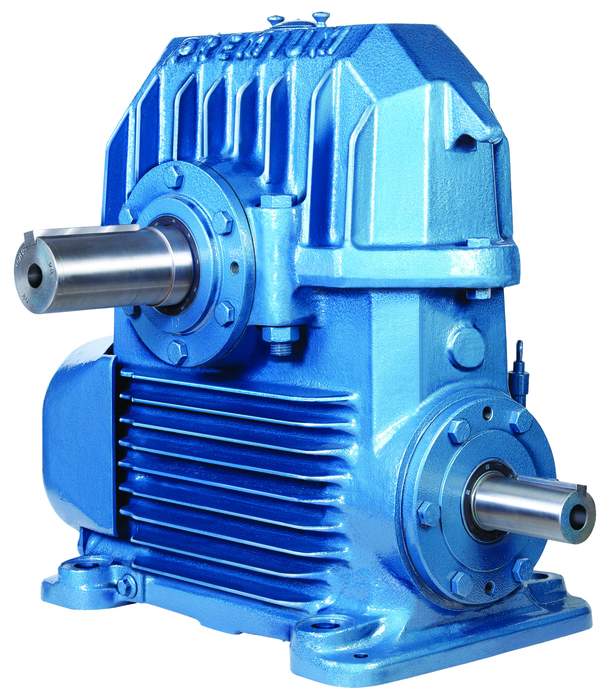

What is a Worm Gearbox? Speaking of Industries, helical gears and worm gears are the two major forms of gears that are commonly employed in several industrial usages. Conventionally, one would go for a helical gearbox model over a worm gearbox. But developments in the worm gearbox model have not only reduced the efficiency gap but have also given worm gearboxes a competitive feature over the helical gearbox.

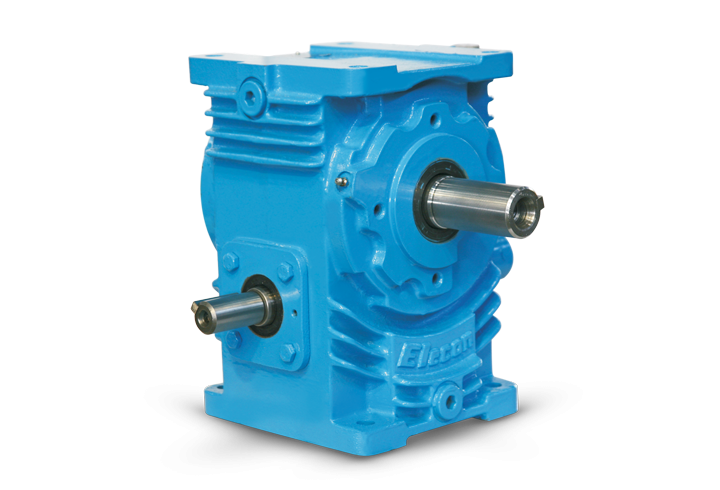

What is a Worm Gear?

A worm gear is a gear including a shaft with a spiral section that engages with and runs a toothed wheel. Worm gears are a traditional form of gear and a sort of one of the six simple machines. Fundamentally, a worm gear is a screw butted up in front of what looks like a normal spur gear with slightly curved and angled teeth.

It modifies the rotational motion by 90 degrees, and the plane of the motion also varies based on the position of the worm wheel on the worm (or simply “the wheel”). They are commonly comprised of a brass wheel and a steel worm.

How do Worm Gears Work?

An electric engine or motor applies rotational energy to the worm. The worm circulates against the wheel, and the screwface pushes on the wheel via the teeth. The wheel is pushed against the force.

Worm Gear Uses

There are a few reasons why one would select a worm gear over other gears.

- The first one is the great reduction ratio. A worm gear can have a high reduction ratio with small effort – all one should do is adding margins to the wheel. Thus, you can utilize it to either greatly improve the torque or highly decrease the speed. It will commonly take several reductions of a conventional gearset to obtain the same reduction rate of a simple worm gear – meaning users of worm gears have fewer moving components and fewer spaces for failure.

- The second reason to employ a worm gear is the inability to reverse the power direction. Due to the friction between the wheel and the worm, it is effectively impossible for a wheel with the load applied to it to begin the worm moving.

- On a normal gear, the output and input can be changed independently when enough load is applied. This makes adding a backstop to a normal gearbox necessary, further raising the complication of the gear configuration.

Why Not Use Worm Gears

There is one especially glaring reason why one would not select a worm gear over a normal gear: Lubrication.

The movement between the wheel and the worm faces is totally sliding. There is no rolling part to the tooth contact or interaction. This makes them comparatively difficult to lubricate.

