The post outlines essential tools for construction workers who handle concrete, brick masonry, leveling, wood, floorwork, slab work, bricklaying, plastering, etc. Construction tools are crucial for achieving good results throughout a project. It is also important for the workers to use some safety tools against unexpected accidents in addition to these tools.

To give you an overview of construction tools, Linquip provides you with an abundance of information. You will find out about essential tools every builder needs right now in order to do their job more efficiently. Visit our “Tools and Instruments” page to learn more about what Linquip can do for you.

If you are a construction worker or are planning to be, it is likely that you do not have a clear idea of what tools you need. Linquip helps you in this regard. As well, Linquip offers a wide range of Tools and Instruments Products, so you can select the right one for your needs. Linquip gives you the opportunity to get quotes from multiple Tools and Instruments Suppliers and Companies.

The construction industry drives the development of residential, industrial, and commercial buildings, with construction workers holding the tools in hand, guided by project planners and architects.

Although construction is considered a craft, it comprises many different trades and crafts, each with its own set of skills and tools.

In this article, we will cover a variety of tools and equipment that construction workers need for a variety of tasks, including bricklaying, masonry, carpentry, demolition, and electrical work.

Types of Tools Needed for Construction

Tools for construction play a crucial role in building construction since they are an important part of anyone working in the field. In ancient times, wood, bones, antlers, and stone were used to cut, scrape, chop, hammer, and move objects, but more modern tools enabled these activities to be more efficient, accurate, and fast. The following tools may be included among these:

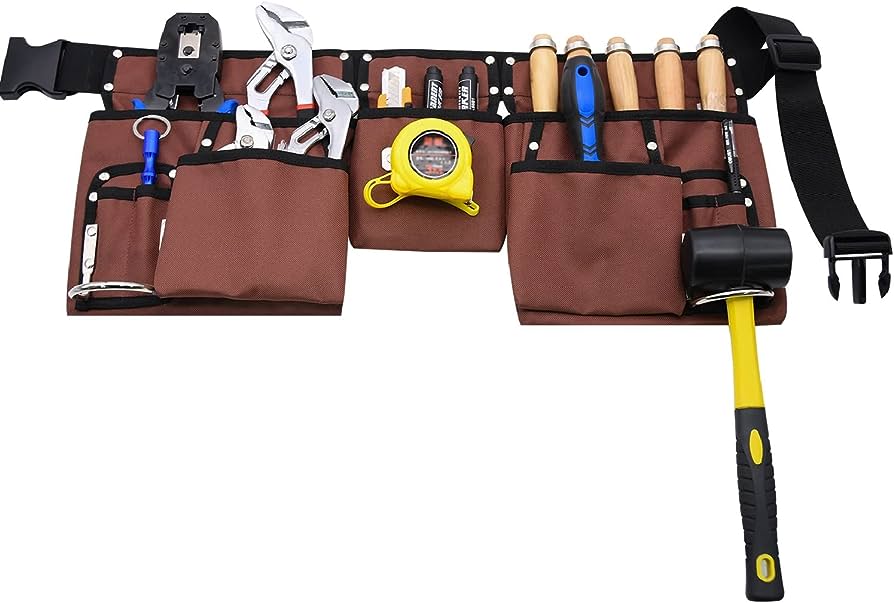

Hand Tools

They are Hand-operated tools (such as screwdrivers, brushes, trowels, wrenches, and clamps).

For thousands of years, stone tools were used to hammer and cut, but they have evolved into durable tools that can handle both indoor and outdoor tasks.

Power Tools

Power tools can either be stationary or portable; portable has more mobility advantages. They operate either with electricity, compressed air, or liquid fuel. When it comes to speed and accuracy, stationary power tools have the edge. As an example, table saws can not only cut faster but also cut smoother, straighter, and squarer than hand saws.

Machine Tools

Machine tools are machines that can cut, bore, or grind materials. Their power comes from something other than human muscle, and they are usually used in manufacturing. The definition of a machine tool varies by user. It is important to note that, although machine tools are used in the making of things, not all machines that perform this function are machine tools.

Generic Tools

The construction industry uses a variety of tools (such as shovels and hammers) for various tasks. In addition to their design and what they are meant to do, they can be made out of a variety of materials as well. But no matter what they are used for, they all play a key role in the construction process.

