Working Principle of Diesel Generator – A diesel generator (sometimes known as a diesel genset) is a device that produces electricity by a combination of a diesel engine with an electric generator (commonly known as an alternator). This is a type of engine generator and although most diesel compression ignition engines are designed to run on diesel fuel, specific models are approved to run on other liquid fuels or natural gas. Diesel generator sets are employed in places where there is no access to the power grid as an emergency power source if the grid fails and for more complicated applications such as grid support, peak-lopping, and power grid export. Diesel generator size is crucial to avoid low-load or power shortages.

There are many product choices available in the market today related to diesel generator equipment, devices, and related products. Linquip offers you all the information you need to make the best decision about what is right for you. If you have any questions about diesel generators, it would be our pleasure to assist you. We are available at any time, so please don’t hesitate to contact us. For more information, please do not hesitate to contact our expert team right away. It would be wise for you to take a few minutes to read Linquip’s article entitled, “What is Industrial Diesel GenSets?“.

Become a Linquip Expert, and then you’ll have complete access to everything Linquip has to offer. With a Linquip account, you can demonstrate your industrial technology skills in a way that is customized to industry-specific needs. Would you be interested in contributing to Linquip as a Guest Poster? If you are interested in Guest posts, Linquip can provide you with the option to publish your content on its platform.

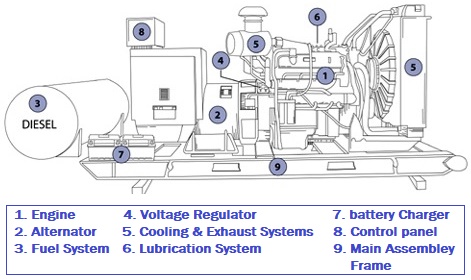

Diesel Generator

Diesel generators are extremely helpful equipment that generates electricity by consuming diesel fuel. A silent diesel generator is a hybrid of a diesel engine and an electric generator that is commonly used as a backup power supply in industrial and residential applications. It can be configured in a variety of physical and electronic ways. These engines are typically installed in rural areas where they are connected to a power grid and can be utilized as a primary or backup power source. Furthermore, diesel generators can be used to offset the grid’s peaking power needs since they can be turned on and off fast, without causing latency. Generators for commercial usage range from 8 KW to 2,000 KW, whereas generators for household usage range from 8 to 30 kW. They are also used on large ships for additional power, which can range from lighting, fans, and switches to providing power to the propulsion system.

Diesel generators, on average, require 0.4 liters of fuel per kWh produced, resulting in a 25 percent efficiency ratio. The efficiency of any diesel generator, on the other hand, is dependent on the situation and how it is used. In essence, the diesel engine is an internal combustion engine. Unlike a gasoline engine, the diesel engine ignites and burns the fuel pumped into the injection chamber using compression heat rather than spark ignition. Diesel engines, in general, have the highest thermal efficiency of any internal combustion engine, especially for continuous and heavy-duty use, allowing for a percentage of the Carnot efficacy. Many crude oil derivatives can be utilized in diesel engines. Natural gas, alcohols, wood gas, gasoline, and diesel are some of the fuels that a diesel engine can burn.

Exhaust gasses are produced when diesel or other fuels are burned. Carbon dioxide (CO2), nitrogen oxide (NOx), and particulates are all produced by diesel generators. These generators release this into the environment, significantly lowering air quality in the surrounding areas. Every liter of gasoline contains 0.73 kilograms of pure carbon, while diesel fuel releases 2.6 kg of carbon dioxide.

The Main Parts of Diesel Generator

The diesel generator is made up of various parts that work together to produce electricity. Some of the most important components of a powerful diesel generator are as follows:

IC Engine: The engine is the most important part of a diesel generator set, as it provides mechanical energy that is later transformed into electrical power. The power output of these generators is proportional to the engine size. The more powerful the engine, the more electricity it produces.

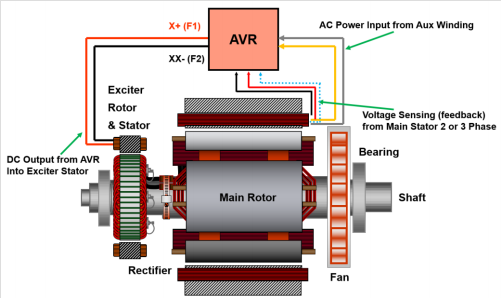

Alternator: The alternator is another crucial component of a diesel generator. It converts the engine’s mechanical input (the spinning of the shaft) into electrical output via induction. An alternator is constructed out of a rotor that creates alternating electricity by producing a magnetic field. Hence, the rotor is regarded as the alternator’s primary component.

