The working principle of a centrifugal pump is based on forced vortex flow. The forced vortex flow means that when a certain mass of fluid rotates by an external force (leading to an external torque), there is an increase in the pressure head of the liquid. This increase in the pressure head causes the water to be transferred from one point to another. It is a centrifugal force applying to the fluid that makes it flow inside the casing.

The Centrifugal pump operates on the forced vortex flow concept. When a specific quantity of fluid or liquid is permitted to rotate by an external torque, a rise in the rotating liquid’s pressure head occurs. Water is delivered from one site to another via this increase in pressure head. The fluid flows within the casing due to the centrifugal force exerted on it. A Centrifugal pump is an important Product for industrial applications.

Centrifugal pumps are available from a variety of Suppliers and Companies, as well as various manufacturers and distributors, and there are many Centrifugal Pumps for Sale on Linquip. A comprehensive list of Centrifugal pump services is available on the Linquip website, which covers all OEM fleets. Linquip vendors can assist you with this. To learn more about how to connect with a wide range of service providers who consistently provide the highest quality goods, please contact Centrifugal Pump Experts on Linquip.

What is a Centrifugal Pump

Centrifugal Pump is the common type of pump for transferring fluids. Simply put, it uses a rotating impeller to move other fluids applying centrifugal force. This is the accepted choice, especially for moving the fluid from one location to another in many industrial applications, including municipal (water and wastewater plants), agriculture, power generation plants, mining, petroleum and chemical industries, and other purposes.

Centrifugal Pumps can generally operate with large quantities of fluids and very high flow rates. Besides, they can adjust the flow rates over a wide range.

In general, centrifugal pumps are designed to be well suited for fluids with relatively low viscosity, such as water or light oil. More viscous fluids require more horsepower for centrifugal pumps to run. For fluids with higher viscosities, positive displacement pumps are better than centrifugal pumps to help reduce energy costs.

Centrifugal pumps are considered for many of the fluid transfer activities. Therefore, these pumps hold more preference in various industries. The most common applications of centrifugal pumps include pumping water, water supply, supporting fire safety systems, and regulating hot water. Some of the areas where centrifugal pumps are utilized are as follows:

- Energy and oil industries for pumping oil, mud, slurry, and refining purposes and power plants.

- Wastewater treatment systems, irrigation, municipal plants, flood protection procedures, and gas systems.

- The chemical and petrochemical, food, and medicinal industries such as hydrocarbons, cellulose, sugar distilling, and beverage production.

- Aerospace and industrial applications in refrigerants and cryogenics.

- Industrial and fire protection systems for ventilation and heating, air conditioning, boiler feed water, pressure boosting, and fire security sprinkler systems.

Operating Principle of Centrifugal Pumps

In this section, we will discuss how a centrifugal pump operates. Centrifugal pumps work to produce flow or raise a fluid from a lower level to a higher level. The working of these pumps is based on a straightforward mechanism. A centrifugal pump turns rotational energy coming from a motor into energy in a moving fluid.

