What is PTC Thermistor? – Temperature-sensitive resistors are known as thermistors. There are two types of materials: polycrystalline ceramics and thermally sensitive silicon resistors. PTC thermistors sold commercially can be divided into two distinct types. Resistors made from silicon are very vulnerable to heat, hence they make up the first group. Polycrystalline ceramics make up the other major class. We’ll go over what PTC thermistors are, how they work, and what kinds of situations they’re most suited for in this post.

On the Linquip website, among the many options available to you, you will find all the information you need to know about the Thermistors, as well as information regarding this marketplace. You can count on Linquip to provide you with as much general and reliable information about this topic, whether you’re a professional or a customer looking for a proper company. We recommend you review a list of all Thermistor Products available in Linquip. You can also be encouraged to visit Thermistor for Sale and find the most suitable device based on your applications and demands.

What are PTC Thermistors?

The abbreviation for “Positive Temperature Coefficient” is “PTC.” Positive temperature coefficient thermistors are resistors whose resistance rises in response to an increase in temperature.

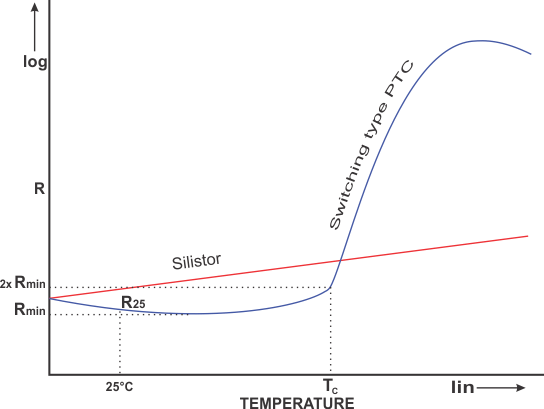

Materials, design, and production methods distinguish two categories of PTC thermistors. Silicon-based thermistors (silistors) are the first category of PTC components. Due to their linear feature, they find application as PTC temperature sensors.

The PTC thermistor switching type constitutes the second classification. A very nonlinear resistance-temperature curve characterizes the switching type PTC thermistor. The resistance of a switching type PTC thermistor decreases when heated, but only up to a specified critical temperature. Resistance increases rapidly as temperature is raised over the critical point. You’ll find these PTC thermistors in many different types of PTC heaters, sensors, etc. This second class includes the plastic-based polymer PTC thermistors that are frequently employed as resettable fuses.

Characteristics of PTC Thermistors

Resistance to temperature for silica-based semiconductors is linear, with a modest slope throughout the vast majority of their useful temperature range. Above about 150 degrees Celsius, they may show a negative temperature coefficient. The resistance of silicon decreases by around 0.7% to 0.8% every degree Celsius in temperature.

Polycrystalline ceramic materials, which are very resistive in their natural form, may be turned semi-conductive by the addition of dopants, and these materials are typically used to make switching PTC thermistors. Most often, they are employed in PTC heaters, which are self-regulating. Most switched PTC thermistors have a transition temperature of 60 to 120 degrees Celsius. But there are produced devices designed for certain applications that can toggle between temperatures as low as 0 °C and as high as 200 °C.

Transition Temperature (Tc)

The graphic shows that up until the point of minimal resistance, switching PTC thermistors have a little negative temperature coefficient. Until it reaches its transition temperature, it has a slightly positive coefficient above this point (TC). The switch temperature, the Curie temperature, and other names are all used to describe this point in the thermodynamic cycle. The resistance of switching type PTC thermistors begins to grow sharply at the switch temperature. Most of the time, the Curie temperature is defined as the point at which the resistance is twice the value of the lowest resistance.

Minimum Resistance (Rmin)

The lowest resistance that can be measured on a switched type PTC thermistor is its minimal resistance, which can be observed on the R-T curve. After this juncture, the temperature coefficient begins to increase.

Resistance Values (R25)

The resistance of a PTC is often stated in terms of its value at 25 degrees Celsius. It’s purpose is to sort thermistors by their resistance. The thermistor is not heated during the measurement since a little current is used.

Dissipation Constant

An rise in internal body temperature as a result of power application is represented by the dissipation constant. The dissipation constant can be affected by a number of variables, including the material of the contact wires, the thermistor’s mounting method, the surrounding temperature, the presence of any conduction or convection routes, the device’s size, and its form. The thermistor’s inherent tendency to self-heat is significantly affected by its dissipation constant.

Maximum Rated Current

A PTC thermistor’s rated current is the highest current that can continuously flow through it at a given temperature and pressure. Its worth is determined by the R-T plot and the dissipation constant. Overloading the thermistor to the point that the temperature coefficient begins to fall again can cause runaway current and destroy the device.

