Welcome to Linquip Blog. Today and in this article, we are going to have a look at the question “What Is Strain Gauge ?” Strain gauges are exceptionally useful measurement tools, often because of their sensitivity. As evidence, strain gages are typically used as the sensing elements in precision load cells, the most precise “load” measurement instruments available. First of all, there is a basic definition of a strain gauge that will make you familiar with its job. Then we move into the working principle. In this section, it will be explained how a strain gauge works. The rest of the article is dedicated to the characteristics and applications of strain gauges.

Our team has gathered all of the necessary information on this topic to eliminate the need for reading diverse content on other websites. Stay with us until the end to find the answer to your question on this topic. We have a long journey ahead of us, so take a deep breath, sit back, and keep reading this article until the end.

What Does a Strain Gage Do?

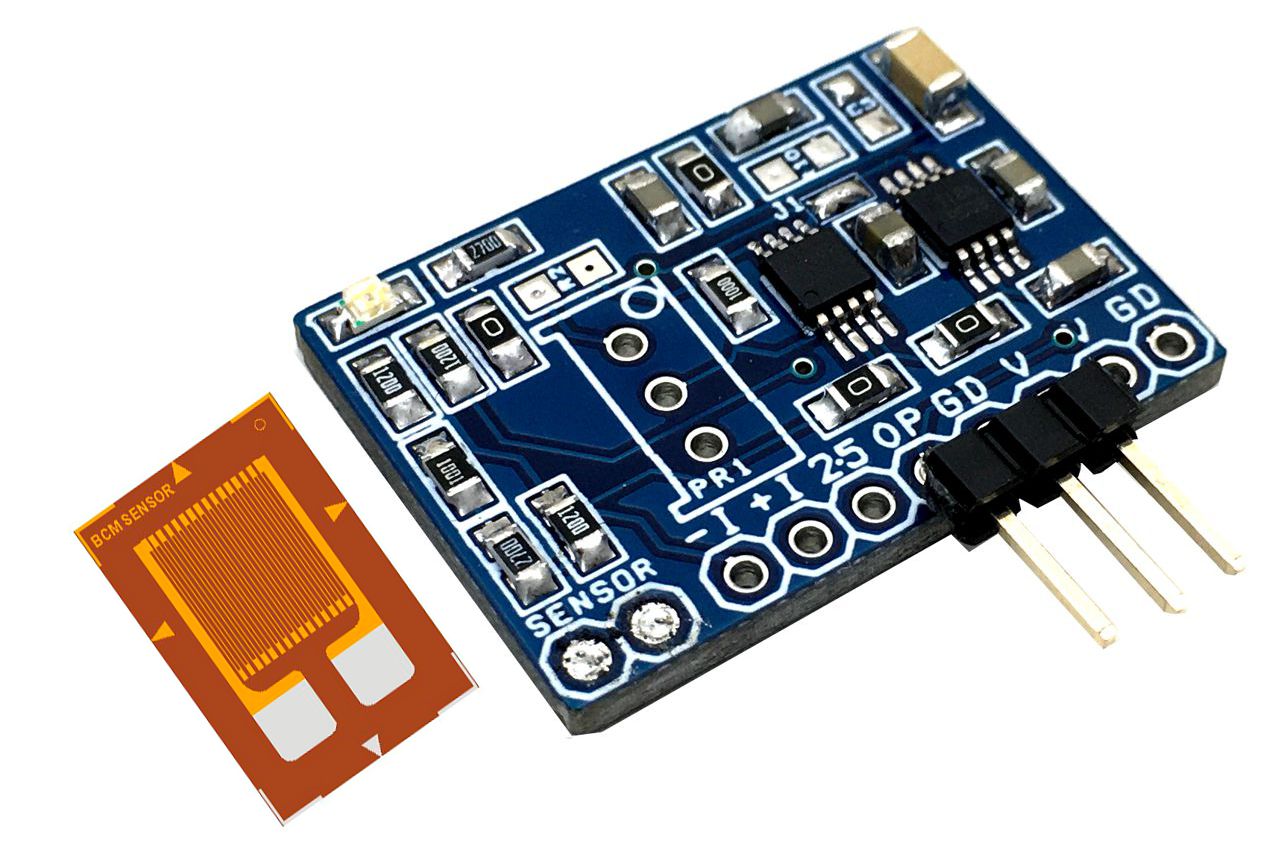

A strain gauge is a type of electrical sensor. Its primary use is to measure force or strain. The resistance of a strain gauge changes when force is applied and this change will give a different electrical output. Strain gauges use this method to measure pressure, force, weight, and tension.