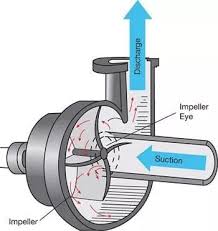

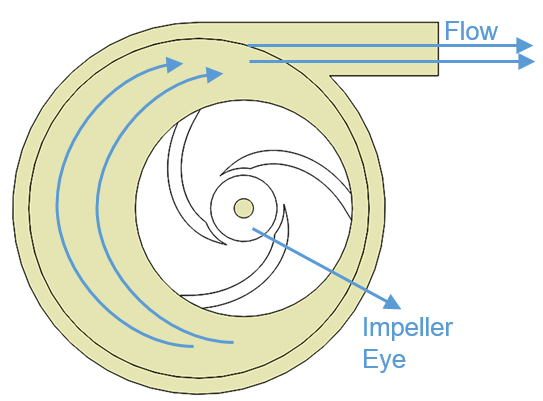

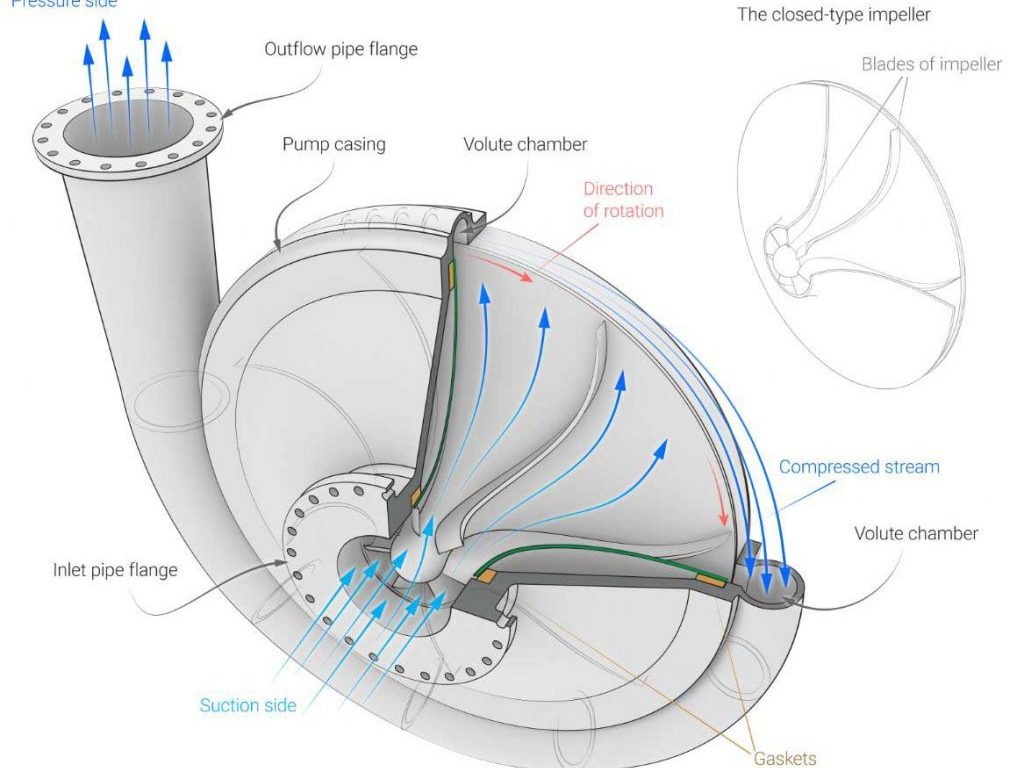

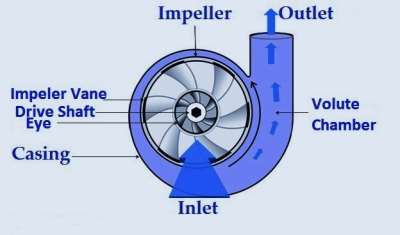

The two main components responsible for this task are the impeller, and the casing, both of which belong to the portion of the pump called the wet end. The impeller is the rotating part, and the casing is the airtight path that surrounds the impeller.

The fluid in a centrifugal pump enters the casing, falls on the impeller vanes at the impeller eye, and rotates radially outward until it exits the impeller through the diffuser (volute) of the casing. As it passes through the impeller, the fluid gains both velocity and pressure.

Working Parameters

Depending on the use in a variety of applications, pumps are offered with different capacities and sizes. You have to consider the pressure and volume required for which you run the pump. Another important consideration is the horsepower required. The following main parameters affect the performance of a centrifugal pump and must be considered when choosing a centrifugal pump:

Fluid Viscosity

This characteristic refers to the shear resistance when energy is applied. Generally, a centrifugal pump is proper for low viscosity fluids because the pumping action produces high liquid shear.

Fluid Density

A fluid density is defined as the mass of the fluid per unit of volume. It directly affects the required input power to pump a fluid. If working with a fluid other than water, it is necessary to consider a parameter called specific density. The specific density (or relative density) of a fluid is defined as the ratio of the fluid density to the density of a given reference (water for liquids) and can be expressed as follows:

RD=\frac{\rho _{liquid}}{\rho _{liquid}}

Operating Temperature and Pressure

The conditions of pumping, such as temperature and pressures, are essential points to consider for any operation. For example, High-temperature fluid pumping may need special gaskets, seals, and mounting devices. Similarly, for high-pressure conditions, a suitable pressure-retaining casing may be required.

