Temperature transmitters are one of the most frequently seen process tools. If you would like more information besides what is temperature transmitters, please follow this article at Linquip. You will find the types and calibration processes of temperature transmitters in more detail.

what are temperature transmitters?

Simply stated, temperature transmitters are electrical instruments that interface the temperature sensor to insulate, amplify, filter noise, and translate the signal from the sensor to the control unit. Temperature transmitters consist of a sensor and a transmitter, all of which affect the final output to the display panel.

Temperature transmitters may be manufactured as stand-alone devices that are connected or inserted into the attachment head of a part to one or more temperature monitors in a process control system.

For an instance, temperature transmitter 4-20ma ranges are typical electrical output signals used in manufacturing plants. 4mA could reflect 0 °C, for instance, and 20mA means 100 °C. As the majority of industrial equipment communicates through this signal range, 4-20ma temperature transmitters are typical in manufacturing. Inside the temperature transmitter, the emitted temperature signal can be scaled to satisfy the specifications of the device, e.g. 4mA can be used to reflect -17.7 ° C or 0 ° Fahrenheit, and 37.7 ° C or100 ° Fahrenheit can be used to represent the highest value in the range (20mA).

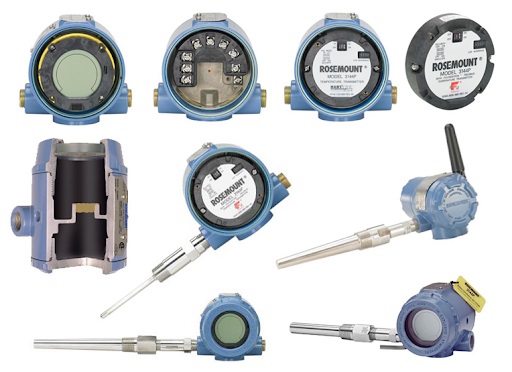

Moreover, temperature transmitter rosemount (e.g., 3144P) offers superior precision, stability, and reliability, making it the industry-leading temperature transmitter used in critical applications for control and protection. Either 4-20 mA/HART or a fully digital base Fieldbus protocol is required for this temperature transmitter. It can receive inputs from either single or dual sensors. This dual-sensor input function enables the transmitter to receive simultaneous input from two distinct sensors, allowing for differential temperature measurement, average temperature measurement, or redundant temperature measurement.

Was this all to know what is temperature transmitters? Of course not! The temperature transmitter calibration is a must. This is because, over time, sensors deteriorate due to varying reactions to environmental effects such as vibrations and high temperatures. Also, the potential occurrence of drift is due to a long duration of constant use when being subjected to various environmental influences.

Temperature transmitter calibration can usually be done based on current equipment utilizing the Temperature Transmitter Instruction Manual. But there are several specifications for the basic equipment used in debugging to maintain debugging efficiency. As normal, the typical interface error should be less than 1/5 of the acceptable temperature transmitter debugging error. And the error should be less than 1/3 of the permissible error for the 0.1 percent level temperature transmitter. Besides, the demands can also be satisfied by the uncertainty and repeatability of the entire range of regular equipment.

Below we share a calibration set-up of temperature transmitters in 5 different ways:

- Actual temperature simulation using metrology well

- Actual Temperature Read-out using a Process calibrator

- Direct temperature Simulation of Electrical Signal Using Fluke 754

- Resistance to temperature simulation using a resistance box

- The temperature to Current (4 to 20 mA) readout

- Calibration set-up for temperature transmitter with a thermocouple sensor

It should be noted that most of the calibration principle remains the same. The only variations are the specifications to be used and the temperature parameter or process signal.

temperature transmitter types

The question of what temperature transmitters is for all types. As mentioned earlier temperature transmitters are used as a means of process control in industrial production because they can provide temperature input at various phases in the manufacturing process. Any transmitter types are named after the method of mounting, which means some correlation between the type and the method of mounting. So, as well as various kinds of mounting set-ups, there are several different kinds of temperature transmitters:

Weather-Proof and Explosion-Proof Transmitters: this is one of the temperature transmitter types. A weather-proof and explosion-proof transmitter is appropriate for applications where a transmitter must withstand the wear and tear associated with continuous exposure to the elements. There is an external enclosure for this particular type of transmitter, usually made of stainless steel or a designated explosion-proof material, which is tightly sealed to protect sensitive internal components. The transmitter is divided into two small chambers inside: one contains the sensor and the other contains the electronics relevant to the temperature measurement and the propagation of a new signal.

Transmitters that are weather-proof and explosion-proof appear to have a high degree of precision and can typically be calibrated and tracked locally, if appropriate.

Panel Mount or DIN Rail Mount Transmitters: To place switches, relays, and transmitters, a DIN rail is used. The rail itself is a piece of metal shaped to accommodate the installation of a gadget, such as a transmitter, using a spring clip that slips into a bend in the metal rail and secures itself. The metal rail may then be connected to a panel or a wall, along with an attached transmitter.

With regard to the question of “what are temperature transmitters?”, each different type in various applications, specifically DIN-rail transmitters, also referred to as panel mount transmitters, are typically used because they are comparatively low-cost and can work with several different sensors. They are also simple to mount due to the DIN rail design. Because of the longer wiring configuration used for securing the transmitter, they are much less accurate than weather- and explosion-proof transmitters. For temperature transmitters, the oldest mounting process is rail mounting.

Head Mount Transmitters: Head mount transmitters incorporate the transmitter into a sensor’s attachment head or outer housing. They are easy to mount and need limited wiring due to this nature, as the sensor head essentially becomes a transmitter for the sensor head.

Field Mounting Transmitters: This special model of temperature transmitter is mounted in its external housing, allowing it to be used “in the field” where environments, such as in high-performance industrial operations, can require additional protection. To maximize the frequency of the signal, field-mounted transmitters may be positioned very close to the sensor.

Field mount: This type of temperature transmitter directly connects to the process, typically mounted for a better signal near the sensor. Therefore, with an amplified signal, this style offers stable signal transmission. With a dual-chamber to shield the housing from humidity and rain, you can have them. Field housings are usually available in die-cast aluminum or stainless steel, so if you need one, you can simply mount a display.

Head mount

These temperature transmitters are directly mounted on the temperature assembly terminal heads. So, this form provides the signal with optimum protection. Plus, as opposed to field mounts, this style requires less wiring, less space, and less money. Extreme movements, however, can require extra cleaning, and atmospheric temperature variations can impair accuracy.

Conclusion

By reading this article you found the answer to the question “what are temperature transmitters?”. You know that they are one of the most commonly seen devices for controlling temperature-controlled processes in any industry. We also provided some ways to calibrate temperature transmitters. Moreover, we included different types of temperature transmitters. To know more about what is temperature transmitters, you can get in touch with our experts at Linquip. So, don’t forget to register.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

The HG-101 humidity calibrator controls to the user set point with a precisely adjusted RH probe supplied with a SCS accredited calibration certificate.

Thanks for sharing a nice informative blog post.

Thank you for your review and for bringing this to our attention. We couldn’t agree more. Please sign up on Linquip to share your question or suggestions with our experts. Again, thank you for taking the time to review our article!