In the early 1830s, Faraday discovered (or at least described) the mechanism of “electromagnetic induction”. When you move a wire (or any electrical conductor) through a magnetic field, an electric current is induced in the wire, according to this principle. If the wire is stationary but the magnetic field moves, the same holds. The electrons flow across the wire simply by traveling through a magnetic field. The electrons flow in one direction if the wire moves north-south and the other direction if the wire moves south-north. The more powerful the field and the longer the wire, the more current is induced. Several massive, powerful magnets are arranged in a cluster around a central, revolving shaft in modern generators. This is referred to as the rotor or armature. The magnets could be permanent or electromagnets, but the essential is that they create a magnetic field that causes the engine to spin. The ‘stator,’ which is effectively a series of tightly bundled coils of wire, all packed closely around the rotor, is another significant sub-component of the alternator. The rotor constantly transfers the north and south poles of its magnetic field(s) across the bundles of wire that surround them when an external force (such as a diesel engine) spins the central shaft. This results in a large amount of electrical current flowing back and forth across the cables, which we refer to as ‘alternating current’ or ‘AC’ mains electricity.

Fuel System: The fuel system stores and distributes the fuel to the generator. The most critical factor in getting the engine to run is fuel. The fuel’s chemical energy is transferred to mechanical energy, which is ultimately converted to electrical energy by the engine.

The most visible component of the fuel system is a tank that holds enough fuel to operate for at least 6-8 hours. For smaller, portable generators, this tank may be built inside the generator housing, or it may be a distinct external structure for bigger, permanently installed generators. Other components of the fuel system include pipework to deliver fuel to the engine, a fuel pump similar to those found in most vehicles, a fuel filter, and a fuel tank ventilation pipe or valve to prevent overpressure or vacuum. There will also be an overflow connection to ensure that if the tank is overfilled, the fuel is routed away rather than sprayed on the engine or alternator’s surface.

Lubricating (oil) System: This component ensures that a diesel generator’s different components work smoothly. As a result, to avoid any problems, it’s critical to keep a constant eye on the generator’s lubricating system. Because a generator has a lot of spinning parts, it’s critical to have a good lubrication system that not only protects the moving parts from friction but also keeps them cool.

Voltage Regulator: This is a complicated but necessary component. Without it, the AC produced would vary in voltage and amperage depending on the engine’s speed. Because modern electrical equipment requires a very stable power supply, something must be done to balance it. The workings of a voltage regulator are highly complex, and this content will not go into detail about them.

Cooling System: In addition to mechanical energy, the engine creates a lot of waste heat, just like in a car. The electrical resistance of the wires generates heat when the power passes through the alternator. This heat is absorbed by a coolant fluid, usually but not always water, which then passes via a heat exchanger, discharging its heat into the air or sometimes into a secondary coolant fluid.

Exhaust System: Exhaust gases are produced by all internal combustion engines. These are poisonous and must be kept away from the engine and any humans around. Exhaust gases are usually carried through pipes and released into the atmosphere. Before installing a new generator, check with your local health and safety standards to see how and where exhaust systems must be channeled.

Starter and Battery System: The diesel motor, like the one in a car or a truck, is started by a small electrical motor. This electrical starter motor is powered by a battery that is charged either by a separate charger or by the generator’s output.

Control Panel: The Control Panel houses the Start/Stop button as well as indicators for various parameters, as listed below:

- Start/shutdown controls

- Phase selector switch

- Frequency switch

- Engine mode switch

- Engine speed

- Engine fuel

- Coolant temperature

- Engine oil

- Battery charge

- Generator output voltage

- Generator output current (amperage)

- Generator Output in kVA

- AC power frequency

It’s critical to keep an eye on these traits when operating a generator to ensure that it works properly.

The Housing/Frame: An open structural frame, weatherproof housing, or a transportable unit will house the diesel generator. All of these functions work together to keep the components connected and secure. It also guarantees that all electrical components are grounded correctly.

Diesel Generator Working Principle

The working principle of a diesel generator is established on the thermodynamics law of energy conversion. This law states that energy cannot be created or destroyed but can only be changed from one form to another.

To produce AC (alternating current) power, diesel generators go through a series of stages. When the diesel generator starts, it goes through its four combustion processes: suction, compression, power, and exhaust. As a consequence, the fuel’s chemical energy is transformed into rotational mechanical energy. This mechanical energy is employed to turn a crankshaft. The spinning shaft is now used to rotate the alternator’s rotor. The rotor and stator are the two crucial parts of an alternator that creates electricity.

The rotor, a cylindrical component surrounded by magnets, spins inside the stator, which is made up of a fixed arrangement of conductive copper wiring. In the end, the movement of the magnets across the wiring is what generates electrical charges in the circuit. Electricity is generated when the rotor spins. The magnets surrounding the rotor are precisely positioned to create a magnetic field as they pass through the stator’s copper wiring. The magnetic field is commonly produced by two polarized magnets in an electric generator application. This magnetic field generates voltage, which is captured by the stator. The voltage regulator then delivers the electricity to the desired location while managing the voltage received.

The alternator produces an AC, which is converted to DC with the help of a rectifier in a diesel generator.

Note that the electromagnetic field in the rotor is created by the excitation system. The electrical power produced in the stator is proportional to the strength of the magnetic field formed. Direct current (DC) is used to generate the electromagnetic field, and it can range from 50 amps to 9000 amps or more, based on the size of the generator. Modern excitation systems are static, with DC generated by rectifying AC power with power potential transformers (PPTs) and saturable current transformers (SCTs).

