What Is Linear Valve? Working Principles & Types – This is the question we will talk about through this article. The linear motion valve is made up of a closure member that moves in a straight line in order to start, stop, or throttle the flow.

There are various types of closure devices, including discs, slats, and flexible materials such as diaphragms. Although linear motion valves operate more slowly, they offer an increased level of precision and control over the position of the closure member.

It is possible to use the device for:

- Moving a disc or forcing a plug against an orifice.

- The movement of a slat, cylindrical, or spherical surface through an orifice.

- Flowing a flexible material into a channel.

There are several examples of linear motion valves, including gate valves, globe valves, fixed cone valves, needle valves, and pinch valves.

On Linquip’s website, there is a great deal of information regarding linear valves that you may find helpful in learning about them before making a purchase. This will help you select the best product that suits your needs. Whenever you require information regarding any type of valve, either in terms of services or products, Linquip is the most suitable choice for you. The Linquip team is available to answer all of your questions about these equipment. It would be beneficial for you to read Linquip’s article entitled, “What is Industrial Valve? Working Principles and Applications“.

If you wish to take advantage of the full potential of the Linquip platform, then you will have to register as a Linquip Expert. By registering with Linquip, you will be able to display your expertise in industrial equipment in a way that is tailored to the needs of potential clients. Would you be interested in contributing a guest post to the Linquip website? Using the Linquip platform, you can add your own content directly to the site by taking advantage of the Guest Posting feature.

We strongly recommend checking out this link for more information on types of valves.

⇒ View a List of Valves for Sale and Their Suppliers ⇐

Working Principle of Linear Valve

Linear valves are the most popular type of valves available today. Their ease of use and simple design have made them extremely common. These valves, also referred to as multi-turn valves, use a sliding-stem design to control the position of a closure element.

The design options and size options available on these types of valves make them highly versatile. Furthermore, linear-motion valves are more resistant to cavitation compared to rotary valves. In spite of their higher cost, linear valves offer precision and 1:1 linear flow control.

The closure member of linear motion valves moves linearly in order to change the flow rate through the valve. They are generally referred to as linear motion valves because of the shape of their closure member. A linear motion valve can be a globe valve, gate valve, diaphragm valve, or pinch valve.