When external forces are applied to a stationary object there are two forces present; stress and strain. Stress is the resisting force of the object like a pushback. strain is the displacement and deformation of the object and this is the force that can be measured by a strain gauge. Because they are small and highly sensitive strain gauges can measure the contraction or expansion of an object even if it is just a small amount when they are correctly bonded to an object or device.

Strain gauges are very thin and come in a wide range of shapes and sizes making them suitable for a variety of applications which we will talk about later.

Strain Gauge Working Principle?

A strain gauge works on the principle of electrical conductance and its dependence on the conductor’s geometry. Whenever a conductor is stretched within the limits of its elasticity, it doesn’t break but, gets narrower and longer. Similarly, when it is compressed, it gets shorter and broader, ultimately changing its resistance.

We know, resistance is directly dependent on the length and the cross-sectional area of the conductor given by R= L/A Where, R = Resistance, L = Length, and A = Cross-Sectional Area

The change in the shape and size of the conductor also alters its length and the cross-sectional area which eventually affects its resistance.

Any typical strain gauge will have a long, thin conductive strip arranged in a zig-zag pattern of parallel lines. The reason behind aligning them in a zig-zag fashion is that they don’t increase the sensitivity since the percentage change in resistance for a given strain for the entire conductive strip is the same for any single trace.

Also, a single trace is liable to overheating which would change its resistance and thus, making it difficult to measure the changes precisely.

Characteristics of Strain Gauges

The most important characteristics of strain gauges are listed below

1. They are highly precise and don’t get influenced by temperature changes. However, if they do get affected by temperature changes, a thermistor is available for temperature corrections.