Advantages and Disadvantages of Diesel Generator

The disadvantages of earlier versions, such as higher noise and maintenance expenses, have been overcome by modern diesel engines. When compared to gas engines of equal size, they are now quieter and require less maintenance.

The following are the key advantages of diesel generators:

- Relatively low maintenance: This is because the generator’s engine requires fewer components to start, so you won’t have to change spark plugs or repair carburetors as frequently as you would with a gas engine.

- Durability: Diesel engines are very durable in the workplace, so they can withstand a lot of tears and wear in a range of environments.

- Secure storage: Diesel, while still flammable, has a significantly reduced chance of igniting than other fuels, such as gasoline.

- Power output: Diesel generators can handle higher power loads and can run for longer periods than other types of generators.

- Strength: More strong and reliable.

- Fuel easily accessible: Portable diesel generators are frequently carried behind diesel vehicles. When you’re out and about performing work, you won’t need to carry two separate types of fuel.

On the other hand, diesel generators have several disadvantages, particularly in terms of the environment. 1 liter of fuel produces an average of 2.7 kg of CO2. Diesel generators pollute the environment significantly more than other power sources. It emits not just carbon monoxide but also particulate matter and nitrogen oxides into the atmosphere. Diesel generators also lead to noise pollution, and when compared to other energy sources, they may have a high upfront cost, as well as costly servicing and maintenance. Regular oil changes are the most important continuing servicing requirement for a diesel engine. Well-maintained diesel generators can survive a long time, while those that aren’t, can’t.

Starting the generator in the winter might be difficult. Glow plugs and other heating components can be used to warm up the engine, including the incoming air, to overcome this problem. However, there is a cost involved with this. Diesel generators can create harmful exhaust fumes, are heavy, and are difficult to transport.

(Portable) diesel generators are frequently used in conjunction with batteries for energy storage, even though this combination has considerable drawbacks. For many applications, batteries are considered too heavy, discharge fast, and take a long time to recharge. It is also well recognized that batteries have a short usable life, that they induce atmospheric acidification, and that their manufacture reduces valuable natural resources like cobalt and nickel.

The following are the primary disadvantages of diesel generators:

- Due to rules on greenhouse gas emissions, the price of diesel will continue to grow.

- To keep the generators working, regular maintenance is required.

- The fuel injection system and other components are more prone to failure, resulting in a lack of reliability and expensive spare part prices. Diesel engines are made up of large, heavy components that might be costly to fix.

- Although less expensive, installation may take longer and be more expensive.

- Noise pollution is a serious problem.

- Since diesel engines may be somewhat noisy, they’re frequently located away from work areas.

- Diesel generators are considered too heavy and massive to be termed mobile and compact.

- They must be kept dry to avoid corroding.

- If you live in a cold climate, you’ll need to winterize your generator.

What Type of Motor Is Used in Diesel Generators?

An electric generator and a diesel engine are used to generate electricity by a diesel generator. In most cases, diesel generators use liquid fuels or natural gas as their primary fuel. A diesel generator works by compressing air and burning fuel.

Are Diesel Generators AC or DC?

By spinning the alternator, the diesel engine creates an AC electrical current. Electrical equipment is powered by this. A variety of applications can be served by them, including schools, hospitals, factories, and homes.

Download the Working Principle of Diesel Generator PDF

Our post includes a PDF document that can be saved for future reference and used whenever you need it. The PDF file can be downloaded by following the link below.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Power System Services

- Power System Maintenance Services

- Power System Installation Services

- Power Systems Services in Texas

- Power System Maintenance Services in Texas

- Power System Installation Services in Texas

- How Long to Wait After Using Ozone Generator

- How to Use Ozone Generator in Home

- The Best Diesel Generator of 2021

- Diesel Generator Parts: A Complete Description

- Efficiency of Diesel Generators Calculation: Formula & Equation

- Working Principle of AC Generator

- What Is a Generator? A Comprehensive Explanation of Working Principles, Types, and Components

- What is the Working Principle of a DC Generator?

- Parts of DC Generator: Explanation of Parts, Working, Types, Advantages & Disadvantages

- How to Connect a Generator to Your Home? (Best Guide in 2022)

- How Much Does It Cost to Install a 22kW Generac Generator?

- How Long Can A Standby Generator Run Continuously?

Hi,

Really happy to say your post is very interesting to read. I never stop myself to say anything about it. We are one of the best-selling generator maintenance company in UAE with a wider presence all around the globe.

Thanks for visiting our website and leaving your comment! You are encouraged to visit Linquip Tech News, where you can find similar posts.

Hi,

I’ve just checked your website and I must admit that you did a great job.

Can we get a guest post from your site, please let me know if you are accepting.

Thanks and looking forward to our collaboration.

Thanks for visiting our website and leaving your comment, Sean! We hope to hear from you again in our other posts. Yes, sure you can get a guest post. Visit our guest post page and find the guideline there.