The lubricants needed are commonly very great viscosity (ISO 320 and higher) and thus are problematic to filter, and the lubricants needed are usually specialized in what they perform, needing a product to be on-site, particularly for that type of equipment.

Where is a Worm Gearbox Used?

For applications that need higher speed, a worm gearbox can be employed. The stainless steel gearbox can also be used. Some of the applications of a worm gearbox are:

- Mining

- Presses

- Rolling mills

- Escalator/ Elevator Drive systems

- Manufacturing and packaging industries

- Small machinery and conveyors

Owing to its special model, the worm gear finds applications in different kinds of Industries. The stainless steel reducer is most commonly used in the food processing industry. Some of the most usual forms or places it is used are:

When there is a requirement for noise control– The contact of two various elements in the worm gearbox decreases the noise pollution, making it comfortable for spaces where noise requires to be detected. Different industrial applications make use of the worm gearbox.

In conditions where swift stopping is required– Because back driving is almost an impractical feat to adapt to the worm gear, they have obtained popularity in the case of instruments where stopping requires to be operated accurately and swiftly, like elevators and lifts.

Where shock loading is a fact– The materials employed in the worm gear are soft in nature, facilitating simple shock absorption with less failure. This special property is extremely beneficial for heavy-duty machines and rock crushers.

When space is a concern– Worm gear is utilized in heavy machinery like trucks barrelling down a deserted highway or great ships in the ocean. Worm gear finds usages in machinery that require to use of torque in limited spaces. The particular shape of the worm gear permits vast versatility and flexibility. They are employed in conveyors, packaging equipment, and commonly all small machinery as well. Visit here to find out more about a worm gearbox.

Advantages of a Worm Gearbox

Due to its mode of performance, a worm gearbox enables high step-down levels. In a worm gearbox, both shafts intersect at a specific distance. This center-to-center space is reflected in the determination of the gearbox shape and size (For Example, center-to-center distance is 100 mm for a typical worm gearbox).

Low-noise Axial-offset Gearboxes

A worm gearbox is a highly accurate and powerful type of axial-offset gearbox. The high-performance gearboxes face today’s high needs in every aspect. They are insensitive to shocks and quiet-running. It is not without reason that they are employed worldwide, inter alia, in transport systems. A worm gearbox is also known as the worm in everyday language.

Worm Gear Lubrication

The basic problem with a worm gear is how it converts power. It is a boon and a curse simultaneously. The spiral motion permits huge values of reduction in a relatively small amount of space for what is needed if a standard helical gear were employed.

This spiral movement also causes an incredibly problematic state to be the primary mode of power conversion. This is usually introduced as sliding wear or sliding friction.

With a common gear arrangement, the power is moved at the peak load section on the tooth (introduced as the pitch line or apex), at least in a rolling wear state. Sliding happens on either part of the apex, but the velocity is comparatively low.

With a worm gear, the sliding output is the only transfer of energy. As the worm moves across the wheel tooth, it slowly wears out the lubricant layer until there is no lubricant layer left, and as a result, the worm wears away at the metal of the wheel in a boundary lubrication section. When the worm surface leaves the top of the wheel, it picks up more lubricant and begins the procedure over again on the next revolution.

The rolling friction on a common gear tooth needs little in the way of a lubricant layer to fill in the places and separate the two sections. Since sliding happens on either part of the apex of the gear tooth, a slightly greater viscosity of lubricant than is strictly required for rolling wear is needed to prevail over that load. The sliding happens at a comparatively low velocity.

The worm on a gear set turns, and once turning, it crushes against the force that is imposed on the gear. The only method to prevent the worm from touching the top of the wheel is to have a layer thickness large enough not to have the total tooth surface wiped off before that section of the worm is out of the power zone.

This scenario needs a particular kind of lubricant. Not only will it have to be a comparatively great viscosity lubricant (and the larger the temperature or load, the greater the viscosity must be), it should have some method to help prevail over the sliding condition present.

Viscosity

Viscosity is the basic feature in preventing the worm from touching the wheel in a gear arrangement. Whereas the size and load of gearing specify the needed lubricant, an ISO 680 or ISO 460 is justly common, and an ISO 1000 is not unheard of. If you’ve ever tried to control this level of viscosity, you learn it is difficult because it is probably that none of the pumps or filters you have on-site will be the appropriate size or rating to perform exactly.

As a result, you would probably require to get a special filter and pump for this form of unit. A viscous lubricant needs a slow working pump to prevent the lubricant from activating the bypass of the filter. It will also need a great surface area filter to allow the lubricant to flow properly.

Lubricant Types to Look For

One lubricant form typically utilized with worm gears is the mineral-based, multiplex gear oils. There are no extra materials that can be put into a lubricant that can prevail over sliding wear indefinitely, but the synthetic or natural fatty additive combination in multiplex gear oils results in good lubricity, providing an additional measure of protection from metal-to-metal touching.