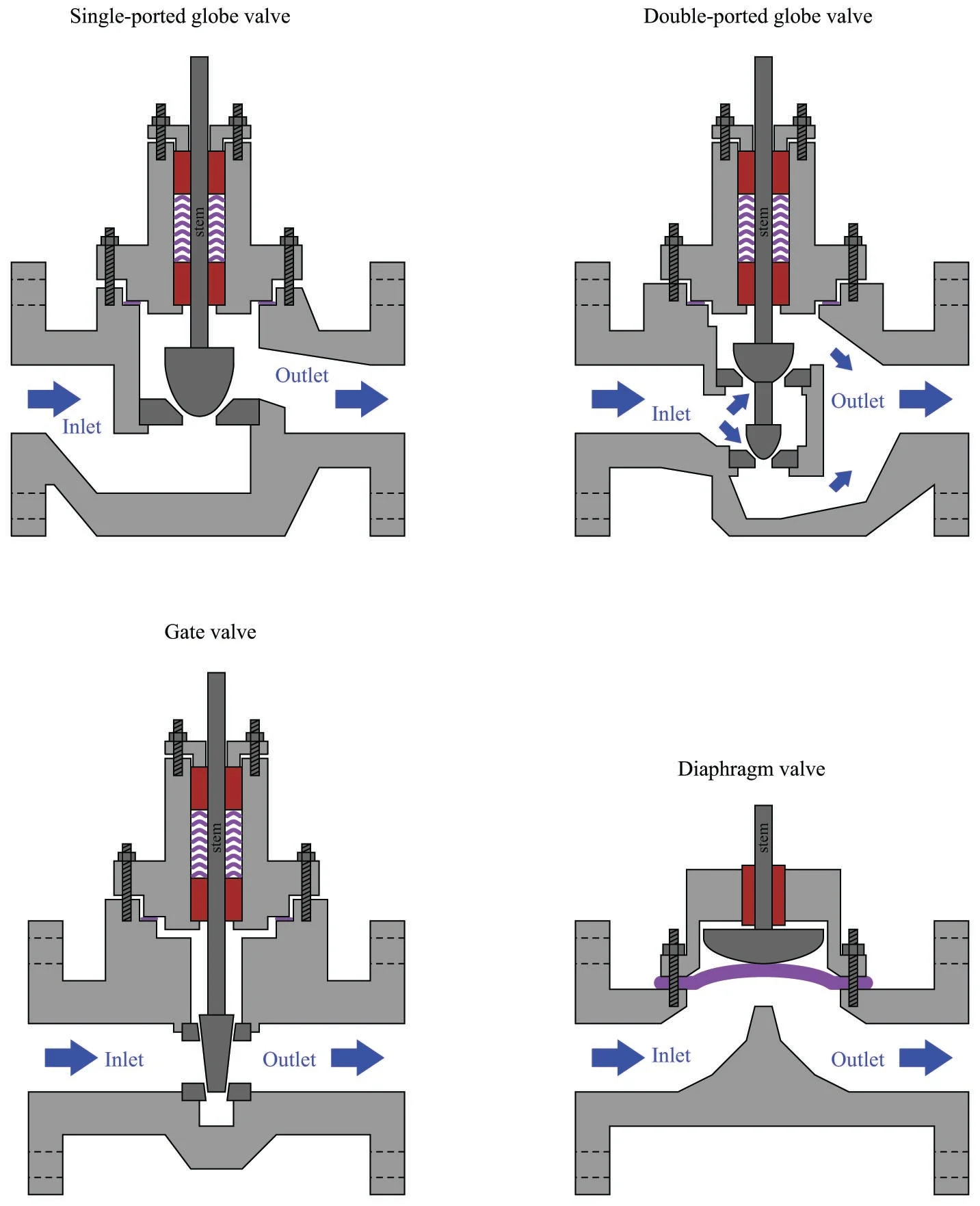

Globe Valve

The globular cavity around the valve seat is what gives globe valves their name. Closure members on globe valves consist of plugs with flat or convex bottoms that slide into a horizontal seat in the middle of the valve. As the plug is raised, fluid can flow through. Despite having good throttling characteristics, globe valves have relatively high-pressure drops because the flow path isn’t linear. The pressure drop associated with globe valves is acceptable in throttling applications and shut-off procedures. Z body, Y body, and angle body designs are the three primary body designs for globe valves.

