Osmotic power, blue energy, or salinity gradient power is the power available from the difference in the salt concentration between river water and seawater. Two practical approaches for this are pressure retarded osmosis (PRO) and reverse electrodialysis (RED). There are enormous advantages with osmotic power, namely that it’s the most reliable, cleanest source of renewable power on the planet, it is always existing and more cost-effective than wind or solar power, recycles natural resources (seawater or wastewater) and has a small ecological footprint.

What is Osmotic Power?

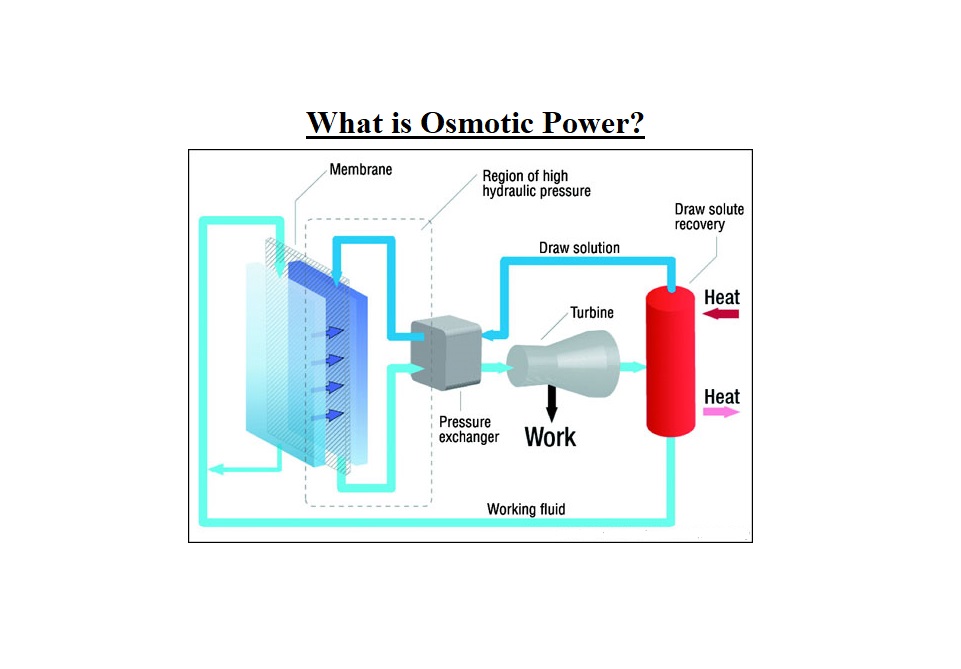

Osmotic Power, also known as Pressure Retarded Osmosis (PRO), is a rapidly growing renewable energy source (RES) that converts the pressure difference between high and low salinity water into hydraulic pressure. This hydraulic pressure can be employed to power a generator that produces electricity. Osmotic power can be created naturally where a river meets the sea or artificially by combining two sources from processing plants (like a wastewater treatment or desalination facility).

Energy Recovery technology operates directly with next-generation PRO membranes to provide cost-effective, stable, and environmentally friendly energy production wherever there is freshwater and saltwater. Pressure Exchangers are an important part of an osmotic power plant because they keep the system’s osmotic pressure high by recycling the water pressure with high efficiency.

