Gear Pump: Working Principles, Function & Diagram

Gear Pumps pump a constant volume of fluid with each cycle, which is why they are positive displacement pumps. Fluid is pumped by displacement caused by gear meshing in gear pumps. They are one of the most common types of industrial pumps used in hydraulic fluid power applications. They can either act as a motor or as a pump. The gear pump is also widely used in chemical installations to pump fluids with high viscosity, such as oils, resins, paints, and foodstuffs. These pumps are preferred for applications requiring precise dosing or high-pressure output. Due to the fact that gear pumps are not greatly affected by pressure, they are also preferred in irregular supply situations.

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteTop Companies in Gear Pump

+9 Companies in Gear Pump

Top Devices in Gear Pump

Related RFQs

Gear pump

LNQ-23101006

Gear pump

LNQ-23051117

Gear pump

LNQ-23041113

gear pump

LNQ-22121449

Gear pump

LNQ-22121335

Rotary gear pump

LNQ-22111042

PRECISION METERING GEAR PUMP

LNQ-22101041

Gear pump

LNQ-22041254

Top Gear Pump Experts

A Brief Introduction to Gear Pump

In a gear pump, there is always a constant volume of fluid pumped per cycle. In other words, the gear pump is a positive displacement pump. The displacement caused in a gear pump by the meshing of gears enables fluid to be pumped. These pumps are among the most common types of pumps used in hydraulic fluid power applications.

Furthermore, the gear pump is frequently employed in chemical installations where high viscosity fluids are needed to pump.

There are two types of gear pumps: external (including two gears attached to the outside) or internal (with an external gear and a gear attached to its inside). As the gear pump design varies according to the type of fluid and the amount of pressure required, selected variations depend on the viscosity of the fluid and the rotational speed limitations.

You can find a complete list of Gear Pumps for sale in Linquip. Linquip also provides a list of Gear Pump Suppliers and Companies as well as Gear Pump Manufacturers.

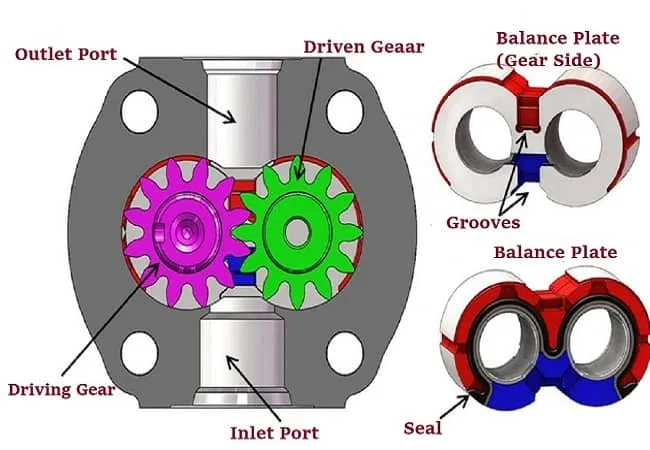

Parts of Gear Pump

Among the major components of the gear pump are:

- Drive shaft

- Seal

- Inlet and outlet ports

- Driver gear

- Drive gear

- Housing

Working Principle of Gear Pump

As the gear pump rotates, it creates a motion that allows it to move liquids. A gear pump operates using the positive displacement principle. The way it works is as follows:

- As soon as the energy is supplied to the drive shaft, the gear pump starts working, and the driver gear, which utilizes the power of the motor, starts rotating as well.

- As with the power or driver gear, the driven or idler gear (that meshes with it) rotates with the power gear, except it does so in the opposite direction. Starting with these two gears rotating, a partial vacuum produces on the pump's suction side.

- As the vacuum is created, the suction-side fluid is sucked into the gear.

- In this process, the sucked fluid is blocked between the gear and housing.

- When the gear teeth rotate, the blocked fluid between the gear teeth and the housing moves, causing the fluid to flow from the inlet to the outlet.

- Likewise, in a driven gear, the fluid transfers from the inlet side to the outlet side, and as a result, the pump discharges high-pressure fluid from the outlet side.

- A gear pump has driven and driver gears that mesh with each other completely, so there is no place for fluid to move. Therefore, fluid cannot flow immediately from the inlet to the outlet side. The flow of fluid inside the pump is very dependent on the movement of these gears, and if these gears do not move, fluid cannot flow.