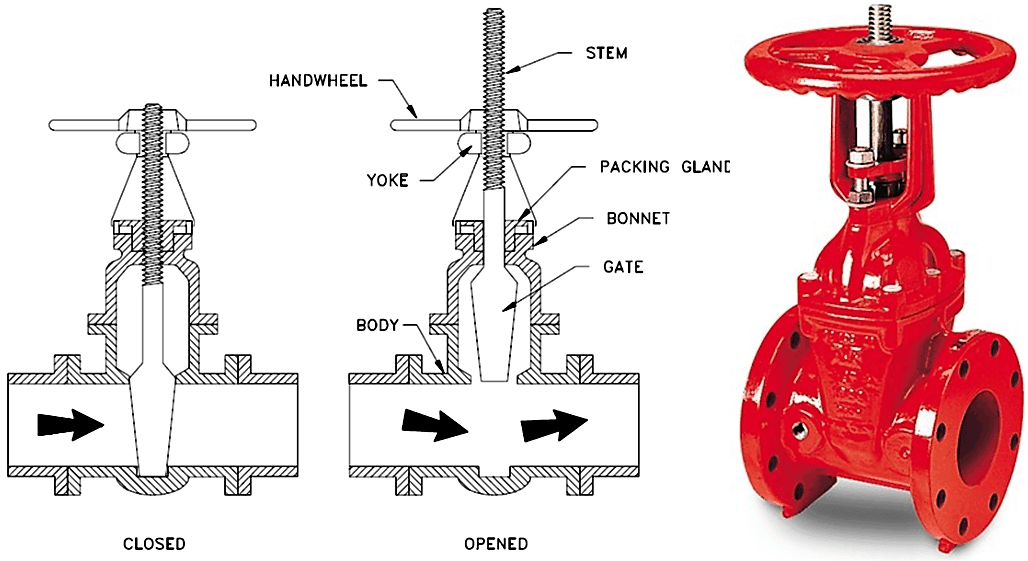

Gate Valve

In a gate valve, the closure member is a flat face, vertical disc, or gate that slides into the valve and blocks the flow. Due to their design, gate valves can only be used in the fully-open or fully-closed position and are typically found in flow shutoff applications. In the fully open position, the disc completely exits the flow stream.

When the gate valve is completely open, it presents virtually no resistance to flow, so it operates with a low-pressure drop. The flow throttling characteristics of gate valves are very poor, and they are not used as throttling devices.

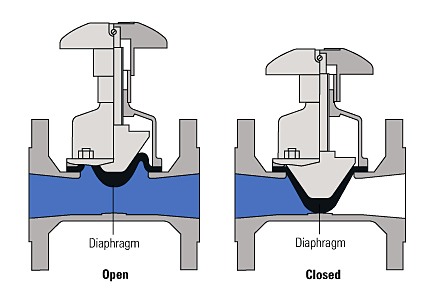

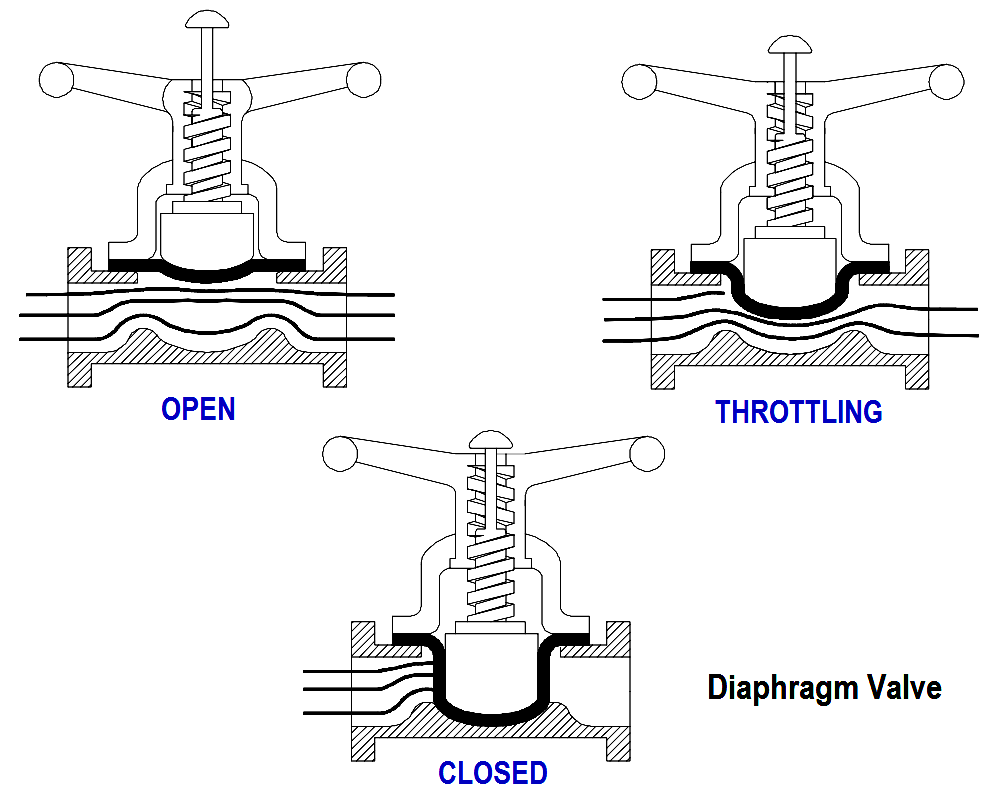

Diaphragm Valve

Diaphragm valves work by deforming a flexible surface (the diaphragm) using the working pressure. Diaphragm valves are primarily advantageous because they do not have stem seals. Diaphragm valves are mainly used to stop slurries or viscous liquids from flowing. They may also be used to throttle fluid flow.