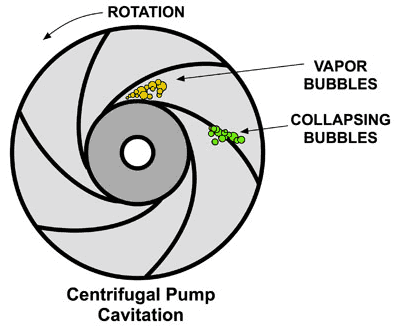

Net Positive Suction Head

Net positive suction head (or NPSH) is a term that indicates the pressure on the suction side of a pump to help you find out if the pressure is high enough to prevent cavitation. Cavitation is an event in which bubbles or cavities in a liquid occur in regions of relatively low pressure around the pump impeller. This phenomenon can cause severe damage to the impeller. It must be ensured that the net positive suction head available is greater than the net positive suction head required, with the appropriate safety margin.

The following relation can be used to find the net positive suction head available:

NPSH_A=\left(\frac{p_i}{\rho g}+\frac{V^2_i}{2g}\right)-\frac{p_v}{\rho g}

The index i denotes the inlet. Also, pv represents the vapor pressure of the fluid. The first law of thermodynamics for control volumes around the suction surface (denoted by 0) and the pump inlet (represented by i) results in the following equation. An assumption is that the kinetic energy at the suction surface is negligible, the fluid is inviscid, and the fluid density is constant.

\frac{p_0}{\rho g}+z_0=\frac{p_i}{\rho g}+\frac{V^2_i}{2g}+z_i+h_f

Using the Bernoulli equation to eliminate the velocity and the local pressure terms, the net positive suction head available is given as:

NPSH_A=\frac{p_0}{\rho g}-\frac{p_v}{\rho g}-\left(z_i-z_0\right)-h_f

Fluid Vapor Pressure

The vapor pressure is the pressure at a certain temperature at which a fluid turns to the vapor phase. To prevent cavitation as well as damage caused by dry running when the fluid evaporates, it must be determined.

Working Steps

Centrifugal pumps are a class of Dynamic pumps. The working principle of a centrifugal pump involves transferring energy to the fluid utilizing a centrifugal force induced by the rotation of an impeller that has multiple blades or vanes. The basic principles of centrifugal pump operation comprise the following stages.

- The fluid enters the pump at the impeller eye.

- The velocity of the fluid increases by the centrifugal force created due to the rotation of the impeller. Therefore, the fluid is radially moved out towards the impeller periphery.

- The fluid is directed to an expanding volute casing or diffuser (depending on the design type), and thus, its velocity energy is converted to a pressure head.

The increase in the fluid pressure head at any point is proportional to the square of the tangential velocity of the rotating fluid. It can be written as:

H=\frac{V^2}{2g}

and

V=r\omega

Therefore, it can be rewritten as follows:

H=\frac{r^2{\omega }^2}{2g}

ω is the rotational speed of the impeller (in rpm).

Priming of Centrifugal Pumps

Priming is the crucial step in the initiation of the centrifugal pump. These pumps are not capable of pumping gases (e.g., air). Priming is needed where the impeller is immersed in the liquid and no air exists inside. Thus, for an initial start-up, priming is an essential action. The other reason that shows the importance of priming is the fill-up of liquid in the casing, which intends to decrease the clearance capacity. There are different ways of priming a centrifugal pump, including manual, using a separator, vacuum pump, and jet pump.

Characteristic Curve of Centrifugal Pumps

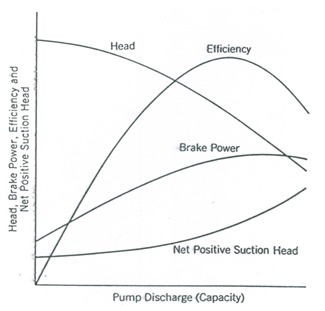

To know the hydraulic calculations of centrifugal pumps, using the characteristic curves is the most common approach. In the following figure, you see the main characteristic curves used to describe the performance of a centrifugal pump over the ranges of flow rates.

Head vs. Discharge Curve

The head-discharge curve shows the relation between the head created by a pump to the water pumped volume per unit time. In general, the pressure head generated by a pump regularly decreases with the increase in the discharge rate of the pump. The values of the pressure head and the discharge at the maximum efficiency point are the parameters known as the design head (normal head) and the design discharge (normal discharge) of a pump.

The trend of the head-discharge curve changes with the specific speed. For radial flow impellers, the head reduces slightly and then drops quickly as discharge increases from zero. Slope changes along the head-discharge curves for the axial and mixed flow impellers are not as high as those for radial flow impellers. The operation of radial flow impellers in the range of the flat portion of the head-discharge curves is well where the head must remain constant as the flow rate fluctuates. However, where a relatively constant discharge rate is desired, and the head fluctuates, the impellers with higher specific speeds work the best.