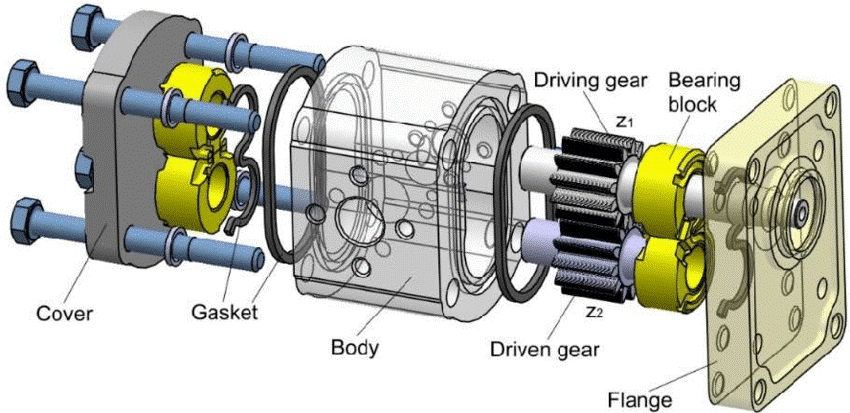

External Gear Pump

Both the power and driven gears of the external gear pump rotate in opposite directions. Power gears are often driven by electric motors or IC engines that rotate further the driven gear. Both shafts can be driven by the same motor. The shafts are supported on both sides of the housing by bearings.

- As the gears on the pump suction side are released from their interlock, the volume increases. Gears moving against pump housing cause fluid to move into the cavity and get trapped by teeth.

- The trapped liquid is then forced to flow around the housing from the inlet to the outlet.

- The volume is reduced when the gear teeth mesh at the pump outlet side, and the liquid is forced to drain under pressure.

- The liquid between the gears cannot return from the center because the gears mesh.

Since the pump gears and housing have a tight tolerance, the pump creates suction on the suction side and prevents liquid from returning from the outlet side (even though low viscosity liquids are more likely to leak). An external gear pump can utilize herringbone gears, helical gears, or spur gears.

Internal Gear Pump

The internal gear pump operates similarly to an external gear pump. However, the internal pump has two meshing gears of dissimilar sizes, and one of the gears rotates inside the other.

Internal gears, which have protruding teeth, are the largest gears. An eccentric external gear is located in this area. It is designed to mesh with the rotor at specific points so that the gear teeth mesh. Pump housings are equipped with bushings and pinions to secure the idler.

It is self-priming, non-pulsating, and can be used for a short period of time while dry. The pump is also bi-rotational, so you can load and unload containers with the same pump. High reliability and ease of use make these pumps a popular choice.

The volume increases upon disengaging the gears on the suction side of the pump. The gears continue to rotate relative to the housing and diaphragm of the pump, causing the liquid to move into the cavity and become trapped in the teeth of the gears.

The trapped liquid travels between the inlet and the outlet of the housing.

Upon meshing of the gear teeth on the pump outlet section, the volume is reduced, and the liquid is forced to drain.

Usage of Gear Pumps

A gear pump is typically used to pump fluids with high viscosities, such as oils, paints, resins, and foodstuffs. Generally, these pumps are preferred when high-pressure output or precise dosing are needed. A gear pump is also selected when the supply is irregular because its output is not affected much by pressure.

Typical Applications of Gear Pumps

Gear pumps are used for a wide range of applications, including:

- Petrochemicals, such as bitumen, pitch, crude oil, lubricants, and diesel fuel.

- Chemicals, such as sodium silicate, acids, mixed chemicals, plastics, and isocyanates.

- Paint and ink.

- Resins and adhesives.

- Acids, soaps, lye, kaolin, lime, latex, sludge, and pulp and paper products.

- Food items, including chocolate, cacao butter, sugar, vegetable fats, molasses, animal foods, etc.

Advantages of Gear Pump

Gear pumps have the following benefits:

- Consistent and even flow is guaranteed.

- Gear pumps are self-priming.

- These pumps are capable of pumping high viscosity liquids. You can use this pump to pump oil and other viscous liquids that a centrifugal pump can't handle.

- Their sensitivity to contamination is very low.

- It is possible to run them in both directions. The pump may therefore be used both for loading and unloading.

- The design of gear pumps is very compact and simple.

- This pump can generate pressures as high as 3000 psi.

- It is inexpensive.

- They have low maintenance costs.

- With a gear pump, it is very unlikely to leak a fluid that is very viscous (such as engine oil). As a result, when pumping a liquid with a very high viscosity, the pump becomes more efficient.

Disadvantages of Gear Pumps

Gear pumps have the following drawbacks:

- Their noise level is very high.

- Since gear pumps use meshing gears, abrasive fluids cannot be used.

- Gear pumps are unable to handle high flow rates due to their limited size.

FAQ about Gear Pumps

- Are Gear Pumps Suitable for Pumping Water?

A gear water pump is beneficial for many applications. However, they aren't solely used on water. Chemical and petrochemical industries use them as well as hydraulic applications. This allows for the handling of viscous and aggressive fluids.

- What Is a Gear Pump Used For?

Gear pumps are commonly used to pump high-viscosity fluids such as oil, paint, resin, and foodstuffs. Additionally, they are the best choice for applications that require accurate dosing or high-pressure outputs.