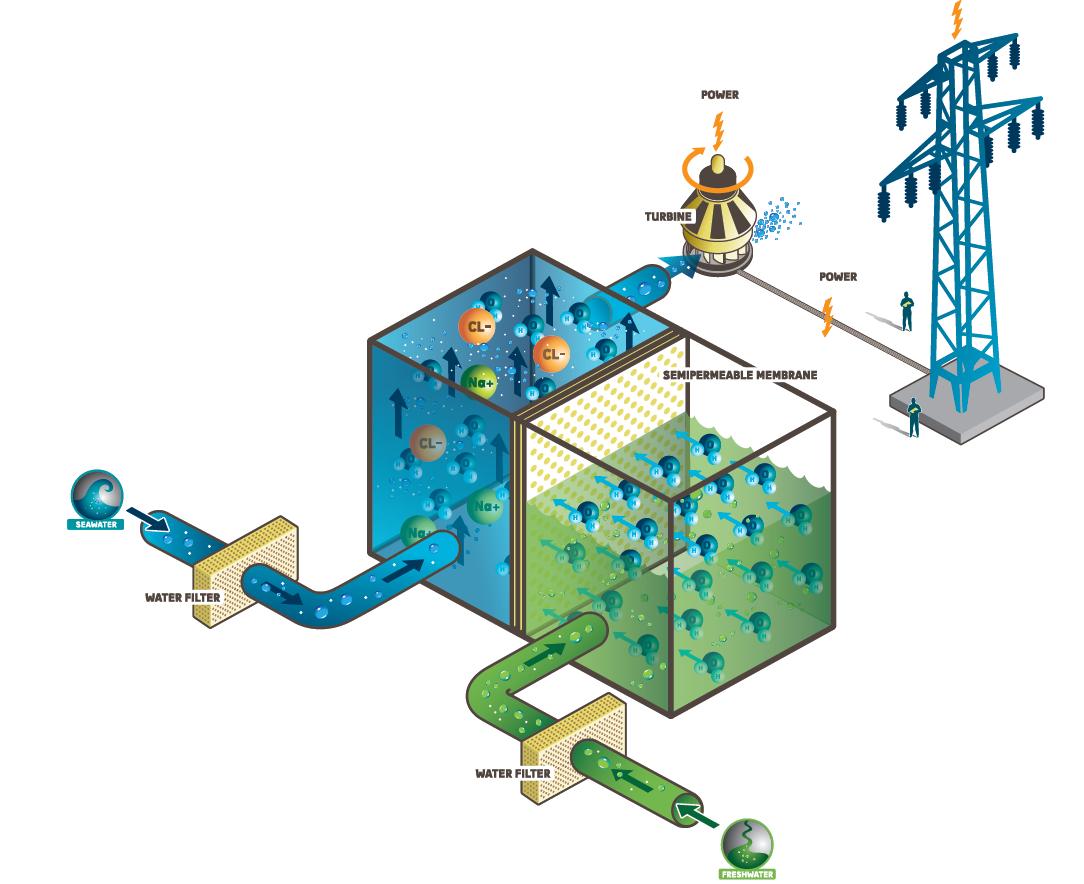

The use of salinity gradients between salt and fresh water to generate electricity is a comparatively modern approach. Even though it was identified and discussed in the 1970s, the study has been slow and much of it has only lately been completed. The reverse electrodialysis (RED) method and pressure retarded osmosis (PRO) are two feasible membrane-based technologies currently being studied. The semi-permeable membrane is used in both technologies.

A semi-permeable membrane has selective permeability, meaning that only certain chemicals can pass through it. Ion-specific membranes are used in both procedures. Both the RED and PRO technologies are still in the research and development stage. The membrane’s cost is the most significant drawback of them. Norway and the Netherlands are particularly active in osmotic power research and development. Furthermore, the hydrocratic generator technique uses salinity gradients to generate electricity.

Introduction to Salinity Gradient of Osmotic Power

The natural mixing of fresh and saltwater is the basis for salinity gradient power plants (IEA, 2009). The energy released by the collision of fresh and saltwater is what this technique tries to capture. Many regions exist where industrial users (such as sewage treatment plants) dump large volumes of fresh or low-salinity water into the ocean; these regions could be suitable for prototyping salinity gradient systems. If you want to explore more about the different approaches used in osmotic power systems, visit here.

Different Types of Osmotic Power Technology

There are different types of osmotic power technology used all over the world. Some of them are presented in this post.