2. They are ideal for long-distance communication as the output is an electrical signal.

3. Strain Gauges require easy maintenance and have a long operating life.

4. The production of strain gauges is easy because of the simple operating principle and the small number of components.

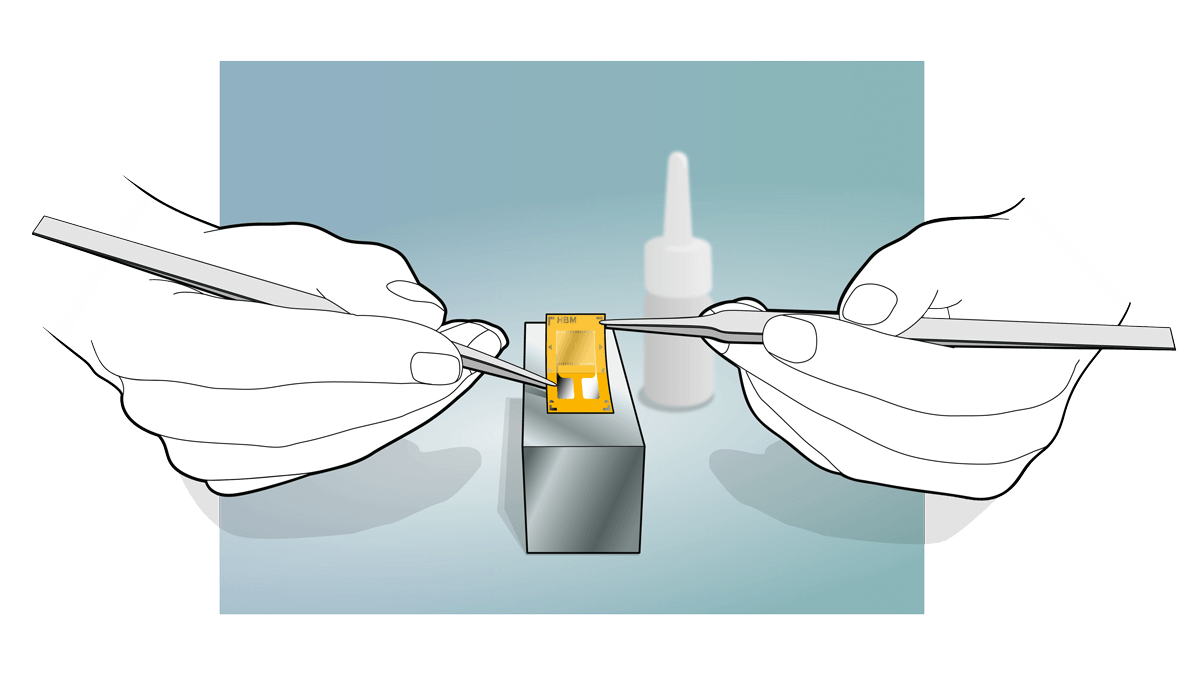

5. The strain gauges are suitable for long-term installation. However, they require certain precautions while installing.

6. They are fully encapsulated for protection against handling and installation damage.

7 The remote digital readout for strain gauges is also possible.

Strain Gauge Applications

Strain gauge technology has a huge range of uses – almost unlimited. Strain gauges are a fundamental sensing element and are used within many different types of sensors. They are well-used in industries such as; rail, aerospace, mechanical engineering, and research and development. Some of the applications they have been used for include:

1. Aerospace

Strain gauges are fixed to the structural load-bearing components to measure stresses along load paths for wing deflection or deformation in an airplane.

The strain gauges are wired into the Wheatstone Bridge circuits and, its application areas include onboard signal conditioning units, excitation power supplies, and the telemetry necessary to read in-site measurements.

2. Cable Bridges

Instrumentation of bridges is done to verify design parameters, evaluate the performance of new technologies used in the construction of bridges, verify and control the construction process, and for subsequent performance monitoring.

Well-instrumented bridges can alert responsible authorities about approaching failure so as to initiate preventive measures. Choosing the proper sensor types, technology, measurement range and location on the bridge is very important to optimize costs and extract the full benefits of instrumentation.

It becomes necessary to monitor the bridges regularly for any kind of deformation as it might lead to fatal accidents. Strain gauge technology is used in the real-time monitoring of huge bridges, making the inspections precise.

3. Rail Monitoring

Strain Gauges have a long history in the safety of rails. It is used to measure stress and strain on rails. Strain gauges measure axial tension or compression with no impact on the rails. In case of an emergency, the strain gauges can generate a warning so maintenance can be done early to minimize the impact on rail traffic.

Why Are Strain Gauges Important?

Strain gauges are extensively used in the field of geotechnical monitoring and instrumentation to constantly monitor dams, inner linings of tunnels, structures, buildings, cable-stayed bridges, and nuclear power plants to avoid mishaps and accidents in case there are any deformities in them.

Timely actions taken can avoid accidents and loss of life due to deformities. Hence, strain gauges are important sensors in the geotechnical field.

Strain gauges are installed on these structures and then, the complete data from them is remotely retrievable through data loggers and readout units. They are considered significant measuring equipment for ensuring productivity and safety.

Conclusion

The present article was an attempt to deliver all the essential information about the question of “What Is Strain Gauge?”. We talked about the job a strain gauge does and the way it works. At the next, we brought 7 specifications of strain gages to complement the last two sections. The rest of the article was dedicated to the applications and the importance of using strain gauges in different appliances.

If you have any experience or have encountered strain gauges and know more about them, we will be very glad to have your opinions in the comments on our website Linquip. Moreover, if you have any questions about this topic, you can sign up on our website and wait for our experts to answer your questions. Hope you enjoyed reading this article.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Ultrasonic Thickness Gauge, Advantages and Applications

- An Easy Overview of Types of Pressure Gauges

- A Complete Answer To What Is A Pressure Gauge