Types of Solder – A metal alloy known as the solder melts and unites two metals. Not all solders are appropriate for connecting all kinds of metals. The primary requirement is that the solder’s melting point be lower than that of the metals that need to be connected. Only then will the solder melt first, fusing the metals together.

Linquip provides a wealth of information on solders to help you make an informed choice. By using Linquip, you will have access to the top tools and instruments available on the market at this time, which will allow you to do your job more effectively. On our “What Are Tools and Instruments?” page, we explain what Linquip can do for you based on the intended use of your solders.

Do you plan to purchase a solder? The extensive Linquip’s selection of Tools and Instruments Products makes it easy to find the right tool for your application. You can use this Linquip platform to get quotes for solders. Using our free online form, you will be able to receive quotes from multiple Tools and Instruments Suppliers and Companies in just a few minutes.

We would be delighted to provide you with more information on how we can help you generate revenue within your industry. Don’t hesitate to contact us if you have any questions! With Linquip’s Solutions for Each Company Level, you will be able to upgrade the capabilities of your organization in order to gain a competitive edge by taking advantage of a wide range of options to enhance your organization’s performance. If you are looking for the simplest or the most sophisticated marketing and advertising package for your business, we can help you ensure that your company gets as many customers as possible to grow your business.

What are Solders?

A substance called solder is used to fuse or join items together, such as connecting an electrical wire to a connector or terminal or a pipe to a pipe fitting. A metal alloy whose melting temperature is lower than that of the items being connected is used in the soldering process. When a junction between a copper pipe and a pipe elbow has to be soldered, heat is delivered using a torch or another method. Once the joint is sufficiently heated, solder can be poured there and will melt and flow to seal the joint and create a solid bond between the copper pipe and the pipe elbow.

The temperatures required to form the bond and the subsequent strength of the bond are two ways that soldering varies from other methods of joining metals, such as brazing or welding. The American Welding Society’s approved definition of soldering is that it occurs at temperatures lower than 840oF. (450oC). Stronger bonds that are resistant to stress-induced creep are produced by bonding techniques carried out at higher temperatures.

The two main industries where solder is utilized are plumbing, where it is used by plumbers to create leak-free connections in pipes, and electronics, where it is used by electrical engineers to join circuit components to things like wiring harnesses, connectors, and printed circuit boards (PCBs).

The three main kinds of solder that are most often used are as follows:

- Solder with acid core

- Solder with rosin core

- Solitary-core solder

Additionally, solders come in a variety of form factors, and there are solders designed for certain uses or industries. This article will give a brief overview of the many kinds of solder, taking into account the core style, alloy or substance, form factor, and application.

Working Principle of a Solder

The alloy composition affects the solidifying behavior. At a specific temperature, pure metals become solid and form crystals of a single phase. Eutectic alloys also solidify at a single temperature, with linked growth referred to as the simultaneous precipitation of all components. When non-eutectic compositions cool, the non-eutectic phase begins to precipitate first; dendrites in the case of metals and huge crystals in the case of intermetallic compounds. A mushy state is a mixing of such solid particles in a molten eutectic. Even a small amount of particles in a liquid can significantly reduce its fluidity.

The liquidus of the alloy is the temperature at which all of its constituents are molten, whereas the solidus is the temperature at which the alloy completely solidifies.

When constructing the joint, the mushy condition is preferred since it allows for the filling of wider gaps or wiping over the joint (e.g., when soldering pipes). Electronics soldered by hand may suffer because the junction could seem solid when it isn’t. Such a joint’s internal structure is therefore disturbed by premature manipulation, which compromises its mechanical integrity.

Types of Solder by Composition

Solders are divided into four basic categories according to their composition. Here are some of them:

Lead Alloy Solders

In order to get the necessary melting temperature and tensile strength, lead is combined with other alloys to create this form of solder. It is also called soft solders. Tin is the most often utilized alloy in this composition, along with lead. Tin and lead are combined at a 60:40 ratio.

This combination has a melting point between 180 and 190 C. Tin is selected because it has a lower melting point than other metals. In addition, tin improves tensile and shear strengths. In contrast, lead prevents the development of tin bristles.

Lead-Free Solders

These solders do not contain any lead, as their name implies. The melting point of lead-free solders is greater than that of lead alloy solders.