Pressure Retarded Osmosis (PRO)

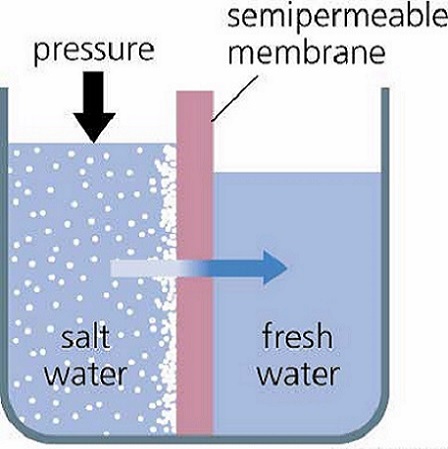

To pressurize saltwater, Pressure Retarded Osmosis (PRO) uses selective diffusion of water across a membrane. On either side of a membrane, freshwater and seawater are arranged, with the seawater side being pressured. As the pressure and salinity of the seawater side rise, part of it is discharged through a turbine, while the rest is pumped into a pressure exchanger to pressurize the incoming seawater, as shown in the figure below.

The main source of energy is the pressure difference across the membrane, which can be as high as 200 meters of the hydraulic head (IEA, 2009). The major research organization investigating PRO is now aiming at membrane performance in the range of 4–6 W/m2. Before the technology can be commercialized, the membrane’s lifetime must be increased to roughly 7 to 10 years. Energy densities of around 1.7 W/m2 have been demonstrated in test modules so far (IEA, 2009).

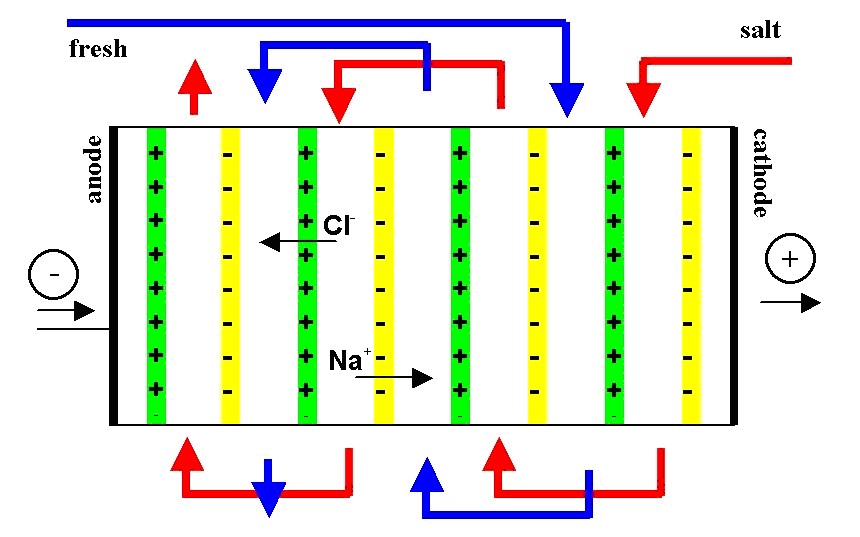

Reverse Electrodialysis (RED)

Another membrane-based method that uses an electrochemical reaction rather than the osmotic pressure is reverse electrodialysis. As shown in Figure below, the device is made up of a stacked series of membranes, half of which are permeable to sodium and half of which are permeable to chloride, with seawater and freshwater flowing alternately between each pair of membranes.

The stack regulates sodium and chloride ion diffusion in the water, causing oxidation and reduction at the iron anode and cathode, respectively. The technology has only been tested on a modest scale (100 mW) so far (IEA, 2009).

Hydrocratic Ocean Energy

The hydrocratic generator is a technology that uses salinity variations to generate power without the use of a membrane. The generator is made up of a tube installed on the seabed with openings in it that allow seawater to enter. A vertically mounted turbine is connected to a generator under the pipe by a shaft.