Maximum Rated Voltage

In the same way that the maximum rated current indicates the maximum current that can be applied to the thermistor at a constant temperature, the maximum rated voltage indicates the maximum voltage that can be supplied to the thermistor at a constant temperature. Like the value of the R-T curve, its worth is dependent on the dissipation constant.

Advantages of PTC Thermistors

Positive-temperature-coefficient (PTC) thermistors are a type of temperature-dependent resistor made from certain semiconductor ceramics (PTC). They have low resistance values while at room temperature. The temperature of a PTC increases as heat is produced by the current flowing through it. Once a PTC’s temperature threshold is passed (the Curie temperature), the device’s resistance increases dramatically.

You may use this effect to safeguard your circuits and gadgets against dangerously high currents. Overcurrent in this situation is limited by heating the PTC to a point where its high resistance prevents further heating. After the problem has been fixed, the PTC can be reset by letting it cool down. As a result of this quality, PC thermistors can be employed in overcurrent protection circuits. In the following usage cases, PTC thermistors are shown to be implemented in overcurrent protection schemes.

Applications of PTC Thermistors

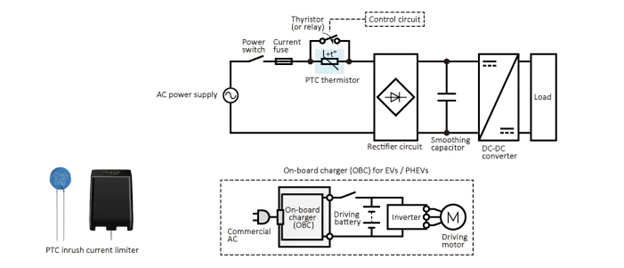

Applications of PTC Thermistors For Inrush Current Limiting

Since they are compact, lightweight, and powerful, switch-mode power supplies (SMPS) are commonly utilized as the electrical power source in electronic equipment. When an SMPS is activated, the smoothing capacitor is immediately charged, resulting in a high-peak inrush current. The smoothing capacitor’s lifespan might be shortened by this inrush current, the power switch’s contacts could be damaged, and a rectifier diode could be fried. As a result, controlling the SMPS’s first surge of current is essential.

An inrush current limiter (ICL) circuit, like the one seen below, uses a PTC thermistor in conjunction with a thyristor (or a mechanical relay).

The uncharged capacitor acts as a short circuit and pulls a large amount of inrush current when the power switch is turned on and the charging process begins. The PTC, which is linked in series to the smoothing capacitor, reduces the inrush current (charging current of the capacitor) while the thyristor is in its high ohmic state (an open state for a mechanical relay). After the capacitor has been charged, the thyristor will provide electrical load by short-circuiting the PTC.

The PTC may fail to short if the thyristor (or mechanical relay) fails to operate properly. When this occurs, the PTC becomes very hot due to the high working current in the circuit. In this high ohmic condition, the PTC is able to reduce the harmful malfunction current to a safe level. A PTC thermistor will not be damaged by this kind of stress.

In the past, it was usual practice to employ a fixed resistor to control inrush current. However, this approach has risks due to the high working current, which might damage the resistor or possibly start a fire.

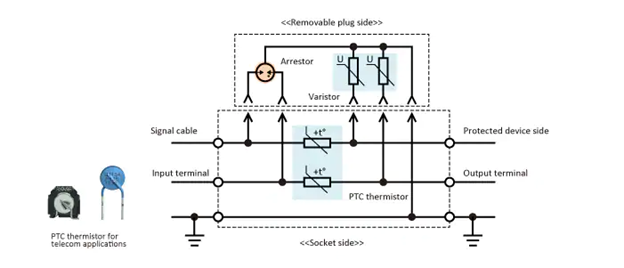

Applications Of PTC Thermistors For Telecom Overcurrent Protection

PTC thermistors are employed in a wide variety of industrial and commercial security applications in addition to their use in telecommunications. Since signal cables used in fire alarm systems, security camera systems, and other network systems that connect numerous sites are susceptible to damage from lightning, surge protection devices (SPD) are installed at crucial points in these systems.

The figure below illustrates one type of protective circuit that makes use of a swappable plug-in SPD. Overvoltage protection is provided via an arrestor and a varistor on the plug side. A PTC thermistor provides overcurrent protection on the socket end.

TDK has a wide variety of PTC thermistors available for use in telecommunications equipment. It is common practice to utilize telecom pair protectors (TPP) for SPDs; these devices typically consist of two PTC thermistors housed in a plastic housing.

The PTC serves a similar purpose to that discussed in the preceding paragraph.