Diaphragm valves may be used for pumping applications that require constant pressure to be applied to the diaphragm. This prevents flow without a motive force (pump), but when there is sufficient pressure to exceed the force on the diaphragm, it allows the flow to continue.

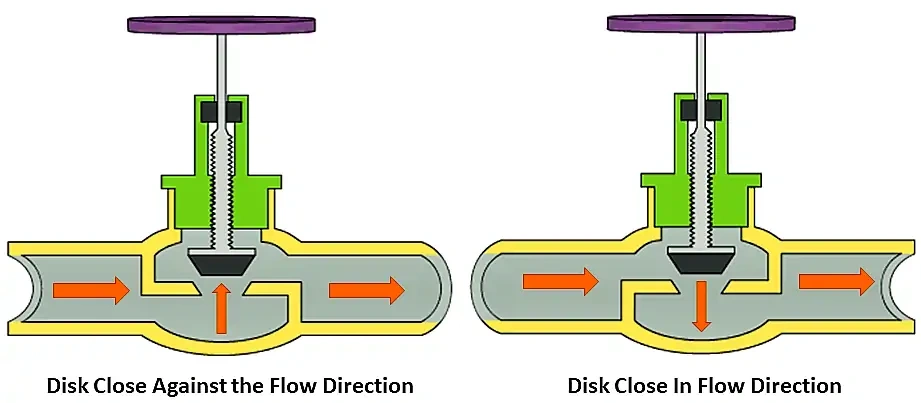

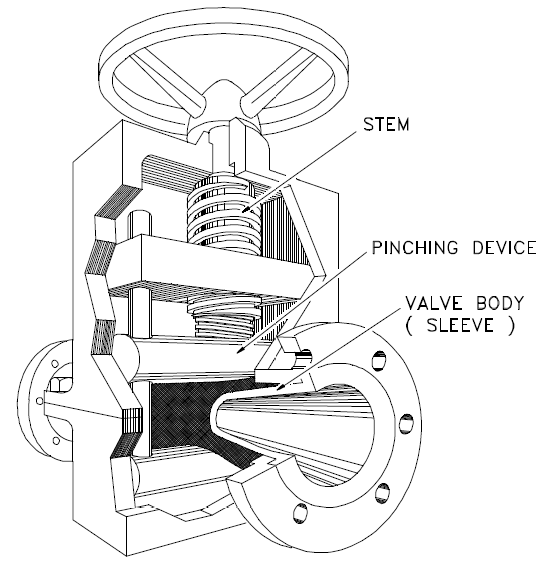

Pinch Valve

The pinch valve functions similarly to a diaphragm valve, except that the entire valve body is flexible, and the closure member closes the valve off to prevent flow. Because pinch valves do not have internal obstructions, they have a low-pressure drop, making them an excellent choice for liquids and slurries containing large amounts of suspended solids.

Types of Linear Motion Valve

There are three types of linear motion valves; the single port valve, the double port valve, and the three-way valve. These should be considered while designing a linear motion valve.

Single Port Valve Body

In the process control applications, the most common valve body type is the single ported design, which is common for NPS (Nominal Pipe Size) 1 through NPS 4. Normal flow direction is most often flow-up through the seat ring.

There are various forms of single port valves, such as globe, angle, bar stock, forged, and split. As high-pressure fluid normally fills the entire area of the port, selecting actuators for control valve bodies with single ports should take into account the unbalance force created. Generally speaking, single ported valves are well suited to small sizes, but they can also be used in 4-inch through 8-inch sizes with high thrust actuators.

Several modern single-ported valve bodies are built like cages to provide guiding for the plug, retain the seat ring, and provide a particular flow characteristic. In addition to offering advantages in ease of maintenance, cage-style trim allows you to change valve characteristics easily by changing the cages.

