What is a Mixing Valve? Working Principle & Function

Thermostatic Mixing Valves combine hot and cold water to keep shower and bath output temperatures consistent and safe, preventing scorching. The temperature at the faucet is lowered by a mixing valve, making it safer for your family to use the sink, shower, or tub. Mixing Valves are an essential part of the pipeline system. Thermostatic mixing valves in your water heater are crucial for preventing scorching and managing water temperature at the delivery point. It allows you to raise the temperature of the heater, effectively killing harmful bacteria.

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteTop Companies in Mixing valve

Top Devices in Mixing valve

Related RFQs

Alfa Laval 9611921783 Fpm Double Seat Valve Service Kit

LNQ-23101024

What is a Mixing Valve?

A mixing valve allows you to raise the temperature of your water heater to lessen the risk of bacteria growth while also preventing scalding. Plus, by combining hot and cold water, you'll be able to boost your available hot water supply.

Mixing valves are utilized in both plumbing and hydronic heating applications in commercial, residential, and institutional settings. The major function of these valves is to manage the output water temperature to either a home hot water supply system or a radiant floor heating system at a low temperature. In many cases, the same physical valve can be utilized for both purposes.

Thermostatic mixing valves are used to keep water at a constant temperature by blending cold and hot water in a steady flow to assure safety while washing hands, showering, and/or bathing. The primary goal of these thermostatic mixing valves, which are designed to manage water temperatures, is to prevent scalding from hot water burns in elderly, young, and vulnerable people.

Valves come in a variety of shapes, sizes, and configurations, each optimized for a specific application. Many particular applications in plumbing necessitate the use of highly specific thermostatic valves. Thermostatic valves are typically three-way valves used for modest to medium-sized projects in most hydronic applications.

By allowing the water heater to be set to a high enough temperature to prevent bacteria growth while maintaining proper outlet water temperatures to the fixtures, the thermostatic mixing valve eliminates both dangers, allowing residents to use the sinks, showers, and tub without fear of scorching.

An additional benefit to the end-user when employing a mixing valve is higher usable hot water capacity. When the water is stored at a higher temperature of 60°C and then mixed down to 49°C at the output, the useful hot water supply increases by around 50% compared to just maintaining the tank set at 49°C. This effectively increases the capacity of a 40-gallon tank to the level of a 60-gallon tank. Because of the increased amount of hot water distributed from the tank, the end-user is less likely to run out of hot water.

You can find a great deal of mixing valve Companies and Manufacturers in Linquip, along with expert Service Providers.

Mixing Valve Function

Thermostatic Mixing Valves work on a basic wax thermostatic basis that blends hot and cold water to control the amount of each. In addition, if the temperature climbs over the setpoint, the mixing valves automatically close, preventing more hot water from flowing through the pipe.

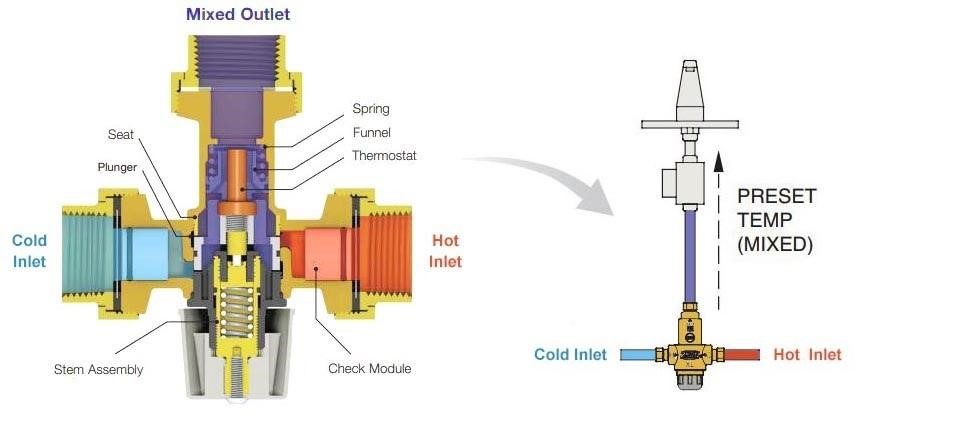

Mixing Valve Components

A Thermostatic Mixing Valve is made up of four different parts. These are the four elements:

Thermostatic Element

These thermostatic elements are temperature-sensitive devices that contract and expand in response to the temperature of the water. When the temperature inside the valve changes, the piston in the valve goes up or down in succession. The proportion of hot and cold water in the valve changes as the piston moves. A thermostatic element's piston movement is critical because it shuts off quickly if the water regulation fails.

Piston

A thermostatic element's piston movement is critical because it moves in response to the thermostatic element's sensor. It prevents scorching by quickly switching off if the hot and cold water temperature regulation fails.

Return Spring

The return spring of a thermostatic mixing valve acts by pulling the piston back to its original position after it has contracted or expanded owing to a change in water temperature.

Temperature Adjuster

This adjuster, as the name implies, is stored under the valve's shield lock and can change the valve's temperature. The adjuster essentially adjusts the position of the piston, hence regulating the amount of hot and cold water in the valve.

Mechanical Thermostatic Mixing Valves were made up of these parts. There are digital Thermostatic Mixing Valves that cool water in a slightly different way. The sensors in the mixer are used to control the Digital Thermostats. The sensor on the Digital Thermostatic Mixing Valve can be turned on and off manually or automatically, with the benefit of a timer setting.

Why is a Mixing Valve needed?

To eliminate Legionella bacteria, hot water is normally held around 140°F. Because this is too hot to deliver to the end consumer, it must be blended with cold water to produce safe, tempered water. Handwashing water temperature must be at least 100°F, but not more than 108°F, according to Health and Safety Code 113953 (c).

Mixing valves are commonly used to regulate the temperature of residential hot water distribution loops such as tubs, sinks, and showers, as well as emergency drench equipment. Commercial establishments like restaurants, pre-schools, nursing homes, and hospitals are frequently required to have a thermostatic mixing valve.

These scald-protection devices are especially important in households with young children, the elderly, and physically disabled people, but they are also suggested for all homes and may be required in some places. When it comes to preventing scorching, exercising caution is always the first line of defense, although scald protection devices assist in maintaining a safe water temperature. This allows the user to set their water heater to a high enough temperature to kill bacteria (the norm for water heaters is 140° F) without worrying about the water getting too hot at the faucet.

Linquip offers a wide variety of Distributers, Experts, and Equipment for Sale of mixing valves.

Applications of a Mixing Valve

A thermostatic mixing valve is a simple method for supplying lower supply water temperatures to a radiant floor heating system in hydronic heating applications in residential and small business applications. A mixing valve is required whenever radiant floor heating is combined with higher temperature distribution methods such as fan coils or baseboard radiators in the same system.

The mixing valve allows the heat source (boiler or water heater) to be set at a greater temperature to meet high-temperature loads, while the radiant circuit is supplied with a lower water temperature via the mixing valve.

A common hybrid system with radiant floor heating in the basement and a fan coil to heat the upper levels is an example. The high mass radiant floor normally requires a supply water temperature of 35 to 45 degrees Celsius, while the fan coil requires a much higher temperature of 65 to 75 degrees Celsius.

If you try to keep two locations at the same temperature, you'll have a lot of trouble. With a high supply temperature, the floor will be dramatically overheated, perhaps causing damage or making heat output difficult to control. The fan coil will not produce enough heat if the supply temperature is too low.

Divide the system into two circuits with two pumps and one thermostatic mixing valve as a solution. The radiant floor will receive lower temperature water via the thermostatic valve, while the fan coil will receive high-temperature water directly from the heat source.

The radiant circuit's circulating pump must be located downstream of the mixing valve; otherwise, the radiant loops will not receive enough flow. Remember that water will always take the path of least resistance, thus if the pump is located upstream of the thermostatic valve, it will flow straight through the valve, bypassing the loops.