Discover cutting-edge solutions and unlock your business’s potential at the Brisbane machinery, tools, and building equipment expo.

Tools Used in Construction

Here is a list of the construction tools you might need for your projects, such as masonry, carpentry, painting, or plumbing.

Claw Hammer

Construction workers use claw hammers as their preferred hammer of choice.

There are a few advantages to using this type over others, such as the claw-shaped tail that can be utilized as a pry bar or to pull out nails.

By pressing against a flat surface, the curved head gives the hammer greater pulling power.

Construction contractors commonly use framing claw hammers, a variant of claw hammers that is commonly used in carpentry. With a checker pattern nose, it allows for better grip when framing lumber, while its head weighs up to 32 ounces, making it much heavier than usual hammers.

Brick Hammer

A distant brother of the claw hammer is the brick hammer, also known as the stonemason’s hammer. A flat, square-shaped nose and a flat, pick-shaped tail make up its appearance.

Bricks, cinder blocks, and small stone pieces are cut or chipped with this tool. Using a carpenter’s pencil, mark the cutting line before you begin cutting.

By striking bricks, concrete blocks, or other building blocks with the flat edge of the hammer’s tail, repeated shockwaves create deep cuts to split the pieces along the edge line.

As soon as the whole body has been cut, minor chips are applied to any protrusions, resulting in a near-flat building piece ready to be inserted into corners, arches, or anywhere else.

Drill Driver

The fundamental drill driver has a piece that opens and closes around a bit. When in operation, the drill driver simply rotates the drill bit clockwise or counterclockwise. This tool is mainly used to drill holes in materials like plastic, wood, and metal but is also useful for securing fasteners in these materials.

Hammer Drill

A hammer drill, also called a hammer drill driver, works much like a drill driver but with an additional hammer mechanism that moves the bit in and out, chipping away concrete or rock. Besides being a multifaceted tool, you can also use it for regular drilling if you turn off the hammer mechanism.

Rotary Hammer

A rotary hammer, also known as a combination hammer, uses the same hammering mechanism as the hammer drill to chip away at materials. Its mechanism is far more powerful and delivers much more power than a hammer drill. When it’s time to demolish a building, you can use a rotary hammer as a jackhammer, and you can also use it to drill into concrete, brick, or stone.

Ground Auger

Dirt can be removed from the ground using a ground auger. With this tool, any construction worker will be ready to perform any hole-digging task faster and more efficiently than with a shovel.

Drywall Knives

If you want to work with drywall, you will need to get a variety of drywall knives in four, six, and twelve inches. Make sure you buy drywall knives specifically, as other putty knives will not work as well. In order to slop mud and tap, you will need four- and six-inch blades, while the 12-inch blades will be used for feathering and finishing.

Sanding Sponges

Abrasive sanding sponges are just as the name implies – sponges with an abrasive side and a smoother side. These sponges should not be relied upon for all sanding needs – they should only be used for touch-ups.

Non-abrasive sponges are more like regular sponges, have no rough surfaces, and are perfect for wet sanding.

Jab Saw

There is only one purpose for this highly specialized tool: cutting holes in drywall.

Cordless Drill

Rather than using hammers and nails to fasten drywall, professional drywallers use screw guns. Corded drills can cause frustration because they are more challenging to control when trying to control the torque.

Screwdriver

It is common to use screwdrivers for electrical and plumbing work that is secured with screws. Furthermore, they are used for framing work, although power tools are usually more efficient.

It is necessary to have screwdrivers of various sizes since screws are used in nearly every aspect of the HVAC system, from thermostats to vents. Find a screwdriver that is available in a variety of sizes and types for screwing and unscrewing.

The minimum set of screwdrivers you should have is a Philips head and a flathead, but other types are also becoming increasingly popular with newer construction materials such as Torx and Robertson.

A set of steel screwdrivers with long shanks and resistant handles is a good idea for a substantial budget.

Tie Tensioning Tool

Plastic ties used in HVAC systems are cut and tensioned using these tools.

Metal Shears Attachment

Among the materials that can be cut via these shears are sheet metal, corrugated metal, and ducting.

Circular Saw

A circular saw is a power tool used for cutting straight lines in wood, metal, and even masonry. This tool has a big, circular blade vertically arranged, surrounded by flat metal framing that forms a shaft.

