Reciprocating Pump: Working Principles, Function & Diagram

A Reciprocating Pump uses a piston or plunger for pumping the fluid from one location to another. Because a reciprocating pump uses a piston or plunger for pumping purposes, therefore, it is also known as a piston pump. Reciprocating pumps are generally designed to pump in low flow, high head applications. These pumps are very efficient and can be made from a variety of material to handle different kind of chemicals. At Linquip, our goal is to help you select and purchase the best pump possible for your application, and we are here to help you on all stages of design, purchase, and maintenance. Feel free to browse our comprehensive list of reciprocating pumps, reciprocating pumps' manufacturers, and service providers, or if you feel overwhelmed, just contact us and our experts will help you on with every stage of your project.

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteTop Companies in Reciprocating Pump

+1 Companies in Reciprocating Pump

Top Devices in Reciprocating Pump

Celeros Flow Technology

Related RFQs

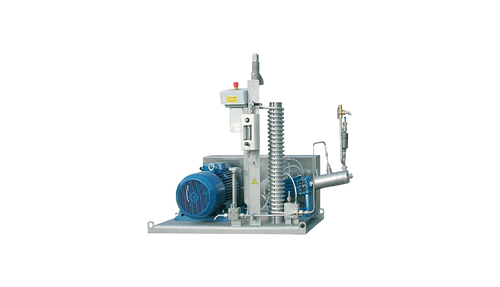

RECIPROCATING PLUNGER PUMP

LNQ-23101197

RECIPROCATING PLUNGER PUMP

LNQ-22121423

RECIPROCATING PLUNGER PUMP

LNQ-22121323

Reciprocating Pumps

LNQ-22121039

RECIPROCATING PLUNGER PUMP

LNQ-22081003

RECIPROCATING PLUNGER PUMP

LNQ-22011146

RECIPROCATING PLUNGER PUMP

LNQ-21111007

RECIPROCATING PLUNGER PUMP

LNQ-21081016

Top Reciprocating Pump Experts

What is a Reciprocating Pump?

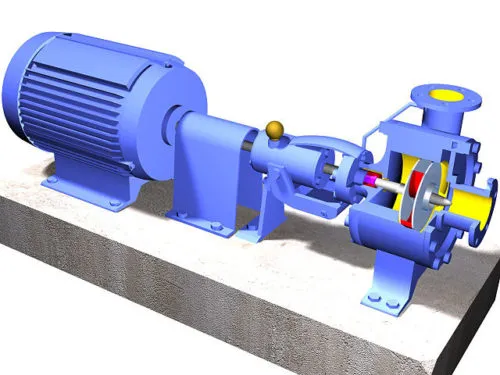

A reciprocating pump is a type of industrial pump. The piston, plunger, and diaphragm pumps are all examples of reciprocating pumps, which are positive-displacement pumps. Reciprocal pumps can endure for decades if they are properly maintained. They may, however, succumb to wear and tear if they are not properly maintained. It's commonly utilized when dealing with a small amount of liquid and high delivery pressure. A stationary cylinder containing a piston or plunger is used in reciprocating pumps to trap the liquid.

Reciprocating Pump Working Principle

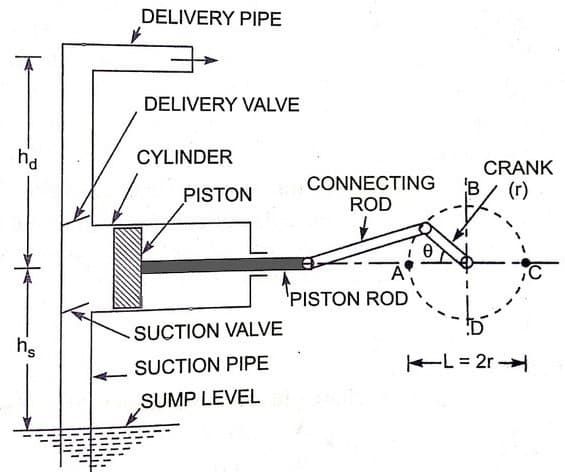

The reciprocating pump operates on the positive displacement principle. The piston of a reciprocating piston pump goes back and forth in a cylinder. With the help of a connecting rod, the piston is connected to the crankshaft. The connecting rod moves as the crankshaft rotates, causing this piston to move. The crankshaft is connected to a rotating motor.

