Heavy Duty Gas Turbine

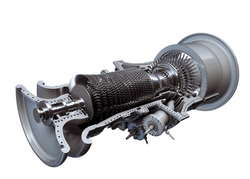

Heavy Duty Gas Turbines are large size (more than 75MW) industrial gas turbines which are generally used in power generation in big power plants. Heavy-duty gas turbines are capable of burning a variety of fuels, ranging from natural gas to heavy liquid residuals. Several generations of heavy-duty gas turbines are installed and operated in utility power plants. heavy duty gas turbine generations are denoted with letters such as D/E, F, and G/H/J classes/frames. D and E-class gas turbines are usually within the range of 75–100 MW and are robust and reliable while don has a superb efficiency and generally burns cheap or is of low-quality fuel. F-class gas turbines are more developed machines in the range of 150–250 MW, mostly designed for combined cycle power plants. G, H, and J classes are recently developed machines in which implementing new high tech technologies resulted in a new generation of gas turbines with an output of more than 250 MW, and superb efficiency of more than 62%. All types and classes of heavy-duty gas turbines consist of three major sections: compressor, combustion system, and turbine section and several auxiliary systems such as air inlet, exhaust, fuel module; lube, and hydraulic systems. Selection of the best type of heavy-duty gas turbine has always been a challenge for the design engineers and keeping gas turbines up and running also is another challenge for the service engineers. At Linquip you have access to the verified list of all heavy gas turbine manufacturers and service providers which helps you to conquer those challenges.

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteHeavy Duty Gas Turbine Subcategories

Top Companies in Heavy Duty Gas Turbine

+40 Companies in Heavy Duty Gas Turbine

Top Devices in Heavy Duty Gas Turbine

Related RFQs

Gas Turbine

LNQ-24021021

Gas Turbine (60 Hz)

LNQ-24011038

Gas Turbine (60 Hz)

LNQ-24011037

Heavy-duty gas turbine

LNQ-23101178

Heavy-duty gas turbine (50 Hz)

LNQ-23091200

Blades & Buckets

LNQ-23081215

Heavy Duty Gas Turbine Spare Parts category

LNQ-23071063

Gas Turbine

LNQ-23031066

Top Heavy Duty Gas Turbine Experts

What is Heavy Duty Gas Turbine?

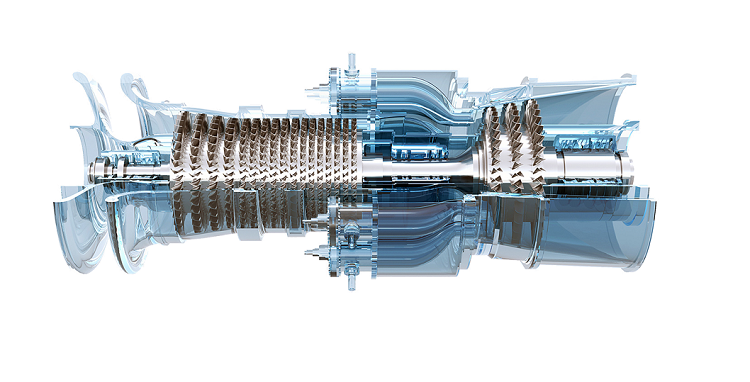

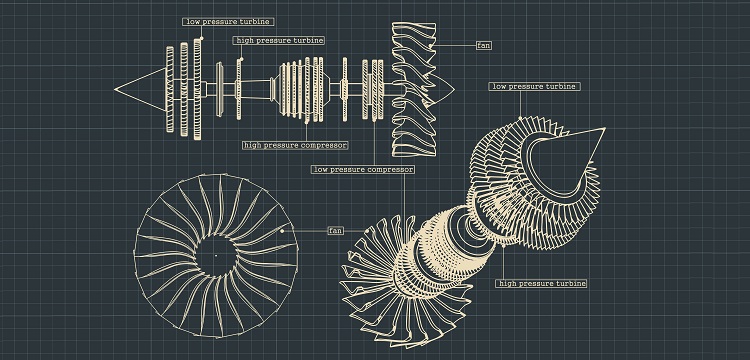

Heavy-Duty Gas Turbines or heavy frame gas turbines can burn various types of liquid fuels ranging from heavy residuals to light petroleum distillates. The combustion process of light distillates such as naphtha, kerosene, and NO2 fuel oil is well proven through millions of operation hours. A gas turbine, also known as a combustion turbine, is internal combustion and continuous engine. A gas turbine derives its power from burning fuel in a combustion chamber and utilizing the flowing combustion gas energy to move a turbine exactly like the high-pressure steam that runs a steam turbine. A gas turbine works on the Brayton cycle principle, that compressed air is combined with fuel and burned under constant pressure. The output hot gas expands through a turbine to produce energy and move blades.

