Fire Hydrant: Working Principles, Function & Diagram

Fire Hydrant Pump systems (also known as fire pumps, hydrant boosters, or fire water pumps) are used to increase a building's fire fighting capacity by increasing the pressure in the hydrant service when the mains pressure is insufficient or the hydrant is tank fed. Pumps like this can also be used for irrigation and water transmission. A fire sprinkler system's fire pump allows high-pressure water to enter the system, allowing the water flow rate to be raised. When there is insufficient water supply, a fire pump is required to meet the flow and pressure needs of fire suppression systems. A fire pump is necessary if the supply cannot keep up with the demand. On the other hand, a fire pump isn't necessary if the water supply meets the required pressure and flow.

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteTop Companies in Fire Hydrant

Top Devices in Fire Hydrant

Related RFQs

Fire Hydrant category

LNQ-22121274

What is a Fire Hydrant Pump?

Fire hydrant pump systems (which is a type of industrial pump and also identified as fire pumps, hydrant boosters, or fire water pumps) are high-pressure water pumps that are used to increase a building's fire fighting capacity by raising the pressure in the hydrant service when the mains pressure is insufficient or when the hydrant is tank fed. They can also be utilized in irrigation and water transfer applications.

Fire Hydrant Pump Working Principle

A fire pump is an important component of a fire sprinkler system because it allows high-pressure water to enter the system, boosting the water flow rate.

To comprehend how a fire pump works, you must first comprehend what a fire pump is. A fire pump is made up of the motor - or driver - and the controller, in addition to the pump itself, which is an important component of the system. A fire pump collects water from an underground water source, a water tank, lake, or reservoir and is driven by electricity or diesel fuel as part of a fire sprinkler system. Water is distributed through the sprinkler system and hose standpipes thanks to the pump's high pressure.