Freshwater is pumped into the tube at the bottom, and the mixture of freshwater and saltwater causes an upward flow of brackish water that is greater than the initial freshwater injection. This flow drives the turbine, which provides electricity. There have been designs made that use the coolant discharge of power plants or the discharge of waste treatment plants as the primary supply of freshwater. At sea, basic tests of water flow via the device were carried out (IEA, 2009).

Feasibility of Osmotic Power Technology and Operational Necessities

The availability of both fresh water and saltwater is the most important condition for a salinity gradient power plant. This makes the technique rather location-specific, though there are still a lot of places where it might be used.

The majority of the components needed for a salinity gradient power plant are currently commercially available. The pressure exchanger and the membrane are the two main components in PRO and RED. To commercialize osmotic power, these components must be improved and scaled up.

The salinity, volume, and purity of the water supply are all factors in PRO and RED. The greater the difference in salinity between fresh and saltwater, the more pressure (and thus energy) builds up in the system. In the same way, the more water that enters the system, the more electricity that can be generated.

Simultaneously, freshwater and seawater must be as pure as possible. Substances in the water may become trapped within the membrane’s support structure or on its surfaces, limiting the flow through the membrane and lowering power output. Fouling is a phenomenon that is linked to the system’s design, the membrane’s characteristics, and the membrane element.

Hydrocratic energy is still in the demonstration phase of research and development. As a result, the main operational requirements and areas for improvement are still unknown.

