Mixed Flow Pump: Working Principles, Function & Diagram

A centrifugal pump with a mixed flow impeller is known as a mixed flow pump. Low-speed mixed flow pumps have specific speeds between 35 and 80 rpm, while higher-speed mixed flow pumps have specific speeds between 80 and 160 rpm (in special cases even higher). Mixed flow pumps are used to bridge the gap between radial and axial flow pumps (e. g. propeller pumps). Mixed flow pumps with a low specific speed combine their impellers with an annular or volute casing, whereas those with a higher specific speed combine their impellers with a diffuser and a tubular casing. With so many different capabilities for various pump designs, we at Linquip recognize that you'll want as many options as possible. The mixed flow pump's unique characteristics allow it to be used in some specialized situations where other types of centrifugal pumps fail, particularly in the range between radial and axial flow pumps. Sewage, industrial waste, seawater, and vaper mills are all pumped with mixed flow pumps. Mixed flow pumps can work with dirty or turbid liquids because of the impeller's distinctive diagonal design. As a result, sewage or industrial liquids containing suspended particulates are frequently pumped using mixed flow pumps. Dewatering and pumping seawater are also done with mixed flow pumps. Pumping pulp in paper mills is another application for mixed flow pumps. The Linquip Team will answer any questions you may have. We recognize that each industry's needs are distinct, and we take pride in providing the most innovative system options available. There is a complete list of mixed flow pump suppliers on the Linquip platform, which can meet all industrial applications.

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteTop Companies in Mixed Flow Pump

Top Devices in Mixed Flow Pump

Mixed flow pumps are centrifugal pumps that have a mixed flow impeller added to them. The fluid flow within these pumps is pumped both axially and radially. Although less prevalent in residential applications, these pumps are essential in many industrial applications. Continue reading to learn more about mixed flow pumps, their applications, and their advantages and disadvantages.

Mixed Flow Pump

Mixed flow pumps are centrifugal pumps that perform the same primary purpose. To put it another way, they work by sucking air through a rotating impeller. Due to the centrifugal force caused by the impeller, after the fluid is sucked in, it is pushed out towards the outlet.

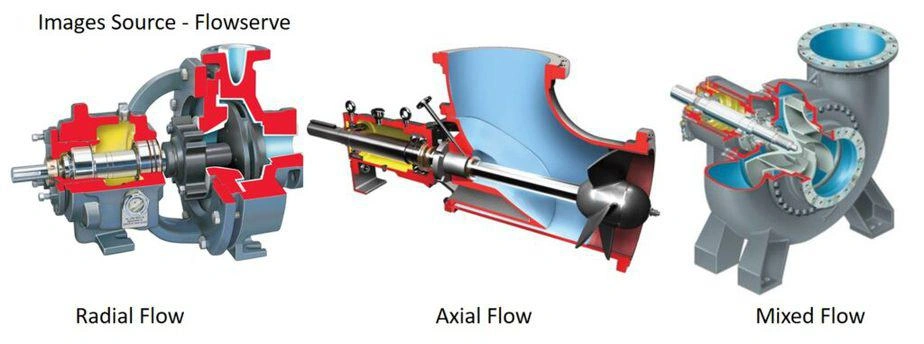

Centrifugal pumps are classified into three groups based on their orientation:

- Axial pumps

- Radial pumps

- Mixed flow pumps

Mixed flow pumps differ from typical centrifugal pumps in that they incorporate design elements from both axial and radial pumps. Their design consists of a diagonally operating impeller that employs centrifugal force to move water out of the pump and provide it with an axial pushing motion. Mixed flow pumps may achieve high flow rates and discharge pressures thanks to this dual pumping action.

Linquip has a variety of Mixed Flow Pump Suppliers and Companies that can provide you with the latest information about mixed flow pump equipment. You are also encouraged to visit the List of Mixed Flow Pump Distributors in Linquip.

Working Principles of A Mixed Flow Pump

The mixed flow pump is a type of water pump that has both centrifugal and axial flow pump features in terms of structure and operation. When the impeller is rotated by power machinery, the blades push the water body on one hand while also rotating the water body to produce centrifugal action on the other. Under the effect of the thrust and centrifugal force of the blades, the water body produces flow and builds pressure. The water enters the impeller axially and exits obliquely along the blades. It is frequently utilized when considerable conveying displacement and mild pressure are required.

Volute and guiding vane types are the two most common varieties. The volute mixed-flow pump has a similar structure to a centrifugal pump. The water flow via the impeller generates kinetic energy, which is converted into pressure energy by the volute-shaped flow channel. A volute construction is commonly used in medium and small mixed-flow pumps. The guide vane mixed flow pump, also known as a diagonal flow pump, has a similar structure to an axial flow pump, with a small radial size and a simple and light structure. Large-scale mixed-flow pumps are mainly made up of guiding vanes, which can be modified in terms of installation angle. The mixed flow pump has a head range of 3 to 10.5 meters, has a low beginning power, and can respond to changes in the water level. The flow rate ranges from 0.1 to 50 meters per second, with a 64 to 86 percent efficiency. Huge mixed flow pumps have advanced rapidly since the 1970s, and they are increasingly being used to replace large axial flow pumps.

You can visit Mixed Flow Pump Equipment in Linquip to get further information on this equipment.