Types of Fire Hydrant Pump

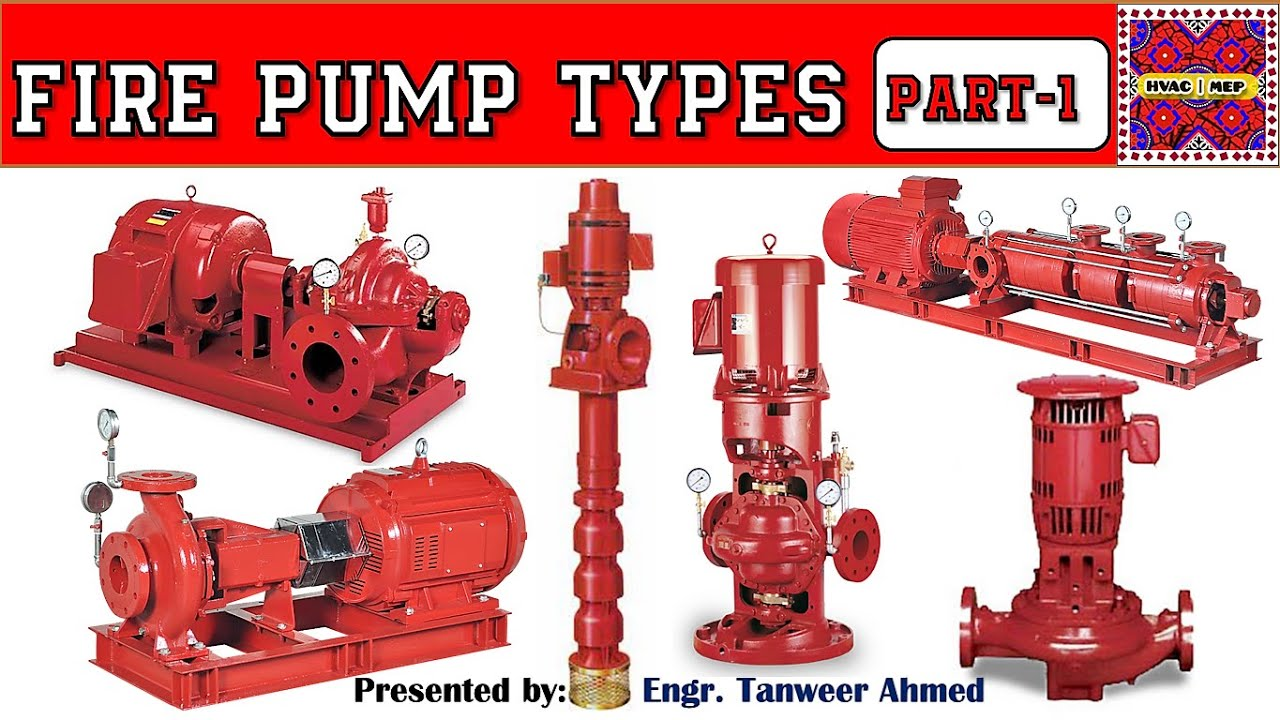

The horizontal split case, vertical split case, vertical in-line, and vertical turbine are all common types of fire pumps.

The horizontal split case is the most popular style of the fire pump. For larger flow applications, these pumps are the most cost-effective, and they are conveniently accessible for repairs and maintenance. They're even more popular because of their extended lifespans and variety of sizes.

Vertical split case fire pumps are comparable to horizontal split case fire pumps, with the exception that they take up less space owing to their vertical construction, which also protects the pump from flooding.

The vertical in-line pump is a single-stage centrifugal pump that is designed for vertical installation, as the name indicates. This pump delivers a steady flow of water throughout the system and is perfect for tiny areas since its suction and delivery are in line with each other. The pump must be removed for any repairs or maintenance due to the design.

The vertical turbine is a centrifugal pump used in firefighting applications when the water supply is underground. There are several varieties of fire pumps, including oil-lubricated enclosed-line-shaft pumps and water-lubricated open-line-shaft pumps. Both varieties are intended for use in drilled wells, lakes, streams, open wetlands, and other underground sources.

The design engineer, a fire safety specialist, and the Local Authority Having Jurisdiction (AHJ) should all be consulted when deciding which pump is best for a certain facility.

Installing and Maintaining Fire Hydrant Pump

Installation and maintenance of any fire system, including deciding which pump and system to utilize, should be done by fire safety specialists. According to the National Fire Protection Association (NFPA) and the International Building Code (IBC), which are revised regularly, there are several factors to consider.

Though trained personnel on-site can perform weekly inspections, monthly, annual, and subsequent inspections and maintenance should be conducted by skilled staff, including factory-trained and certified personnel, personnel certified by a nationally recognized fire protection organization, or personnel registered, licensed, or certified by a state or local authority.

In many structures, a fire pump is essential fire and life-safety equipment. Before the installation of any unit, there are several needs and aspects to consider. To guarantee a well-planned and compliant final installation, the building owner, engineer, architect, local fire marshal, and fire protection supplier should all engage in the pump and system conversation.

You can find various Pump Suppliers and Companies in Linquip that can completely cover your requirements. You are also encouraged to visit the List of Fire Hydrant Pump Distributors in Linquip.

FAQs about Fire Hydrant Pump

- What is the use of a fire pump?

Fire pumps are used to boost the pressure of water coming from a municipal underground pipe system or a static supply (e.g., tank, reservoir, lake).

- What is a fire pump motor?

A fire pump is an electric or diesel-powered component of a fire sprinkler system's water supply. Electric motors, diesel engines, and, on rare occasions, steam turbines power fire pumps.

- Is a fire pump required?

When there is insufficient water supply, a fire pump is required to meet the flow and pressure needs of fire suppression systems. A fire pump is necessary if the supply cannot match the demand. A fire pump, on the other hand, is unnecessary if the water supply can match the pressure and flow requirements.

- What is the pressure of the fire pump?

At their rated flow, the manufacturer certified fire pumps to create a specified amount of net pressure (usually between 40 and 250 psi). It's worth noting that the rated net pressure is normally only reached after the pump's rated flow is reached.