The following equation gives the specific speed of a centrifugal pump (n is the pump rotational speed in rpm):

n_s=\frac{n\sqrt{Q}}{H^{0.75}}

Efficiency vs. Discharge Curve

The pump efficiency versus discharge curve of a typical centrifugal pump shows that the overall efficiency gradually increases to a peak with increasing Q from zero and then declines with further increasing Q. Normally, for a given impeller type, there is only one peak efficiency.

The efficiency of a centrifugal pump is given as:

\eta =\frac{P_{water}}{P_{shaft}}

It can be defined as the ratio of output power to input power. The output power is related to the water and input to a shaft. The shaft power is the power provided to the pump shaft and the water power is calculated by the following formula:

P_{water}=\rho gHQ

where, H and Q are pressure head (in meters) and flow rate (in kg/m3).

The pump efficiency is a function of impeller design, specific speed, and pump discharge. The larger the capacity of the pump, the higher efficiency. The overall efficiency is related to the materials used in construction, the castings, the machining quality, and the bearings used. For example, very smooth surface impellers are more efficient than rough-surfaced impellers.

Moreover, the efficiency versus discharge curve is usually for a particular number of stages. If a varying number of stages are required for a specific condition, efficiencies must be set up upward or downward based on the number of stages.

Power vs. Discharge Curve

The shaft power (SP) versus discharge curve for a pump can be derived from the head-discharge and efficiency-discharge curves. The shape of the power-discharge curve is dependent on the specific speed and impeller design of the pump. For radial flow impellers, the power rises from a non-zero value to a peak and then drops slightly as the flow increases.

For mixed flow impellers, the power increases steadily from a non-zero value with the increase in the flow.

For axial flow impellers, however, the power is maximum when the discharge flow is zero, and it gradually reduces as the flow rate increases from zero. Therefore, when starting the axial flow pumps, the discharge valve must be open to the atmosphere to minimize the start-up load. Conversely, the discharge valve must be closed as radial flow, and mixed flow pumps are starting to operate.

NPSH vs. Discharge Curve

This characteristic curve illustrates the net positive suction head required (NPSHR) trends versus the pump discharge. It can be seen from this figure that NPSHR gradually rises as the pump discharge increases.

Cavitation

Cavitation includes the creation and breakdown of vapor bubbles in the liquid due to the variation in pressure values. The overall performance of the pump would be affected by the cavitation. To find out if the pump is affected by cavitation or not, the following signs can be helpful:

- Increase and decrease in discharge pressure values

- Inconsistent power use

- The reduction in the efficiency

- Distinct crackling sounds

By reducing the length of the pumps to 4 meters ahead of the water level, the effect of cavitation disappears.

The Structure of Centrifugal Pumps

A centrifugal pump consists of a set of components that some (e.g., shaft, bearing, etc.) are responsible for maintaining the mechanical structure of the pump, and others (impellers and casing) determine the hydraulic function of the pump.

Impeller

The impellers are the rotating parts of centrifugal pumps. An impeller is installed on a shaft that is connected to an electric motor. The motor rotates the impeller. They are available in different shapes and sizes for various applications and the properties of the pumped liquids and are composed of a set of backward curved blades.

The impellers can be made of a range of materials depending on the chemical properties of the pumped liquid. All impellers must be dynamically balanced before they are mounted on the pumps.

Casing

The casing is an air-tight passage surrounding the impeller. The casing design is done so that it is able to convert the kinetic energy of the water coming from the outlet of the impeller into a pressure head before leaving the casing.

There are two major types of casing in centrifugal pump:

Volute

Volute is a spiral casing in which the passage of the liquid gradually increases. This decreases the fluid velocity and increases the fluid pressure.

Diffuser

The impeller is surrounded by several guide blades. These blades are located on a ring called a diffuser. The design of the diffuser-type casing allows the water leaving the impeller to enter the guide blades without shock. The area of flowing water through the blades increases, decreasing the fluid velocity and increasing its pressure. After the guide blades, water moves through the surrounding casing, which usually remains concentric with the impeller.

Shaft

The shaft of a centrifugal pump is the central part of the rotor where other components, including the impellers, the shaft sleeves, the bearings, are installed. The mechanical energy from the motor is given to the shaft. The shaft delivers this power to the impeller to rotate.

Shaft Sleeve

A shaft sleeve of a centrifugal pump is a hollow metal cylindrical tube, which is installed over the shaft assembly to safeguard it in a corrosive environment. Shaft sleeves are usually found in single-stage pumps.