Another lubricant type typically employed in worm gears is mineral-based, industrial Extreme Pressure (EP) type of gear oils. There are some difficulties with this form of lubricants if you are using a worm gear with a component that is yellow metal (brass). However, if you have comparatively low-performing temperatures or no yellow metal existing on the gear tooth surfaces, this lubricant operates well.

Polyalphaolefin (PAO) gear lubricants operate properly in worm gear applications since they generally have good lubricity features. It is essential to watch the additive package with a PAO gear oil since these can have EP additives. A normal-duty antiwear (AW) fortified gear oil will commonly be admissible, but check that the features are compatible with most metals.

Famous manufacturers recommend precisely watch the wear metals in oil analysis checking to make sure that the AW arrangement isn’t so reactive as to cause considerable leaching from the brass. The result must be far less than what would be detected with EP even in a worst-case situation for AW reactivity, but it can show up in metals checking. If you require a lubricant that can tolerate lower- or higher-than-usual temperatures, an appropriate PAO-based lubricant is likely available.

Polyalkylene Glycols (PAG), the fourth form of lubricant, are becoming more usual. These lubricants have perfect lubricity features and do not include the waxes that cause low-temperature issues with several mineral lubricants, making them a perfect low-temperature option. Caution should be taken when employing PAG oils since they are not matchable with mineral oils and some paints and seals.

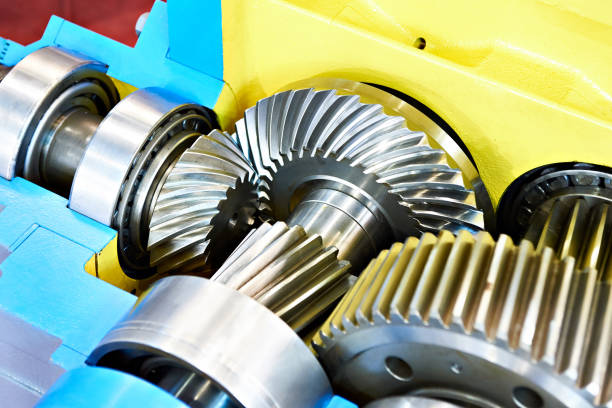

Metallurgy of a Worm Gearbox

The most usual worm gears are constructed with a steel worm and a brass wheel. This is because the brass wheel is commonly simpler to remodel than the worm itself. The wheel is constructed of brass since it is modeled to be sacrificial.

If the two sections come into contact, the worm is usually safe from wear since the wheel is softer, and therefore, most of the wear happens on the wheel. Oil analysis reports on this form of unit almost often demonstrate some level of copper and low values of iron – as a result of the sacrificial system.

This brass wheel throws another issue into the lubrication state for the worm gears. If a sulfur-phosphorous EP gear liquid is set on the sump of a worm gear with brass material, and the temperature is great enough, the EP additive will operate. In standard steel gears, this performance generates a thin film of oxidation on the surface that helps to keep safe the gear tooth from shock forces and other extreme mechanical states.

On the brass surface, however, the performance of the EP additive results in considerable corrosion from the sulfur. You can lose a remarkable portion of the load surface of the wheel in a short amount of time and cause significant damage.

Other Materials

Some of the less usual substances found in small worm gearbox sets include:

Steel worm and steel wheel – This application does not have the EP issues of brass gearing, but there is no place for error built into a worm gearbox like this. Repairs on worm gear arrangements with this junction of metal are commonly more time-consuming and more costly than with a steel/brass worm gear set. This is due to the fact that the material moving associated with failure makes both the wheel and the worm unusable in the rebuild.

Brass worm and brass wheel – This application is most probably found in modest to thin load conditions since the brass can just hold up to a lower amount of load. The lubricant option on this metal combination is adoptable due to the lighter load, but one should still consider the extra restrictions regarding EP since the yellow metal.

Plastic on metal, on plastic, and other equivalent combinations – This is commonly found in comparatively light load usages, such as automotive components and robotics. Choosing the lubricant is based on the plastic in use since many plastic varieties respond to the hydrocarbons in special lubricants, and thus will need silicon-based or other nonreactive lubricants.

Although a worm gear will often have a few issues compared to a normal gear set, it can simply be a reliable and effective piece of equipment. With a little attention to lubricant selection and installation, a worm gearbox can supply appropriate service as well as any other form of gear configuration.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

Exceptional in-depth article. Very informative and very well written. Kudos

Thanks for sharing your experience with us, Jayson! You can also visit our industrial directories, where you can find thousands of various industrial equipment based on your application and demand.