A universal motor is universal because it can operate with nearly identical characteristics on both AC and DC supply. It has many benefits due to the property of operation at all types of voltage sources and compactness. In this article at Linquip, we will discuss the universal motor, its construction, different types, and applications. But before that, let us define the universal motor.

What is the Universal Motor?

A universal motor is an engine that runs on both DC and AC power supplies. The features of this motor primarily include variable speed and high transmission torque. It provides a high starting torque; the speed can change, it is small in size, and cheap. The key parts of the universal motor are armature, field winding, stator stamping, frame and plate, and polish.

The universal motor is a type of electric motor that can run on either AC or DC power and creates its magnetic field with an electromagnet as its stator. An essential product of employing Industrial Tools is the Universal Motor. Universal Motors are available from a variety of Suppliers And Companies, as well as various manufacturers and distributors, and there are many Universal Motors For Sale on Linquip.

There is a comprehensive list of universal motor services on the Linquip website that covers all OEM fleets. Linquip vendors can assist you with this. Please call Universal Motor Experts in Linquip to learn more about how to connect with a diverse network of service providers who consistently deliver high-quality products.

Many universal motors are designed to run at higher speeds of more than 3500 rpm. They operate at a lower speed on the AC supply than they run on the same voltage DC supply due to the reduction in the AC voltage and not DC voltage.

Which Is Called Universal Motor?

This is an AC commutator motor of the kind. It rotates on both AC and DC power, although being mostly utilized on single-phase AC. It’s also known as a “commutator motor” or “universal motor.” The Universal motor’s great power density is one of its key advantages. It’s fairly uncommon for a Universal Motor to have more than twice the continuous output power of an AC motor of the same size. It’s also worth considering because of its inexpensive cost, mobility, and ability to run without a controller.