Circular saw blades are specialized for working with specific materials, such as wood or metal. Make sure that you have the appropriate blades for each material before you use your circular saw.

Reciprocating Saw

Saber saws and jigsaws are both power tools classified as reciprocating saws. There is a lot of use for this versatile tool in construction, especially demolition work requiring quick curved cuts at difficult angles.

Reciprocating saw blades move back and forth to produce cutting force, and it goes without saying that they are extremely maneuverable for irregular cuts.

Wall Chaser

The wall chaser is very similar to other cutting tools. It is a smaller version of a circular saw. The purpose of these cutters is to cut plywood or drywall sections for the purpose of installing electrical, piping, and HVAC systems.

Oscillating Tool

An oscillating tool can be used for cutting wood, metal, and a variety of other materials. The utility of this saw makes it stand out from other entries.

You can attach oscillating tools to many different attachments for different types of cuts, some of which come with sandpaper for sanding.

Read more about High Strength oscillating tool blades at WonderBlade

Grinders

Grinding machines can be divided into three categories: angle grinders, surface grinders, and die grinders.

Angle Grinders

In order to fit an end portion of the material properly, angle grinders are used. In addition to grinding on flat surfaces, angle grinders can be used for many other purposes, including polishing and sanding. An angle grinder can be used on construction sites because it works on angles as well as flat surfaces.

Surface Grinders

The purpose of a surface grinder is to create a specific kind of surface finish on materials such as cast iron, steel, and aluminum.

Die Grinders

Originally designed for grinding the precise shape of a die, die grinders are now used to sand and polish finer details.

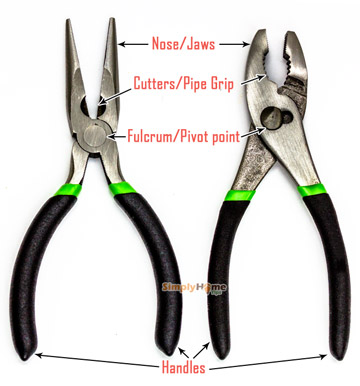

Pliers are versatile hand tools, but they’re primarily used for electrical work. Plier types vary in their capabilities, such as cutting wires, bending them, creating crimp connections, and using them to squeeze and hold objects.

Due to their simple design of two levers connected to a fulcrum, they are capable of creating substantial force by multiplying the gripping force.

Pickaxe

Pickaxes are hand tools with hard-pointed edges attached perpendicularly to their handles. They are used to break concrete surfaces, hardened stone, and dried earth.

Utility Knife

In construction, a utility knife consists of a blade enclosed in a handle that provides a handle for gripping. Among the objects that it can cut are rope, fiberglass, plastic sheets, and drywall.

Utility Vise

The utility vise is a mechanical working tool with two parallel jaws that are fixed and moveable. The jaws are threaded to enhance grip and are used in construction to hold wood and metal materials while a worker works on fabric.

Wedge

It is an object with two inclined edges used for lifting or separating heavy objects. It can also be used for fastening or stopping.

Bolster

Boosters are hand tools with beveled edges and handle used to break hard materials like stone, metal, and bricks in construction. They work when used with hammers or mallets.

Air Compressors

The use of an air compressor can involve blasting off sawdust or other debris from sensitive or tight surfaces. The compressed air is often replaced by a cartridge, while others use surrounding air to compress and release it.

Caulk Guns

Caulking guns are also known as skeleton guns. A silicone or latex material that bonds materials together and fills gaps. It is possible, for instance, to use caulking guns to seal holes or cracks in metal, ceramic, or glass surfaces. There are two types of caulking guns: battery-powered and pressure-powered. Caulking guns use disposable tubes of caulk and a long tube-and-plunger apparatus to deposit the material.

Pliers

You can find dozens of types of pliers for various purposes (for instance, fencing pliers). This variety makes pliers the most diverse hand tools, but you can get by with just a few types as a starting point.

Choosing pliers with insulated handles that provide high electric shock protection is important if you plan to work with live wires or electrical equipment.

As a standard wire cutter, you need diagonal or side-cutter pliers. Unlike lineman’s pliers, which are very similar in jaw size, side-cutter jaws have two blades, but the bladed jaws are shorter to allow them to grip and bend metal, as well as cutting wires.