All kinds and classes of heavy-duty gas turbines in power plants have three main parts: combustion system, compressor, and turbine section. Also, there are many vital systems and accessories for operating correctly in a heavy-duty turbine, which is outfitted together with the turbine. Some of them are:

● Exhaust system

● Air inlet system

● Fuel module

● Lube and hydraulic oil module

● Compressor washing

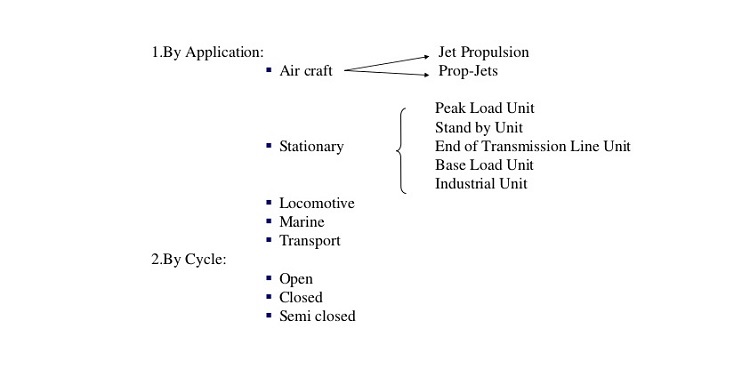

Classification of Heavy-Duty Gas Turbines

Heavy Duty Gas Turbines are the types of gas turbines for generating a different amount of power required in the industry. Several generations of heavy-duty gas turbines are installed and run in a combined and simple power plant's thermal cycle. These types are turbines with a gross output range from a few dozens up to more than 500 MW. Traditionally, they are categorized with capital letters like B, D, E, F, etc., classes or frames. Usually, gas turbine turbines presented in the market for applications are mostly G/H/J and D/E, F classes.

Currently, available D and E-class gas turbines are providing the range of 75–100 MW of power. They can be considered as a robust and reliable workforce for those applications where superb efficiency is not expected and wherever the fuel is low-quality or cheap. They usually employ unique combustion systems to reduce emissions, comply with regulations, and simultaneously deliver required power with average performance.

F-class gas turbines work at the range of 150–230 MW and are designed for applications like a combined cycle. This type is a development class of the D and E class machines. Due to the complicated combustion system, they have optimized designs for the air and hot gas flow passages and are more efficient. As a result, certain limitations exist regarding the quality of fuel (mostly natural gas) in these machines. Though, in countries with strict regulations and high fuel prices, increased efficiency pays back.

Current developments in gas turbine technologies presented G, H, and J classes that have been established for a couple of decades. They are a new generation of units with a larger than 250 MW output. The efficiency of the combined cycle mode is more than 62%. These power units use state-of-the-art elements and technologies to accommodate the most efficient and clean gas-fired power.

Heavy Duty or Aero-derivative Gas Turbine

Heavy-duty industrial gas turbines are heavier, narrower in operating speed range, more extensive in size, slower in start-up and speed, have higher airflow, and need more time and spare parts for overhaul. Heavy frame industrial gas turbines employ hydrodynamic bearing in the system.

Aero-derivative gas turbines have anti-friction bearings. The aero-derivative gas turbines are lighter weight variations of a gas turbine. They are designed for working with mixed fuel and air to be ignited and achieve the desired output. Modern aircraft engines and space technologies use aero-derivative gas turbines because of being maintainable, lightweight, flexible, and compact. The critical feature of maintainability is the modular concept that enables the removal and replacement of components without switching the gas turbine support mounts.

On the other hand, heavy-duty industrial power systems require more effort to remove and replace parts (notably combustor elements), and it is much harder to inspect, repair, and overhaul the sections. We should consider the needs and requirements of each of the variety of gas turbines which are offered to us. Generally, aero-derivative units are preferred in remotely located applications (including offshore) and installing heavy-duty industrial units in effortlessly available base-load applications. Heavy-duty industrial gas turbines utilize more fuel and air compared to aero-derivative gas turbines.

Aero-derivative gas turbines are 10-15% more efficient compared to heavy-duty industrial gas turbines. Some scientists and researchers predict the replacement of usual heavy-duty industrial type gas turbines with the aero-derivative gas turbines because of their fast development every day!

Is Heavy Duty or Aero-derivative Gas Turbine Used in Airplanes?

One of the widespread applications of gas turbines is using aero-derivative gas turbines in aviation. In this system, the power of the compressor is produced by the provided power in the turbine. The hot air at the turbine's outlets is used for forcing the air into the atmosphere at the exhaust nozzle. Except for the gas turbines in aircraft or other aviation-related devices, others use some of their power to reinforce the compression device that is the compressor.

The left power goes to drive energy conversion devices, which can be a propeller vessel or generator. In some cases, Turbines can be small enough to be launched on large trucks to be used in portable implementations or large projects requiring months to develop.