitable in applications that require positive isolation and are designed for accurate flow and pressure control.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Provider

Read More In Linquip

- 5 Main Types of Isolation Valve

- 10 Types of Water Valves: The 2022 Ultimate Guide

- The 6 Best Tubeless Valve Stems in 2022

- What is Poppet Valve? Working Principle, Types & PDF

- What is Manifold Valve? With Function & Types

- What Is Linear Valve? With Example, Working Principles & Types

- What is Balancing Valve? Working Principles,Types & Function

- What Is Actuated Valve? Working Principle & Types

- What is Air Valve? Working Principles & Types (Clear Guide)

- What are Rotary Valves? Working Principles & Types

- 6 Types of Non Return Valve (Ultimate Guide)

- Best Pressure Reducing Valves of 2022