Compound pliers can be considered a jack of all trades, as they can grip, squeeze, and cut simultaneously, but are not good at any of these functions, so specialized sets are recommended.

Diagonal Cutting Pliers

An ironworker is someone who constructs a building’s framework using their own set of tools. With diagonal cutting pliers, it is easier to cut wire and pins when working with rebar because they can reach places other tools cannot.

Flame-Resistant Canvas Bag

This flame-resistant canvas bag is necessary for ironworkers. Check to make sure your gear meets NFPA-170’s flame-resistant requirements.

Spud Wrench

The spud wrench is also known as the construction wrench. It’s used by ironworkers to align girders and beams during the construction process.

Adjustable Wrench

It is no secret that wrenches are plumbers’ and mechanics’ best friends. However, unless you want to carry a large set of wrenches around all the time, It is recommended that you pick up a high-quality adjustable wrench.

The adjustable wrench is commonly known as the adjustable spanner in English-speaking countries other than the United States.

While adjustable wrenches offer many conveniences, keep in mind that they cannot handle nearly the same amount of torque as standard wrenches.

The best way to gain more torque on a bolt is to switch from an adjustable spanner to a long-handled fixed wrench if the spanner doesn’t move the bolt with one hand.

Set of Fixed Wrenches

Having explored adjustable wrenches’ limitations, let’s explore their simpler counterparts – the fixed wrenches.

For their sturdiness and resistance to abrasion and rust, fixed wrenches are typically made of chrome or stainless steel.

Various types of wrenches are used for turning nuts, bolts, and other rotary fasteners, including open wrenches, ring wrenches, ratchets, Torx wrenches, and more.

Shovel

Shovels

Construction sites are stacked with shovels for a good reason. They create a strong foundation for future construction. They are used to dig trenches for piping, move material from the ground to a container, and prepare foundations.

When choosing a shovel, choose one with steel blades and maple wood handles. This type of shovel will last long and be durable.

Spade

Despite their similar appearance, spades are superior at digging due to their sharp blades. They are used for carrying loads, while shovels are used for digging.

Hoe

In the context of construction, the Hoe is not a commonly used tool, but it can prove valuable when it comes to preparing the ground for the foundation.

Excavation and leveling are necessary before a foundation can be poured. Compared to shovels, hoes are sharp, and their pointed blades are more effective at digging into the ground.

Trowel

Trowels are iconic hand tools used in construction, resembling miniature shovels or flat-surface triangles for masonry work.

Construction work involves two types of trowels – the masonry trowel, for applying cement or other bonding materials, and the flat trowel, which is used in leveling cement or freshly poured concrete.

A trowel may seem like a straightforward tool at first, but it is quite a challenge to master the art of properly utilizing it, and it takes many years to become a master at masonry or concrete laying. Due to their complexity, these skills are often referred to as art forms rather than crafts.

Invest in a trowel that won’t rust, is easy to clean, and also has a comfortable, sturdy handle. You’ll be using this tool for many years, and a durable one will make learning easier.

Rake

Another horticultural tool widely used in preparing construction sites is the rake. Leveling highly granular areas, such as gravel stones and small pebbles, is made easier by their use.

Screed

A screed is used to level and remove excess concrete material evenly from the top of a concrete surface.

Many contractors prefer wider screeds because they are easier to use when concrete is still wet after it has been poured.

Rammer (Hand Rammer Tool)

For ramming layers of soil or material together, the rammer is a simple hand tool. In general, it consists of a wood handle that absorbs vibrations and a square-shaped, reinforced metal head.

When the square head is repeatedly struck against a surface, it will cause soil particles to be pushed together, removing air gaps and preparing the surface for further foundation work.

To ensure the success of the project, the earth must be rammed before the foundation pouring. Water, slipping, and earthquakes are much less likely to damage rammed earth.

Plate Compactor

The plate compactor resembles the rammer hand tool but is more convenient and useful with a power model. In order to ram soil elements together, the bottom plate moves back and forth.

Considering its weight and power, it’s much more convenient than hand ramming, but it’s best used on rough soil for larger projects. In that regard, plate compactors are very easy to operate because they have handles for pushing and steering.

Sawhorse

As the name implies, the sawhorse is more than just a tool; it’s a whole workstation. Basically, it’s a four-legged bench that looks like a horse. With a foldable stand, a sawhorse can be set up anywhere. On construction sites and in small DIY projects, they are a common sight.