With a suction valve and a delivery valve, the pump cylinder is linked to a suction pipe and a discharge pipe. The input and exit valves act as check valves, allowing only one direction of fluid flow. Through the input valve, the fluid is sucked into the cylinder. The outlet valve allows the fluid to exit the pump's cylinder.

When the crankshaft is in the A position, the piston is at the far-left position inside the cylinder, as noted in the diagram above. The piston in the cylinder advances to the extreme right side when the crankshaft revolves from A to C (θ= 0 ° to 180 °).

A partial vacuum is formed inside the cylinder when the piston moves to the right. The air pressure, on the other hand, operates on the surface of the fluid in the sump, which is higher than the pressure in the cylinder.

The pump suctions fluid from the sump into the suction pipe due to a pressure difference between the cylinder inner and sump pressures.

The fluid opens the pump's inlet valve and begins to flow into the cylinder. The crankshaft revolves from C to A (θ= 180° to = 360°) when the suction process completes, and the piston moves from the right to the left position of the cylinder.

The cylinder capacity is reduced when the piston inside the cylinder advances to the left. The cylinder's internal fluid pressure rises above air pressure as a result of this.

The input valve closes and the discharge valve opens as the piston pressurizes the fluid and the cylinder inner pressure rises above atmospheric pressure, allowing fluid to flow into the delivery pipe and to the appropriate place.

Various Types of Diaphragm Pumps

Reciprocating pumps can be categorized based on various perspectives.

By source of employment:

- Reciprocating pump that can be controlled by hand. The bicycle pump, for example, is ubiquitously used to inflate bicycle tires and other forms of sporting balls. Because it causes more compression than volume displacement, the phrase "bicycle pump" isn't quite accurate.

- Deep well reciprocating pump with an electric motor.

By way of mechanism:

- A single-acting reciprocating pump has a piston with only one side engaged with the fluid to be moved. A syringe is the most basic example.

- With a double-acting reciprocating pump, both sides of the piston are engaged, and each piston stroke performs both suction and expulsion at the same time. As a result, two inflow pipes and two outflow pipes are required.

- Reciprocating pump with three acts.

By Numbers of Cylinders:

- A single cylinder attached to a shaft is referred to as a single cylinder.

- A double cylinder is made up of two cylinders that are joined by a shaft.

- Three cylinders are connected to a shaft in a triple cylinder.

You are also encouraged to visit the List of Reciprocating Pump Distributors in Linquip.