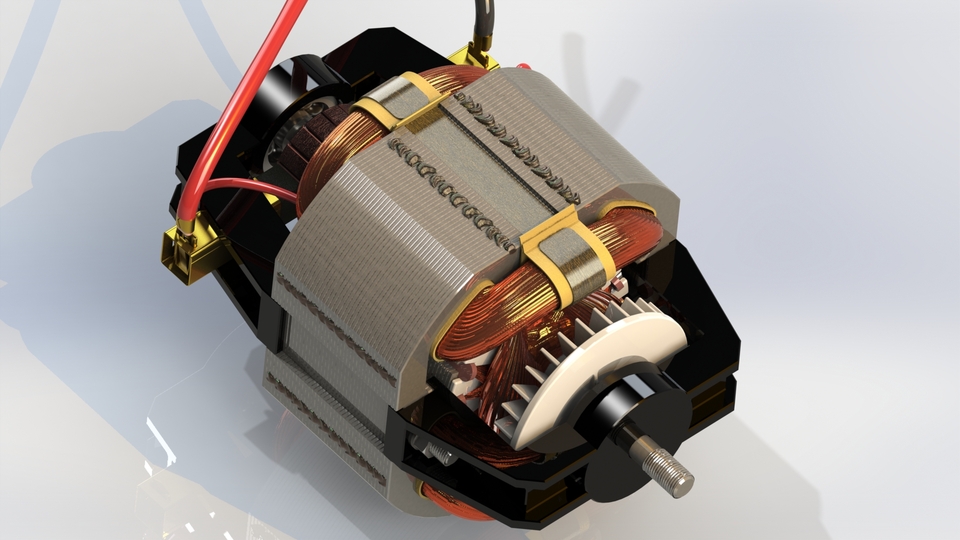

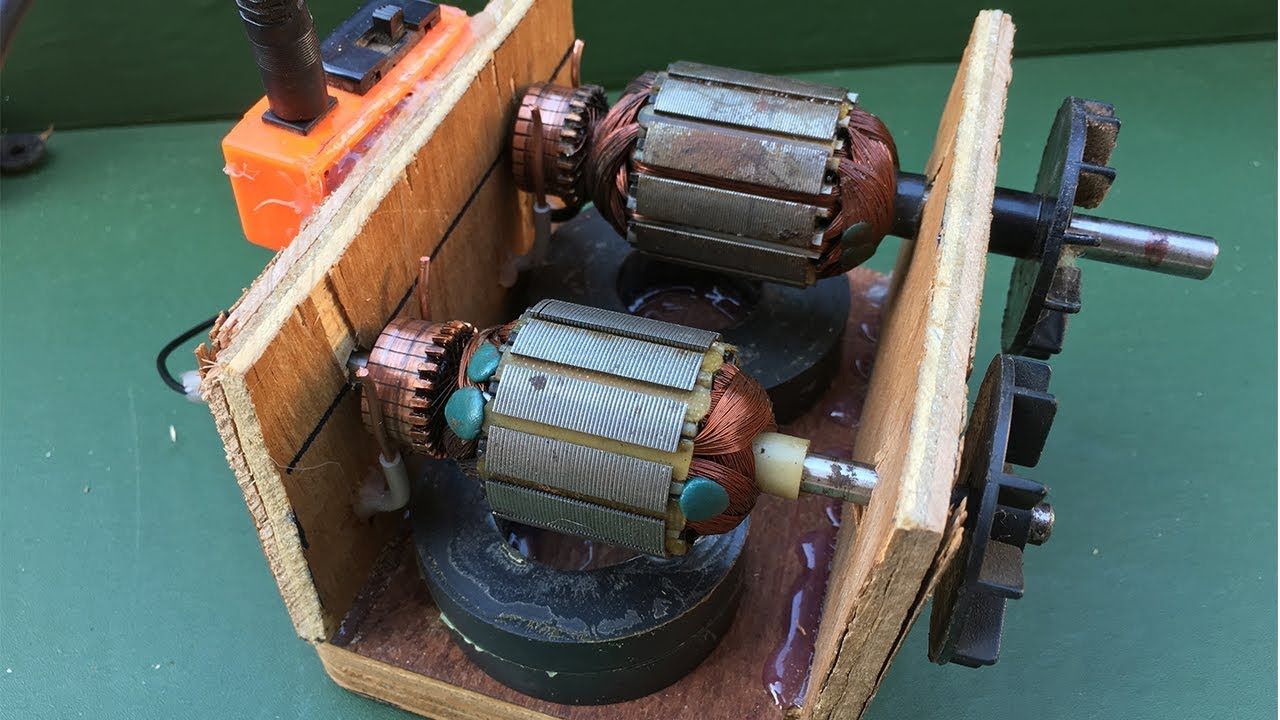

Construction of universal motor

The construction of the universal motor is highly related to the construction of a DC motor. It is composed of a stator on which field poles are placed. Field coils are wound to the poles of the field. However, the entire magnetic path, the circuit of the stator field, and also the armature, is laminated. Lamination is important to reduce eddy currents. The rotary armature is of a wound form with straight or twisted slots and a brush turn sitting on it. AC switching is poorer than DC switching. Because of the current caused by the coils of the armature. For this reason, the brushes used have high resistance.

The diagram is pretty easy for a universal motor. By way of carbon brushes, the stator windings are connected in series with windings in the rotor. In the universal generator, the condition is remarkably different. Stator windings and rotor windings are used in a universal engine. The current in the rotor windings, as in the induction motor, is not purely the product of inductive coupling. About its construction, the distinguishing characteristic of the universal motor is that the stator and rotor windings are wired in order. This helps to create a voltage gap between them so that the rotor can pursue the rotating magnetic field of the stator. The current is channeled by brushes into the rotor.

universal motor controller

Universal Motor Controller (UMC) is a software and hardware-based on Arduino designed to operate a universal brushed motor. It consists of two parts:

- software: a C/C++ code running on Atmel Atmega-328p (Arduino Uno and compatibles boards)

- hardware: divided into three parts:

- zero-crossing detector circuit used for synchronizing Arduino on the main power

- power circuit used for feed motor

- feedback circuit used for monitoring the speed of the motor and adjust feed power consequently

What is universal motor speed control?

There are different techniques for controlling the speed of a universal motor:

- One technique is used to build the engine in a system to avoid the engine from operating at no-load condition.

- A fixed resistor in the circuit is used as a speed regulator. The resistor is short-circuited unless the engine is going too fast. Then the shortening contacts open to connect the capacitor to the motor circuit.

