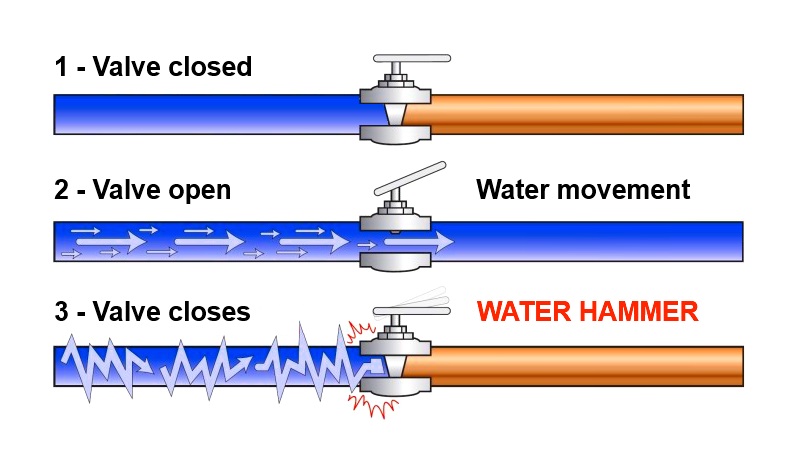

What is water hammer? It is the colloquial form of hydraulic shock that occurs when a moving fluid (usually a liquid) is forced to stop or change its direction abruptly. This momentum change commonly happens when a valve at the end of a pipeline system closes suddenly, and a pressure wave propagates through the pipe.

This pressure wave can cause serious problems, including noise, vibration, pipe rupture, or collapse. The effects of the water hammer pulses can be reduced using accumulators, surge tanks, blow-off valves, expansion tanks, and other features. Avoiding adverse effects is possible by ensuring that valves will not be closed too quickly with the significant flow.

Definition of Water Hammer

Water hammer may occur in any piping system that uses valves to control the flow. The water hammer phenomenon is the consequence of a pressure surge or high-pressure shockwave propagating in a piping system in which the fluid is forced to change its direction or stop suddenly. The shockwave is also usually known as a hydraulic shock or hydraulic surge. Due to the enormous shockwave, a marked banging or knocking sound on the pipes is heard immediately after shutoff.

Water hammer can happen when an open valve abruptly closes and causes the water to bang into it. Additionally, suddenly shutting a pump down and the reverse direction of the flow back to the pump may lead to this phenomenon. Because water is incompressible, the strike of the water creates a shock wave that propagates at the sound speed between the valve and the adjacent elbow in the system or in the water column after the pump.

Causes of Water Hammer

When a piping system is suddenly closed downstream, the mass of water is still moving before the closing, resulting in high pressure and a shock wave. In domestic plumbing, this manifests itself as a loud banging similar to the sound of a hammering. Water hammer can break the pipelines if the pressure is high enough. Sometimes air traps or standpipes (open at the top) are added to water systems as dampers to absorb potentially harmful forces generated by the moving water.

Other reasons for the water hammer include pump failure and check valve slam (due to abrupt deceleration, depending on the dynamic specifications of the valve and the water mass between the valve and tank, a check valve may slam shut quickly). To overcome this situation, it is advised to use non-slam check valves because they are not dependent on gravity or fluid flow for their closure. In the case of vertical pipes, some suggestions include applying a new piping design that contains air chambers to mitigate the probable shockwave of water due to excessive water flow.

IN Hydraulic Power Stations

In hydropower plants, closing a valve may prevent the water from entering a turbine along the tunnel or pipeline. For example, if there is 14 km of the tunnel of 7.7 m diameter filled with water at a speed of 3.75 m/s, this indicates about 8,000 megajoules (2,200 kWh) of kinetic energy to be captured. This harnessing of the power is frequently performed by a surge shaft that is open at the top, and the water flows into it. As the water rises from the shaft, its kinetic energy is transformed into potential energy, slowing the water down in the tunnel.

At Homes

At home, the water hammer may happen as a dishwasher, washing machine, or toilet shuts the water flow off. The result may be a loud, repetitive noise (as the shock wave moves forth and back in the plumbing system), or vibration.

Read More on Linquip

- Your Handy Guide to Water Softener Installation Cost for 2021

- Your Handy Guide to Water Heater Installation Cost in 2021

- How to fix Water Hammer? Dangers and Tips

- How to Plumb an Expansion Tank

- What Is A Septic Tank And How Does It Work: The Ultimate Guide

Effects of Water Hammer

The impact force on the valve produced by the momentum change of the fluid can create pressure peaks that may exceed ten times the operating pressure of the system. These sudden stopping of the flow motion and the increases in pressure resulting from the shock waves can cause considerable damage to the overall piping system. This may occur either due to a single event or cumulative damage over time.