If you utilize lead-free solders, you may be eligible for tax incentives in the USA. Both the environment and your health are poisoned by lead. As a result, the federal government offers businesses incentives to use lead-free solders.

To avoid tin whiskers, you can employ additions like nickel and conformal coatings in place of nickel.

Silver Alloy Solders

Lead-free or lead-based solders are both acceptable for use with silver alloys. Silver was first solely used in lead-based alloy solders. This was done to stop a phenomenon known as silver migration.

The silver from the silver plating makes its way into the solder. The joints become brittle and more prone to breaking if this solder is applied to the metals before soldering.

The ratios of silver, lead, and other alloys in the silver alloy solders vary. The ratio of these alloys affects how much these solders cost.

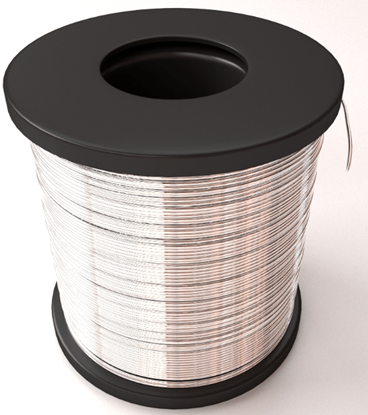

Flux-Core Solders

The flux core solder can be found as wires cut on a cylindrical object. At its heart, a reducing agent is present. The flux is released during soldering, and it eliminates the oxidized coating that has built up on the metal’s surface. The metal surface is thus made clean and prepared for soldering.

It improves the wetting characteristics of the solder in addition to eliminating the oxidized layer. Rosin is used as a flux while soldering electrical components. Acid cores are used as a flux in the plumbing and metal joining industries.

Types of Solder by Core Style

Solders are divided into three categories according to the type of core. Here are some of them:

Solder with Acid Core

The solder in this acid core solder takes the shape of wires that are coiled around a hollow core. The flux inside the hollow core is an aggressive, powerful acid.

The metal oxide layer that has developed on the surface of the metal can be effectively removed by the acid-based flux. Additionally, it shields the metal from further oxidation. It results in joints that are strong and durable as a result.

Steel and other metals are joined with the help of these solders. To stop metals from corroding, you must clear the flux residue after soldering.

In plumbing applications, copper pipes and sheet metal are often joined together using acid core solders.

Rosin Core Solder

The rosin core solder features a hollow core inside the solder wire, the same as the acid core solder. The sole distinction is that this solder utilizes a moderate rosin-based flux.

The key benefit of this flux is that none of its residues will corrode. Because it is challenging to clean up the residue in electrical connections, it is most frequently used while soldering electrical products.

Solder with Solid Core

Instead of using a hollow core, solid core solder employs a solid wire that contains the solder alloy or substance. Flux is not present in them. If you use this solder, you must use separate applications of the flux.

Types of Solder by Form Factor

The most prevalent type of solder is wire solder coiled around a spool. In addition to this, solder comes in a wide variety of different forms.

Solder strips, solder rods, solder pellets, solder rings, solder foil, and ribbon solders are some of the additional popular solder shapes. Depending on the need and the kind of metal to be soldered, the solder form is selected.

In addition to this, pre-coated solder washers are another option that, in the case of electronics, can automate the soldering procedure for through-hole components.

Types of Solder by Application

Plumbing and applications are the areas where soldering is most frequently used.

In addition to these, soldering is utilized in the home, automobile, airplane, and radiation repair. But for soldering operations in these domains, the solders must adhere to specific requirements.

For instance, solders used in airplanes must be resilient to vibration and temperature cycling. Automotive solders are employed in radiation repairs to stop leaks in the coolant heat exchangers of cars.

Additionally, several specialist solders have been created to solder just certain metals. These metals cannot be soldered as effectively using standard solders. Cast iron and aluminum solder are two examples of these solders.

Understanding Solder Blends

Lead, tin, and flux are the three major components of solder; do you remember them? Based on the relative ratios of these ingredients, there are innumerable solder types on the market. There are other chemicals and other metals that may be added to solder to give it certain qualities or improve its conductivity, further complicating issues. A few examples of alloy additives and what they accomplish are as follows:

- While preventing tin pests, antimony promotes mechanical strength without affecting wettability.