Bearings

The function of the bearings is to hold the shaft or rotor in the correct alignment with the fixed parts under the action of radial and axial loads. Bearings that provide a radial positioning to the rotor are called line bearings, and those that place the rotor in an axial position are known as thrust bearings. Often, the thrust bearings actually act as both thrust and radial bearings.

Sealing Arrangements

The sealing arrangement is an element that seals the rotating shaft as it passes through the non-rotating casing of the centrifugal pump. It reduces the fluid leakage to the atmosphere or the entrance of air from outside to a certain extent and prevents the wear of the sealing faces as much as possible.

Types of Centrifugal Pumps

The centrifugal pumps can be classified based on many factors such as construction, design, application, service, and industrial standards. Therefore, one centrifugal pump can be placed into different groups at the same time. A common way of classification is based on the number of impellers applied within the pump. Accordingly, centrifugal pumps are categorized into the following types.

Single-Stage Pumps

The single-stage centrifugal pump has a single impeller. The design and maintenance of this type are very simple. These pumps are excellent for applications with high flow rates and also, low-pressure purposes. Single-stage pumps are usually used in pumping services like high-flow and total dynamic head (TDH) from low to moderate ranges.

Double-Stage Pumps

The double-stage pumps are built with two impellers working side by side. These pumps are generally applied in middle-head applications.

Multiple-Stage Pumps

The multi-stage pumps are designed with two or three impellers connected in series. The applications of these pumps include high-head services.

Advantages of Centrifugal Pumps

- These pumps do not have any drive seal, which reduces leakage complications.

- These pumps are used to deal with hazardous fluids.

- Magnetic coupling protects the pump from external pressures.

- There is no chance of heat transfer.

Disadvantages of Centrifugal Pumps

- They may lose energy because of magnetic coupling, which causes minimal magnetic resistance.

- An intense load implies the possibility of failing the pump.

- When the pump does not operate for a long time, rusting occurs and leads to damage.

- There is a chance of overheating.

D0wnload Working Principle of a Centrifugal Pump PDf

Read More In Linquip

- Parts of Centrifugal Pumps

- Hydraulic Pump Working Principles: Ultimate Guide

- What Is a Multistage Centrifugal Pump Used for

- 3 Types of Positive Displacement Pump + Name & PDF

- 5 Types of Vacuum Pump and Applications + PDF

- 5 Main Types of Fuel Pump & How They Works?

- Types of Piston Pumps

- The 8 Best Water Pumps of 2022 with Pros. and Cons

- Types of Water Pumps and Their Principles

- Types of Submersible Pumps: All Classification With Details

- Parts of Oil Pump

- Parts of Water Pump

- Working Principles of Hydraulic Pump (With Videos)

- How and When to Replace Your Sump Pump?

- What is Sump Pump and How Does It Work?

- What is Hydraulic Pump: Learn The Basics, Boost Your Knowledge

- Different Types of Hydraulic Pumps: a Complete Guide

- How Does a Hydraulic Pump Work? A Definitive Guide

- Centrifugal Pump Working Principle with Diagram

- 3 Types of Oil Pumps + Working Principle & PDF

- 3 Types of Vane Pumps: Working Principles & Application

- Hydraulic Pump Working Principles: Ultimate Guide

- Types of Water Pumps and Their Principles

- Types of Centrifugal Pumps: All Classification & Working Principles

- 10 Parts of Reciprocating Pumps + Function, Application and Working

- 5 Main Types of Fuel Pump & How They Works?

- How and When to Replace Your Sump Pump?

- What is Sump Pump and How Does It Work?

- Types of Screw Pumps: How Each Type Gives Benefits?

- What Is a Water Booster Pump and How Does It Work?

- 13 Parts of Concrete Pump with Name & PDF

- 6 Parts of Pool Pump + Diagram & PDF

- 20 Parts of Submersible Pump + PDF

A real good post. Appreciated from my end

We’re so happy to hear you had a great experience at Linquip. Your review made our day! Our whole team works very hard to keep our visitors happy, but we can only do it thanks to amazing visitors like you. Thanks again, and we hope to serve you again soon.

Your kind words are much appreciated, Saswato! It was a pleasure having you visit us.

A real good post.Centrifugal Pump Construction, Working, Advantages and Disadvantages

Thanks for visiting our website and leaving your comment! You are encouraged to visit Linquip Tech News, where you can find similar posts.