Ignoring the water hammer can eventually cause catastrophic failure of the flow system. As you will see, it is necessary to immediately take action after the first signs of a water hammer appear. Failure to do so will eventually lead to widespread system damage and may spread from the flow system to other components or facility infrastructure.

The long-term consequences of water hammer include:

Pump and Flow System Damage

Repeated water hammers may lead to severe damages to the system components, including the pumps and valves. This can cause the catastrophic failure of joints, and adversely affect the integrity of the pipe walls and welded joints.

Leakage

The Water hammer can degrade fittings and joints and lead to leaks. These leaks often start gradually, increasing in severity over time. Smaller leaks may go unnoticed for a while and damage surrounding equipment.

Ruptured Pipelines

Repairing ruptured pipes due to pressure spikes is very expensive. A Rupture can damage a local pipeline and fail the overall system and other equipment. Thus, a large replacement operation will be needed.

External Equipment Damages

If left unchecked, water leakage can cause a failure to electrical equipment and the corrosion of other equipment or infrastructure.

Risk of Subsequence Accidents

Pipeline rupture can also threaten the health and safety of operators and maintenance personnel. Depending on the industry and facilities, uncontrolled leaks can also increase the risk of slipping, falling, and electrocution.

Complications of Downtime

Damages to the equipment can lead to expensive repairs or replacements. It may also incur additional financial losses due to downtime needed for further maintenance, repairs, or establishments.

Types of Water Hammer

We can divide water hammer into different major classes discussed below.

Hydraulic Shock

A small portion of the water hammer issues in a steam system is due to hydraulic shock. This type can be explained by using a home faucet. When the home faucet opens, a solid shaft moves through the pipes from where it enters the home to the faucet outlet. When the faucet is suddenly closed, a remarkable “bang” is heard in the system. This shockwave sound is like the blow of a hammer on a piece of steel. The shock wave pressure, which is about 300-psi, is reflected from one end to the other end until its energy is dissipated in the piping system.

This is the same process that can occur in the discharge piping in a condensate pump system when the pumps are employed in an on/off action with large condensate pumping capacities. The pumping system usually has check valves placed at the pump outlet. By starting and stopping the pump, hydraulic shock can happen as the condensate flow immediately stops, and the check valves block the flow in one direction.

Thermal Shock

The main source of water hammer is a thermal shock in which steam collapses, and water quickly reaches into the generated vacuum from all directions. One pound of steam at 0 psi fills 1,600 times the volume of one pound of water at normal atmospheric conditions. As the condensate line pressure rises, this ratio decreases proportionately.

Flow Shock

Flow shock often occurs due to improper discharge ahead of the steam line isolation valve or control valve.

For example, suppose that a steam line isolation valve (usually used with a pipe of 3 inches or larger) is opened without using a warm-up. In this case, when the large valve opens, the steam rushes down a cold pipe, creating a large amount of condensate at high velocity. These condensates continue to form a mass traveling along the pipe and creating a large wave of condensate. The wave will move at high speed until a sudden change in direction occurs, possibly due to an elbow or valve in the line. Therefore, the sudden stop causes a water hammer.

Differential Shock

Similar to the flow shock, this type happens in bi-phase systems or the condensate system. It occurs when the steam and condensate flow through the condensate line but at different speeds. In bi-phase systems, the steam velocity is usually ten times the liquid velocity. If the condensate waves rise and occupy a pipe, a seal is made temporarily between the upstream and downstream sides of the condensate wave.

Because the steam cannot flow into the condensate seal, the pressure reduces on the downstream side. The pressure differential then pushes the condensate seal downstream at a high velocity, hastening it like a piston. As it is transported downstream, more liquid is absorbed, which adds to the existing slug mass, and the velocity increases.

Signs of Water Hammer

There are usually three symptoms that a water hammer has occurred.

- Pressure impact surge on a floating measure.

- Expansions union on a steam line destroyed by the steam hammer.

- Pressure wave due to losing a valve in a pipe.

How to Prevent Water Hammer

One of the primary considerations of the water hammer can be choosing the right check valve type. The suitable type of valves, such as swing, piston style check valves, tilting disc, depends on the gravity and the flow reversal in order to return the valves to the closed position. This slams the water into the valve mechanism and creates a pressure wave propagating in the piping system.

On the other hand, silent or spring-assisted check valves are fitted with an internal spring that silently turns the valve to a closed position before the flow reversal. Thus, it eliminates the possibility of a water hammer.

Another effective solution for the water hammer problem is air chambers. These systems include a short piece of pipe, normally in a tee-fitting, with an empty/air-filled chamber working as a shock absorber for the water to expand as it suddenly turns direction. This diminishes the amount of shock that is otherwise directed towards the pipeline.