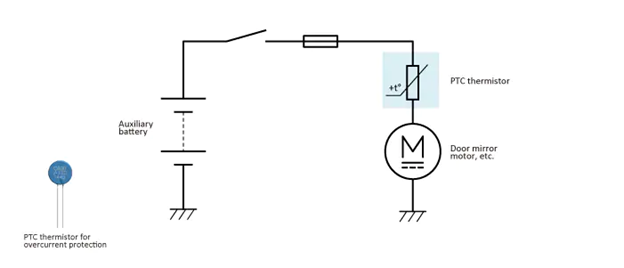

Applications Of PTC Thermistors For Overcurrent Protection

Overcurrent runs through a motor when it is either overloaded or its spinning is halted (locked). Overheating of the coil may ensue. Overcurrent in motors can easily be prevented by using PTC thermistors.

If something is blocking a car’s side mirror and the driver tries to set or retract the mirror, the motor will lock. Overloading the motor winding will have this effect. A PTC thermistor is employed as a safeguard against thermal overload. PTCs get hot due to the strong current flowing through them. When that happens, the PTC’s resistance goes way up, bringing the excessive current down to safe levels where it won’t overload the system. The motors that power features like power locks and power chairs also utilize these overcurrent protection thermistors.

Modes of Operation of a PTC Thermistor

PTC thermistors have two modes of operation—self-heated and sensing—that are selected based on the required temperature range (also called zero-power).

Self-Heating Setting

Since a thermistor’s temperature rises in response to an applied voltage and a sufficient current flow, this property is used in self-heated applications. Resistance increases considerably and much less current can flow when the Curie temperature is approached. The left-hand diagram illustrates this sort of behavior. Near the Curie temperature, the resistance can fluctuate by several orders of magnitude over a very small temperature range. As the thermistor approaches thermal equilibrium, the current will level out if the voltage is held constant. The thermistor’s thermal dissipation factor and the applied voltage both influence the equilibrium temperature. Whenever developing a time delay circuit that responds to changes in temperature, this style of operation is typically used.

Zero-Power Sensing Mode

In contrast to the self-heated mode, this mode of operation has a minor impact on the thermistor’s temperature and, hence, resistance. The sensing mode is typically employed when taking temperature readings in accordance with the R-T curve.

Properties and Construction of PTC Thermistors

The resistance-temperature characteristics of silica resistors are very close to linear, and they are based on the bulk properties of doped silicon. They are manufactured from silicon wafers of varying forms and purities. The relationship between temperature and resistance changes as doping is increased or decreased.

Polycrystalline materials form the switching type of PTC thermistors. Barium carbonate, titanium oxide, and sometimes other elements including tantalum, silica, and manganese are used in their production. After being milled and combined, the components are compacted into disks or rectangular forms before being sintered. After that, contacts are applied before being coated or encased. The production process calls for stringent monitoring of all inputs to ensure quality. A few parts per million of contamination can drastically alter thermal and electrical characteristics.

In order to create polymer PTCs, carbon grains are placed on a plastic substrate. When the gadget is at room temperature, there is little space between the carbon grains, so electricity can flow easily through it. The overall resistance of the gadget increases as it warms up because the plastic expands and the grains migrate further apart.

FAQs about PTC Thermistors

Where are PTC thermistors used?

Some circuits employ resettable fuses or overcurrent limiters in the form of switched PTC thermistors. The body temperature of a thermistor soon approaches the transition temperature in the event of an over-current condition.

What is PTC temperature?

A semi-conductive disc with a positive temperature coefficient (PTC) is used for both temperature control and as a heat source, with typical controls set at 90 °C. The chemically processed wax has a melting point of 70 °C. To control the opening and closing of the single or multiple zone valves, the element expands to propel the stem along its length of travel.

What does PTC explain?

A technique that uses x-rays to examine the liver and common bile duct. After injecting a contrasting chemical into the liver or bile duct, x-rays can be used to locate the blockage. Transhepatic cholangiography percutaneously is another name for this procedure.

Conclusion

You may acquire all the details you want about the Thermistors and details about this market on the Linquip website, one of the numerous possibilities available to you. Whether you’re a professional or a client seeking for a reputable business, you can rely on Linquip to give you as much basic and trustworthy information on this subject. We advise you to look through the whole range of Thermistor Experts and take advice from our professionals. If you need any services required for your product, you can count on Linquip and visit Thermistor Services.

Download PDF for What is PTC Thermistor?

You can download the PDF format of this post from the link provided here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More On Linquip

- What is the core difference between Thermistor and RTD?

- Types of Thermistor; A Fundamental Comparison Between Them

- Difference Between Thermistor and Thermostat: which one outperforms the other?

- Thermistor Resistance: How does it Calculate?

- Thermistor vs. Thermocouple: Complete Comparison & Practical Selection Guide

- What is a Thermistor and How its Working?

- What is NTC Thermistor? (Types, Applications & Advantages)