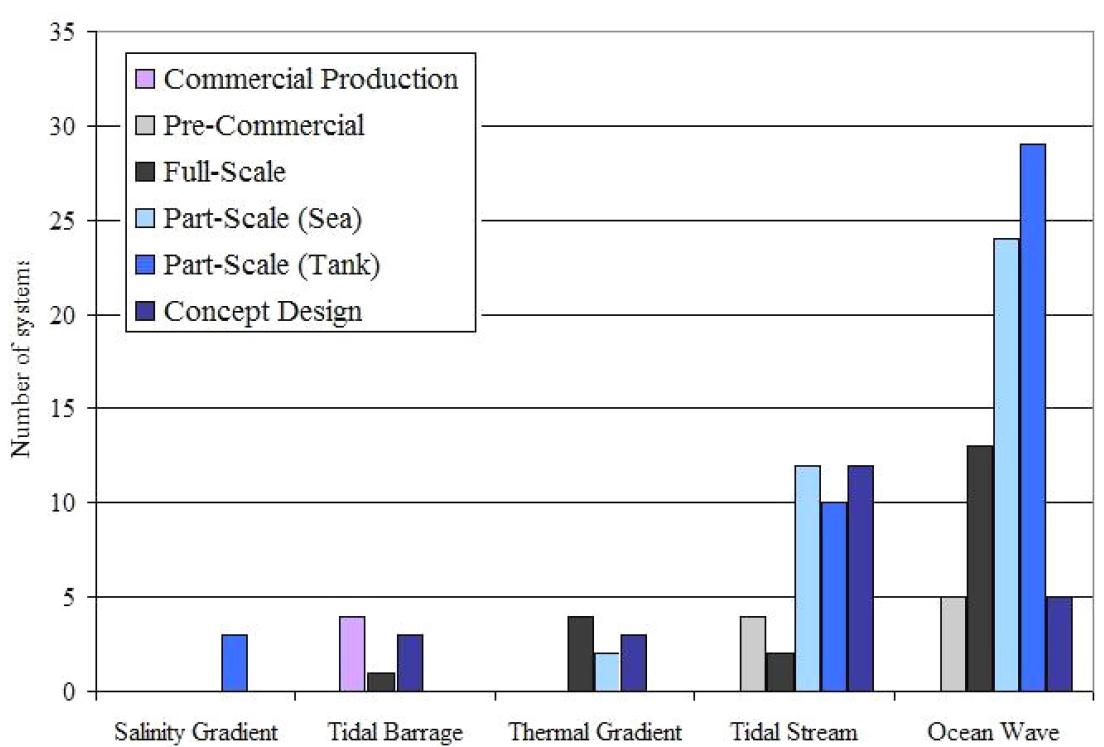

Status of the Osmotic Power Technology and Its Future Market Potential

As shown in the figure below, the technology is still in its infancy. The salinity gradient technologies are now at the part-scale (tank) phase, implying that concepts and prototypes are being tested in a laboratory setting. Other ocean energy technologies have clearly progressed further in the R&D process. The global potential of using the salinity gradient for energy, on the other hand, is estimated to be around 2000 Tera watthours per year (TWh/year). In the figure below, salinity gradient technologies consist of PRO, RED, and hydrocratic energy.

In Norway, a PRO pilot project capacity has been built. The pilot plant’s scope and production capacity are limited to 4 kW, and it’s designed primarily for testing and research. The pilot project has two main goals: a) to ensure that the modeled system can reliably provide power 24 hours a day, and b) to further evaluate the technology developed through parallel research activities in order to significantly improve efficiency. The main areas of emphasis are membrane modules, pressure exchanger equipment, and power generation. A modest RED trial project with a capacity of 1 kW has been installed in the Netherlands.

Why Is Energy Recovery Focusing on Osmotic Power?

Osmotic power has matured; however, it is impossible to implement effectively without Energy Recovery technology. The sweet area for us is where high fluid and high-pressure fluxes coexist. Whether it’s reverse osmosis desalination, oil and gas midstream processing, or osmotic power, our energy recovery solutions absorb pressure that would otherwise be wasted and put it to good use – in a closed-loop pressurized process or converting it to electrical power. Energy recovery has always been on the cutting edge of technology, and osmotic power is undoubtedly the next-generation renewable energy source.

What Does Energy Recovery Technology Do to Facilitate Osmotic Power?

Osmotic power has a lot of potential, but it can only be commercially viable if the cost of producing it is reduced. Energy recovery devices decrease energy use, allowing osmotic power plants to generate sustainable energy. The devices, which run at 98 percent efficiency, reduce energy use by up to 60 percent by recycling energy traditionally wasted as part of the reject stream, helping to make desalination an affordable solution to the global water crisis.

In osmotic power systems, Energy Recovery’s game-changing technology works on a similar basis. Modern technology boosts energy output while lowering energy consumption during the osmotic power generation process, resulting in net-positive electricity production.

How does Osmotic Power Work?

The search for renewable energy consists of attempting to duplicate, harness, or concentrate the natural energy that is always spinning around us into something powerful enough to power a factory, a car, or millions of appliances. In an attempt to collect the energy in the sun’s rays, we replicate photosynthesis. To spin a turbine, we need wind generated by the Earth’s rotation and heat of the sun. To make gasoline, we use bugs that excrete alcohol.

Researchers are getting closer to harnessing osmosis, one of nature’s most subtle and crucial phenomena—one that keeps us alive but is mostly neglected, and certainly nothing we would consider powerful enough to power even a flashlight.

Water tends to chemically balance itself, and in order to accomplish so, it must pass through a membrane. Water containing a low concentration of a substance such as salt will desire to mix with water with a high concentration of the same ingredient. Life depends on this. It’s how plants take water into their roots, and it’s also how basic bodily functions like blood pressure regulation, vitamin absorption, and metabolism work.

History of Osmotic Power Principle and Concept

When water tries to do something but is unable to, it creates pressure. Also, pressure can be used to get things done. Oasys Water, a new company established on Yale University technology, and Statkraft, a big Norwegian renewable energy provider, are both attempting to harness osmosis.

Oasys, based in Cambridge, Massachusetts, has created a new approach to use osmotic pressure to store energy or desalinate water. Statkraft is attempting to refine and industrialize an older concept: capturing the energy provided by osmosis by combining fresh river water and saline seawater at a river mouth. Statkraft is finishing up a demonstration plant that it hopes will demonstrate for the first time that osmosis can actually generate power.