There are several other practical ways for preventing water hammer as follows:

- Flushing old systems

- Decreasing operating pressure

- Placing pressure reducers and regulators in the supply line

- Pumping station bypass

- Investing in piping systems that have air chambers as elements of the design

- Reducing pressure severity using silent check valves

How to Fix Water Hammer

Below is a series of actions to be taken when faced with the phenomenon of water hammer:

- Shut all the water supply to the house off.

- Open all water griffins starting from the highest one.

- Rinse out all the house toilets.

- Let the water drain for about 20 or 30 minutes.

- Turn on the water supply to the house again.

- Wait for 5 to 10 minutes to allow the griffins to recover a lot of the water stream.

- Close all the griffins again and start with the lowest one this time.

- Toilets have to be filled automatically.

- Finally, when all the griffins are closed, and the toilets are filled, wash the toilets to check the situation of the water hammer.

Applications of Water Hammer

The use of the concept of water hammer phenomenon in the uses mentioned below is well known.

- The water hammer basics can be applied to make a simple water pump known as a hydraulic ram.

- Leakage can sometimes be discovered using a water hammer.

- Water hammer can help detect enclosed air pockets in pipelines.

Water Hammer Analysis

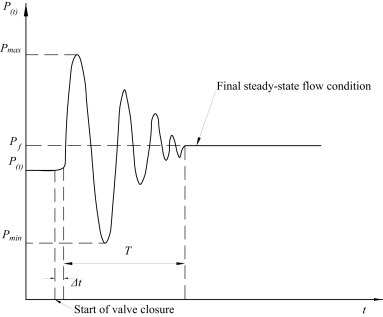

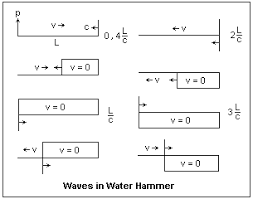

Water hammer can be analyzed using two different methods: rigid column theory, which ignores fluid compressibility and elasticity of the pipe walls, or a complete analysis including elasticity. When a valve closing time is long compared to the propagation time of a pressure wave along the pipe, the rigid column theory is suitable.

Otherwise, elasticity may be needed. In the following, two approximations for the peak pressure are presented, one with consideration of elasticity but assuming that the valve closes immediately. The other one neglects elasticity but includes a limited time for valve closure.

First Approach: Compressible Fluid and Instant Valve Closure (Heading 3)

The pressure of the water hammer pulse can be expressed using the Joukowsky equation:

\frac{\partial P}{\partial t}=\rho a\frac{\partial v}{\partial t}

Therefore, for an instantaneous valve closing, the maximal quantity of the water hammer pulse is:

\mathit{\Delta}P=\rho a_0\mathit{\Delta}v

The magnitude of the pressure wave is measured in Pa, ρ is the fluid density (in kg/m3), a0 is the speed of the sound in the fluid medium (in m/s), and Δv is the change in the fluid velocity (in m/s).

Wave Speed

The speed of sound in a fluid is given as:

a=\sqrt{\frac{B}{\rho }}

So, the peak pressure depends on the compressibility of the fluid if the valve is suddenly closed.

In the above equation, B is the equivalent bulk modulus of the fluid–pipe system elasticity and can be calculated as:

B=\frac{K}{\left(1+\frac{V}{a}\right)\left(1+c\left(\frac{K}{E}\right)\left(\frac{D}{t}\right)\right)}

K and E are modulus of elasticity of the fluid and the pipe, respectively. Also, D and t are internal diameter and wall thickness of the pipe, and c is a dimensionless parameter.

Second Approach: Incompressible Fluid and Slow Valve Closure

When the time of valve closure is less than the transit time for a pressure wave to propagate through the pipe, the elasticity can be ignored, and the phenomenon can be explained by rigid column theory:

F=ma=PA=\rho LA\frac{dv}{dt}

If the water column deceleration is assumed to be constant, we will have:

\frac{dv}{dt}=\frac{v}{t}

Thus,

P=\frac{\rho Lv}{t}

In the above relationships, m is the mass of the fluid column. Also, P, F, A, L, and t are pressure, force, cross-sectional area of the pipe, pipe length, and closure time, respectively.

Excess Pressure Due to Water Hammer

When a valve is closed at flow rate (Q), additional pressure ΔP is produced upstream of the valve is given by:

\mathit{\Delta}P=ZQ

where, Z is the hydraulic impedance (in kg/m4/s) which is defined as:

Z=\sqrt{\frac{\rho B}{A}}

As a result of the above physical analyses, the water hammer can be reduced by:

- Increasing the diameter of the pipe at constant flow (This decreases the flow velocity and, therefore, the deceleration of the liquid column.)

- applying the solid material as tight as possible

- Using a method that increases the overall hydraulic system flexibility (such as a hydraulic accumulator)

- Increasing the portion of undissolved gases in the liquid where possible

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers