Most of our daily used products and Hi-Tech products can be manufactured by precision machining, and precision machining performs when large parts of materials undergo cutting, turning, milling, etc., to produce more precise components. The computer numerical control equipment can be used to create these precision machined parts. The machined parts are composed of exact conditions and more complex features. These various small features that perfectly fit with others make functional components. The small features may include:

- Tapers

- Threads

- Grooves

- Holes

As CNC equipment can produce these parts, there are no or negligible chances of errors resulting to produce more accurate parts. They show high performance and proper functioning because of their high accuracy and precision, which can be used to manufacture various components in various industries.

How to Make Precision Machined Components?

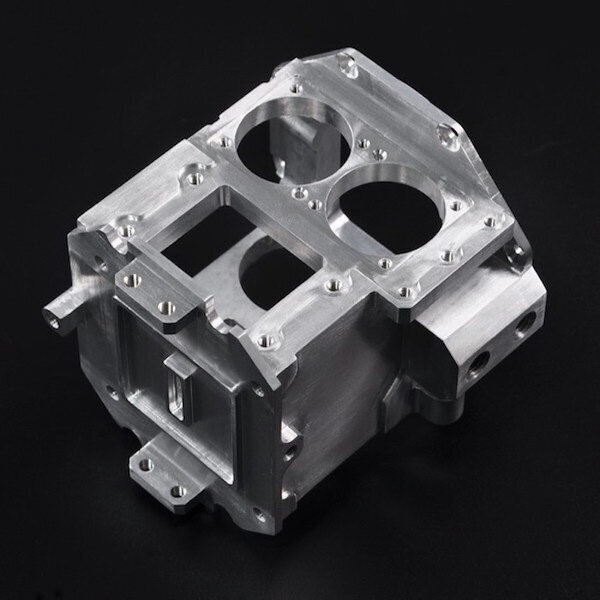

Alt tag “manufacturing of precision parts”

Manufacturing precision machined parts needs complex, state-of-the-art machinery and different types of tools. If you want to perform the equipment manufacturing, very skilled and professional operators are required.

The precision machining parts can manufacture under higher supervision in controlled and safe conditions. Here is a complete process of manufacturing precision machined components.

Step-1

The manufacturing of precision machined components begins with the formation of a sketch or drawing and choosing the correct size for the raw material.

Experienced engineers take an idea from the sketch of the part. The drawing exactly looks like the final product. Any mistake in the sketch can result in an undesirable final part. Therefore the sketch is carefully designed to prevent any flaws and wrong manufacturing. Usually, computer-aided design software uses to sketch the parts.

Step-2

In the second step, the engineers draw a 3D diagram of the sketch. AutoCAD software uses to draw the 3D diagram.

Step-3

After making a 3D diagram, the machinists put the part design into the computer-aided manufacturing program or CNC machines. The more precise and accurate components can produce through the computers’ removal of raw materials.

Step-4

Computer software may provide the instructions to the machines. The machines make fine cuts in the parts according to instructions with higher accuracy and precision.

Step-5

Finally, exact and accurate parts can produce with desirable features. Hundreds of similar pieces manufacture by this precision machining process. The tolerances of the final parts range from 0.01mm to 0.05mm with the exact specifications.

Methods Used for the Manufacturing of Precision Machined Parts

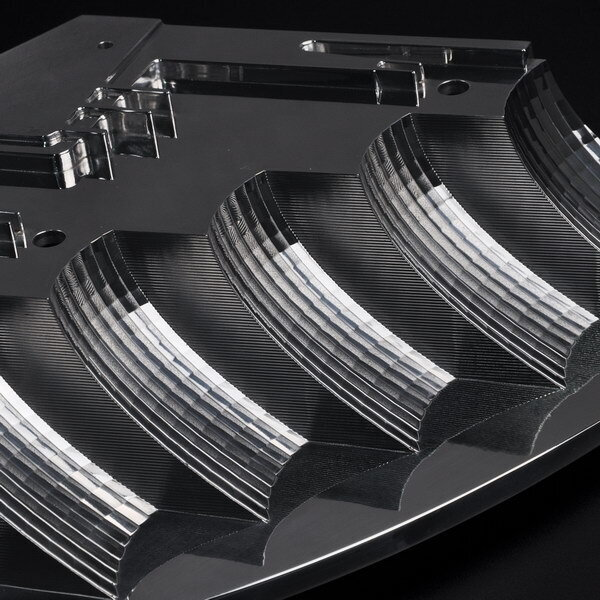

Alt tag “close-up of-lathe-machine-tool-used-for-the-manufacturing-of-precision-parts”

The precision machined parts can manufacture by removing material from components. The manufacturing of these parts accomplishes through the following methods.

Milling

In milling, a rotatory cutting tool uses cutters to remove the material from the workpiece. The milling machines are available in 2-axes and 5-axes. They can do cutting at various angles of a workpiece. The machine shops widely used this versatile method to remove material.

Boring

Boring is the most widely used method for manufacturing precision machined parts and is mainly used to enlarge and finish the pre-existing hole. You can easily replicate this boring method on a workpiece with higher accuracy.

Turning

Turning involves the movement of the metal against the cutting tool to rotate a workpiece to produce the desired shape. These can find in 3-axes, 4-axes, and 5-axes varieties. In turning, a computer-controlled turret uses to mount the tooling. The most commonly used machines in turning are the lathes that rotate the workpiece to remove material.

Drilling

In drilling, a rotating cutter creates new holes in the workpiece. This method also involved the refinement of pre-existing holes. The creation and the improvement of holes are complete with the help of drill presses. It may use with mills or lathes for the production of holes.

Reaming

It is a method in which a rotary cutting tool is used for the smoothness of holes present in a workpiece. The primary purpose of the reaming is to make the walls of the holes even. It also acts as a cutting process; thus, it uses to remove material from a workpiece.

Where are Precision Machined Components Used?

As we know that precision machined parts are highly accurate and precise, and can manufacture by computer-controlled processes, which significantly reduces the risk of errors in the final pieces. Therefore, these highly accurate and precise parts can use for manufacturing various functional products worldwide. The following are some industries that use precision machined parts.

Aerospace

Precision machined parts are widely used in the aerospace industry. While using other industries’ components with minimum accuracy may result in unfunctional parts and additional costs.

As we know, these industries require parts with minimum errors. It means this industry needs the parts with high accuracy and precision for the manufacturing as final components.

The precision machined parts are used in the engines, aircraft bodies, and other vital parts for their accurate and proper functioning. The aerospace industry often requires more rigid materials to manufacture various components. This hardness of material can be achieved by using hard precision machined parts, which may be impossible to accomplish with other machined parts.

Some important machined parts used in the aerospace industry are:

- The landing gear parts

- Fuel flow parts

- Fuel access panels

- Engine mounts

Oil and Gas

The oil and gas industries rely on precision machined parts because of their tight tolerances and high reliability. These industries use parts that are safe to use and prevent any leakage. This selection is because a bit of carelessness can cause oil and gas combustion, resulting in immeasurable damage to lives and property. Some of the CNC machinable parts used in oil and gas industries include:

- Valves

- Rods

- Pistons

- Pins

- Cylinders

These are highly accurate functional parts with minimum errors. These machined parts you can commonly use in refineries and pipelines. The oil and gas industries often require small parts, so these machinable parts are considered the best choice. They not only fit properly but also perform specific functions very well. The most commonly used metal in these industries is Aluminum 5052, a highly corrosion-resistant metal.

Automobile

CNC Precision machined parts are considered the first choice for the automobile industry. The automobile industry requires the parts to manufacture reliable and highly efficient vehicles such as cars, vans, motorcycles, etc. These parts often show minimum deformation and tight tolerance.

Moreover, these parts can be designed with complex features that make these machining parts unique from other components. It also enhances the uniqueness of the vehicles along with functionality. The most common precision parts used in automobile industries include:

- Exhaust parts

- Engine parts

- Valve retainers

- Gearboxes

- Engine

- Brakes

- Steering system

- Fittings and Fasteners

The precision machined parts can use in the fittings and the fasteners. The fittings are the small parts that are commonly used in pipe systems. They can be used for the connection of straight parts of tubes and pipes. Because of the high durability of machined parts, they form durable connections.

CNC precision machined parts are also used in the manufacturing of the fastener. It is a hardware device that operates to combine multiple objects. Most fasteners include:

- Studs

- Screws

- Bolts

- Nuts

- Bolt Clip

- Washers

The precision machined parts make them able to fit perfectly in the things.

Heating, Ventilation, and Air Conditioning (HVAC)

Heating, air conditioning, and ventilation, also known as HVAC, is an automation system that controls the quality of air and heat in a specific environment. The precision machined parts are used in manufacturing heating, ventilation, and air conditioning components.

Precision machined parts are used in the heat pumps that control heat. In cold conditions, these heat pumps provide heat from a hot environment, while in warm conditions, these pumps remove extra heat, thus maintaining a stable climate.

The ventilation and the air conditioning system can control air quality in a specific place. They use exhaust fans manufactured with precision machined parts. These exhaust fans work by removing bad air from a particular area, and this lousy air may include:

- Airborne bacteria

- Carbon dioxide

- Heat

- Smoke

- Dust

- Moisture

The exhaust fans are enormous and efficiently remove the bad air. The exhaust fan used in bathrooms designed the removal of foul odors. Because of precision machined parts, heat pumps, ventilation, and air conditioners are more durable and perform efficiently.

Conclusion

Precision machining parts are formed as a result of the most efficient precision machining process. These machining parts are gaining popularity because of their higher durability, accuracy, efficiency, and tight tolerances. Specific functions controlled by computers use to design the machined parts by removing material through the workpiece.

These processes may include CNC milling, drilling, boring, turning, reaming, etc. Being high-quality parts, they show applications in aerospace, oil and gas, and automobile industries. Moreover, they may use fasteners and HVAC for high performance. In short, precision machining parts make parts more durable, accurate, and efficient.