Water from the river will be transferred to one side of a membrane, while saltwater will be sent to the other. Because the membrane stops salt ions from passing through, the saltwater draws fresh water, increasing the water pressure on the salty side. This pressured water will be used to spin a turbine using pressure exchangers similar to those seen in standard desalination plants.

The concept is straightforward. The membrane isn’t one of them. Of course, the membrane must be permeable to freshwater yet impervious to salt ions. However, it must be thin enough to keep the saltwater relatively close to the freshwater, because the greater the osmotic pressure and thus the power, the greater the difference between salty and freshwater. Today’s membranes are quite thick—they have to be thick to avoid tearing—but their thickness creates an area of mixed water that muddles the distinction between salty and freshwater, lowering osmotic pressure.

The membrane used by Statkraft can only produce three watts of power per square meter. Statkraft’s Osmotic Power operation is led by Stein Erik Skilhagen, who believes that osmotic power needs to produce five watts before it can be commercialized. Even a modest 25-megawatt power plant would use a large amount of membrane—five million square meters. (A typical coal power station has 1,000 megawatts of capacity, while a typical wind turbine has 1.5 megawatts of capacity.)

The current Statkraft facility is a long way from achieving this goal. “I would consider it a great achievement if we could create two to three kilowatts,” Skilhagen says. “Nothing like this has ever been done before.”

How about two to three kilowatts? Only enough to power a couple of toasters with that amount of power. Statkraft is investing the time and money ($6 million), according to Skilhagen, because it believes the global potential for osmotic power, if solved, could be huge—as much as 1.5 billion megawatts.

Oasys is attempting to assist nature by substantially raising osmotic pressure. Robert McGinnis, the company’s creator, developed the idea as a doctoral student at Yale University, working under Menachem Elimelech, the director of Yale’s Environmental Engineering program.

Oasys hopes to use this technique to purify wastewater first, and then to desalinate seawater. Reverse osmosis, a method in which salt water is pressed against a membrane that allows freshwater through but not salt ions, is now used to desalinate water. How may reverse osmosis and osmosis be used to accomplish the same goal?

Reversed Osmotic Power Technology

Oasys distinguishes saltwater and saltier water rather than salt water and fresh water. This saltier water is made up of water mixed with a special sort of salt known as thermolytic salt, which is made up of ammonia and carbon dioxide in this case. When these salts are heated, they transform into a gas.

The brine is left behind when this extremely salty solution draws fresh water from industrial wastewater or ocean over the membrane. The thermolytic combination is next given a little quantity of heat, which boils away the ammonia and carbon dioxide, leaving just freshwater. (To repeat the process, the ammonia and carbon dioxide are recombined into a salt.)

Oasys claims that all it needs is waste heat from a power plant or manufacturing because the quantity of heat required is so minimal, under 20 degrees Celsius. Oasys says it can create fresh water for one-tenth the cost of today’s reverse osmosis facilities since it uses just waste heat and a little amount of electricity for pumping water (unlike reverse osmosis, the water doesn’t have to be pressured).

Oasys hopes to finish a small pilot facility by December and is working with industrial partners to put a small system in a factory by the middle of next year.

Then Oasys is looking for a bigger prize. It believes that their approach can be used to create a large, low-cost utility-scale electricity storage device. As we all know, osmosis may be utilized to generate electricity. Because of the strong osmotic pressure produced by its ammonia-carbon dioxide salt, Oasys’ membrane can produce closer to 200 watts per square meter than Statkraft’s.

The concept is to build two massive storage tanks next to a power plant, one for saline water and the other for freshwater. Desalinate the water using the plant’s waste heat. When additional power is required during peak demand periods, mixing the salt and fresh water is used to generate electricity. Its efficiency isn’t remarkable, ranging from 50% to 80%, but that’s not a big deal because the majority of the energy input is waste heat.

