Capacitors store electric charges. This charge storage can be accomplished by employing several types of capacitors. Mica capacitor is one type of capacitor. This type is the most stable, dependable, and precise capacitor. In this new article in Linquip you will receive basic knowledge of mica capacitors, their characteristics, construction, uses as well as pros and cons. So, follow us.

The mica capacitor

The name “Mica” refers to a grouping of natural minerals. It is a silicate mineral that occurs naturally in granites and other rocks. Mica is one of the oldest dielectric mineral materials used in capacitor design, and it is extremely electrically, physically, and chemically robust. It has been used as a dielectric by capacitor manufacturers for many decades. It has a dielectric constant between 5 and 7.

Other elements found in natural mica include iron, sodium, ferric oxide, and lithium. Because natural mica’s composition varies, mica slated for use in capacitors must be thoroughly examined and categorized, adding to the production cost. While mica capacitors are far less common than aluminum, ceramic, or plastic film devices, their impressive stability and reliable performance make them suitable for a wide range of applications. They are also low-loss capacitors that are utilized where high frequency is required and their value does not vary much over time.

Mica can also be found in trimmer capacitors. Mica capacitors employ a variety of dielectric materials, including Muscovite or white mica, ruby or rose mica, and amber mica.

Mica capacitor is available in a range of voltages from low to high. It has capacitance values ranging from 20 pF to 10 F. It can function well at high frequencies.

The quality of a mica capacitor is impacted by the mica utilized, which is exacerbated by air bubbles, foreign inclusions, and pores. The use of thicker, lower-quality mica may decrease, but not eliminate, the danger of default.

Characteristics of Mica Capacitor

The mica capacitor’s properties are below.

Precision & Tolerance

The least tolerance value of a mica capacitor might be as low as 1%. This is far better than nearly all other types of capacitors.

Strength and Stability

The Mica capacitor is extremely stable and accurate. Its capacitance varies just slightly over time. This is because there are no air gaps in the design, which might alter over time. An epoxy resin also protects the assembly against other outcomes. This implies mica capacitor is not affected by external factors such as air humidity. Their capacitance is not only constant over time, but it is also consistent throughout a wide temperature, voltage, and frequency range.

Low Losses

Low inductive and resistive losses characterize the mica capacitor. Their properties are generally frequency-independent, allowing them to be used at high frequencies. These improved properties come at a cost: like silver mica capacitors that are large and costly.

Performance

Silver mica capacitors’ performance qualities will make them helpful in a wide range of applications that require low-loss and high stability components. As a result, they are suitable for coupling circuits, tuned circuits with high frequencies, power RF circuits, and pulsed applications. The low loss feature of mica capacitors in RF oscillators enables low phase noise and excellent stability.

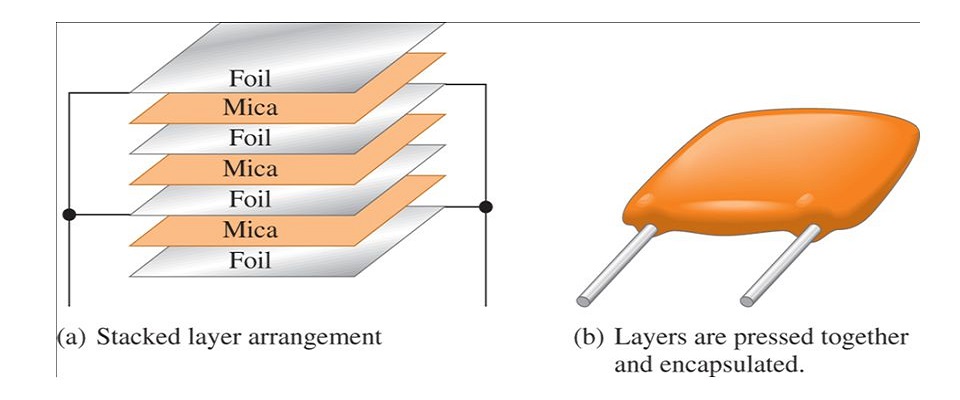

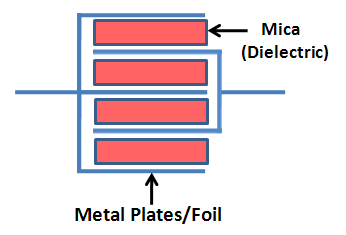

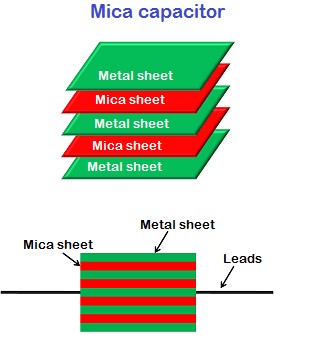

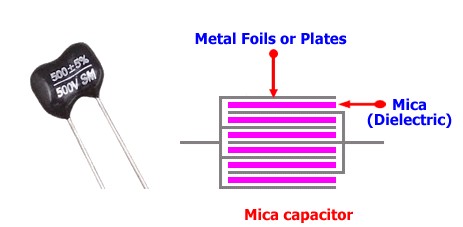

What Construction and properties does a mica capacitor have?

A mica capacitor may be built by stacking metal-coated mica sheets one on top of the other on both sides. Following that, this structure may be coated with epoxy to protect it from the elements. Because of the binding of its precise crystalline characteristic layered structure, mica minerals are electrically, physically, and chemically stable. This capacitor’s thin sheets may be constructed with diameters ranging from.025mm to 0.125mm. But let’s say a little bit more about the previous and present ones.

Mica capacitors in the past were made from thin sheets of mica covered with thin sheets of silver. Although the thin layers were secured and electrons were supplied, there were small air gaps that harmed the accuracy of clamped mica capacitors owing to physical flaws in both layers. Furthermore, mechanical pressures may cause difficulties with the air gaps, and the capacitance value would change over time.

When aluminum and copper were substituted with silver, the performance of mica-metal capacitors increased. Thin sheets of mica separated by thin sheets of silver were stacked to form an assembly in these clamped mica capacitors. Before connecting the mica-silver layers, they were clamped. Because of the air gaps that developed between the two materials, the accuracy of clamped mica capacitors was low. The physical flaws in the two materials produced the air spaces. Because of air gaps, it was typical for capacitance to vary over time in these capacitors. To prevent components from moisture and mechanical damage, manufacturers encased mica-metal systems in plastic casings. Layers of silver-coated mica are used to make silver mica capacitors.

Different Uses for mica Capacitors

Mica capacitor has long been utilized in electrical circuits. It is appropriate for applications that need excellent operational stability, dependability, and temperature resistance.

Mica capacitor is typically employed in designs that require robust, dependable capacitors with relatively tiny values. This sort of capacitor can function efficiently at high frequencies. Mica capacitor is appropriate for high-frequency tuned circuits, coupling circuits, and pulsed applications. Furthermore, the mica capacitor is resistant to extreme temperatures and voltages. It has extremely low inductive and resistive losses. As a result, the quality factor of these passive components is high (Q).

The low-loss feature of these components provides for excellent stability and minimal phase noise in RF oscillators. The performance parameters of the mica capacitor are heavily influenced by the purity of the mica used to make it. These properties can be greatly influenced if the dielectric material contains foreign pores and air bubbles.

Advantages of mica capacitor

The benefits and drawbacks of the mica capacitor are mostly as follows:

- stable capacitance,

- high-temperature operation,

- tolerance at extremely high voltages,

- low losses,

- high accuracy and dielectric offers good insulation,

Disadvantages of mica capacitor

Although mica capacitor was previously highly popular as a high-quality capacitor, it is now gradually being displaced by other types of capacitors due to its size and high cost, which can approach several dollars per piece. Ceramic capacitors are an excellent alternative for mica capacitors in low-power RF applications, for instance.

Conclusion

Briefly, the mica capacitor is the most stable, dependable, and high accuracy capacitor among the various types of capacitors. It has been utilized in the electrical industry for many years. It is available in a range of voltages from low to high. Mica capacitor is utilized in applications that need great precision and minimal capacitance variation over time. It can function well at high frequencies. Thus, this is an overview of the mica capacitor, its features, uses, and pros and cons. We hope you now have a better grasp of what we’re talking about. Furthermore, if you have any questions about this concept, please leave a comment below. Don’t forget to register at Linquip first.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- What is a Non-Polarized Capacitor? Types & Function

- Difference between Capacitor and Inductor- Capacitor vs. Inductor

- What is a Paper Capacitor?

- What is Mica Capacitor Used for?

- What is Electrolytic Capacitor? Usage & Application

- What is Film Capacitor & What is it used for?

- What is Capacitor and How Does it Work?

- 7 Types of Capacitors and Their Uses

- What is Ceramic Capacitor Used for?

- What are Mica Capacitors? Comprehensive Overview

- What is Electrolytic Capacitor?

- What is Film Capacitor? Different Types & Working

- What is Ceramic Capacitor? A Basic Description

- Types of Capacitors: All You Need to Know

- Difference Between Condenser and Capacitor in a nutshell 2022

It would be nice to find somewhere how to read the value code on the brown drop mica capacitor or a statement saying they are labled like other capacitors.

Mica is one most used materials in electric industry, although now due technological advances it is being replaced day by day with more application specific materials. Insightful blog post!

We appreciate you stopping by our site and expressing your thoughts. In future articles, we welcome your feedback and comments.