- Speed controlling can also be achieved by an electronic controller. Some controllers use a silicone-controlled rectifier.

- Another approach is to use a gear train to minimize the speed of real load; and

- the other techniques are centrifugal system, resistance, and ground tapping.

working principle of universal motor

The working principle of the universal motor is like a DC series generator. When the current flows into the field winding, it generates an electric field. The same current is still emanating from the armature conductors. When a current conductor is put in an electric field, a mechanical force is encountered. Owing to this magnetic force, the rotor is beginning to spin. The position of this force is provided by the left-hand rule of Fleming.

It also generates unidirectional torque when fed with an AC supply. Since armature winding and field winding are linked in sequence, they’re in the same process. Thus, when the polarity of the AC varies regularly, the direction of the current in the armature and field winding is reversed at the same time. Thus, the orientation of the magnetic field and the direction of the armature current are reversed in such a manner that the direction of force encountered by the armature conductors remains the same.

What is the universal motor application?

Regarding universal motor applications, we can mention the primary uses, and they are mechanical vacuum cleaners, power tools, and vacuum cleaners. Also, there are higher rating universal motors used in portable drills, blenders, etc. Universal motors are also found in various kitchen appliances such as vacuum cleaners, drinks, and food mixers, domestic sewing machines, etc. Moreover, Poly Higher rating universal motors are used in handheld drills, blenders, etc.

types of universal motor

There are two basic types of universal motor:

Non-compensated Motor

This engine can be built with two wide poles and is laminated. The armature in the engine is a wound form, and the laminated core is either skewed or straight slots. The winding leads can be attached to the switch. This form of engine uses high-resistance brushes to enable improved commutation.