FAQs About Osmotic Power

What Applications Do You Believe Are the Best Suited to Use Osmotic Power?

Water covers 70% of the earth’s surface, with 97 percent of that being salt water. By mixing seawater and freshwater, the innovative process of Pressure Retarded Osmosis (PRO) is formed, and the resulting osmotic power acts as a renewable and steady source of electricity. While still in its early phases, the best estimates of osmotic power’s global production potential surpass 1,600 Terawatt-hours or half of Europe’s total energy demand.

The process of converting the pressure differential between high-salinity water and water with lower or no salinity into hydraulic pressure is known as osmotic power. This hydraulic pressure can be employed to power a generator that produces electricity.

There are two basic methodologies for osmotic power:

- Natural occurrence globally where river water meets the sea

- Bringing together two man-made water sources from processing plants

Both ways work, but one generates more power than the other. Method A: Seawater contains 40 grams of salt per liter on average + River Water has a lower power output than Method B: Brine (from desalination) has an average salt content of 60 grams per liter plus treated water. The more power that can be generated, the higher the salinity.

How Long Has Energy Recovery Been Working with Osmotic Power and Where Do You See It Going Next?

Energy Recovery is a procedure in the development of this industry, holding osmotic power patents and piloting the technology. As you may be aware, major engineering companies are examining the potential of this renewable energy source and determining their own entry points. Osmotic power is expected to become the next worldwide development sector for alternative energy due to its ability to be online, supplying power 24 hours a day (compared to solar and wind, for example), and the existing availability of water stream resources.

Do You Think Osmotic Power Is a Viable Alternative Energy for The Future?

According to some estimations, the worldwide osmotic power potential might provide up to 1700 Terawatt hours of energy every year. Osmotic power provides base load energy storage and usage, which is more reliable than other renewable energy sources. Energy recovery methods are well-known around the world for their accessibility and high efficiency, both of which benefit osmotic power.

They have faith in the technology’s ability to deliver consistent results. Their systems are so dependable that they’ve been used in seawater reverse osmosis facilities (desalination) for over 10 years – which is one of the main reasons why major industries choose the energy recovery devices to the competition. Using Energy Recovery technology to reduce the running costs of an osmotic power plant makes osmotic a viable alternative energy source.

Energy Recovery is a global clean-tech approach whose technology captures vast amounts of previously untapped fluid energy from the water, oil & gas, and chemical sectors that would otherwise be wasted, decreasing overall operating costs and carbon emissions. Energy Recovery technology can “complete the loop” on wasted fluid pressure, converting liabilities into assets. The unused energy generates profit and aids in the implementation of long-term technologies on a wide scale and across industries.

Energy Recovery holds a 90 percent market share in the desalination business, with over 15,000 devices installed worldwide. Clean technologies developed by this method have saved 14 billion kilowatt-hours of energy per year and produced over 12 billion liters of clean water per day. For decades, Energy Recovery has been a major energy efficiency pioneer in significant desalination plants across the world, saving its clients $1.4 billion in energy costs. The Carlsbad Desalination Plant recently chose Energy Recovery devices, which will save the plant $12 million per year in energy expenditures while supplying 50 million gallons of water per day.

Does Energy Recovery Have Any Other New Developments in The Alternative Energy Field That You Would Like to Talk About?

Constructors are currently focusing on the global desalination sector, which is growing in regions like China and the Middle East, as well as California and other parts of the United States.

Desalination-based energy recovery systems are presently being explored and adapted for the oil and gas industry. The high pressure utilized in the amine gas sweetening process is now captured and reused, resulting in energy savings of up to 70% and a reduction in natural gas production costs. The advancement of this technology could go a long way toward helping the industry in reducing its carbon emissions. Mining, chemical processing, and other high-fluid-flow operations are all excellent growth potentials for energy recovery devices, and they will continue to be a part of the growth strategy of this approach.

Read More In Linquip