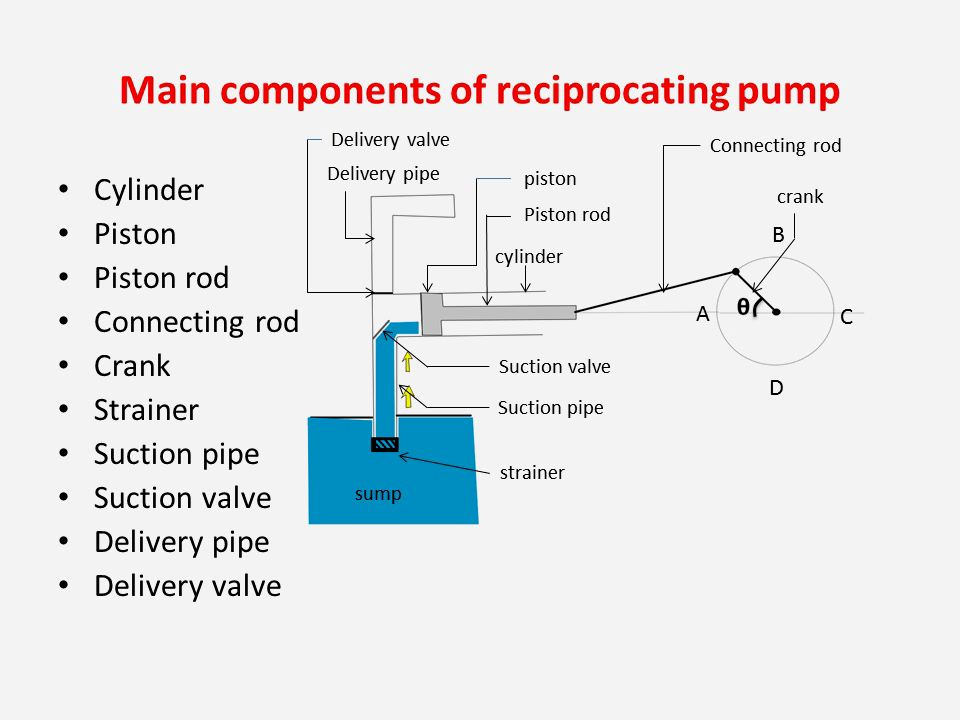

Main Components of Reciprocating Pump

The basic notion of a reciprocating pump has many applications, and it is vital to understand the basic pieces in order to understand the basic idea.

The fundamental components, as well as their functions;

- Water reservoir - It is not a part of the reciprocating pump, but it is the primary source of water for the reciprocating pump. It could also be a source of other fluids.

- Strainer - To keep the pump from being clogged, it eliminates all contaminants from the liquid.

- Suction Pipe - It is a pipe through which the water from the reservoir is pumped.

- Suction Valve - It is a non-return type valve that is positioned on the suction pipe and allows water to flow from the reservoir to the pump rather than the other way around.

- Cylinder or liquid cylinder - The principal component that is subjected to higher pressure. It's a hollow cylinder with various coatings on it. It is made up of piston and piston rings.

- Piston or plunger and Piston rod - The piston is attached to a rod called the piston rod. The connecting rod is connected to the piston rod once more. The piston creates pressure inside the cylinder by revolving in a forward and backward motion.

- Piston rings - Piston rings are a small but important component that protects the piston and cylinder inner surfaces from wear and strain. It aids in the smooth operation of the pump.

- Packing - Packing is required for all pumps to ensure appropriate cylinder-to-piston sealing. It aids in the prevention of leaks.

- Crank and Connecting rod - The power supply is connected to the crank, and the connecting rod connects the crank to the piston rod. This component aids in the conversion of circular motion to linear motion.

- Delivery valve (non-return valve) - The delivery valve, like the suction valve, is a non-return valve that aids in the build-up of pressure. It acts as a backflow preventer for the pump.

- Delivery pipe - It assists in the delivery of fluid to the desired location.

- Air Vessel - An air vessel is seen in a few reciprocating pumps, and it serves to lower the frictional head or acceleration head.

You can find various Pump Suppliers and Companies in Linquip that can completely cover your requirements.

Reciprocating Pump Application

The following are some examples of how reciprocating pumps are used:

- Cleaning of vessels, pipes, tanks, tubes, condensate pipes, heat exchangers, and so on.

- Drilling, refineries, production, disposal, and injections are all aspects of the oil industry.

- Applications involving pneumatic pressure.

- Cleaning of the vehicle.

- Cleaning of sewer lines.

- Sandblasting in the wet

- Feeding the boiler

- Pumps for the RO system that operate at high pressures (Reverse osmosis)

- Tanks, vessels, and other structures are subjected to hydro testing.

- System for battling fires.

- System for sewage treatment.

FAQs about Reciprocating Pumps

- What is the Difference Between Centrifugal and Reciprocating Pumps?

The major distinction between a centrifugal and a reciprocating pump is that a centrifugal pump operates at a low, medium pressure head, whereas a reciprocating pump operates at a high, medium pressure head.

- Which Is an Example of a Reciprocating Pump?

The bicycle pump, for example, is ubiquitously used to inflate bicycle tires and other forms of sporting balls. Because it causes more compression than volume displacement, the phrase "bicycle pump" isn't quite accurate.

- Which Pump is More Efficient?

A reciprocating pump is more efficient than a centrifugal pump in general. Reciprocating machines are commonly used in low-flow/high-head applications. On low-flow/high-head operations, centrifugal pumps can have efficiency as low as 40%.