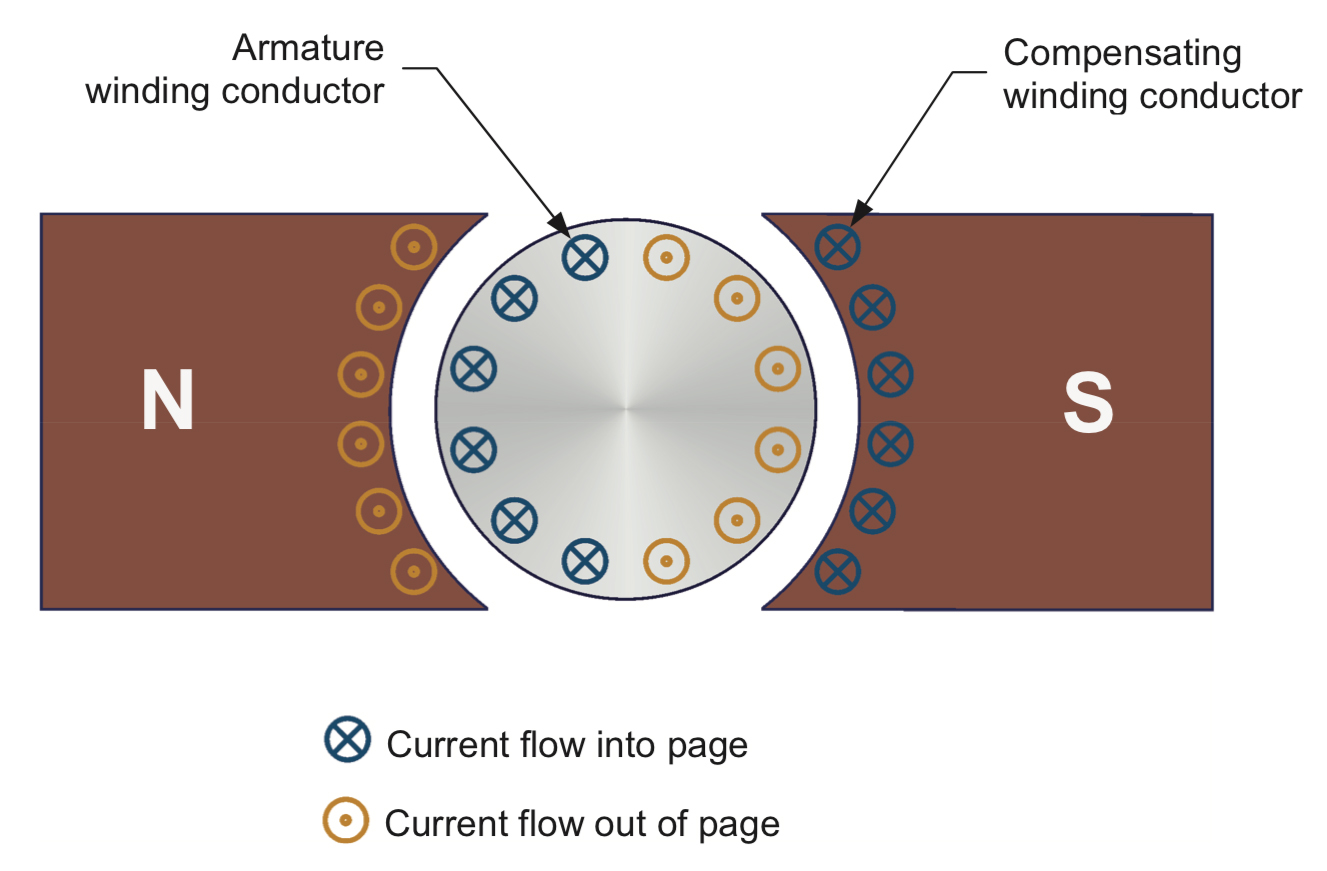

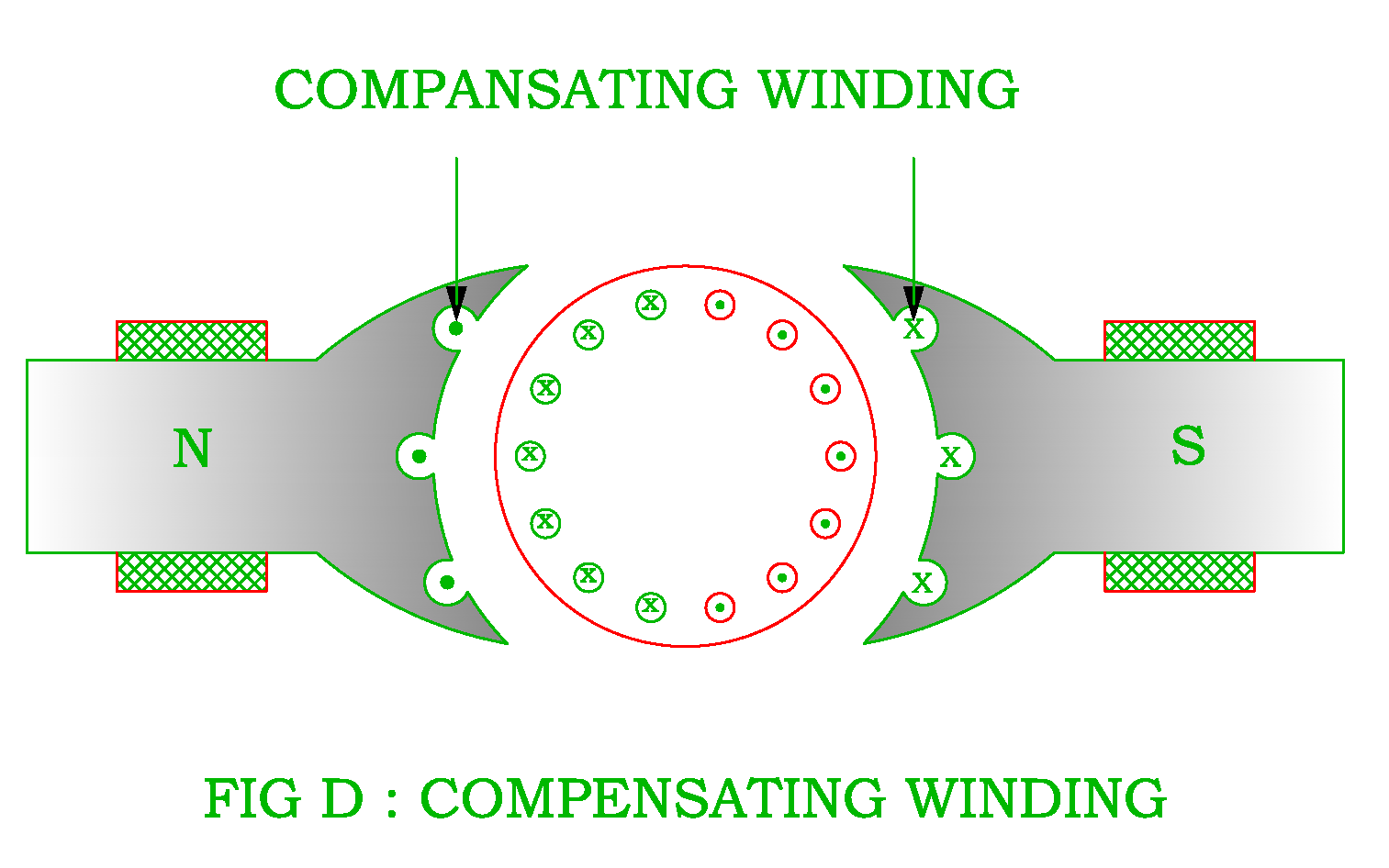

Compensated Motor

This type of universal motor involves the scattered field winding and the stator core is connected to the split-phase motor. These engines have an extra winding in addition to major winding. Same as split-phase motors; this type of engine requires extra winding. Compensating winding decreases the voltage of the reaction due to the alternating flow as the engine runs using the AC source.

universal motor vs induction motor

Induction and universal motors are the two types of motors that control electric pressure washers. Induction motors are typically used on commercial-grade pressure washers used for heavy-duty washing. On the other hand, universal motors are more common in small pressure washers, which are more suitable for domestic use. Besides, there are other factors in which the induction pressure washer varies from the universal motor pressure:

-

Size & Weight

In terms of size and weight, the induction motors are larger and heavier. Universal motors do not take up too much space and are smaller in comparison. As a result, pressure washers running on a universal motor are often smaller. The electric pressure washer with an induction engine would be much larger and thus less compact.

-

Power-Efficiency

Induction engines are more powerful in any sense they require less fuel to produce power. Moreover, they’re not generating a lot of heat. This is why they are suitable for commercial electrical pressure washers where there is a strong demand for fuel.

-

Noise

The induction motor is much quieter than the universal motor, which can be very noisy. The induction motor has only one moving part, the rotor. The fact that this is a brushless motor means that it generates less detectable sound. On the other hand, universal motors have brushes that can make a vibration, and that’s why the pressure washers that operate on a universal motor are noisy. Although the universal motor is less efficient, its sound is higher than that of the brushless induction motor.