It is also possible to modify cage-style single-seated valve bodies by changing the trim parts so that the flow capacity is reduced, noise is attenuated, or cavitation problems are abated.

These valve bodies feature the following characteristics:

- The maximum pressure drop is usually 150 psi (10 bar).

- Vibrations caused by speed can occur.

- Typically, seat rings are screwed in, making it difficult to remove them after use.

The valves are generally designed for applications requiring tight shutoffs. It is possible to handle most service requirements using metal-to-metal seating surfaces or soft seating materials that are made of nitrile or other elastomeric materials forming the seal.

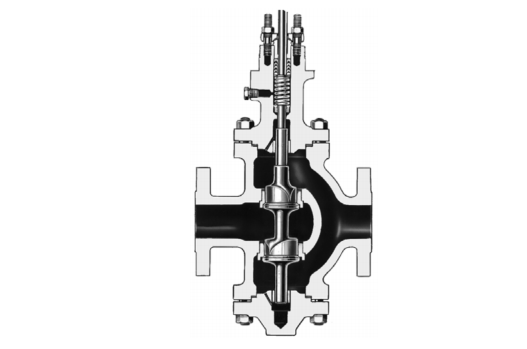

Double Port Valve Body

Double port valves are special trim designs used for the same reasons as pressure-balanced trims: to reduce the force of the process on the plug, thereby reducing the thrust requirement and allowing the use of small actuators.

From the inlet port, flow is directed into the body gallery and trim, which consists of two seats and a single plug with two plug heads.

In refineries, double-ported designs are often used with extremely viscous fluids or where dirt, contaminants, and process deposits are an issue.

The following features are available on port guided double ported valve bodies:

- In the presence of flow, the dynamic force on the plug tends to be balanced since one port opens and the other closes.

- The capacity of bodies of the same line size is generally higher than that of single ported valves.

- As a result, many double-ported body valve plugs are reversible, so they can be installed either as push-down-to-open or push-down-to-close valve plugs.

- A port-guided valve plug is typically used for on-off or low-pressure throttling applications. In severe service conditions, top-and-bottom guided valve plugs provide stable operation.

Three-Way Valve Body

Two types of three-way valves are available: a double-seated valve and a single-seated valve. They each have different applications.

The double-seated configuration is typically used for diverging (flow splitting), while the single-seated configuration is used for mixing (flow mixing). Valve bodies of this type have cage-like trim that provides good valve plug guiding and is easy to maintain.

In refineries and chemical plants, three-way valves are often used around heat exchangers to control heat transfer.

Linear Characteristic Valve

In the case of linear characteristic valves, their position is linearly related to their flow rate. Depending on the position of the valve stem, the flow through a linear valve varies. This flow-travel relationship is approximated as a straight line when plotted in rectilinear coordinates, which gives equal volume variations for equal lift changes regardless of the valve opening percent.

Controlling liquid levels with these valves is often used with various flow control applications requiring constant gain.

There are numerous practical applications for linear valves, not only theoretical ones. There are multiple references for the specific applications.

Some classic examples of linear valve applications include:

- Temperature control using a bypass valve around a heat exchanger.

- A trim valve parallel to a larger main valve.

- For liquid level control or flow control.

- For systems in which the pressure drop across the valve is expected to remain relatively constant (steady-state system).

- When a large percentage of the total pressure drop occurs across the valve.

Download What Is Linear Valve PDF

This article is available as a PDF file by following the link below.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What is Air Valve? Working Principles & Types (Clear Guide)

- What is Solenoid Valve and How Does It Work? 2022 Guideline

- What is Automatic Expansion Valve: A Basic Guide

- Strainer Valve: a basic guide to know it better

- What Is Actuated Valve? Working Principle & Types

- What is Balancing Valve? Working Principles,Types & Function

- What is Industrial Valves? Working Principles & Application

- What is Drain Valve? Working Principle, Types & Applications

- What are Coaxial Valves? Working Principles and Type

- What is Isolation Valve? Working Principle & Types

- What is Block Valve? Working Principle & Types

- Backwater Valves: Working Principles & Types