With saw horses, you can not only make cuts but also use them as stools, benches, tables, and stands to accomplish various construction tasks.

Ladders

In construction and other trades, ladders are essential, but picking the right ladder can be a challenge. There are three main types of ladders: step ladders, platform ladders, and extension ladders.

Each of these three offers different height levels, so a set of all three will cover the majority of building needs for ordinary houses and smaller structures.

Wheel Barrow

Construction requires a lot of moving and logistical work. Materials need to be transported long distances across difficult terrain. You can make your job easier and faster with the wheelbarrow’s features.

Your body strength is the only limit to the cart’s deceptively big carrying capacity.

Wheelbarrows can also come with a single wheel in front or two wheels at the sides. In general, a one-wheel wheelbarrow is ideal for pushing across flat, curved surfaces.

Tile Cutter

The process of laying tiles is simple and enjoyable when you have the right-sized tiles. In places like bathrooms and kitchens, tiles are usually cut to fit door frames, window shafts, and irregular walls.

The tile cutter is easy to operate and has a simple design. By placing a tile into a cutter and aligning its position with the lever, a tile is cut. When the lever is lowered, and mechanical force is applied, the tile breaks perfectly straight across. In order to create smaller sizes, such as one-fourth of a tile, the process can be repeated with the smaller pieces of the tile.

Measuring Tape

Measuring tapes are essential for ensuring that all measurements are accurate during construction. Measuring is required at every stage of the construction process. A successful project requires accurate measurements since any errors can result in poor results and dissatisfaction.

As a compact and durable measuring tool, the tape measure is widely used. Whenever you need a tape measure, you can take it with you wherever you go. You don’t need to set it up before using it.

Often, they are brightly colored and have large lettering, making them easy to read, even in low lighting.

In selecting the right type of tape, it’s important to consider the length, the material that covers the tape, the fabric encasing the tape, and the standout of the tape – the distance it can cover while remaining straight.

Magnetized tips that stick to metal surfaces are preferred by some. Using this kind of tool, the worker can move backward with confidence that the tape is in place and that the measurement is accurate.

Line Levels

In construction, a line level can be used to check whether your line is straight, such as floors, tiles, windows, and doors. Unless a building is leveled properly, pressure will always be greater on one side than the other, which will negatively impact the structure and result in more expensive repairs.

There are two types of line levels: the spirit line level and the laser line level, with the latter being used primarily in construction.

Due to its simplicity, the spirit line level has been around for a long time in use since the 17th century.

Spirit levels are small tools that contain a vial filled with alcohol that, if the line isn’t straight, shifts to the left or right.

Laser line levels are mostly used on construction sites. They are more accurate than standard line levels because they can project straight lines in multiple planes.

Crowbar

Crowbars or pry bars are long metal bars with one curved end that is split in the middle and another flattened end. Crowbars make it easy to separate objects.

For use on specific job sites, titanium crowbars can be a better choice due to their weight and non-magnetic properties. The curved tip of these tools is used for pulling nails from the material and providing enhanced pressure when separating larger objects, such as floor tiles.

With a crowbar, you are able to pry away objects with greater force, as they serve as first-class levers.

You can also use them to break bigger objects into pieces during demolition.

The wrecking bar is useful for pulling nails from upholstery, the sleeve bar is for removing nails without damaging things nearby, and the molding bar is for removing nails without damaging them.

Sledgehammer

One of the best hand tools for demolition is a sledgehammer, which usually has wooden or plastic handles and a metal head larger than a regular hammer’s. In addition to demolition, this tool can smash rock and concrete, push wooden walls into place, and drive a stake through walls to keep them in place.

It is necessary to use a sledgehammer with two hands as opposed to a regular hammer, not just for its more powerful force but also for its durability. It is necessary to check the safety of this tool often based on the type of work you do with it.

As sledgehammers can be dangerous, workers should always wear safety goggles while using them, along with protective clothing, helmets, and gloves.

Portable Concrete Mixer

The concrete mixer facilitates the work of the workers by providing fresh concrete on-site without having to wait for it.

It’s an easy, time-saving tool that many construction sites use to maximize efficiency. All you need is cement, water, and an aggregate, such as gravel or sand.

Whenever workers handle a portable concrete mixer, they should wear protective gear to avoid splatter injuries.