- The melting point is greatly lowered by bismuth, which also increases wettability. Tin whisker growth is prevented.

- In the molten state, copper’s wetting qualities are improved and its melting point is lowered.

- Due to its great resistance to temperature changes, indium lowers the melting point, increases ductility, and is utilized for cryogenic applications or for soldering to gold. Alloys made of indium are pricey and prone to corrosion.

- Under bump metallization layer can be shielded from deterioration by the nickel in the solder alloy.

- Silver has less ductility than lead but offers mechanical strength. In lead-free solders, it can increase resistance to thermal cycle fatigue.

When selecting solder mixes, it’s crucial to be aware of any potential galvanic corrosion or brittleness brought on by bringing different metals into contact with one another. Thanks to the large range of solder blends, you can discover the ideal mix of qualities for your electrical equipment.

A solder blend’s particular composition can frequently be employed to achieve a certain outcome.

For instance, whereas solder typically melts between a particular range, a eutectic mixture like Sn63Pb37 melts at precisely 183°C. Low gold leaching makes In70Pb30 compatible with gold contacts, and it has strong resilience to fatigue during heat cycling.

SAC (Sn-Ag-Cu) is a lead-free solder that is well-liked in Japan for use in wave soldering and reflow soldering, both of which involve passing the circuit board over a pan of molten solder. The components on the board are soldered as waves sweep across it.

It all relies on the goals you’re pursuing, the qualities you’re seeking, and the requirements your electrical product must fulfill (e.g., corrosion resistance, thermal resistance, etc.).

FAQs about Types of Solder

1. Which Of The Three Primary Solder Kinds Are They?

Lead-free solder, lead-based solder, and flux-core solder are the three primary varieties of solder. The silver alloy solder is a different kind. These kinds are created using alloy composition. Other solder kinds exist as well, depending on the shape, core type, and application.

2. What Kind Of Solder Is The Strongest?

When soldering metals together, an alloy composed of 60% tin and 40% lead produces the strongest joints. Additionally, due to its low melting point, it is simple to deal with. The drawback is, though, that it is pricey.

3. What Distinguishes Silver Solder From Normal Solder?

More than 45% of the silver in silver solder is silver. It can either be made with lead or without lead. Silver solders are employed to stop a phenomenon known as silver mitigation. It is utilized in mechanical connections and is stronger than normal solder. Due to its high melting point, silver solder cannot be used to link metals with low melting points.

4. Which Solder Works Best For Electronics?

A lead-free rosin core solder works best for soldering electrical components. Tin and copper alloys make up the solder in a 60:40 ratio. Lead can be used in place of copper. But because lead poses a health risk, we do not advise it.

Download Types of Solder PDF

You can download the PDF format of this post from here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- 13 Types of Rivets + Applications & Working Principle

- 33 Types of Pliers & Their Names: A Comprehensive Explanation

- 7 Types of Solder + Working Principle & PDF

- The 10 Best Angle Grinders of 2022

- The 10 Best Welding Machines in 2022 + Buying Guide

- 16 Types of Scaffolding + Components & PDF

- 28 Types of Clamps: A Complete Guide

- The 10 Best Electric Lawnmowers in 2022

- The 6 Best Leaf Blowers of 2022 + Buying Guide & PDF

- The 10 Best Welding Machines in 2022 + Buying Guide

- 9 Types of Pop Rivet + Working Principle (Clear Guide)

- What is Pop Rivets and How Does It Work? (A Comprehensive Guide)

- 9 Types of Pop Rivet + Working Principle (Clear Guide)

- 18 Types of Machining Vises (Clear Guide)

- 8 Types of O-Ring + Applications (Clear Guide)

- The 10 Best Snow Blowers of 2022 + Buying Guide & PDF

- The 10 Best Electric Pressure/Power Washers in 2022

- The 10 Best Torque Wrenches For 2022 + PDF & Buying Guide

- The 8 Best Attic Ladders in 2022 + Buying Guide & PDF

- The 10 Best Electric Space Heater in 2022 + Buying Guide

- The 8 Best Soldering Irons in 2022 + Buying Guide