-

Lifespan

Induction engines are very popular for power tools and can easily last for years. Universal motors can have a respectable life cycle, but not as long as the induction engine. They are likely to burn out and require repairs or replacements. The lifetime depends on its parts and efficiency, even with a universal motor.

-

Cost

Induction engines are more expensive than universal engines. They require more materials, such as copper, steel, and aluminum. As a consequence, their cost directly impacts the cost of the pressure washer. Universal engines are inexpensive and most widely found in small power tools.

Conclusion

Now you know what a universal motor is and what the various types are. This article addressed this motor as a special form of an electric motor, and that the power of this motor depends on AC & DC. This motor also has a high starting torque and inconsistent speed characteristics. Moreover, we covered ways of controlling the speed of the universal motor. However, if you have any further more queries on the universal motor, register at Linquip and leave the comments section below.

Download Universal Motor PDF

Click here to explore more about Universal Motor Construction, Types, and Working.

Read More In Linquip

- What Is CNC Machining & How Does It Work?

- Universal Motor: a Simple Guide to Construction, Types and Working

- Brushed DC Motor: A Comprehensive Explanation of Working Principle, Parts, and Types

- Shunt DC Motors: An Easy-to-Understand Explanation of Working Principle and Components

- Series DC Motors: A Comprehensive Guide

- Synchronous Motors: Definition, Working Principle, Types, and Applications

- What is a Hysteresis Motor: Ultimate Guide

- A Complete Guide to Repulsion Motor