Sand Screening Machine

For mixing concrete, sand is an essential material. There’s no need to purchase large amounts of fine industrial sand. Natural sand can be found in many types of soil, but it must be screened before being used.

There are several types of screening machines, such as rotating cylinders, shake screeners, and industrial-level machines, that are used for removing rocks, branches, stones, or junk.

Floats

Floats are used by construction workers to eliminate any ridges, holes, or indents after screeding.

The purpose of floating is to smooth the surface with a float, letting the water come out of the concrete since it doesn’t close it, which makes it a crucial step in construction.

These floating structures are usually made from wood, aluminum, or magnesium, and they come in a variety of sizes. Professionals prefer to use magnesium since it slides over surfaces without closing them or dragging concrete.

A bull float is a larger tool that needs to be pushed around using a long handle. This tool covers an area quickly. When a bull float can’t reach a smaller area, workers usually use a hand float or a darby.

Nail Gun

By using nail guns in construction, workers are able to drive nails much faster than using hammers and nails. As a result of their ease of use and ability to increase efficiency, they are most commonly used in housing construction.

In order to avoid injuries, workers should understand the trigger mechanism of the tool. Worker training, explaining trigger mechanisms, and providing proper equipment are therefore necessary. In order to avoid workplace accidents, workers should wear safety goggles, hard hats, and earplugs.

Welding Tool

Any work involving metal requires the use of a welding tool. Using flames or electricity, welding connects pieces of metal into a stable structure.

There are two main types of welding: arc welding and torch welding.

During arc welding, pieces of metal are melted together using an electric welding tool. An even pace and steady hand are required when welding to produce a good weld. A welding rod is often used as a filler material.

By contrast, torch welding heats the metal and connects it with high temperatures using gas-fueled flames.

Concrete Sander

There is often a need to finish concrete surfaces after they are poured. It is necessary to sand the surface before polishing, even with the best leveling efforts and using screeds.

As with regular sanders, concrete sanders work the same way, except that their sanding surfaces are more durable and strong.

Download PDF for Tools for Construction Workers

By clicking this link, you can download the PDF version of this article for future reference.

linquip.com-Tools for Construction Workers (1)

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- The 10 Best Grease Gun + Buying Guide

- The 10 Best Brush Cutter + Buying Guide

- The 10 Best Tire Inflators

- The 10 Best Collapsible Wagon

- The 8 Best Battery-Powered Leaf Blower

- The 5 Best Self-Leveling Concrete + Buying Guide

- The 10 Best Chain Saw Sharpener

- The 8 Best Fuel Injector Cleaner

- The 10 Best Plunge Router

- The 9 Best Truck Bed Extenders

- The 10 Best Air Compressor for Spray Painting

- The 6 Best 3D Printer for Home + Buying Guide

- The 8 Best Pop Up Canopy For Camping

- The 8 Best Pop Up Canopy For Beach

- The 8 Best Reel Mower + Buying Guide

- The 8 Best Canopy Tent

- The 6 Best 3d Printer for Beginners + Buying Guide

- The 9 Best 3D Printer for Under $300

- The 10 Best 3D Printer for Under $500

- The 7 Best 3D Printer for Under $1000

- The 10 Best Industrial 3D Printer

- 10 Types of 3D Printing: A Comprehensive Guide

- What Is 3D Printing and How Does It Work? + Applications

- The 10 Best Expandable Garden Hose

- The 8 Best Commercial Vinyl Cutter

- The 5 Best Chisel Sets for Woodworking + Buying Guide

- The 6 Best Dual Action Polishers

- The 10 Best Tool Box Organizer + Buying Guide

- The 7 Best Jigsaw + Buying Guide

- The 10 Best Drywall Anchors + Buying Guide

- The 10 Best Box Cutter/Utility Knife Options

- The 8 Best Soldering Irons + Buying Guide

- The 9 Best Commercial Patio Heaters + Buying Guide

- The 10 Best Glues for Metal + Tips for Choosing

- The 8 Best Cordless Drills + Buying Guide

- The 8 Best Paint Sprayers + Buying Guide

- The 10 Best Angle Grinders

- 12 Types of Industrial Sewing Machine + Advantages

- Different Types of Bolt Heads + Benefit of Bolts and Nuts

- Different 5 Types of Fasteners: A Practical Guide